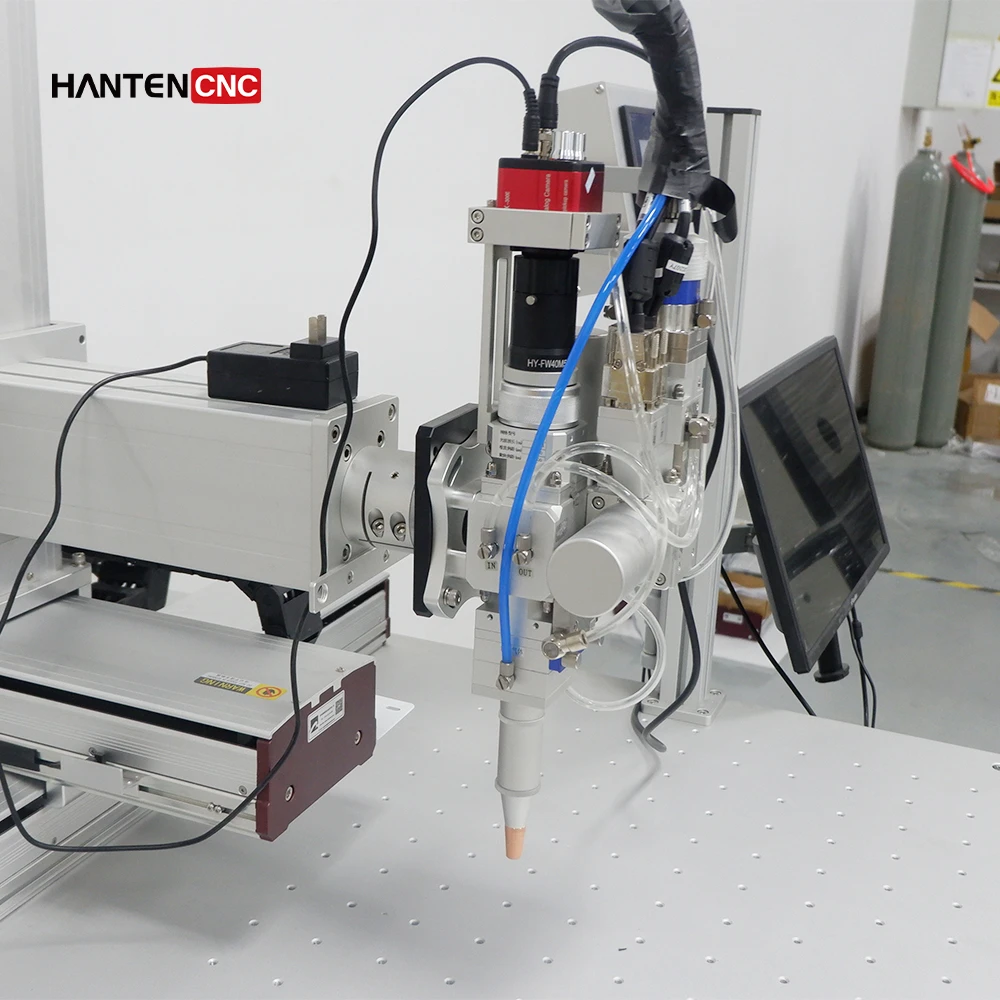

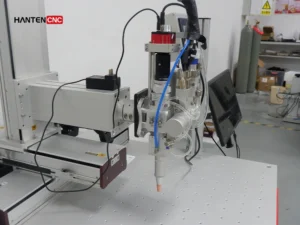

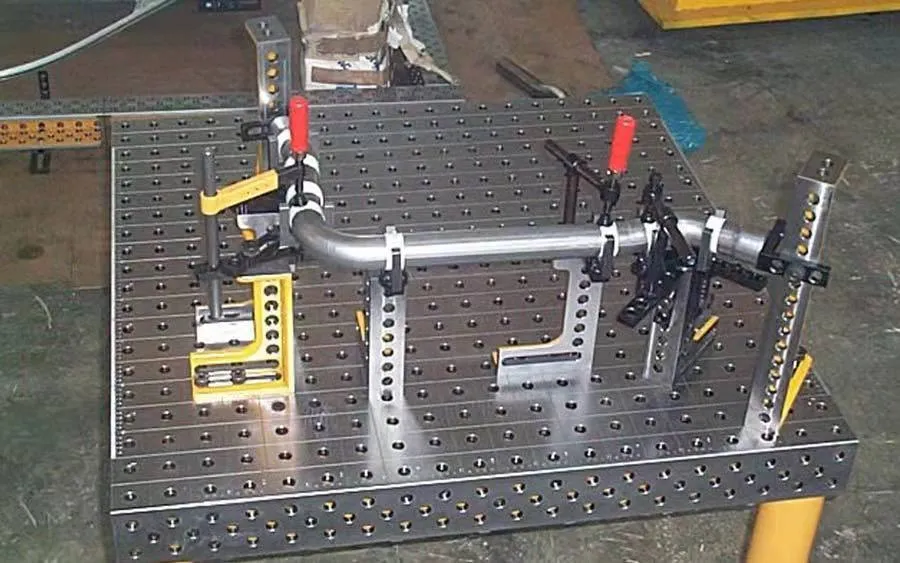

HANTENCNC’s platform automatic laser welding machine, equipped with an XYZ axis in a large working area, enables precise positioning and flexibility for various workpieces, which is an ideal solution for automated, accurate, flexible, and efficient laser welding.

HANTENCNC’s automatic laser welding machine integrates with automation systems and ensures high speed, adaptability, and a streamlined production process.

1000W Automatic Laser Welding Machine Demonstration Video

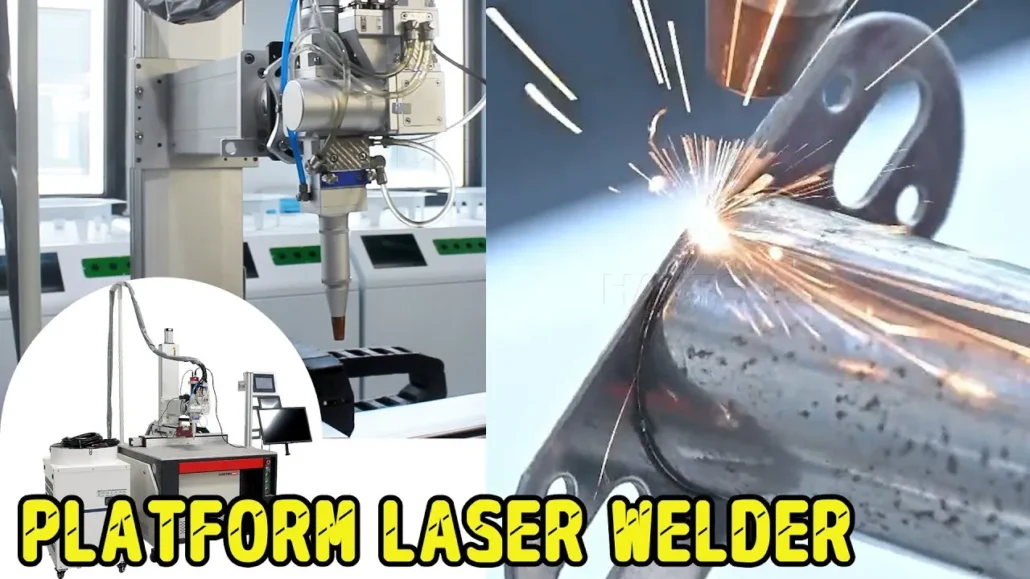

Display of Platform Automatic Laser Welding Machine

1000W Platform Automatic Laser Welding Machine Parameters

| Model | HTW1000/1500/2000/3000 |

|---|---|

| Laser source | MAX/Raycus/JPT |

| Laser power | 1000W//1500/2000/3000 |

| Fiber cable length | 10M/12M/15M/Maximum20M |

| Wavelength | 1080nm |

| Spot diameter | 0.5-3mm |

| Welding focal length | F=150mm |

| Maximum oscillation speed | 20000mm/s |

| Laser divergence angle | ≤5rad |

| Total power | 6KW/6KW/7KW/8KW |

| Running accuracy | 0.2mm |

| Coaxial accuracy | 0.02mm |

| Working Voltage | 1000W and 1500W: 220V 2000W and 3000W: 380V |

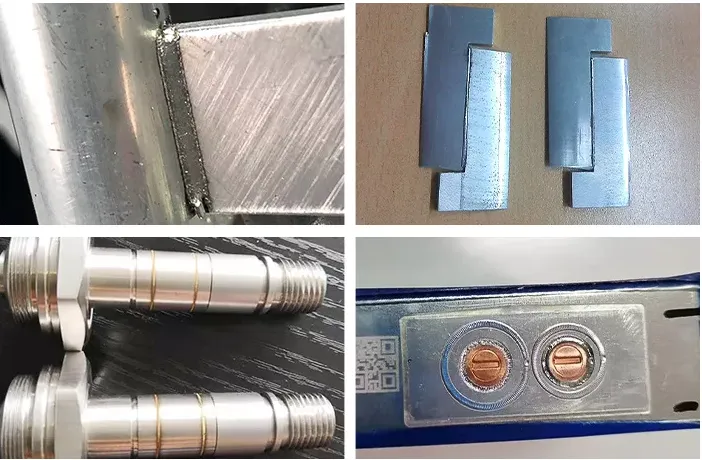

Sample Display

Advantages of Platform Automatic Laser Welding Machine

High Precision

Automatic platform laser welding machines offer exceptional precision in welding operations. The laser beam allows precise control over the heat input, resulting in accurate and consistent welds. This is particularly beneficial for applications that require tight tolerances and intricate welds.

Speed And Efficiency

Laser welding is faster than traditional welding methods. Platform laser welding machines can perform rapid and continuous welding, significantly reducing cycle times and increasing production efficiency. This speed advantage translates to higher throughput and reduced production costs.

Versatility

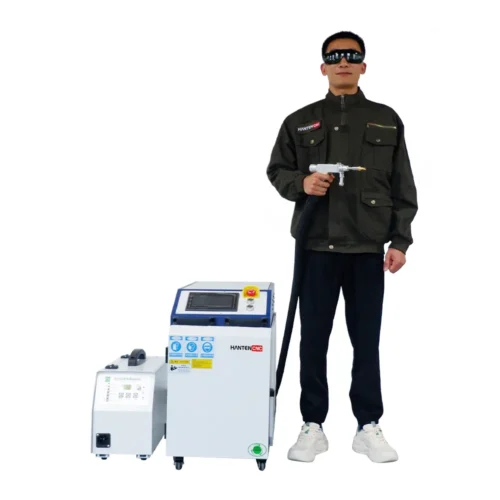

Platform automatic laser welders are highly versatile and can handle various materials. Including metals and alloys. They can easily weld different thicknesses and combinations of materials. This makes them suitable for diverse applications across automotive, aerospace, electronics, and more industries.

Minimal Heat Affected Zone (HAZ)

Laser welding generates a concentrated, localized heat source. It results in a minimal heat-affected zone (HAZ) around the weld area. This reduces the risk of material distortion, preserving the surrounding material’s mechanical properties.

Weld Quality And Consistency

Laser welding offers excellent weld quality with high joint strength and integrity. Platform automatic laser welding machines ensure consistent welds throughout production, eliminating variations commonly associated with manual welding. This leads to improved product quality, reduced rework, and enhanced reliability.

CNC Laser Welding Machine Maintenance

Clean the protective lens: Gently wipe the dusty protective lens surface with a small amount of absolute ethanol.

It can only be wiped in one direction, not back and forth, so as not to wipe the protective lens back and forth.

Avoid causing secondary pollution: Repeat wiping in the same direction several times until the protective lens is wiped clean.

If the protective lens is found to be stained and cannot be cleaned or the protective lens is broken, it should be replaced in time.

Customer Visits

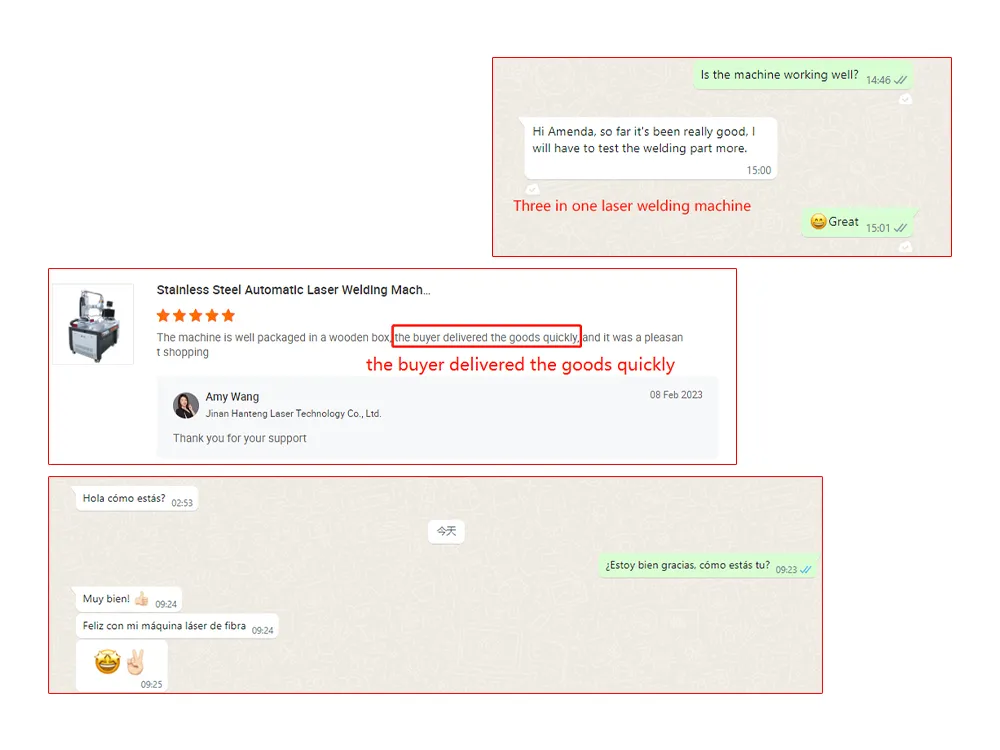

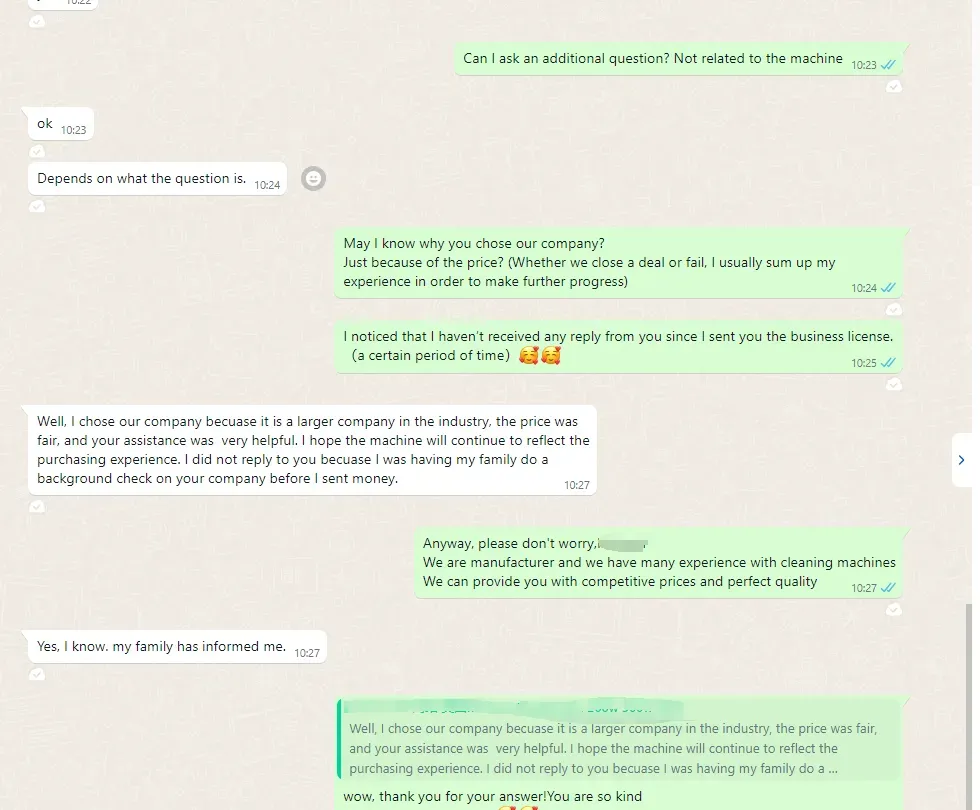

Customer Reviews