What is protective lens on the welding head of a laser welding machine?

The protective lens on the welding head of a laser welding machine includes a protective lens, focusing lens, and collimating lens, which can prevent damage to the sensitive components of the welding head from spatters, debris, or intense heat generated during the welding process and extend the equipment’s lifespan.

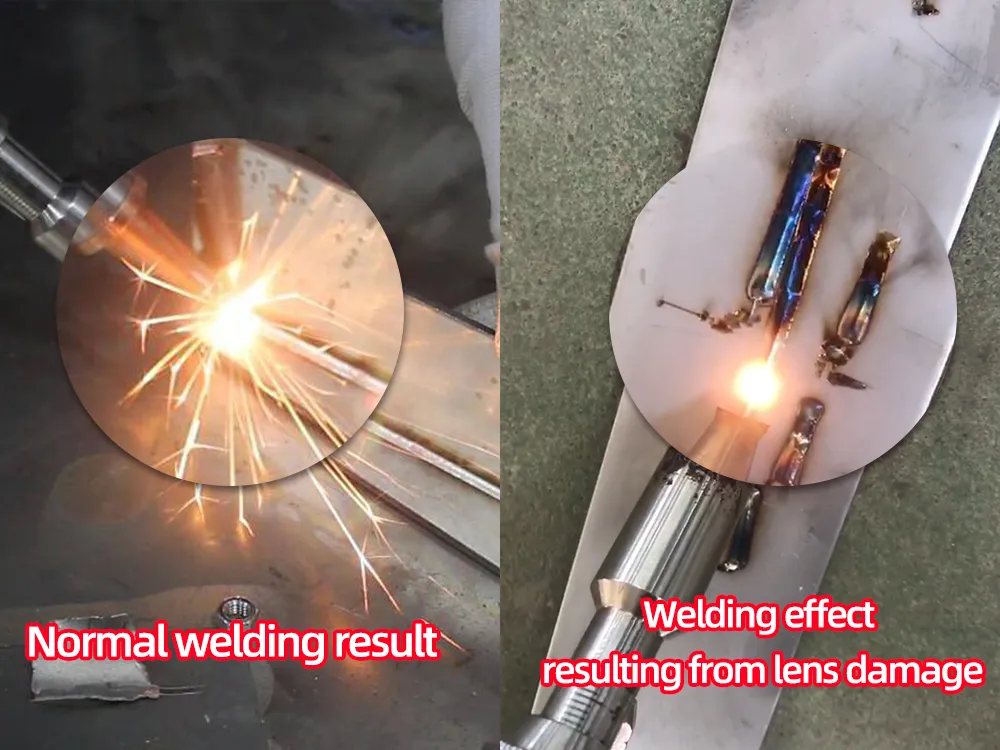

How can we confirm the protective lens is damaged?

When the protective lens is damaged, how can we quickly confirm the protective lens is damaged?

When this fault occurs, the following two situations often accompany it:

- When first started, the laser usually works. Still, it will gradually become weaker until it cannot melt the welding wire.

- There is an apparent flame at the welding copper nozzle.

Failure analysis

When the above situation occurs, it can be initially determined that the protective lens inside the welding gun is damaged.

Still, it is still being determined which group of protective lenses is faulty, whether it is the protective lens, focusing lens, collimating lens, reflective mirror, or any one or more of these lenses. The above situations will occur when a fault occurs. The order of checking the lenses is to replace the protective lens first, then check the focusing lens, then the reflector and collimating lens, and replace them according to the inspection results.

Apparent flames produced at the welding copper nozzle are most likely a focus issue.

Finally, check whether there is any contamination or damage to the QBH connector of the laser.

Whether a protective lens needs to be replaced?

Whether a protective lens needs to be replaced based on its condition:

- There are prominent black spots on the protective lens, which are caused by anti-slag or failure to replace the protective lens in time.

- Laser abnormalities caused by the laser’s Gaussian beam being too sharp will cause a white spot to appear in the middle of all lenses.

- If the lens swings abnormally due to interference or the position of the red light is too biased, in this case, the sealing ring will burn out together.

- If the convex surface of the automatic welding head lens is damaged, it is usually caused by pollution, and the damage will be black spots.

- If the flat surface of the automatic welding head lens is damaged, it is due to diffuse reflection of the laser, and the damaged state will be white spots.

How to avoid protective lens damage?

How to avoid damaging the protective lens? And what can we do to avoid damaging the protective lens?

- It is recommended to use the original protective lenses

- Pay attention to protecting against contaminants when replacing lenses

- During the welding process, the welding gun should not be perpendicular to the welding object, especially when welding high-reflective metal materials

- Replace damaged lenses promptly.

- Ensure proper grounding by securing the machine ground wire.