UV laser marking machines have revolutionized the world of marking and engraving. It offers precision, versatility, and durability. In this comprehensive guide, we will explore the ins and outs of UV laser marking technology. These include its applications across various industries and how to choose the suitable machine for your needs.

What is A UV Laser Marking Machine

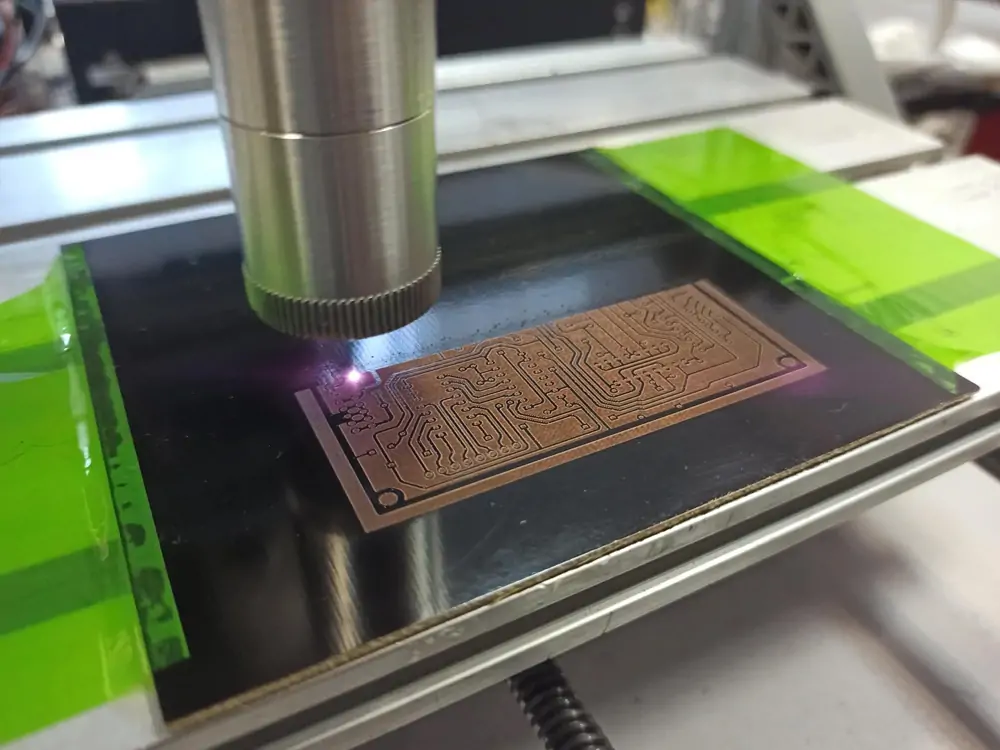

UV laser marking machines use high-energy ultraviolet light to create permanent markings on various materials. These machines operate on the principle of photo disruption. The high-intensity UV laser beam removes or alters the surface material, leaving behind a precise mark. This process ensures high resolution and clarity in the markings.

Laser Source

The core of the UV laser marking machine is the ultraviolet laser source. It typically uses diode-pumped solid-state lasers such as Nd: YAG or Nd: YVO4 crystals. These lasers produce high-energy, short-wavelength ultraviolet laser light.

Stimulating Materials

The laser source converts electrical energy into light energy by exciting materials such as Nd: YAG or Nd: YVO4 crystals. These materials are excited to high energy levels and then release laser photons in a controlled manner, producing a laser beam with a specific wavelength and energy.

Frequency Conversion

In some UV laser marking machines, the laser may need to be frequency converted to a shorter UV wavelength. It is usually achieved through the use of frequency doubling or mixing techniques. It ensures that a UV laser is produced suitable for the specific application.

Beam Control

By using optical components such as lenses and mirrors, UV laser marking machines precisely focus the laser beam onto the surface that needs to be marked. The beam’s focus directly affects the resolution and clarity of the mark.

Material-laser Interaction

A photochemical reaction occurs when a UV laser beam interacts with the material surface. These may include oxidation, evaporation, or surface color change, depending on the nature of the material. This interaction results in the formation of marks.

Control System

UV laser marking machines are usually equipped with advanced control systems. It can precisely control the laser’s intensity, speed, and position. It allows users to adjust marking parameters according to specific needs to achieve markings of different depths and shapes.

Types of UV Laser Marking Machines

A laser UV marking machine is a device used to create marks on various materials. It can be divided into types according to working principles and application requirements. The following are some common types of UV laser marking machines.

DPSS UV Laser Marking Machine

This type of laser UV marking machine uses a diode-pumped solid-state laser. It usually uses Nd: YAG (yttrium aluminum oxide) or Nd: YVO4 (yttrium vanadium oxide) crystal as the laser medium. They have high energy density and are suitable for deep engraving and engraving applications. Such as marking metal and ceramics.

Fiber UV Laser Marking Machine

This UV laser marking machine uses optical fiber as the transmission medium. It usually uses diode-pumped solid-state lasers, such as Nd: YVO4. They have a compact design and good beam quality, making them suitable for high-precision marking and delicate engraving. Such as creating tiny marks on electronic components.

CO2 UV Laser Marking Machine

Although the CO2 laser is not a UV light source, in some devices, a UV beam can be obtained through frequency multiplication and mixing. These machines are suitable for specific special applications. Such as marking ceramics, plastics, and some organic materials.

Excimer Laser UV Marking Machine

The Excimer laser is a laser specifically designed to produce UV laser light. It typically operates around a wavelength of 193 nanometers. They are used for high-precision, high-resolution markings, especially in the semiconductor and electronics industries.

Applications of UV Laser Marking Machine

UV laser marking machines are widely used in various industries. High precision, efficiency, and clarity make it ideal for marking and engraving applications. Here are some of the main application areas for laser UV marking machines.

1. Electronics Industry

- Electronic Component Marking: UV laser marking machines can create tiny markings on small electronic components. Such as chips, circuit boards, and connectors.

- Phone And Tablet Marking: Mark electronic devices using UV lasers to ensure mark durability and traceability.

2. Medical Device And Pharmaceutical Industry

- Medical Device Marking: UV lasers can create clear, durable markings on medical devices, ensuring device traceability and quality.

- Pharmaceutical Packaging Marking: Use a UV laser to mark pharmaceutical packaging to achieve high-definition serial numbers, production dates, and other information.

3. Industrial Manufacturing

- Parts Identification: UV laser marking machines can mark unique identification, serial numbers, or brand information on parts.

- Metal Marking: UV laser is suitable for high-precision marking on metal surfaces. For example, marking car parts.

4. Automobile Industry

- Auto Parts Marking: UV lasers can mark auto parts permanently for traceability and quality control.

- Auto Glass Marking: Marking on auto glass using a UV laser. For example, add vehicle identification or production date to the glass.

5. Aerospace Industry

- Aerospace Parts Marking: UV laser marking machines are used in the aerospace industry to create high-precision marks on parts to meet industry standards and requirements.

- Aircraft Marking: Marking using UV laser on aircraft surface. For example, add the aircraft model and registration number.

6. Plastics And Packaging Industry

- Plastic Product Marking: UV laser can make clear markings on plastic products. For example, add the production date or company logo on injection molded parts.

- Food Packaging Marking: Use a UV laser to mark food packaging to ensure clear and safe marking.

What to Consider When Choosing A Suitable UV Laser Marking Machine

Choosing a suitable laser UV marking machine requires careful consideration of multiple factors. It ensures that the equipment meets your specific needs. Here are some key factors.

Ⅰ. Application Requirements

Different UV laser marking machines are suitable for different types of materials. Determining the materials you need to mark is the first step in choosing the right equipment. Again, consider your mark depth and clarity requirements to determine the laser power and beam quality required.

Ⅱ. Technical Specifications

The wavelength of a UV laser can affect its ability to penetrate different materials. Choose the appropriate wavelength to match the marking material. Also, select the proper laser power based on the application’s requirements. High power is generally suitable for deep engraving and engraving. Low power is ideal for surface marking.

Ⅲ. Accuracy And Resolution

The machine’s beam quality directly affects the accuracy and resolution of marking. Choose equipment with high beam quality to get clear marks. Again, consider the device’s focusing system to ensure that the required marking accuracy can be achieved.

Ⅳ. Production Speed

For high-volume applications, faster marking speeds are required. Understand your machine’s marking speed to ensure it can meet your production needs.

Ⅴ. Costs And Budget

The price of a standard UV laser marking machine ranges from US$4,000 to US$10,000. Consider the purchase cost of a laser UV marking machine, but also pay attention to operating and maintenance costs. Conduct a cost-benefit analysis of equipment before purchasing. Ensure the equipment you choose will be cost-effective for your business in the long term.

Ⅵ. Customization Requirements

If you need to mark on particular materials or have unique marking specifications, ensure the equipment you choose meets those custom needs.

Ⅶ. Manufacturer And Supplier Selection

Investigate the reputation and brand of the UV laser marking machine manufacturer to ensure you choose reliable equipment. Find out about the after-sales service and support provided by the manufacturer. These include maintenance, training, and technical support.

Conclusion

In this comprehensive guide, we look in-depth at how laser UV marking machines work, their application areas, and the critical factors in choosing one that’s right for your needs. With its high precision, efficiency, and diversity, UV laser marking technology has become an ideal choice for marking and engraving in industrial, medical, electronics, and other fields.

Choosing a suitable laser UV marking machine is crucial. This guide’s key factors and considerations will help you find the device that best suits your needs among the many options available. Whether you are pursuing high-precision marking or an efficient production line, UV laser marking machines will continue to play an irreplaceable role.