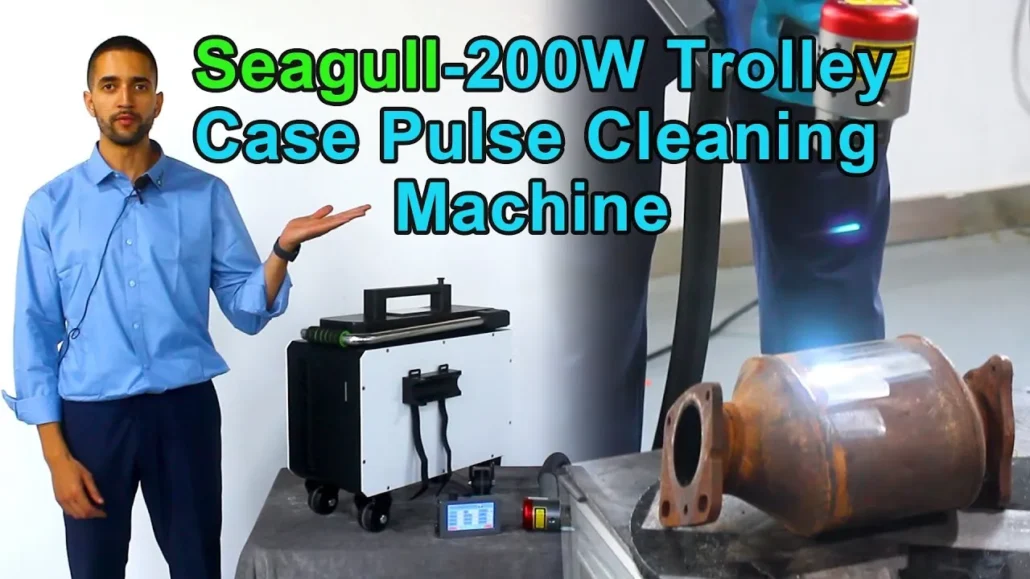

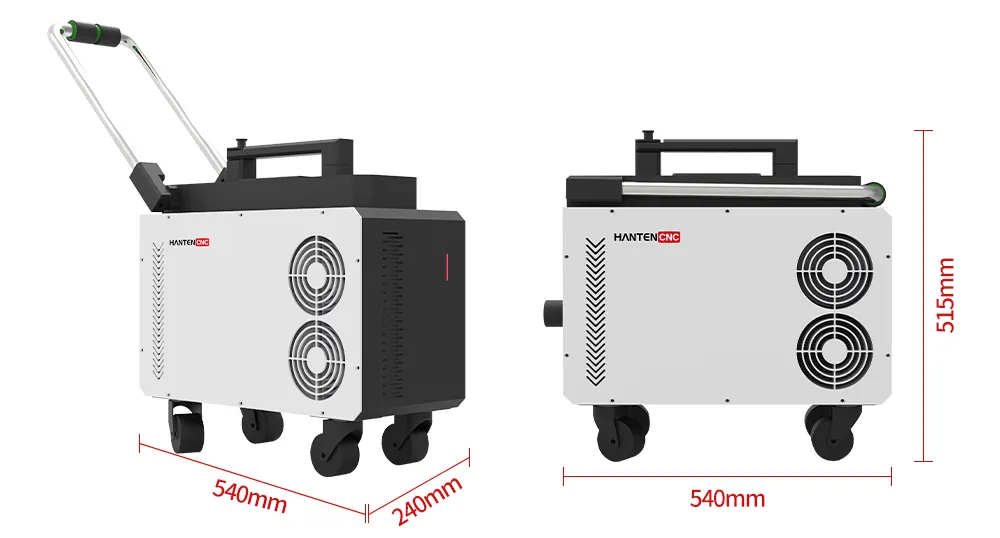

200W pulse laser cleaning machine SEAGULL1, adopts a luggage-type design, which can be easily moved. The drawbar can be folded for easy storage and placement into a vehicle for carrying.

When in use, you can open the drawbar and pull it into where you need to work, and it is very convenient for mobile work in the workshop.

A 360° rotating handle is designed above the control screen to protect the control screen.

The wheels of the machine can be turned at will, making it perfect for taking out to work.

The overall design of the machine is small and lightweight, so you can drive it anywhere to provide cleaning services to your customers.

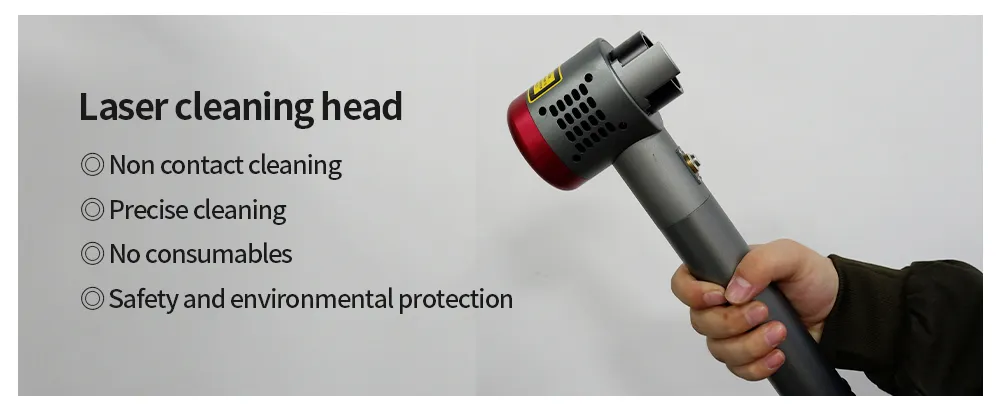

The cleaning head is very lightweight at 0.8kg, and the lens is made of quartz for durability and heat resistance.

We have designed a wrist control screen for the machine; you can change the parameters at any time without limitation.

SEAGULL1 200W Pulse Laser Cleaning Machine Demonstration Video

SEAGULL1 Pulse Laser Cleaning Machine Display

SEAGULL1 200W Pulse Laser Cleaning Machine Components

SEAGULL1 200W Pulse Laser Cleaning Machine Dimensions

200W Pulse Laser Cleaning Gun

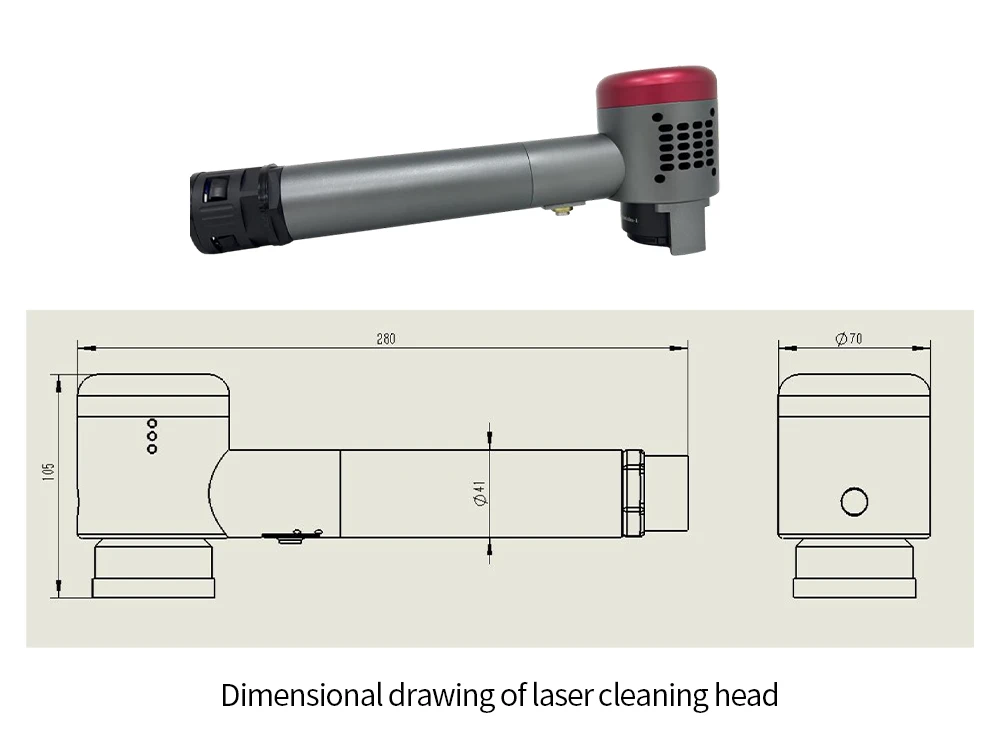

The cleaning head of HANTENCNC’s 200W pulse laser cleaning machine comes with lightweight and portable design, it weighs less than 0.75kg.

Dust-proof and anti-interference design to ensure stable and reliable operation in various environments.

Professional laser lens cleaning can meet a variety of laser cleaning applications.

Air-blowing Fixture

The HANTENCNC 200W laser cleaning head is equipped with the Air-Blowing Fixture.

This fixture uses high-pressure airflow to remove dust, dirt, and leftover particles during laser cleaning, helping to improve cleaning results. It also protects the protective lens from dust and extends its lifespan. When used with inert gas, it can reduce oxidation on metal surfaces and keep them smooth. This helpful tool is popular among customers and improves the overall cleaning quality.

-

Remove dust and impurities:

During the cleaning process, the air-blowing fixture uses high-pressure airflow to blow away dust, contaminants, and residues to ensure that the surface is clean. This work is crucial to the effect of laser cleaning because if there is any dust or impurities on the surface of the workpiece, it will affect the cleaning and even lead to incomplete cleaning.

-

Protect protective lens:

When the laser cleans the materials, the dust generated by the laser beam will stick to the protective lens, which will cause contamination to the protective lens, affect the cleaning effect, and reduce the lifespan of the protective lens. In that case, HANTENCN’s air-blowing fixture can avoid dust contamination during the cleaning process.

-

Reduce oxidation reactions:

The air-blowing fixture can reduce oxidation reactions by jetting inert gas, creating a gas-protective film, which is very important for some metal materials that are easily oxidized, preserving the surface’s smoothness and quality. Many customers told us that they are satisfied with the upgraded cleaning machine’s cleaning effect.

Safety Lock

HANTENCNC’s 200W pulse laser cleaning head is equipped with a safety lock to prevent accidental operation effectively.

The laser will only emit when the safety lock button is pressed. If the button is not pressed, the laser cannot be triggered, ensuring operator safety.

200W Pulse Laser Cleaning Gun Dimensions

Pulse Laser Cleaning Machine Applications

A pulse laser cleaning machine is a device that uses laser technology to clean surfaces and remove dirt. The pulse laser cleaner machine uses a high-energy pulsed laser beam to irradiate the surface of the target object instantaneously. Through the focusing and instantaneous heating of laser energy, it quickly evaporates, peels, or cracks dirt, coatings, oxides, paints, etc.; thereby, cleaning and treating the surface is done.

Pulse laser cleaners are used in various fields for different cleaning tasks. Here are some examples.

Industrial Application

A pulse laser cleaning machine can be used to clean oil stains, oxides, and coatings on the surface of metal, wood, buildings, etc. It is widely used in auto parts manufacturing, aerospace, machinery manufacturing, and other fields.

Cultural Heritage Protection

Traditional cleaning methods may cause damage to ancient buildings, sculptures, cultural relics, etc. The pulse laser cleaning machine will cause damage to the substrate’s surface during cleaning.

It can be used for the restoration of cultural relics without any damage.

Electronic Device

In the electronics manufacturing process, a pulse laser cleaning machine can be used to clean the surface of circuit boards, chips, and so on. It can quickly remove oxides, soldering residues, etc.

Aerospace

In aerospace manufacturing, precise cleaning of component surfaces is critical to ensuring performance.

HANTENCNC’s pulse laser cleaning machine is an ideal solution for cleaning rocket engine nozzles, aircraft wings, and other parts.

In conclusion, HANTENCNC’s pulse laser cleaners suit extensive applications across various fields. They can clean a wide range of contaminants and coatings efficiently while preserving the integrity of the substrate.

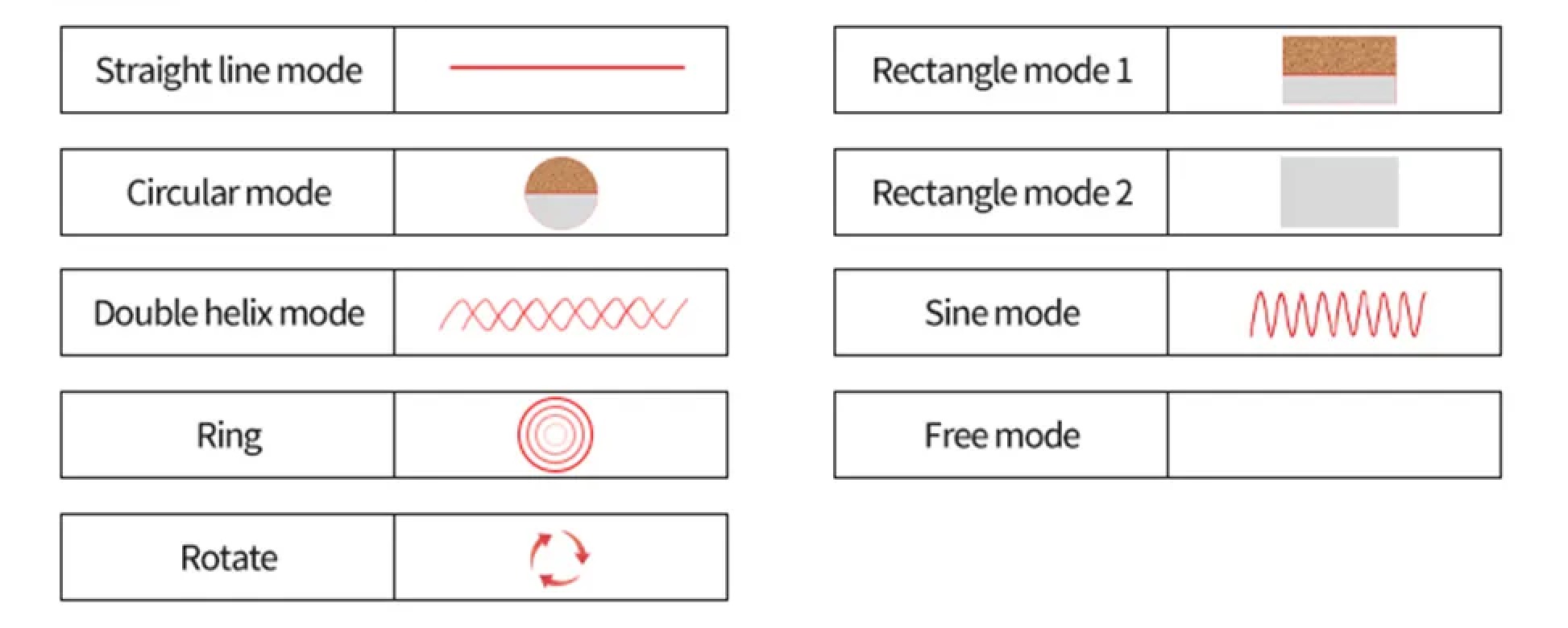

9 Cleaning Modes for 200W Pulse Laser Cleaning Machine

The operation interface of the HANTENCNC’s 200W pulse laser cleaning machine offers 9 cleaning modes:

- Straight Line Mode

- Rectangular Mode 1

- Rectangular Mode 2

- Circular Mode

- Sinusoidal Mode

- Spiral Mode

- Free Mode

- Ring Mode

- Rotation Mode

You can switch these modes by clicking on the “Scanning Mode” option on the interface.

Some cleaning modes are gentler, suitable for materials with higher surface requirements, and can reduce or eliminate traces after cleaning. Some cleaning modes are more powerful and ideal for removing stubborn dirt or coatings.

Choosing the right cleaning modes ensures minimal traces and enhances the appearance and quality of the product, which is especially crucial in industries like automotive manufacturing, aerospace, electronics, and more.

16 Supported Languages for the Pulse Laser Cleaning Machine

HANTENCNC’s 200W pulse laser cleaning machine currently supports Chinese, Traditional Chinese, English, Russian, Japanese, Spanish, German, Korean, French, Polish and 16 other languages.

You can easily switch between these language options directly on the machine’s interface. If you require any other languages, we also provide customized language services.

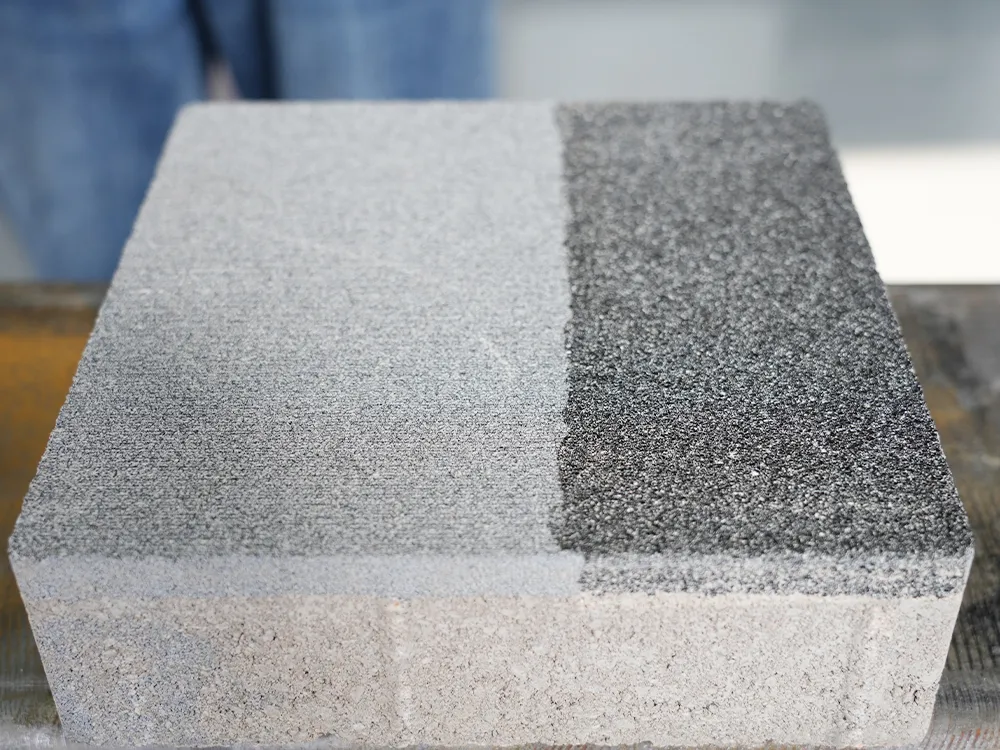

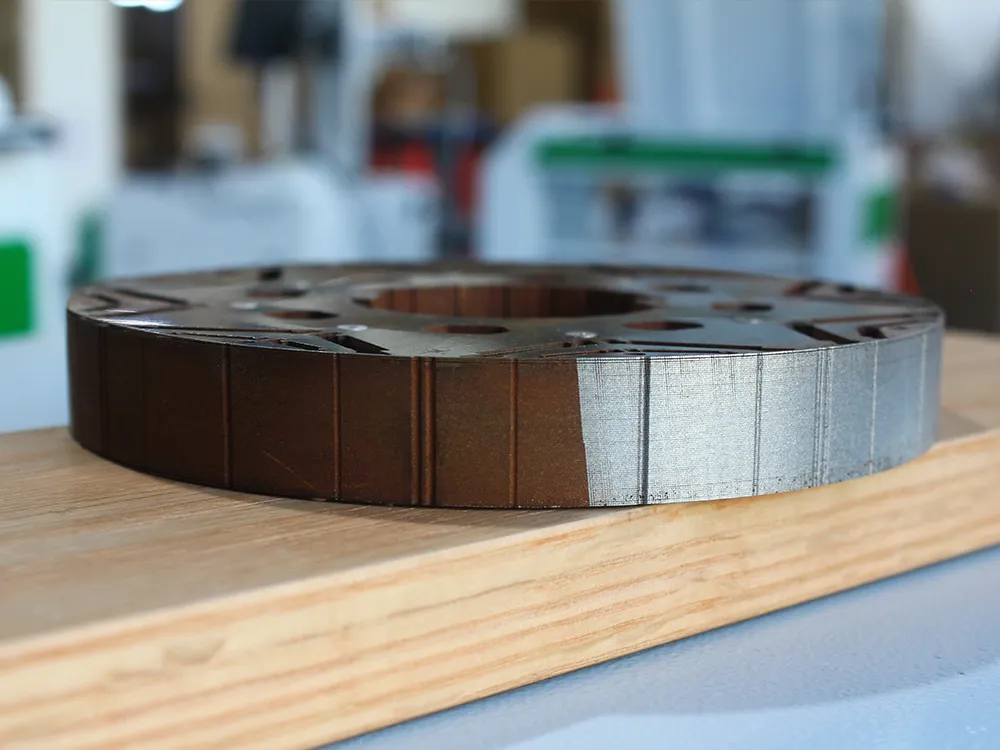

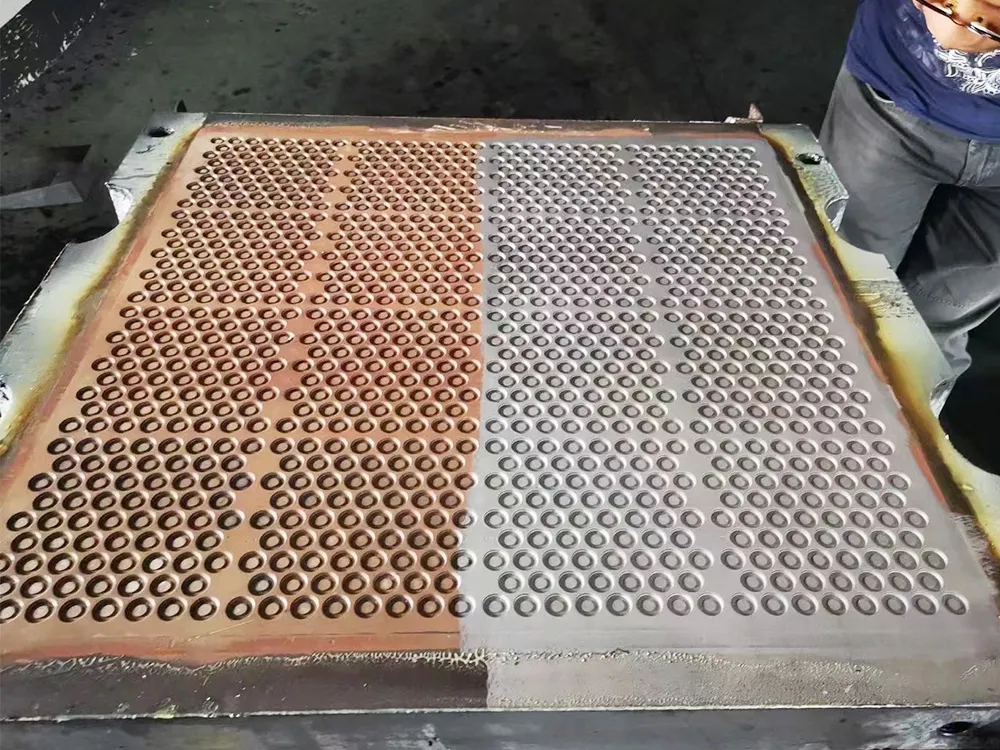

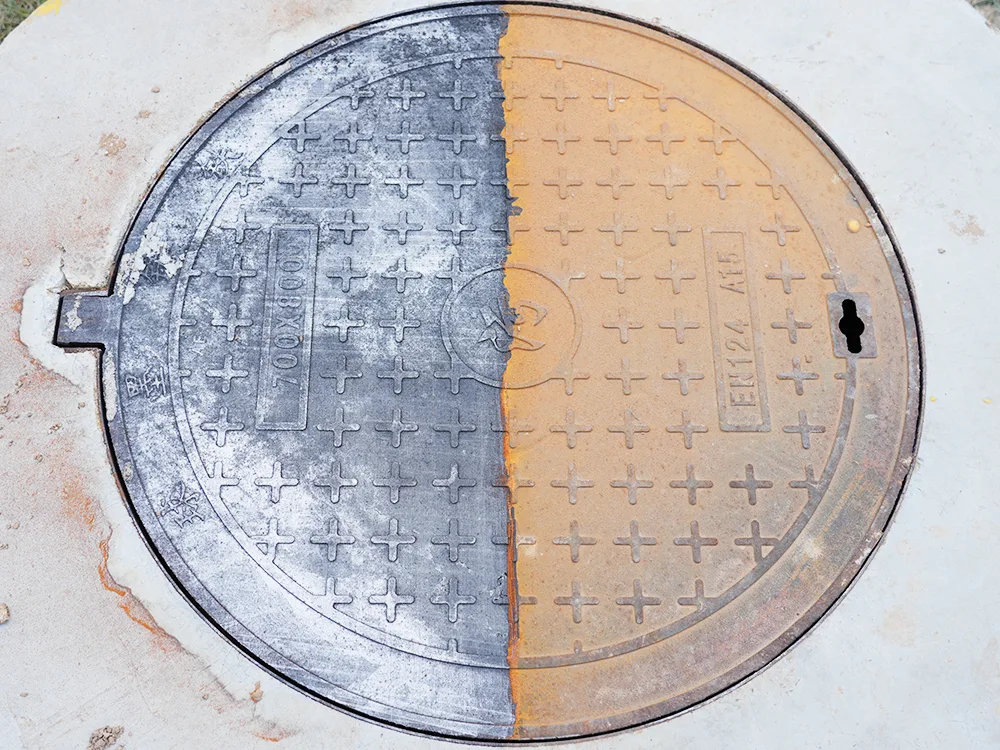

Pulse Laser Cleaning Effects: Before vs. After

SEAGULL Pulse Laser Cleaning Machine Parameters

| Model | SEAGULL1-HTCM200 |

|---|---|

| Supply voltage | Single Phase 110V/220V± 10%, 50/60Hz AC |

| Fiber Cable Length | 5m |

| Average output power | >200w |

| Maximum pulse energy | 2mJ / 5mJ |

| Frequency adjustable range | 1-3000kHz |

| Pulse Width | 13-500ns |

| Output power instability | <5% |

| Cooling system | Air-cooled |

| Power regulation range | 0~100% |

| Operating temperature range | 0~40℃ |

| Storage temperature range | -10~60℃ |

| Central wavelength | 1064nm |

| Machine Dimensions | 540*240*515mm |

| Laser Cleaning Gun Weight | <0.75Kg |

| Scanning Frequency | 1-4000Khz |

| Maximum Scanning Speed | 20000mm/s |

| Scanning Range | 105/140/160/185/300mm Optional |

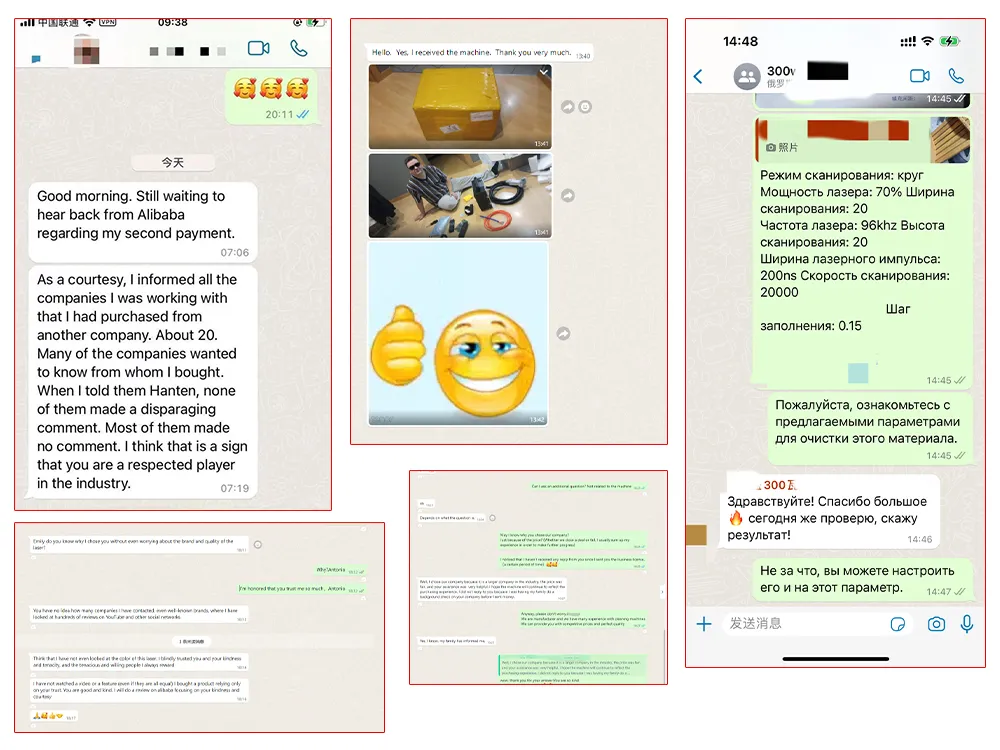

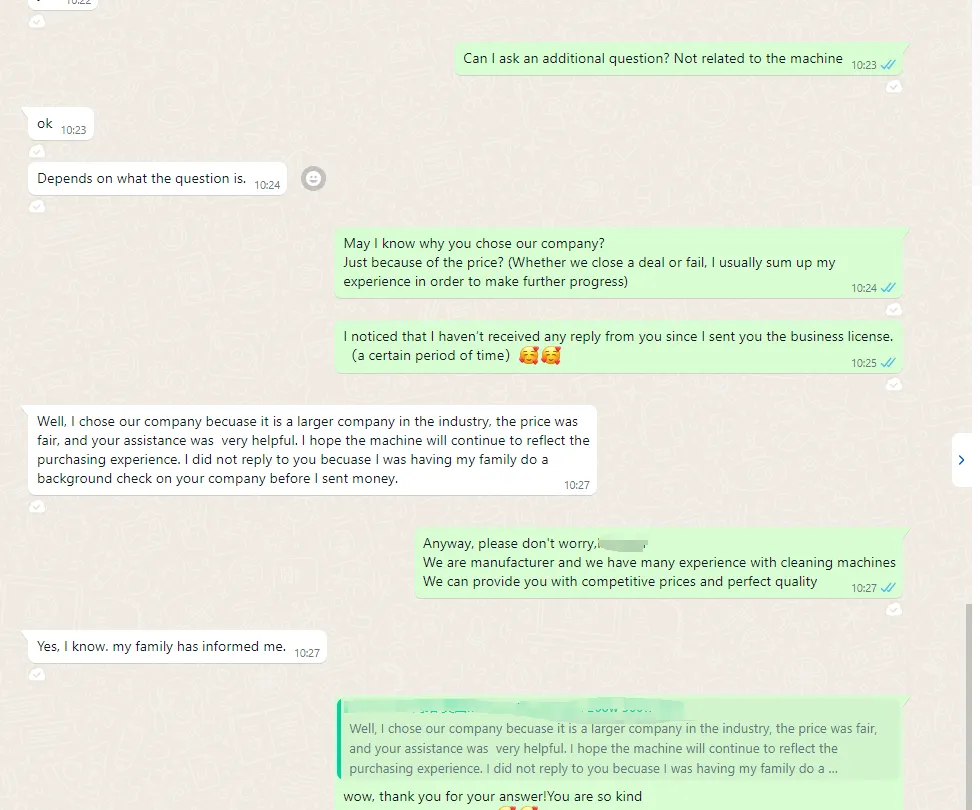

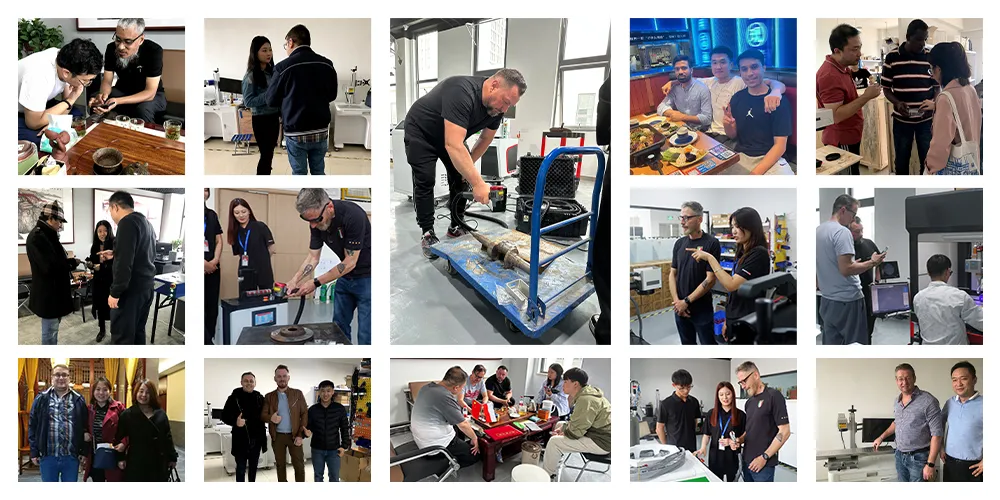

Customer Visits

Customer Reviews