Today, as science and technology continue to develop and update, we have seen the impact of technology on life. The continuous innovation and development of science and technology has helped us achieve a lot of work quickly, efficiently, at low cost and with zero pollution. Among them, laser cleaning machines are an important and constantly developing field. With the work needs of all walks of life, laser cleaning machines, as a high-speed, efficient, and environmentally friendly cleaning method, are gradually replacing most traditional cleaning machines.

Here, we can see the advantages of HANTENCNC’s laser cleaning machine. First of all, it is a professional cleaning machine. The new laser of HANTENCNC can be customized according to the needs of customers to meet their different cleaning needs.

Many customers come into contact with the laser cleaning machine for the first time. We at HANTENCNC hope that this article can help you understand our HANTENCNC laser cleaning machines and choose a laser cleaning machine that can meet your needs and help your career develop better.

This article will use simple and easy-to-understand language to introduce to you the working principle of HANTENCNC’s laser cleaning machine, the advantages and disadvantages of laser cleaning, and the suitable application range of laser cleaning.

After the emergence of laser, laser technology has been applied to various industries and continues to develop. Most traditional cleaning methods require the use of some media to achieve the cleaning effect, and there is also the problem of damaging the surface of the material. To achieve better cleaning results, laser cleaning appeared and achieved good cleaning results.

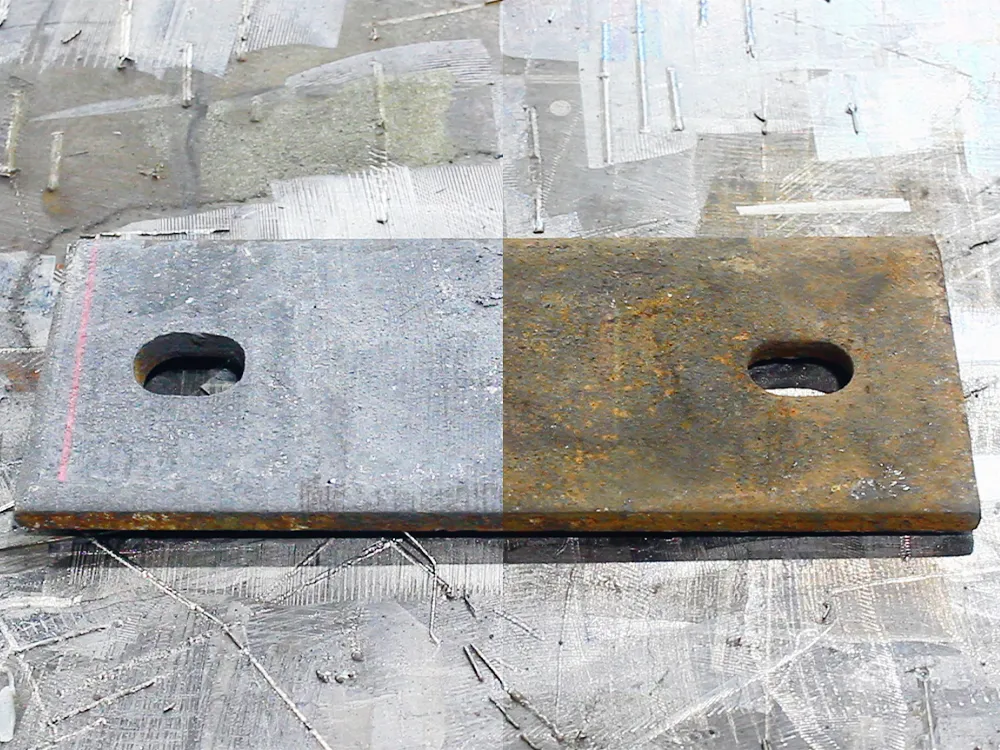

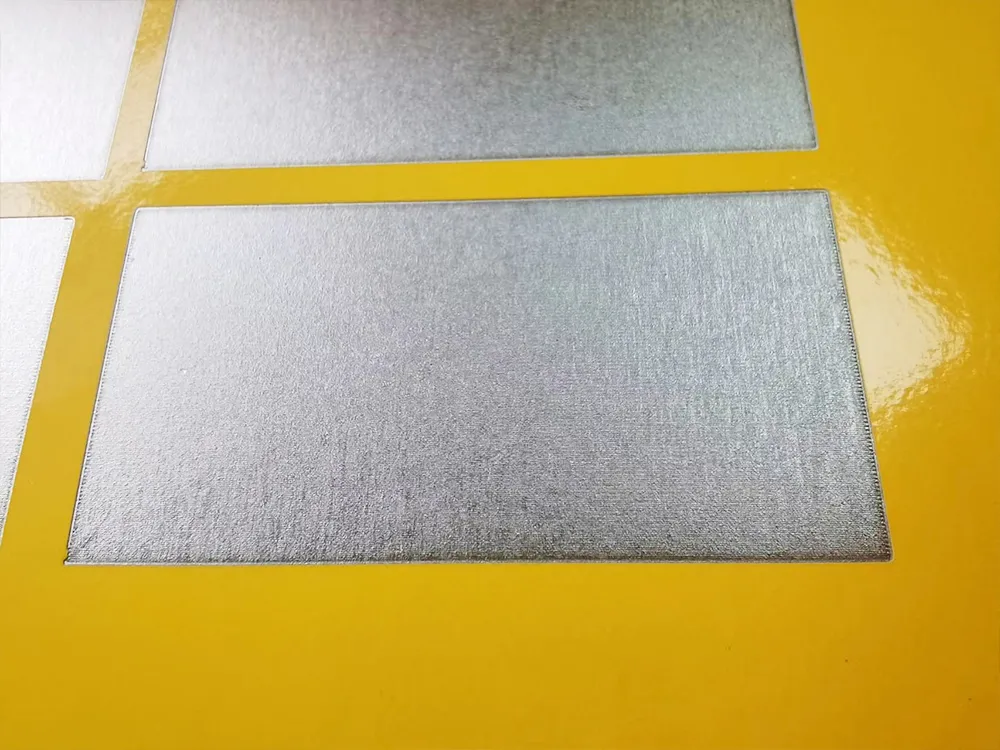

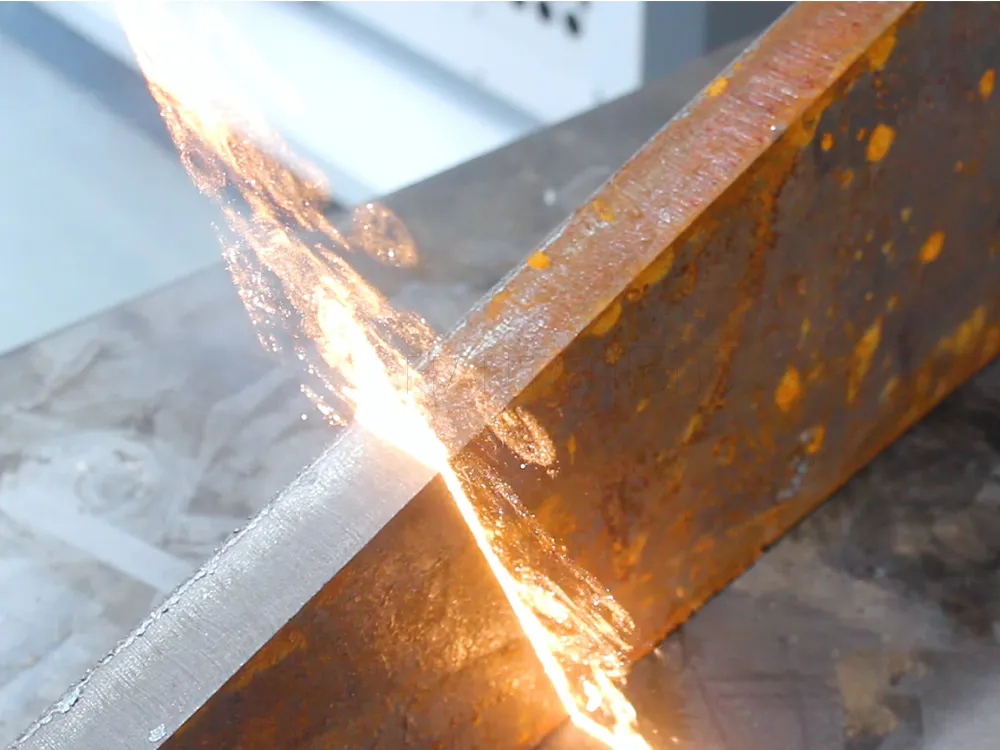

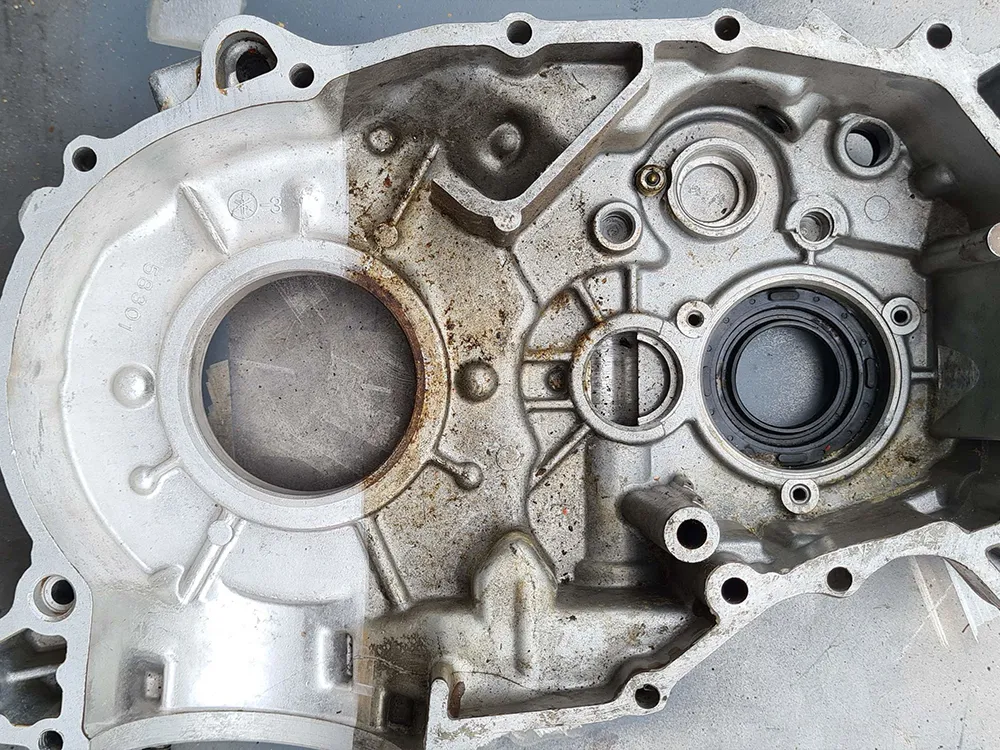

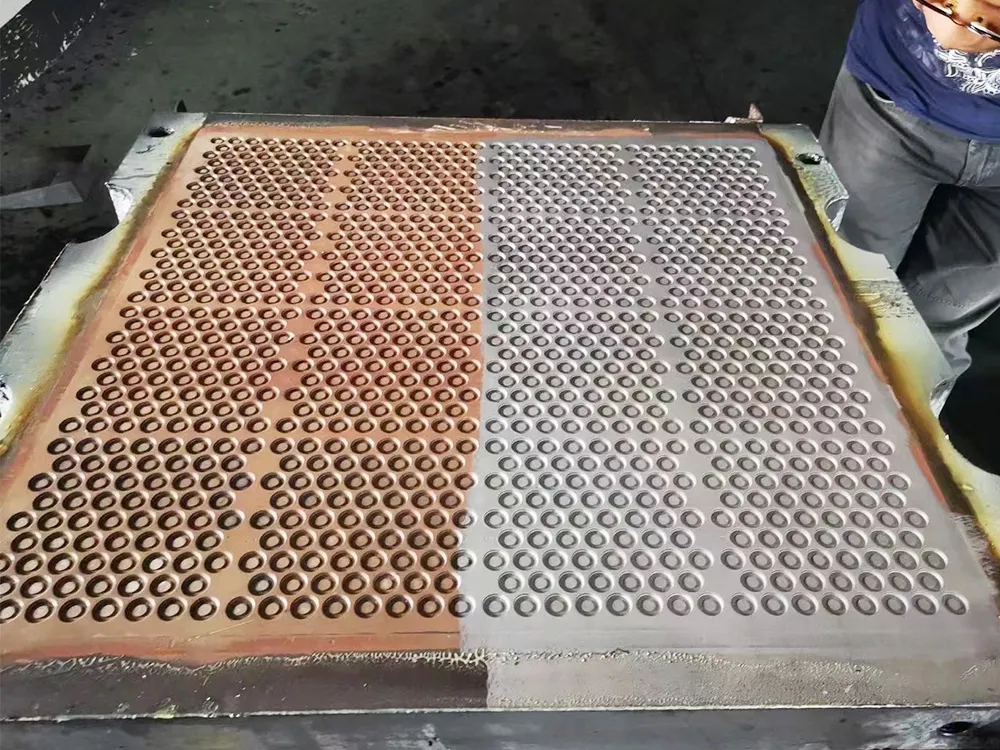

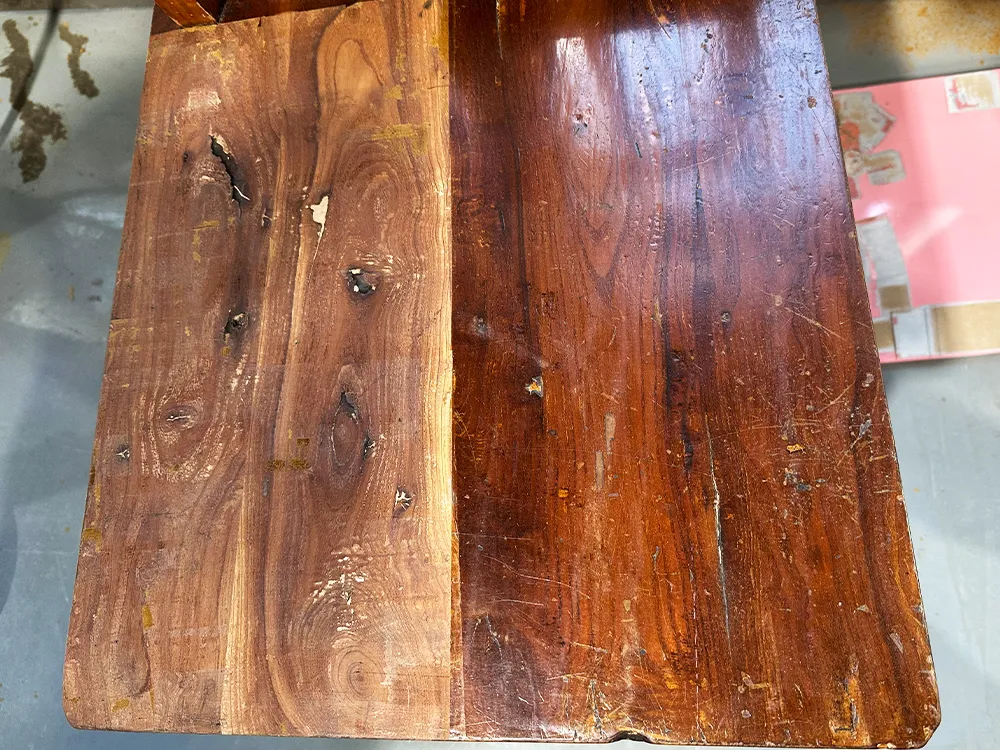

Laser cleaning is an advanced and outstanding material surface cleaning technology. HANTENCNC’s laser cleaning machine uses the high heat of the laser to evaporate paint, rust or dirt on the surface of the material to be cleaned after being heated. HANTENCNC’s laser cleaning machine does not require any other media or chemicals. It can be used when plugged in. It is very simple to operate and gradually replaces most traditional cleaning methods.

Laser cleaning machines can be divided into pulse laser cleaning machines and continuous laser cleaning machines. The two machines have different advantages and disadvantages:

Advantages of laser cleaning machine:

1. Suit for cleaning precision parts, cause no damage

HANTENCNC’s laser cleaning machine can adjust the cleaning width to achieve precise cleaning of the Ario surface. The pulse laser cleaning machine can not only complete meticulous cleaning but also leave almost no traces on the surface of the material. HANTENCNC’s pulse laser cleaning machine is very suitable for cleaning precision parts, cultural relics, or objects that have strict requirements on the surface base of the material.

2. Non-contact cleaning

HANTENCNC’s laser cleaning machine is a handheld laser cleaning head. Still, during the cleaning process, HANTENCNC’s laser cleaning machine and cleaning materials are non-contact cleaning processes. This not only ensures the safety of the operator but also reduces the use of the laser cleaning head. Wear and service life, improve cleaning efficiency. During use, this non-contact cleaning method can avoid the impact of human factors on cleaning quality.

3. Multiple cleaning modes

HANTENCNC’s pulse laser cleaning machine has multiple cleaning modes. The operator can switch the cleaning mode by clicking the scan mode option on the operation interface. Therefore, HANTENCNC’s pulse laser cleaning machine can be used to clean materials of different shapes and can be cleaned according to the surface of the material, thereby achieving the purpose of efficient cleaning.

4. High speed and high efficiency

HANTENCNC’s laser cleaning uses a laser to achieve the purpose of cleaning. Compared with most traditional cleaning methods, laser cleaning has the advantages of high speed and high efficiency. Most customers believe that the greater the laser cleaning power of HANTENCNC, the faster the cleaning speed and effect. This doesn’t seem right. HANTENCNC’s engineers will recommend machines that are suitable for them and can meet the needs of customers based on their different needs.

5. Use no chemicals, environmentally friendly cleaning

Most traditional cleaning methods require the use of some chemicals or cleaning media, which will produce a large amount of waste and pollution after cleaning. However, HANTENCNC’s laser cleaning machine does not use any chemicals. Therefore, HANTENCNC’s laser cleaning machine will not produce a lot of waste and pollution after cleaning, and it also reduces the cost of using consumables. Thus, the laser cleaning machine can be called an environmentally friendly cleaning machine, suitable for long-term development and use.

6. Save labour costs.

The operation of HANTENCNC’s pulse laser cleaning machine is effortless. It does not require the operator to obtain an operating certificate. HANTENCNC’s laser cleaning machine has a display screen. The operator can modify parameters through the display screen. Laser cleaning parameters can be set on the operation interface, including laser power, laser frequency, scanning speed, number of scans, scanning range (width, height), etc. The operator can accurately control the laser output through the operation interface to prevent the substrate from deforming due to excessive temperature. At the same time, it ensures that the material surface is not bent or damaged, thereby achieving different cleaning effects for other materials. Therefore, HANTENCNC’s laser cleaning machines can help factories save labour costs.

7. Safe and easy to operate

HANTENCNC’s laser cleaning machine is safe and easy to operate. The machine can adapt to various complex working environments. Under regular use, the laser has a service life of up to 100,000 hours. HANTENCNC’s laser cleaning machine has an efficient and fast cleaning process. HANTENCNC’s laser cleaning machine can help factories improve production efficiency and thereby obtain more profits.

8. Suit for various materials and can be widely used in various industries

HANTENCNC’s laser cleaning machine can be applied to a variety of materials. HANTENCNC’s laser cleaning machine can clean impurities on the surface of most objects, such as oil stains, paints, oxides, rust, coatings, etc. It can be widely used in various industries.

In fact, everything is a “sharp double-edged sword”. Laser cleaning machines have not only various advantages but also some disadvantages.

Disadvantages of Laser Cleaning Machine

1. Expensive

The price of a laser cleaning machine is more expensive than that of a traditional cleaning machine.

The initial investment cost of a laser cleaning machine is relatively high.

The price of a pulse laser cleaning machine is more expensive than a continuous laser cleaning machine in the market.

2. Certain safety risks

The operation of a HANTENCNC laser cleaning machine is relatively simple. However, the operator is required to wear laser-proof goggles. When using the HANTENCNC laser cleaning machine, a laser light will be emitted. Suppose appropriate safety protection measures are not taken. In that case, operators looking directly at the laser for a long time may cause dizziness. But don’t worry. HANTENCNC will provide high-grade anti-laser goggles for every customer who purchases a HANTENCNC laser cleaning machine.

The essence of a laser is a high-energy beam, which has certain safety risks. When using the HANTENCNC laser cleaning machine, please follow the safe operating procedures to prevent accidents.

3. Cannot clean all materials

Laser cleaning machines can clean most materials, but Laser cleaning cannot clean all materials, such as barnacles, thick oil and sensitive materials, etc.

-

Barnacles and Marine Biofouling: These organisms form a hard, calcified attachment to surfaces like ship hulls, which can be difficult for laser cleaning to fully remove without damaging the underlying material. Laser cleaning may not efficiently break the strong bond they form with surfaces.

-

Thick Oil or Grease Layers: While laser cleaning can remove surface contaminants, thick, sticky, or layered substances like heavy grease may require multiple passes or different cleaning methods, as laser cleaning is more effective on thin, brittle coatings.

-

Soft or Sensitive Materials: Materials like plastic, rubber, or other heat-sensitive substances can be damaged or warped by laser cleaning due to excessive heat or energy absorption.

-

Porous or Rough Surfaces: Laser beams may struggle to clean deep into the pores or crevices of highly textured or porous surfaces, potentially leaving behind residue or uneven cleaning.

However, some exceptional cases require testing. For example, cleaning paint from hoses involves testing.

If you have any needs, don’t hesitate to get in touch with HANTENCNC, we can conduct cleaning tests for you and recommend suitable machines to you.

4. Need add laser-specific antifreeze

The use of laser cleaning machines requires certain temperature conditions. 10-35 degrees Celsius is the most suitable room temperature for the HANTENCNC laser cleaning machine to work. If the temperature is too high, the machine needs to work and rest for some time. If the temperature is too low, water-cooled laser cleaning machines need to add laser antifreeze to the water-cooled machine.

The car’s antifreeze cannot be used, users must add laser-specific antifreeze.

The recommended ratio to add is:

-02~05℃, antifreeze: water=2:8

-12~15℃, antifreeze: water=3:7

-22~25℃, antifreeze: water=4:6

-32~35℃, antifreeze: water=5:5

-42~45℃, antifreeze: water=6:4

5. Continuous Laser Cleaning Machines: Micro-Damage to Substrates

Continuous lasers emit high energy in a constant, uninterrupted stream. However, this can lead to overheating of the surface, potentially causing issues such as micro-scratches or surface abrasions on the substrate.

Continuous laser cleaning machines are suitable for rough machining or large-scale cleaning tasks, including rust removal and cleaning of large equipment. They are ideal for large-scale cleaning and have high cleaning efficiency.

If you want 0 scratches to the substrates, then pulse laser cleaning is a suitable choice. Still, the prices of pulse laser cleaning machines are commonly higher than continuous laser cleaning machines.

6. Laser cleaning machines are not suitable for all Environments

Not all workplaces are suitable for laser cleaning machines, especially those containing flammable and explosive gases and liquids. Such places include: refineries and petrochemical plants, gas stations, chemical warehouses, paint or coating workshops, pharmaceutical plants, coal mines or natural gas extraction sites, alcohol or strong beverage breweries, etc.

Such places do have the risk of fire and explosion, especially in the case of flammable and explosive gases and liquids. Using laser cleaning machines will generate sparks, which may become potential ignition sources in flammable environments.

Therefore, laser cleaning machines are not recommended for all environments, and in specific cases, laser cleaning equipment generates sparks during work.

About HANTENCNC

HANTENCNC is a professional laser cleaning machine manufacturer with over 19 years of experience in designing and manufacturing laser rust removal machines, HANTENCNC offers a wide range of laser cleaners ranging from 100W to 3000W in power. Our laser cleaner collection includes portable, backpack, and trolley-type machines catering to various applications.

If you are interested in laser cleaning machines, click here to learn more: https://hantencnc.com/laser-cleaning-machine Or feel free to contact us; our sales manager will recommend a suitable laser rust removal based on the materials you want to clean.