HANTENCNC’s composite laser cleaning machine has a dual laser system, which combines a 2000W continuous laser and a 300W pulsed laser into one machine. It is designed for heavy rust and thick paint and can handle heavy cleaning tasks more efficiently than traditional methods.

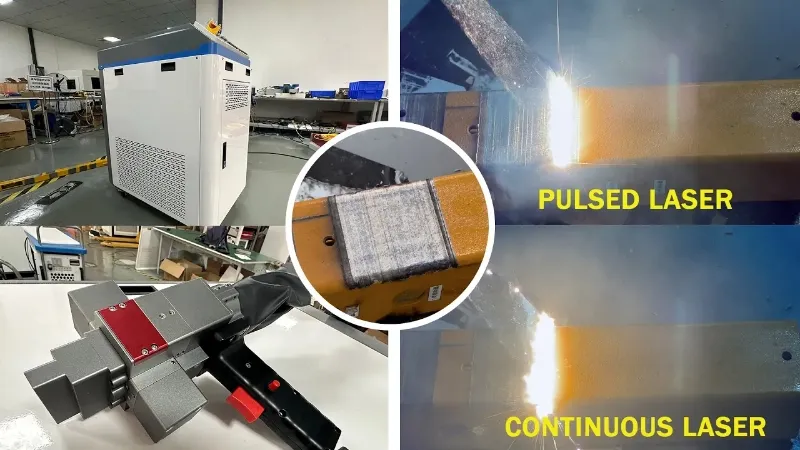

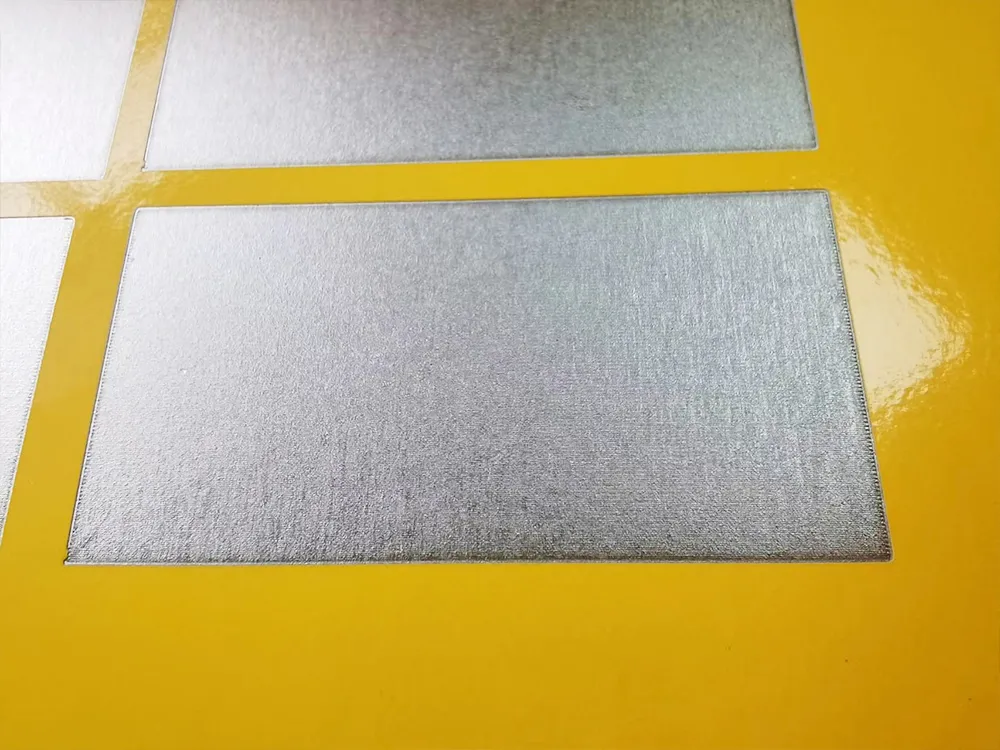

The composite laser cleaning machine operates on the principle of rapid substrate heating with continuous light, followed by equipment cleaning with pulsed light. This process results in swift and non-damage cleaning, making it ideal for ships, metal structures, oil derricks, and other applications where highly resistant paint needs to be removed to the machine’s required thickness.

The composite laser cleaning machine can effectively remove rust layers up to 25mm thick during the cleaning process. It can also easily remove heavy protective paint layers up to 2mm thick, such as epoxy resin paint and fluorocarbon paint, etc.

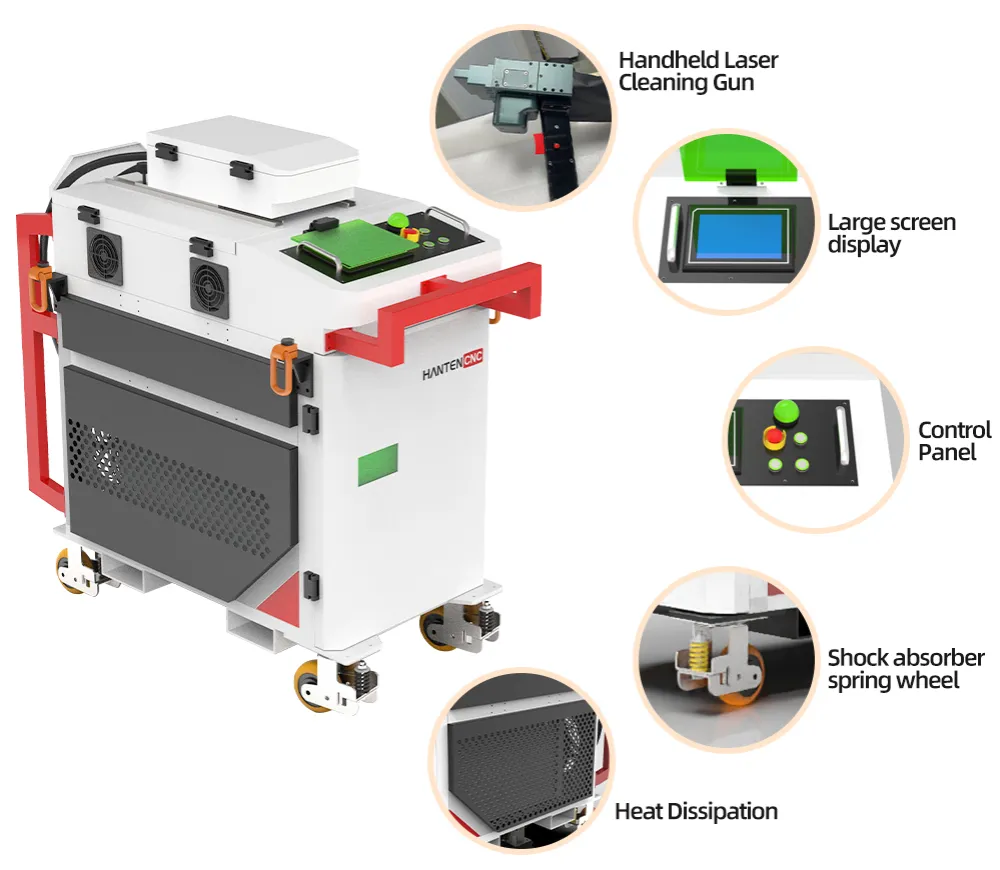

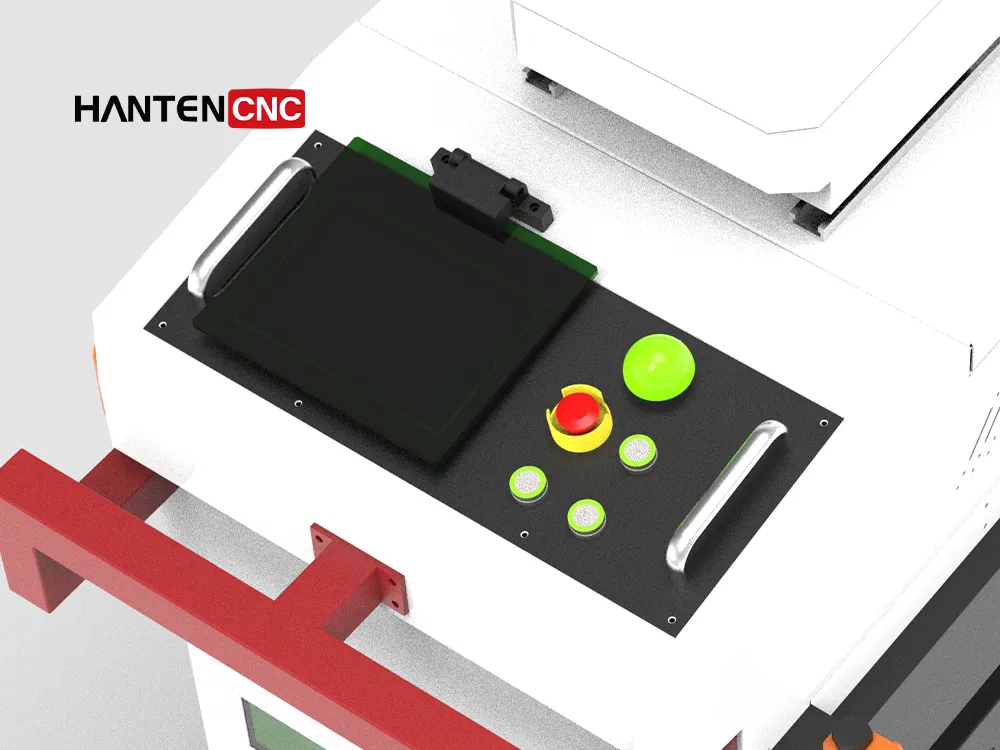

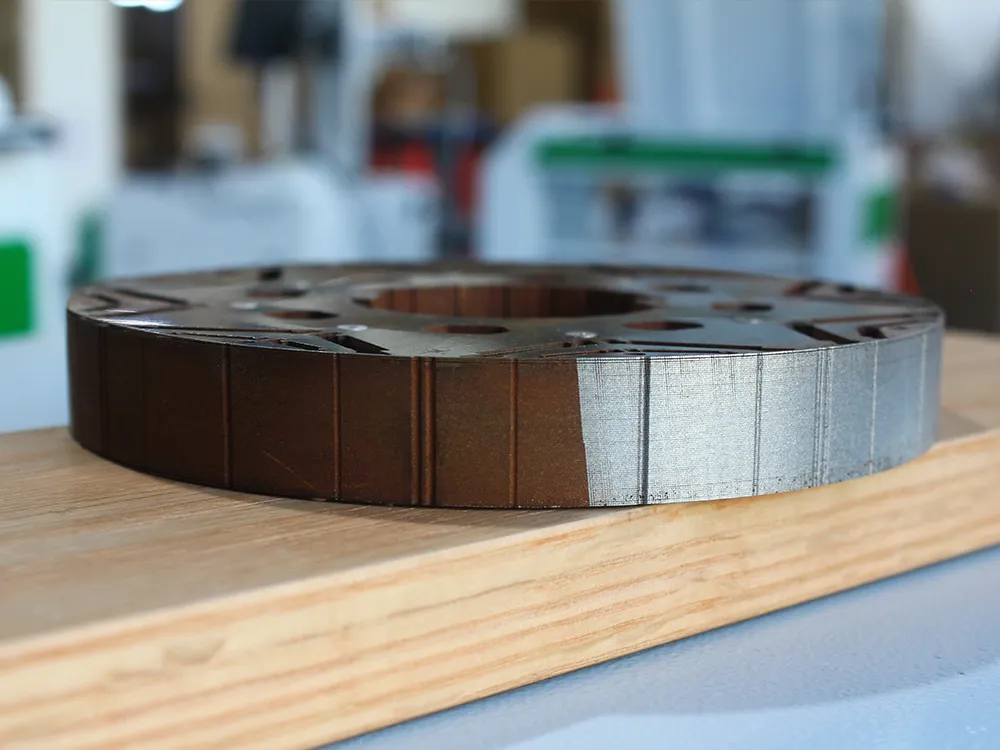

Composite Laser Cleaning Machine Display

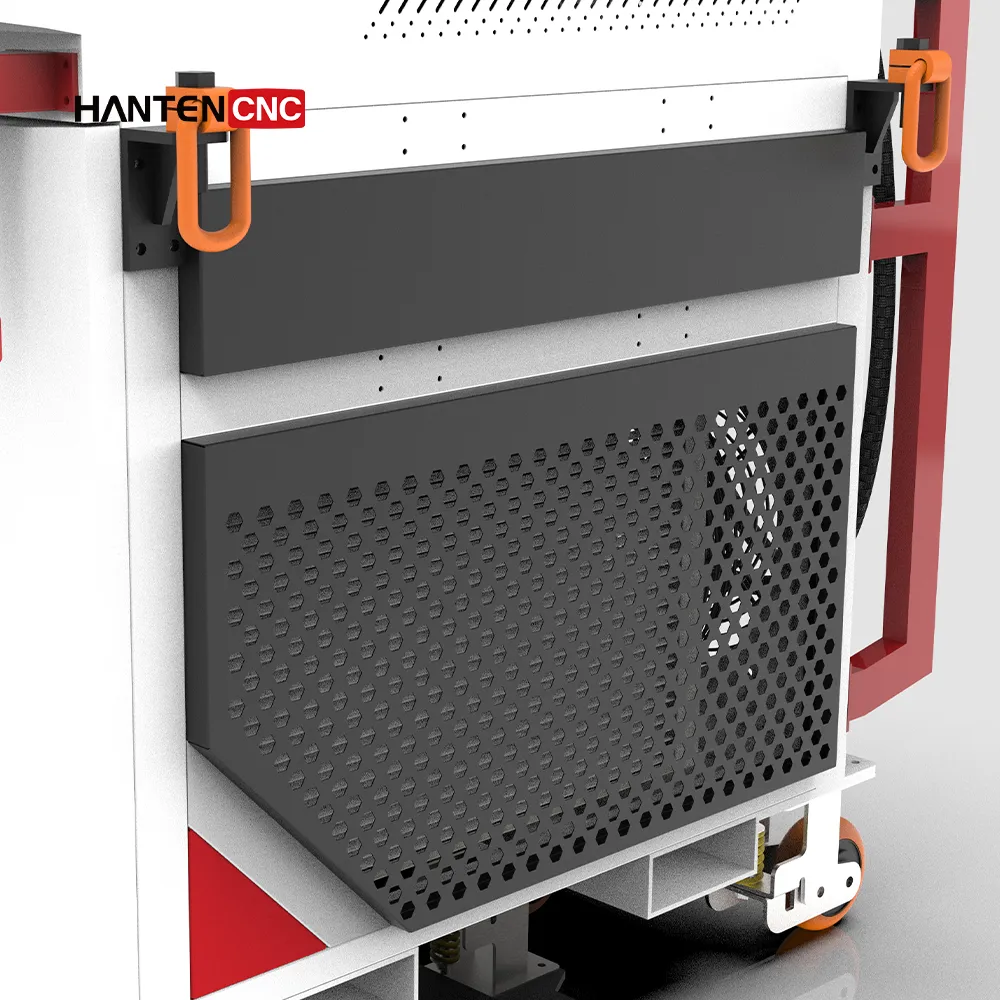

Composite Laser Cleaning Machine Components

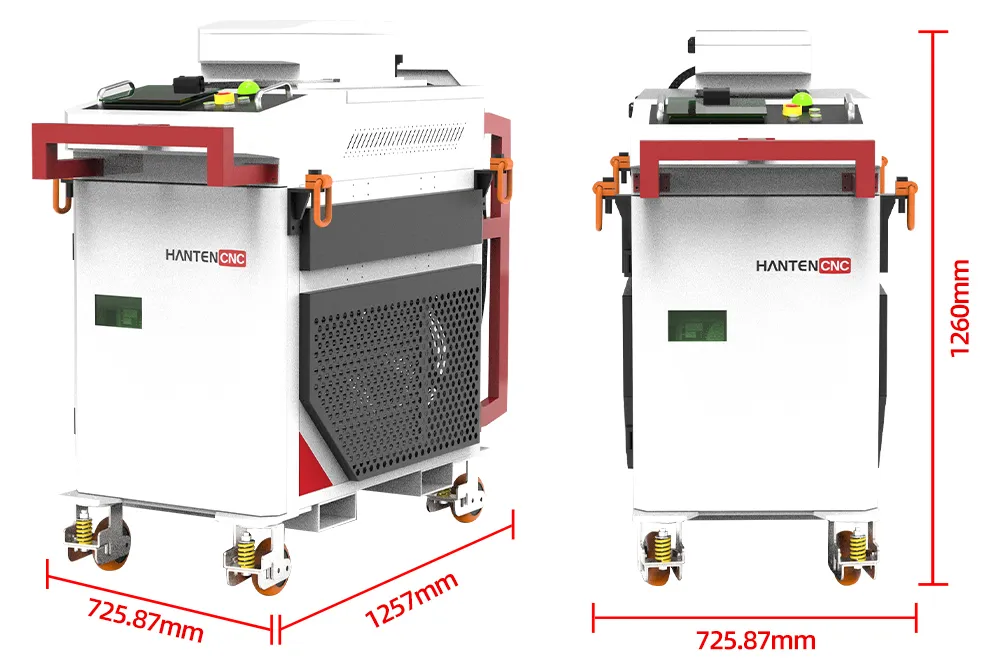

Composite Laser Cleaning Machine Dimensions

Composite Laser Cleaning Machine Features

2-in-1 Laser Cleaning Head: Pulsed & Continuous Laser

HANTENCNC’s composite laser cleaning gun weighs only 1kg, is compact, and is easy to use.

Our 2-in-1 laser cleaning head combines the power of a 2000W continuous laser with the precision and flexibility of a 300W pulsed laser, suiting a wide range of applications.

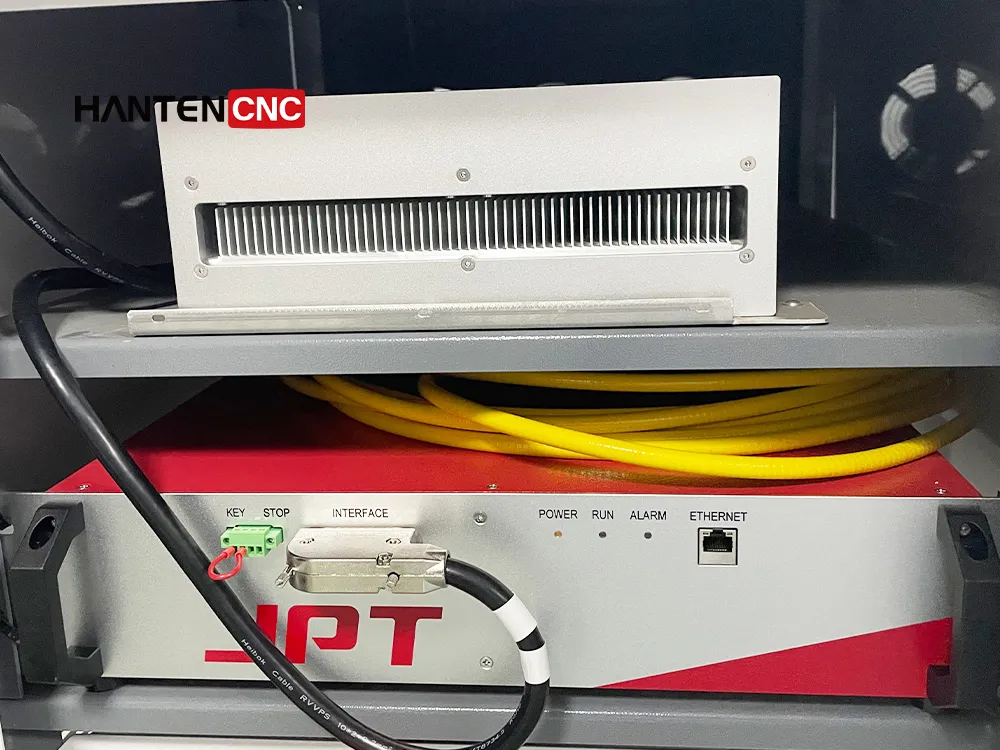

Hanli’s water chiller & Raycus’s laser Source

Our composite laser cleaning machine adopts HanLi’s water chiller and Raycus’s laser. We use Hantech’s top-quality cooling technology and Raycus’s laser technology together, thus enhancing the machine’s durability and achieving perfect cleaning efficiency.

Hanli’s water chiller cooling technology guarantees temperature control at the required setting; meanwhile, Raycus’s excellent-quality laser technology easily removes tough coatings, such as rust and paint leveling.

Dual Laser System:

The cleaning head combines a 2000W continuous laser and a 300W pulsed laser, which can easily switch between laser cleaning modes.

Versatile Applications:

Due to its dual-laser construction, it’s great for heavy-duty cleaning tasks like removing rust layers and paint coatings in industrial, automotive, and marine applications.

Composite Laser Cleaning Machine Parameters

| Optical Technical Parameters | ||

|---|---|---|

| Category | Pulsed Laser | Continuous Laser |

| Average Laser Power (W) | 300 | 2000 |

| Power Adjustment Range (%) | 0-100 | 10-100 |

| Power Instability (%) | <5 | ≤3 |

| Central Wavelength (nm) | 1064 | 1080nm ± 5 |

| Frequency Adjustment Range (kHz) | 1-4000 | / |

| Operating Mode | Pulsed | Continuous/Modulated |

| Modulation Frequency (Hz) | / | 1-5000 |

| Laser Interface | QCS | QBH |

| Supply Voltage | 380 ± 10% V AC, 50/60Hz | 380V AC ± 10%, 50/60 Hz |

| Operating Temperature | 0℃ ~ 40℃ | 0℃ ~ 40℃ |

| Operating Humidity | 10% ~ 60% | 10% ~ 60% |

| Composite Cleaning Head System Parameters | ||

| Dimensions (mm) | 160*82*124mm (Excluding handle) | |

| Weight (kg) | 1KG (Excluding jumpers, water pipes, etc.) | |

| Cable Length (m) | 10m | |

| Operating Mode | Onboard | |

| Focusing Lens Focal Length (mm) | 210mm | |

| Maximum Scanning Speed | 20000mm/s | |

| Laser Scan Width (mm) | 0mm – 100mm adjustable | |

| Cooling Method | Water Cooling | |

| Cooling Flow Rate | ≥4L/min | |

| Cooling Pressure | ≥0.6MPa | |

| Cooling Interface | PU Tube 6mm | |

| Operating Temperature | 0℃ ~ 40℃ | |

| Operating Humidity | 10% ~ 60% | |

| Overall Machine Parameters | ||

| Machine Dimensions (L×W×H) | 1257*726*1260mm | |

| Machine Weight | About 290KG | |

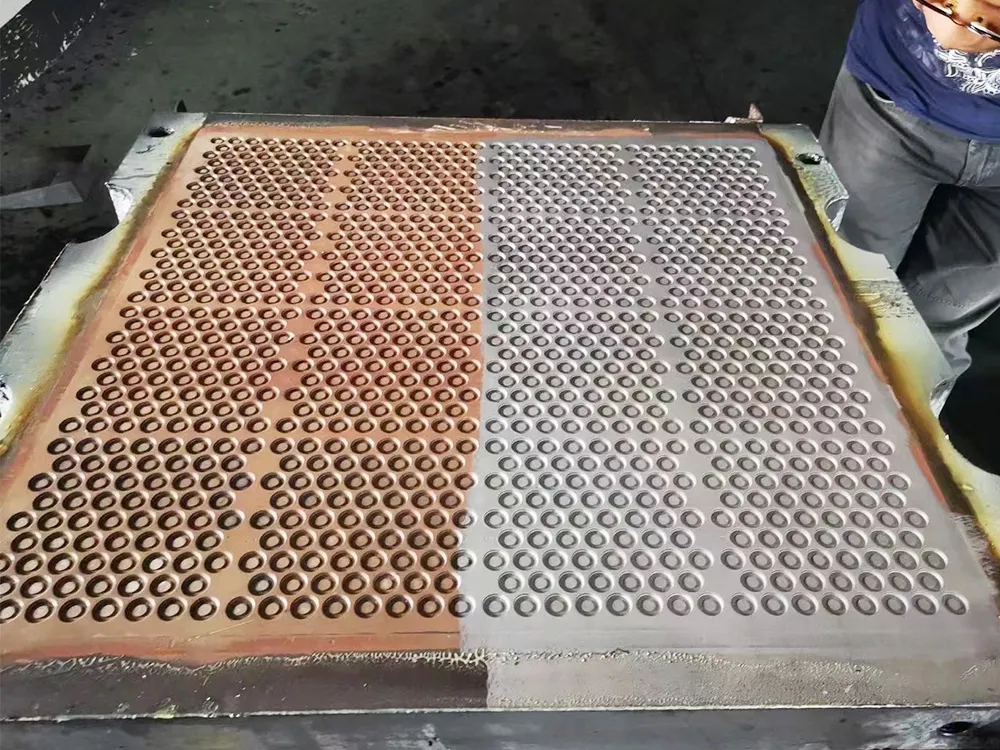

Composite Laser Cleaning Machine Cleaning Effects: Before vs. After

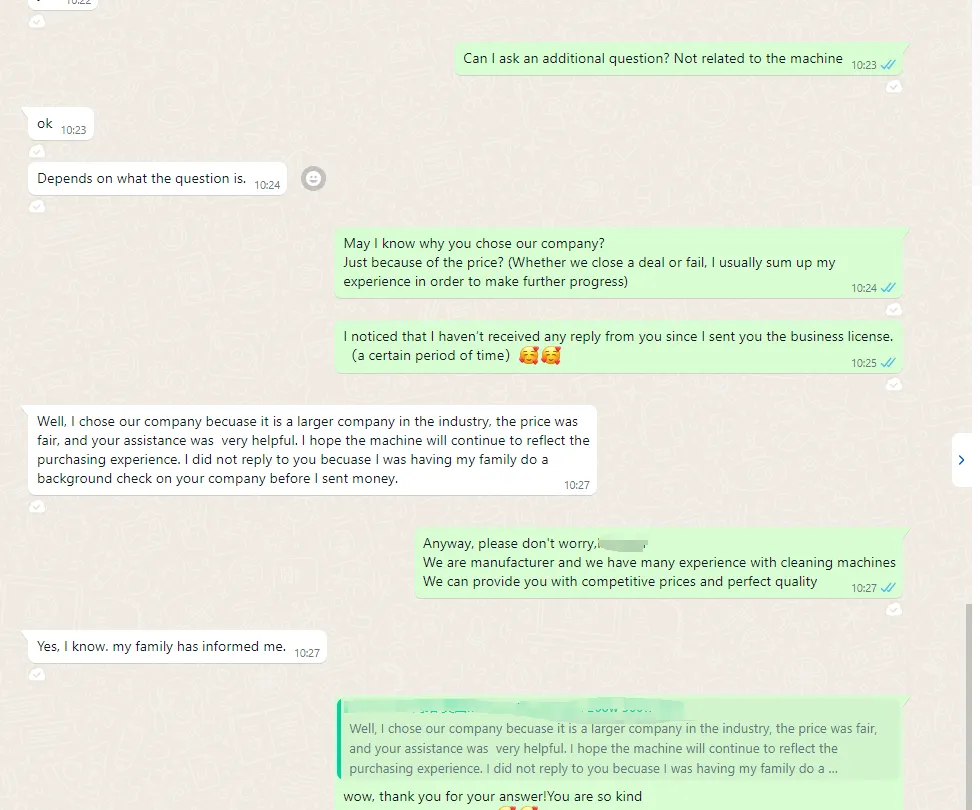

Customer Visits

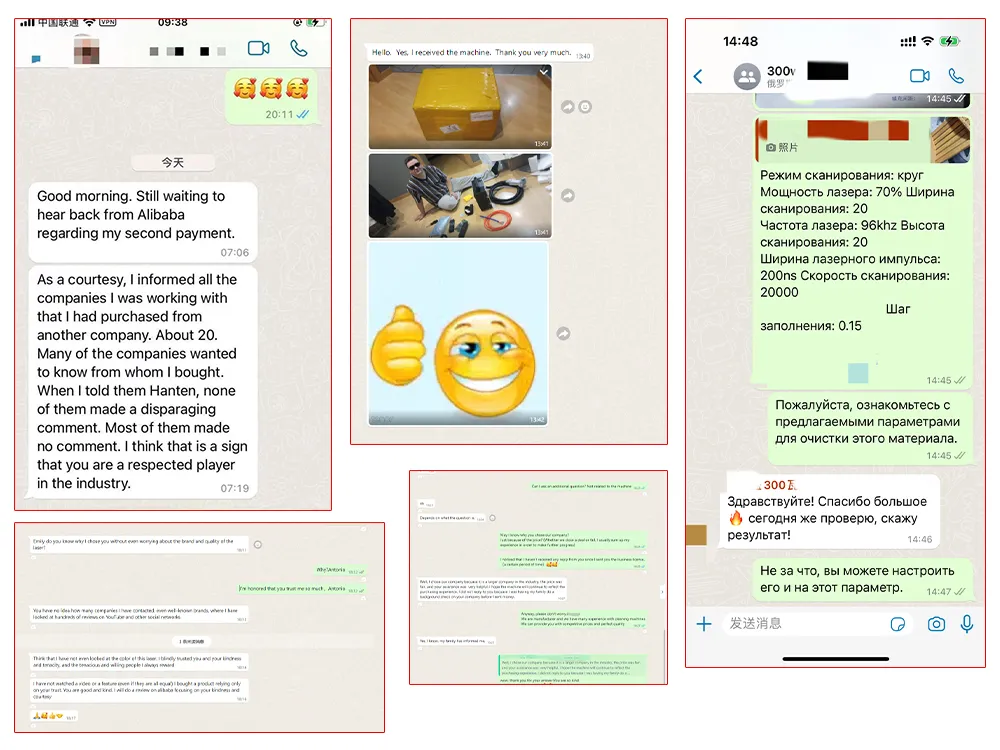

Customer Reviews

Certificates

HANTENCNC Partnerships

HANTENCNC Service

HANTENCNC’s laser cleaning machines are CE and FDA-certified. We offer a 2-year warranty for the laser source and a 1-year warranty for the whole machine, sample testing, OEM customization, remote guidance, and lifelong after-sales support.