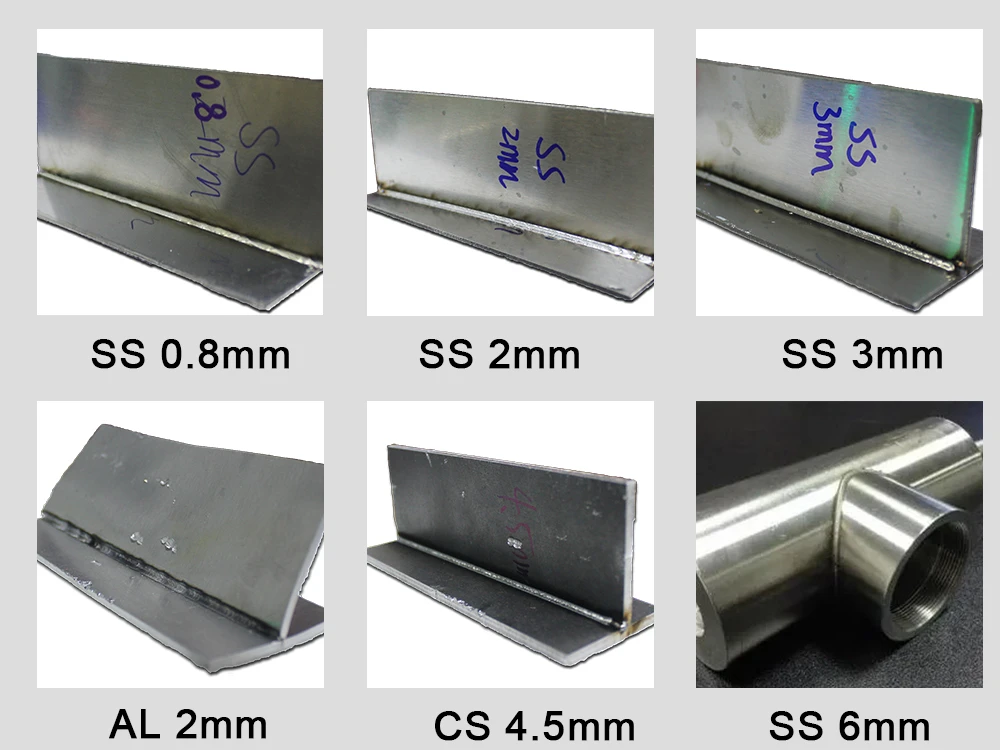

The powerful and flexible fiber laser welder machine is suitable for a wide range of metals, such as stainless steel, aluminium, copper, and titanium, which can meet various welding needs.

This handheld laser welder machine supports various hardware configurations, including a laser welder machine, a 3-in-1 laser welder machine, a 4-in-1 laser welder machine, or even a 5-in-1 laser welder machine. If you only need an essential welding function, it can be used only as a laser welding machine. You have the flexibility to select the hardware configurations according to your budget and needs.

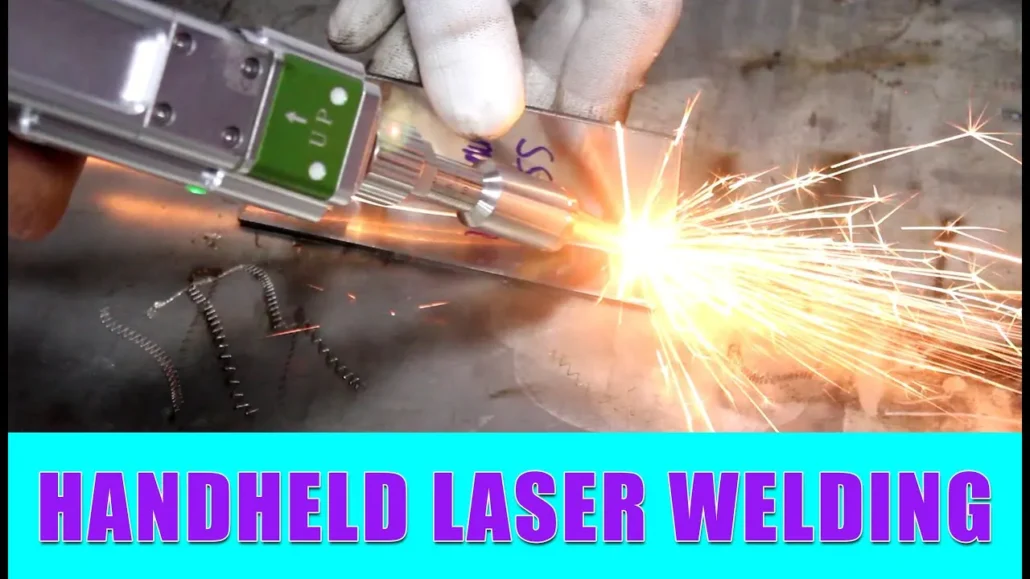

Handheld Laser Welder Machine Demonstration Video

Handheld Laser Welder Machine Details

Component Details Display of Fiber Laser Welder Machine

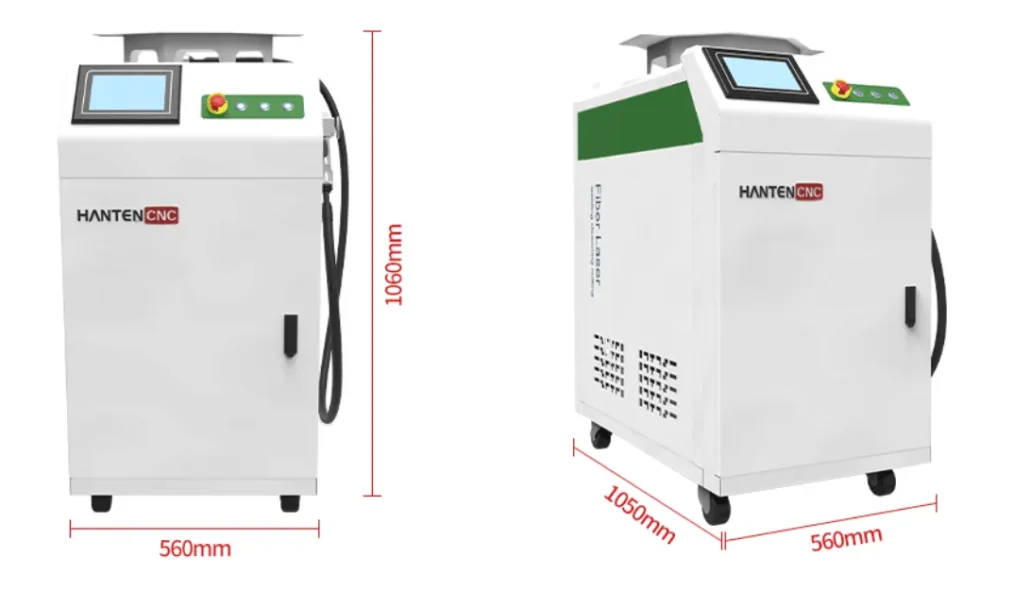

Handheld Fiber Laser Welder Machine Dimensions

Fiber Handheld Laser Welding Machine Parameters

| Model | HTW1000/HTW1500/HTW2000/HTW3000 |

|---|---|

| Laser power | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1080nm |

| Fiber length | 10M/12M/15M/Maximum20M |

| Operating mode | Continuous Welding |

| Maximum Oscillation Speed | 20000mm/s |

| Operating system | Handheld Welding System |

| Optimal operating temperature | -10℃-40℃ |

| Humidity range Operating environment | < 70% non-condensing |

| Working voltage | 220V/1P for 1000W and 1500W 380V/3P for 2000W |

| Cooling mehod | Water Cooled |

| Welding gap requirements | ≤0.5mm |

| Welder dimensions | 1050*560*1060mm |

| Welder net weight | 165KG |

| Package dimensions | 1530*770*1380mm |

| Package weight | 260KG |

How to Choose Single Pendulum And Double Pendulum Head?

- The maximum laser welding seam of the single pendulum is 4mm. And the maximum laser welding seam of the double pendulum is 5mm.

- Use a double pendulum for materials over 3mm. Triangular pattern for use with wire feeder and semicircular pattern for welding aluminum.

Comparison With Other Welding

| Compare items | Traditional welding | YAG laser welding | Hantencnc new generation laser welding machine |

|---|---|---|---|

| Heat input to workpiece | very high | Low | Low |

| Deformation of workpiece, undercut | Big | small | small |

| Bonding strength to female edge | Generally | Good | Very good |

| Follow-up | Polished | No sanding, or very little sanding | No sanding, or very little sanding |

| Welding speed | Generally | More than 2 times that of argon arc welding | More than 2 times that of argon arc welding |

| Weld spot | Large welding spot | Fine welding spot, adjustable spot | Fine welding spot, adjustable spot |

| Applicable materials | Stainless steel, carbon steel, galvanized sheet | Stainless steel, carbon steel, galvanized sheet | Stainless steel, carbon steel, galvanized sheet |

| Consumables | Lots of consumables | less consumables | less consumables |

| Difficulty of operation | Complex | Generally | Simple |

| Operator safety | unsafe | Safety | Safety |

| Environmental impact | Not environmentally friendly | Environmental Protection | Environmental Protection |

| Welding tolerance | Good | Not good | Good |

| Swing welding | none | none | Have |

| Spot width adjustable | none | none | Have |

| Welding quality comparison | Difference | Generally | Very good |

| Beautiful | Unsightly and expensive to polish | Smooth and beautiful, low grinding cost | Smooth and beautiful, low cost |

| Perforation | Easy to pierce | Non-perforated, energy adjustable | Non-perforated, energy adjustable |

| Protective gas | Argon gas required | Argon gas required | Argon gas required |

| Precision of machining | Generally | Precision | Precision |

| Addition time sum | Time consuming | Short time | Short time-consuming, ratio 1:5 |

More Choices

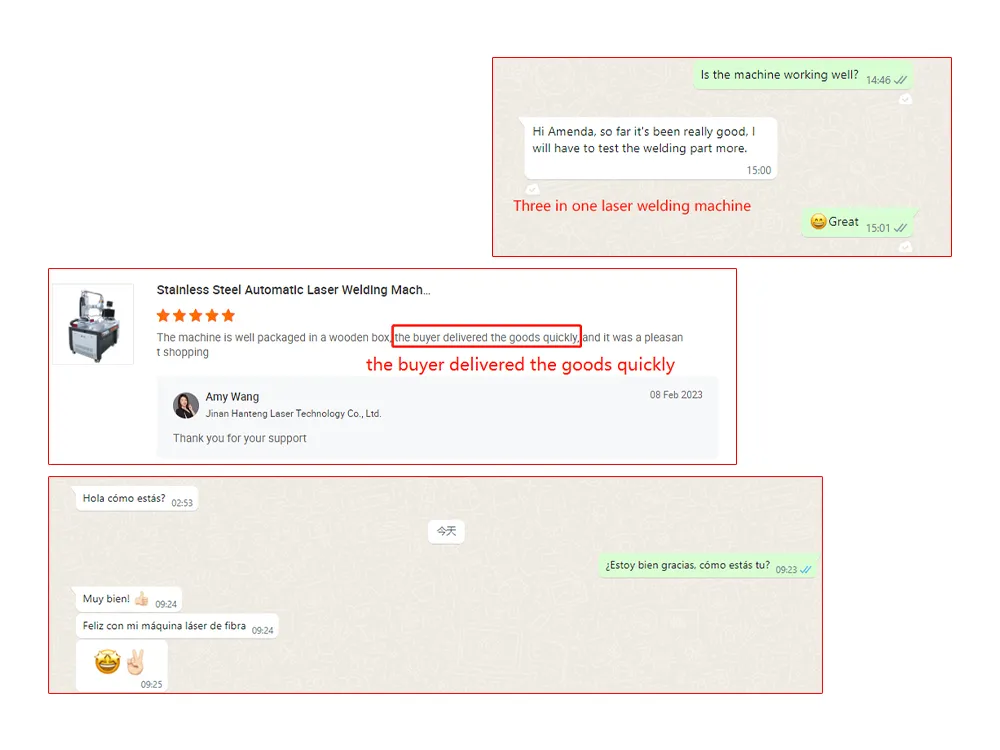

We have launched a 3-in-1 laser gun that integrates cleaning, welding, and cutting functions.

One machine with three functions can reduce purchasing costs for users. This handheld fiber laser welder is suitable for aluminum, stainless steel, and other metal parts that need to be welded.

It can also be used to clean, remove rust, and treat certain metal surfaces. During use, welding and cutting share the same laser head, requiring only a nozzle change. However, the cleaning function requires a specialized cleaning head, while the handle remains unchanged. This design enables the same laser system to adapt to different job requirements flexibly.

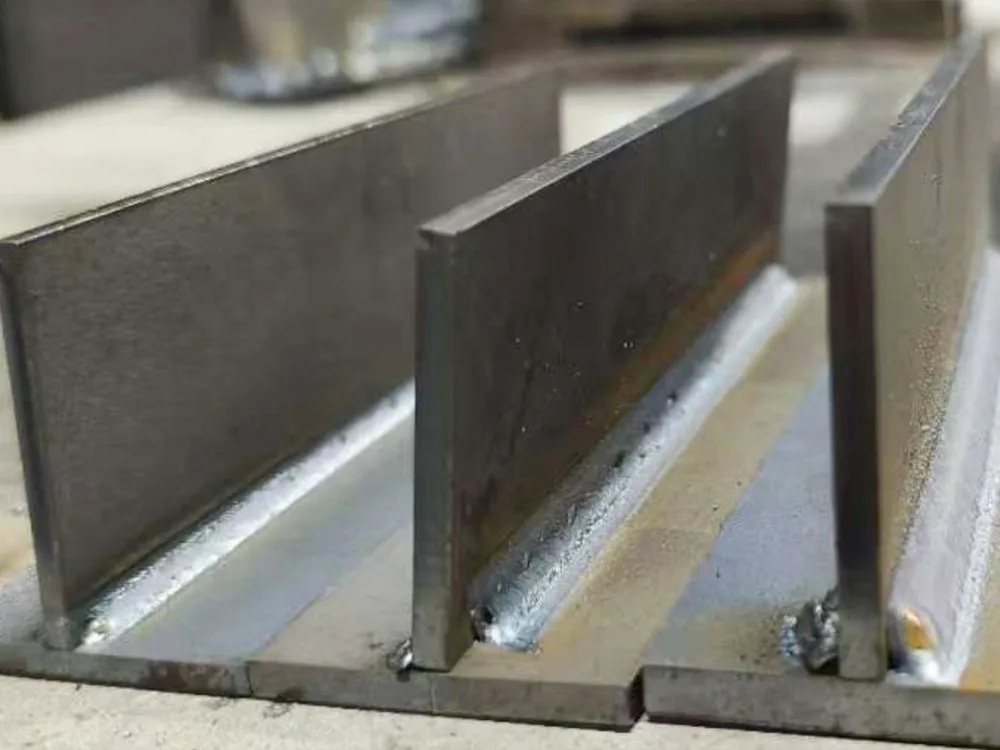

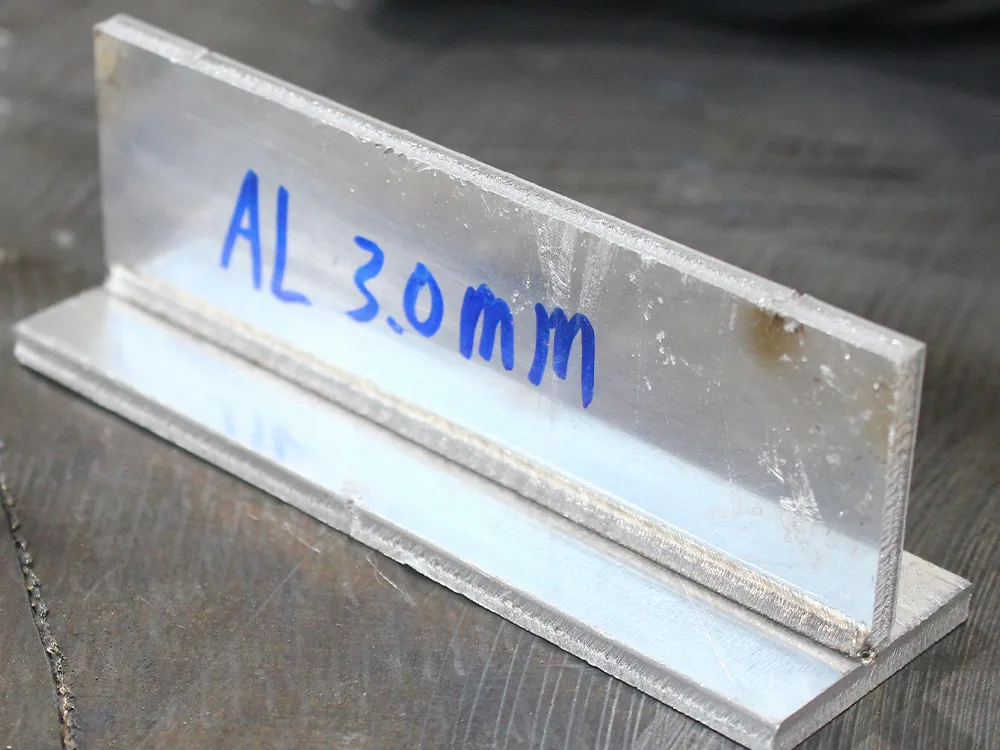

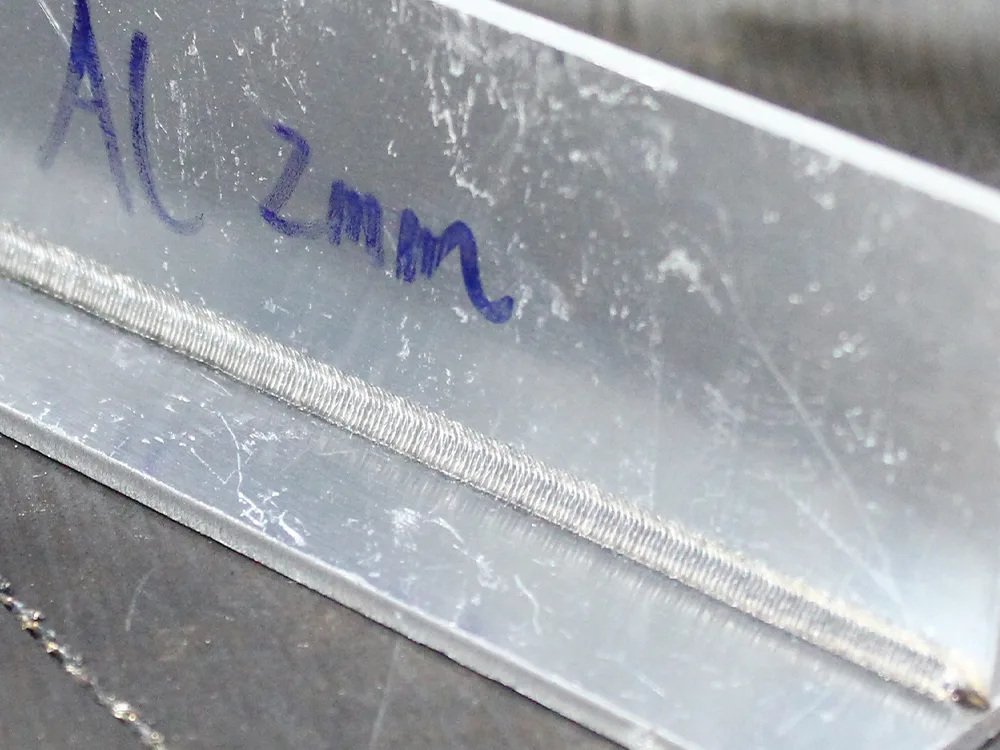

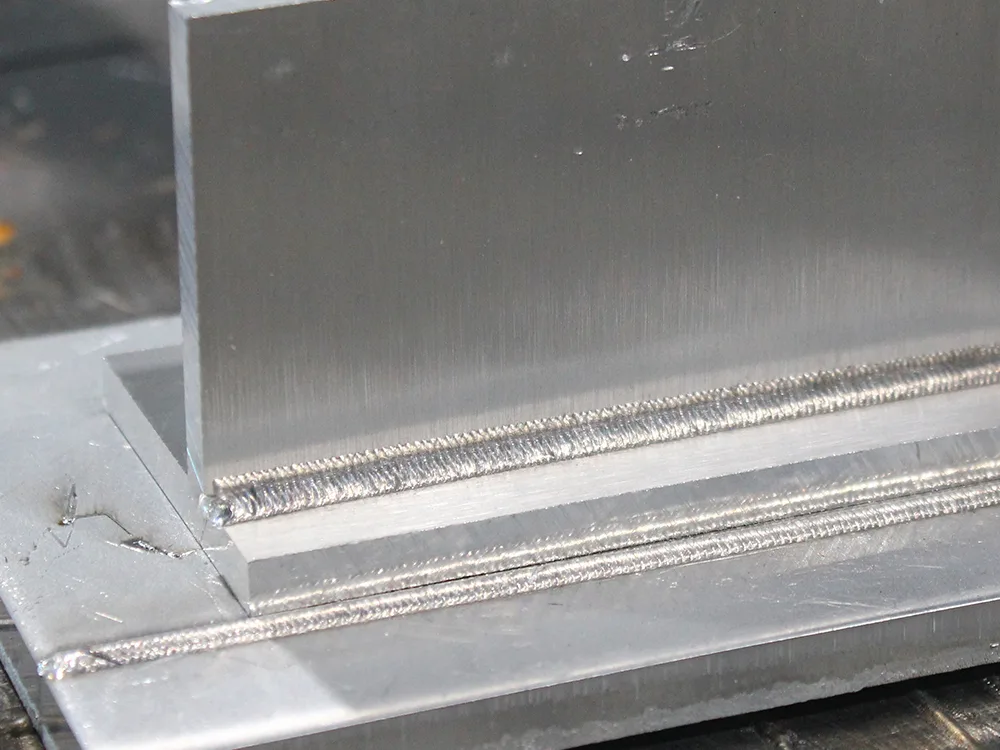

Welding Results Display

Customer Visits

Handheld Fiber Laser Welder Machine Certificates

HANTENCNC owns trademark registration certificates, utility patent certificates, software copyright certificates, etc.

HANTENCNC’s handheld fiber laser welder machines are CE and FDA-certified, ensuring high quality and safety.

You can trust HANTENCNC and HANTENCNC’s handheld fiber laser welder machines backed by these certificates.

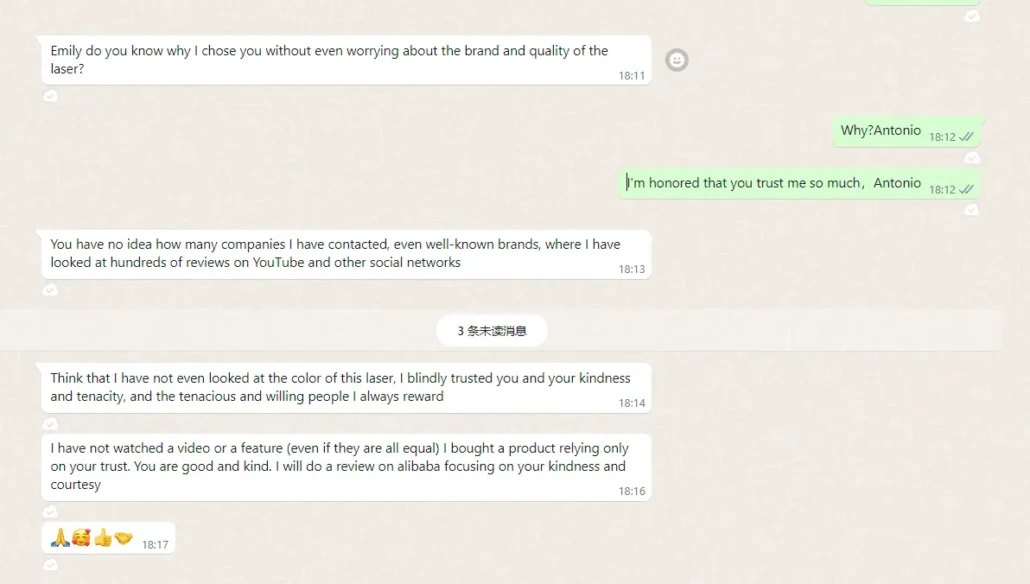

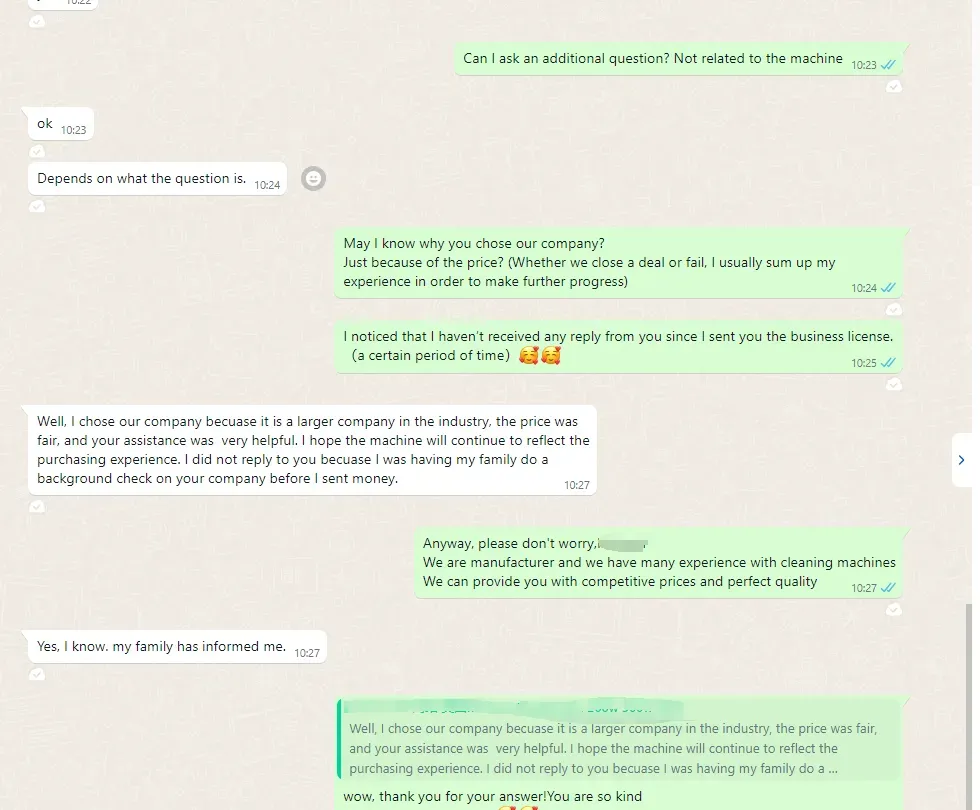

Customer Reviews

HANTENCNC Partnerships

HANTENCNC Services

HANTENCNC provides free sample testing, a 2-year warranty for the laser source, a 1-year warranty for the whole machine, and ODM services.