Equipped with a manual articulating galvanometer mirror, the 1500W laser welder is suitable for small-batch welding and repair welding in lithium battery welding production. HANTENCNC’s 1500W laser welder is designed for high-precision welding of lithium-ion battery tabs and components.

1500W Laser Welder Machine Display

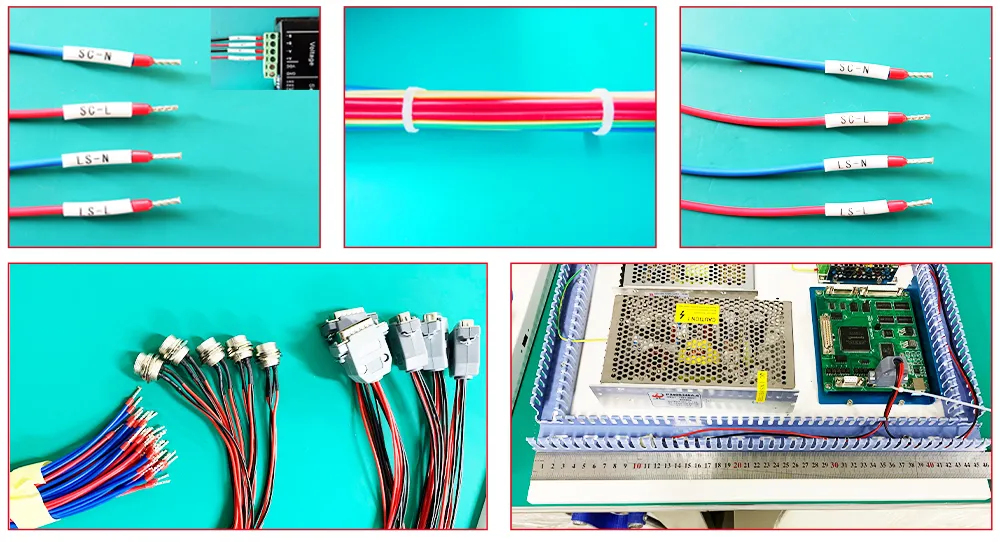

Component Detail Display of 1500W Laser Welder

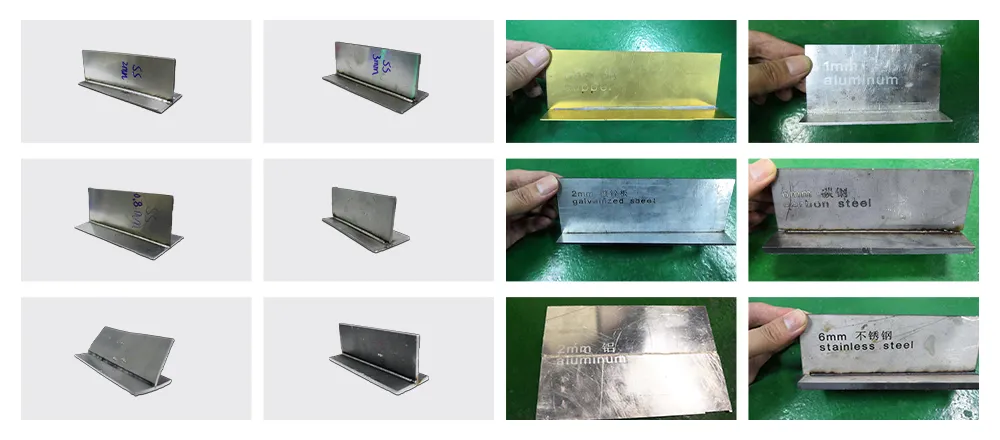

1500W Laser Welder Dimensions

1500W Laser Welding Machine Parameters

Machine Parameters |

|

| Model | HTW1500W |

| Laser Power | 1500W |

| Working voltage | Single phase 220v AC 50/60Hz |

| Machine dimensions | 900*400*1380mm |

| Machine weight | 40kg |

| Wavelength | 1060nm |

| Fiber cable length | 10M/12M/15M/Maximum20M |

| Power regulation range | 10%-100% |

| Modulation frequency | 5kHz |

| Welding range | 60mm*5mm |

| Maximum Oscillation Speed | 20000mm/s |

| Power dissipation | 4.5kw |

| Cooling method | Water-cooled |

1500W Laser Welder Details

Handheld Control Lever

The handheld control lever allows the welder to move and adjust the welding position more flexibly during the welding process. Suitable for various complex welding environments and positions.

The control screen can display real-time parameters during the welding process, such as current, voltage, welding speed, etc. This enables welders to monitor the welding status in real-time, ensuring that parameters are within the expected range and reducing welding defects.

Compact Body

The compact body structure comprises a laser parameter interface, key switch, emergency stop button, heat dissipation port, dual-temperature water chiller, and laser generator, ensuring complete functionality.

Its compact size allows for easy mobility, simple operation, and robust durability.

Water-cooled

The water cooling system effectively reduces the temperature of welding equipment (such as welding guns, welding cables, and welding machine bodies), reducing the damage of heat to the equipment.

The water cooling system can stably maintain the working status of the equipment, thereby improving the continuity and production efficiency of the production line.

Well-organized Internal Wiring

The use of carefully designed internal wiring significantly improves the reliability, safety, and usability of the equipment, while optimizing device performance and user experience.

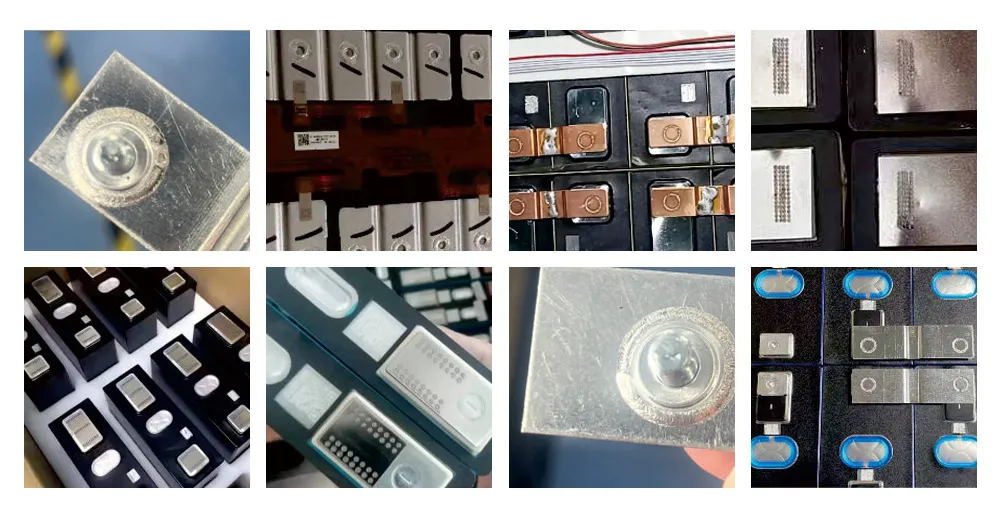

1500W Laser Welder Results Display

Customer Visits

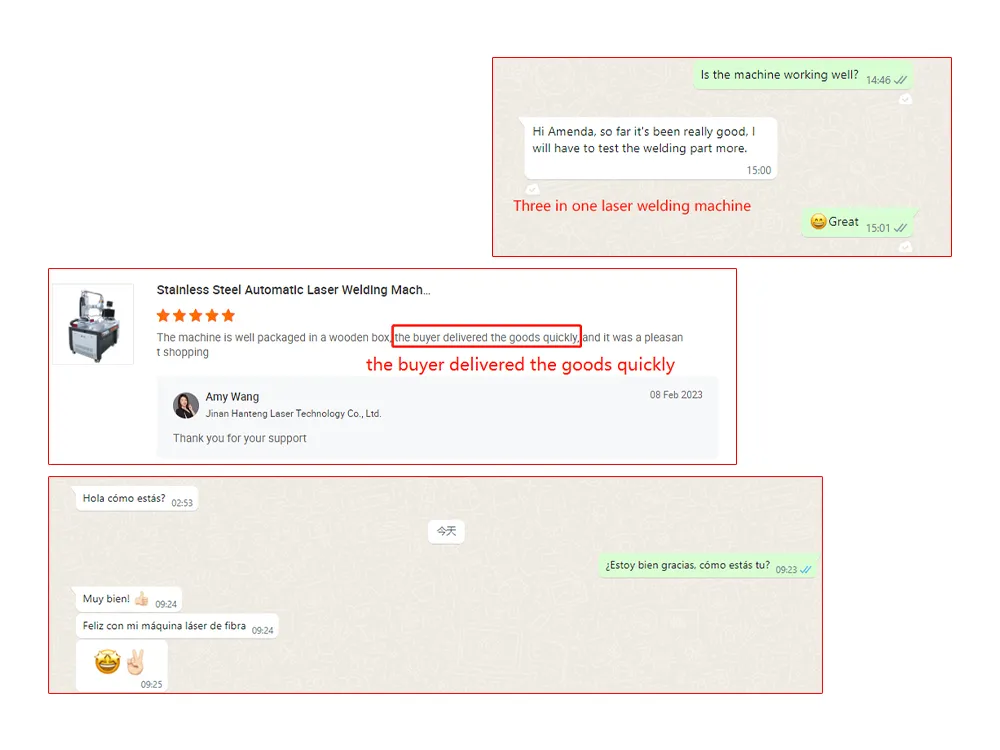

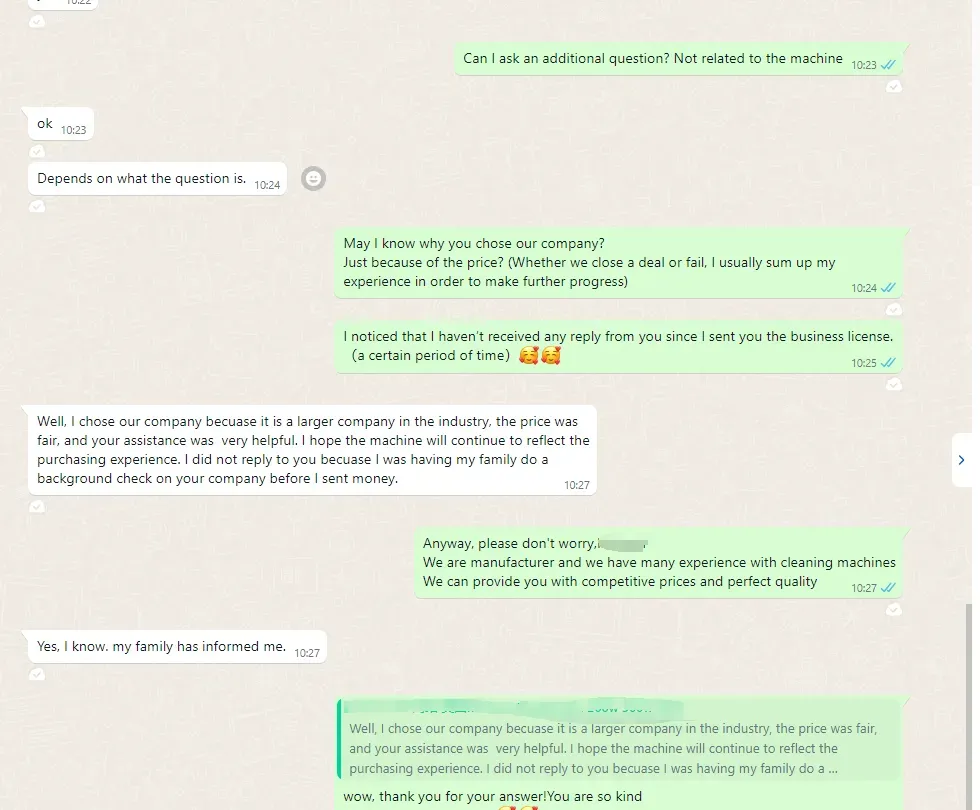

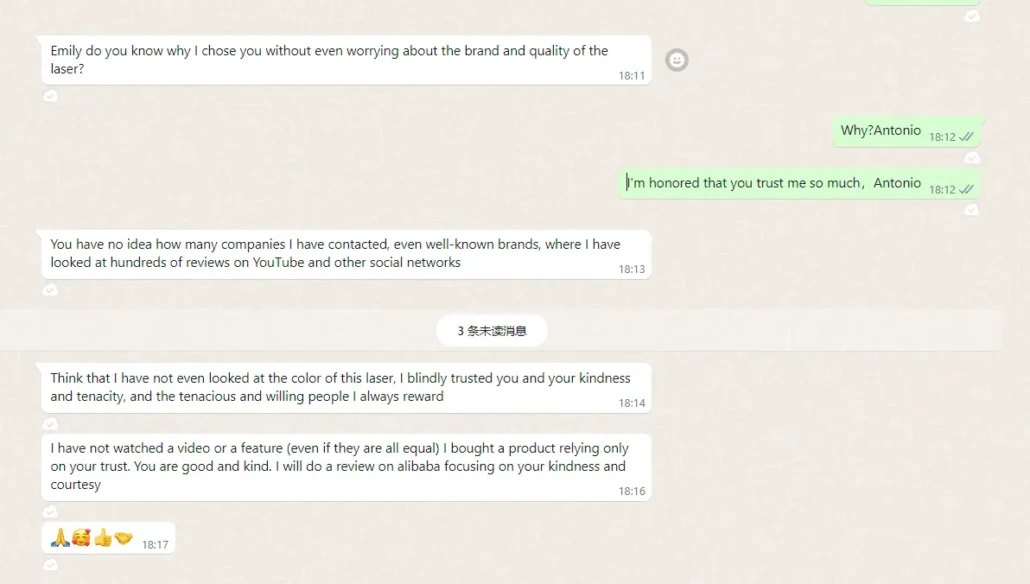

Customer Reviews

Certificates