The powerful and flexible 3000W 3 in 1 laser welding machine is suitable for a wide range of metals such as stainless steel, aluminium, copper, and titanium, which can meet various welding needs.

Because of its high precision and quality welding, it is also used in precision component manufacturing.

3000W 3 in 1 Laser Welding Machine

3 in 1 Laser Welding Machine Details

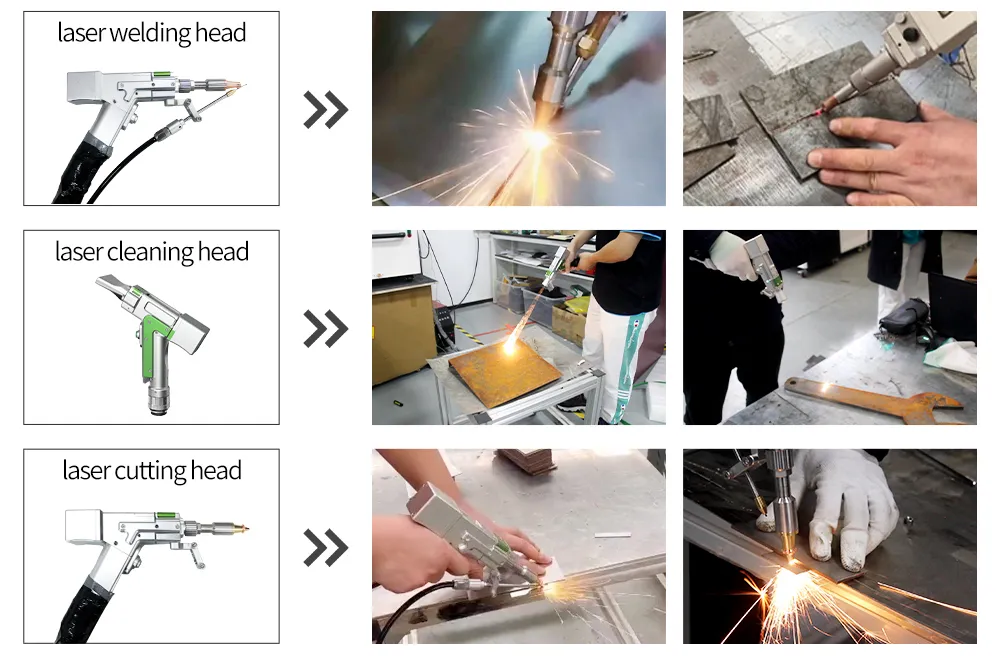

Functions Introduction of 3 in 1 Laser Welding Machine

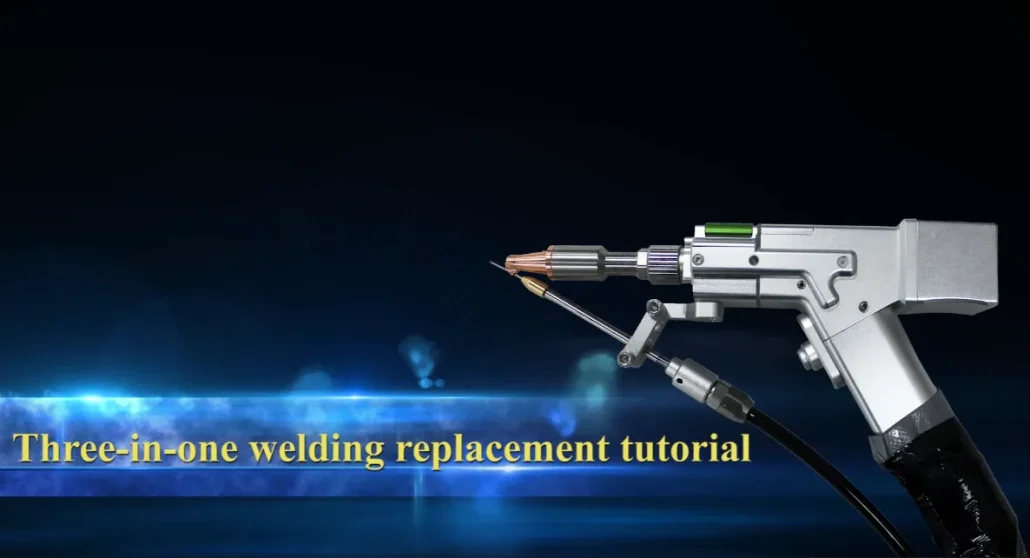

The 3-in-1 laser welding machine is designed to perform three different functions such as welding, cleaning, and cutting. These functions require different nozzles to perform.

For instance, if you need cutting functions, you’ll need to install the cutting head onto the portable laser gun while taking back the welding wire and shortening the wire tip to prevent the wire from obstructing the cutting.

Different nozzles can perform different functions, and they are designed to perform different tasks efficiently. We recommend you follow the instructions provided in the tutorial video for proper nozzle installation to ensure safety and optimal performance.

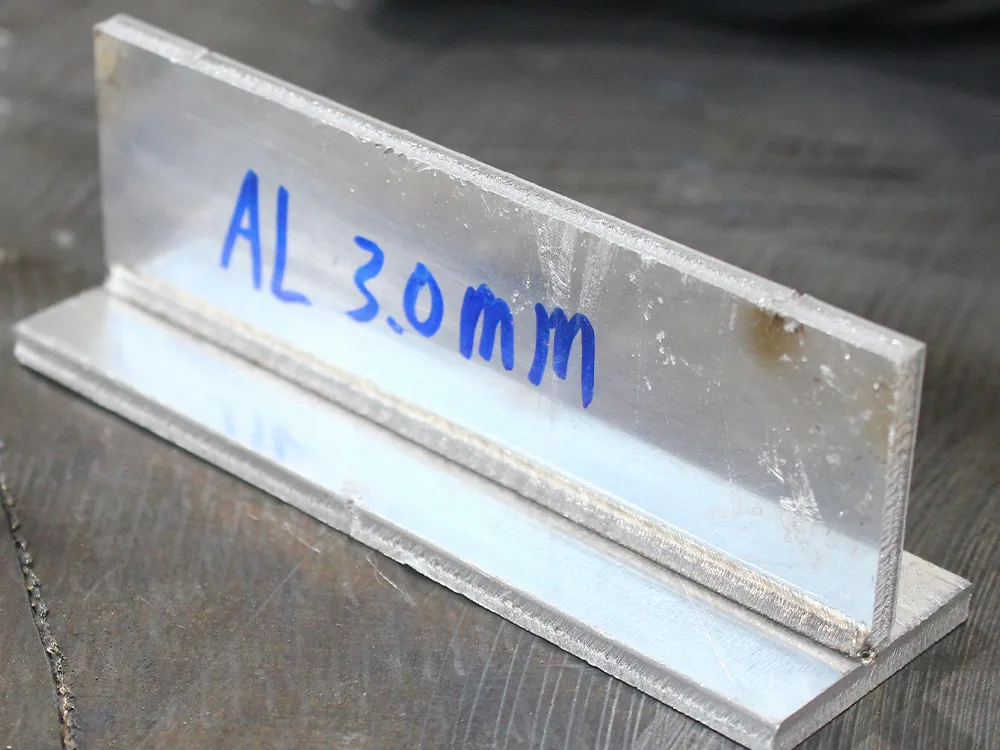

Welding Function

The powerful and flexible 3000W 3 in 1 laser welding machine is suitable for a wide range of metals such as stainless steel, aluminum, copper, and titanium, meeting various welding needs.

Because of its high precision and quality welding, the 3000W 3 in 1 laser welding machine is also used in precision component manufacturing.

Cutting Function

HANTENCNC’s 3000W 3 in 1 laser welding machine shows powerful cutting capabilities. It is widely used in cutting tasks of various metal materials, including stainless steel, aluminum, copper, etc.

This 3 in 1 laser welding machine performs efficiently and accurately, especially in cutting thin sheet materials.

Cleaning Function

The 3 in 1 laser welding machine has a cleaning function that is designed to clean rust, oxides, welding residues, etc.

It is suitable for various applications, such as metalworking, automotive manufacturing, and electronics production.

It improves workpiece quality, streamlines production processes, and ensures consistent and reliable welding results.

Tutorial Video on 3-in-1 Laser Welding Machine:

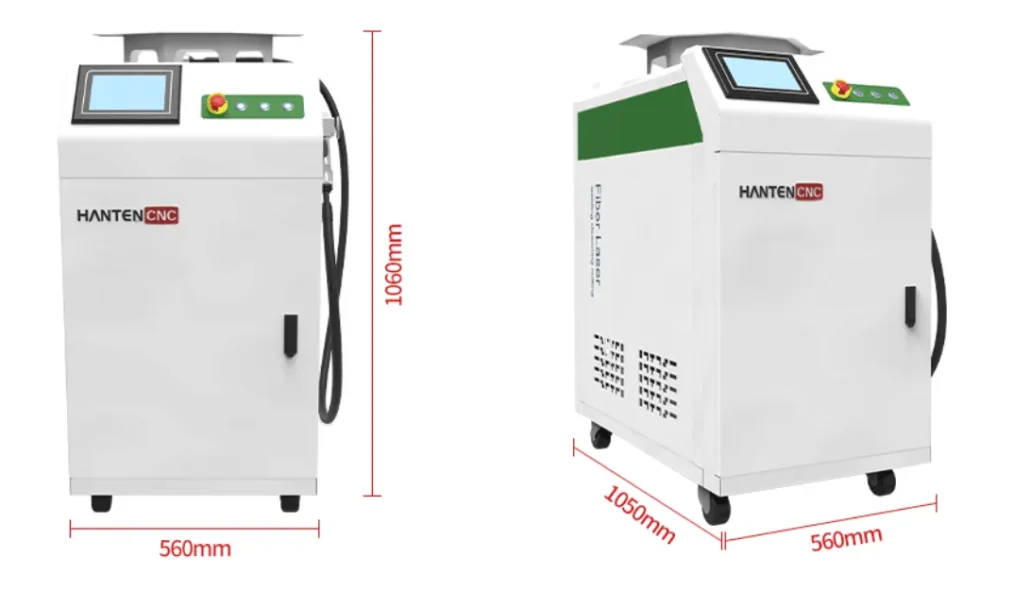

3 in 1 Laser Welding Machine Dimensions

Component Details Display of 3 in 1 laser welding machine

3 in 1 Laser Welding Machine Parameters

| Model | HTW3000 |

|---|---|

| Laser wavelength | 1080nm |

| Fiber length | 10M/12M/15M/Maximum20M |

| Operating mode | Continuous Welding |

| Maximum oscillation speed | 20000mm/s |

| Laser power | 3000 Watts |

| Operating system | Handheld Welding System |

| Optimal operating temperature | 15-35℃ |

| Humidity range operating environment | < 70% non-condensing |

| Cooling | Water Cooled |

| Welding gap requirements | ≤0.5mm |

| Operating Voltage | 380V, Three Phase |

| Machine dimensions | 1050*560*1060mm |

| Welder Net weight | 165KG |

| Package dimensions | 1170*770*1350mm |

| Package weight | 220KG |

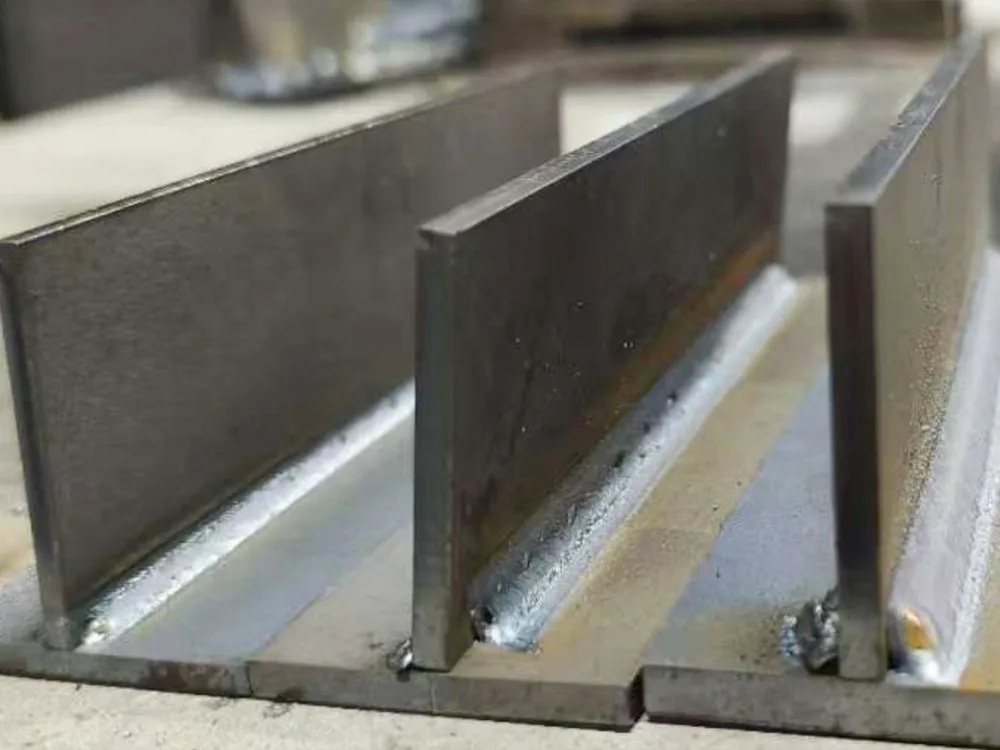

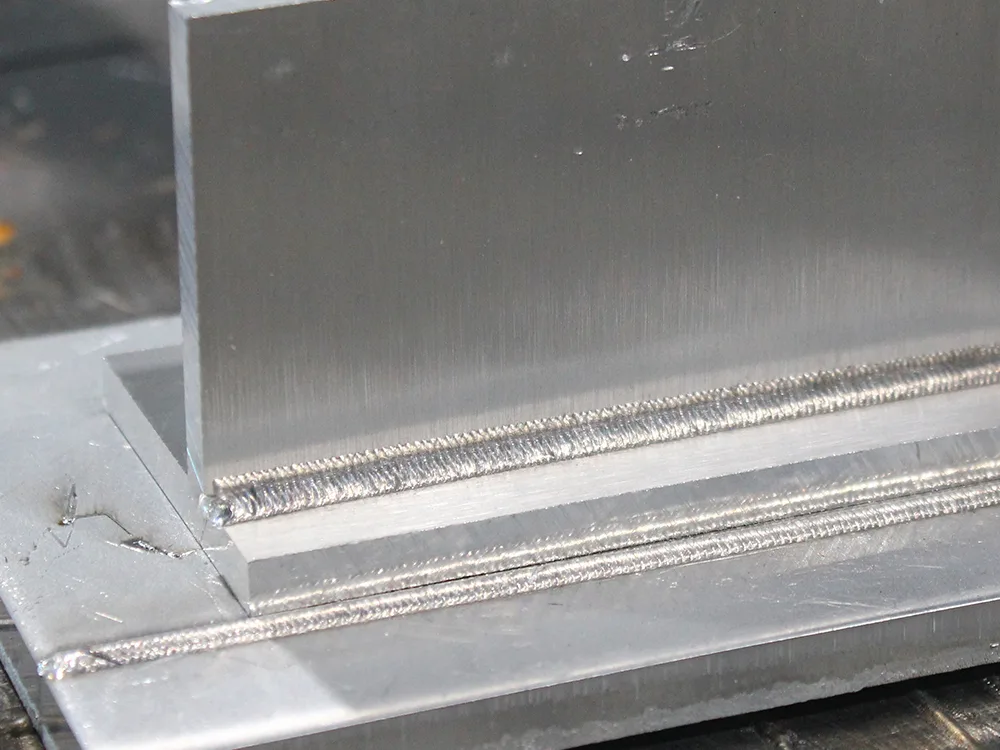

Welding, Cutting and Cleaning Results Display

The 3000W laser welding machine, with its versatility and high performance, has become an indispensable tool in the modern manufacturing and processing industries.

The 3000W 3-in-1 laser welding machine features cleaning, cutting, and welding modes.

In the metal processing and manufacturing sector, it efficiently welds and cuts various types of metals, including stainless steel, aluminum, and copper, for the production of a wide range of metal components and products.

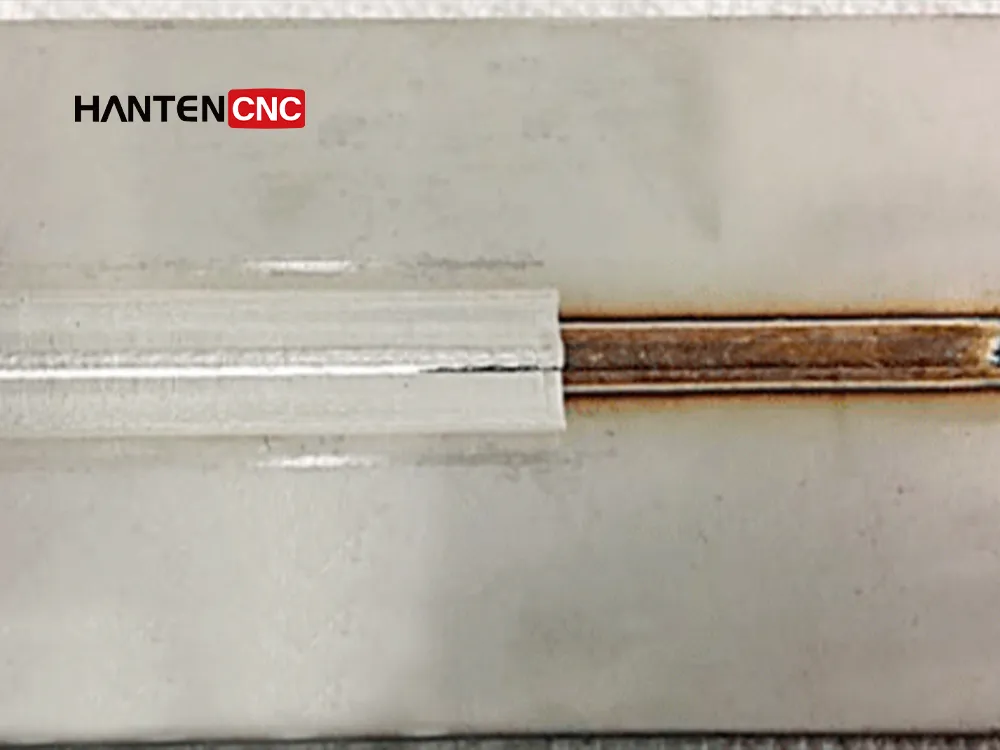

Welding Effects

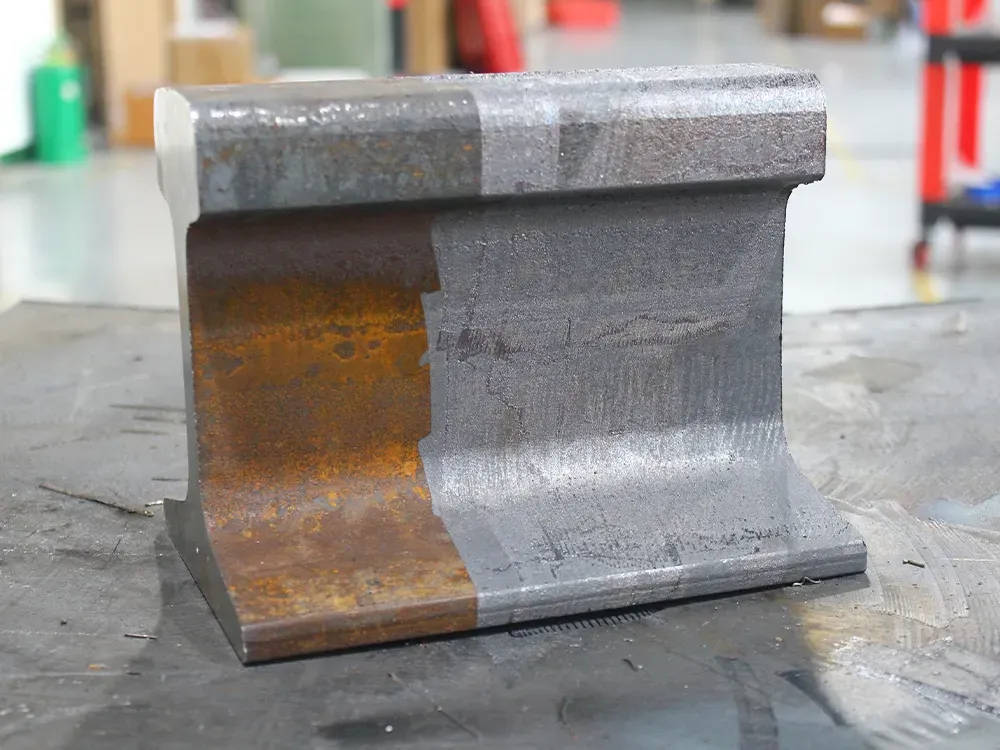

Cleaning Effects

Before welding, the 3-in-1 laser welding machine can be used to clean rust, oxide layers, and oil stains from the metal surface.

The cleaning function ensures better welding quality.

The maximum cleaning width depends on the focal length of the focusing lens.

The maximum cleaning widths of focusing lens with focal lengths of 150mm, 400mm, and 800mm are 30mm, 60mm, and 120mm respectively.

You can choose different lenses based on your cleaning needs—shorter focal lengths for precise work and longer ones for wider coverage.

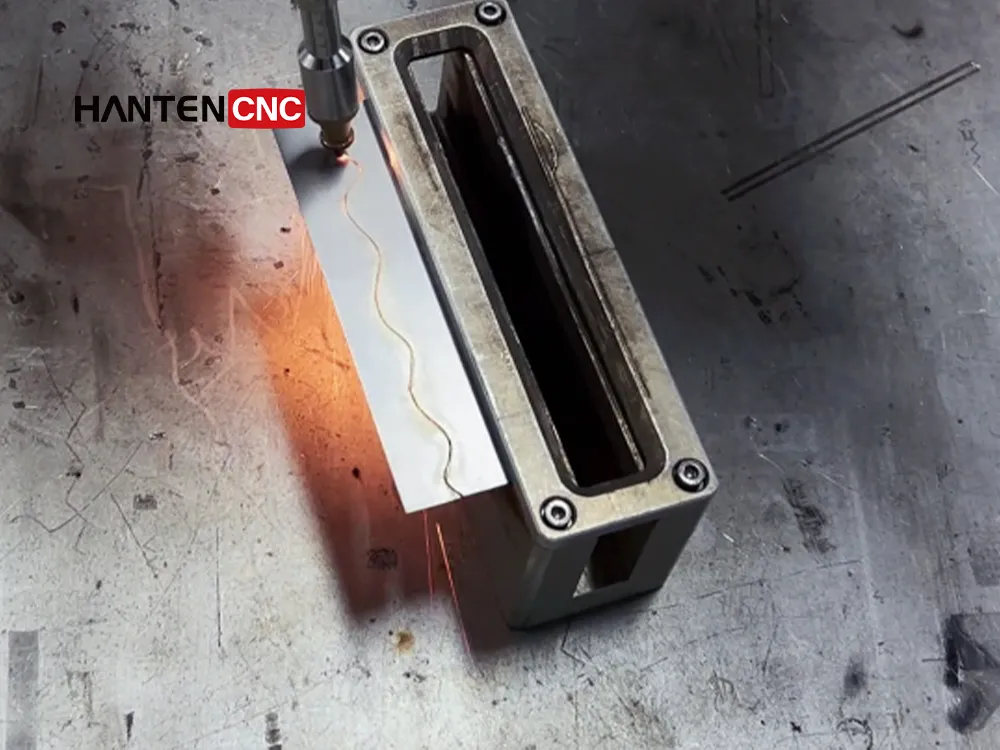

Cutting Effects

The cutting function of the 3-in-1 laser welding machine is designed for cutting metal sheets within 2-3 mm, and can efficiently complete the precise cutting of thin metals.

Since the 3-in-1 laser welding machine is designed for both welding and cleaning, we’ve adjusted the cutting power to better suit thin sheet metal rather than thick or heavy materials.

If you need to cut thicker metal materials, we recommend that you use a high-power laser cutting machine to ensure a stronger cutting effect.

Customer Visits

3 in 1 Laser Welding Machine Certificates

HANTENCNC owns trademark registration certificates, utility patent certificates, software copyright certificates, etc.

HANTENCNC’s 3 in 1 laser welding machines are CE and FDA-certified, ensuring high quality and safety.

You can trust HANTENCNC and HANTENCNC’s 3 in 1 laser welding machines backed by these certificates.

HANTENCNC Partnerships

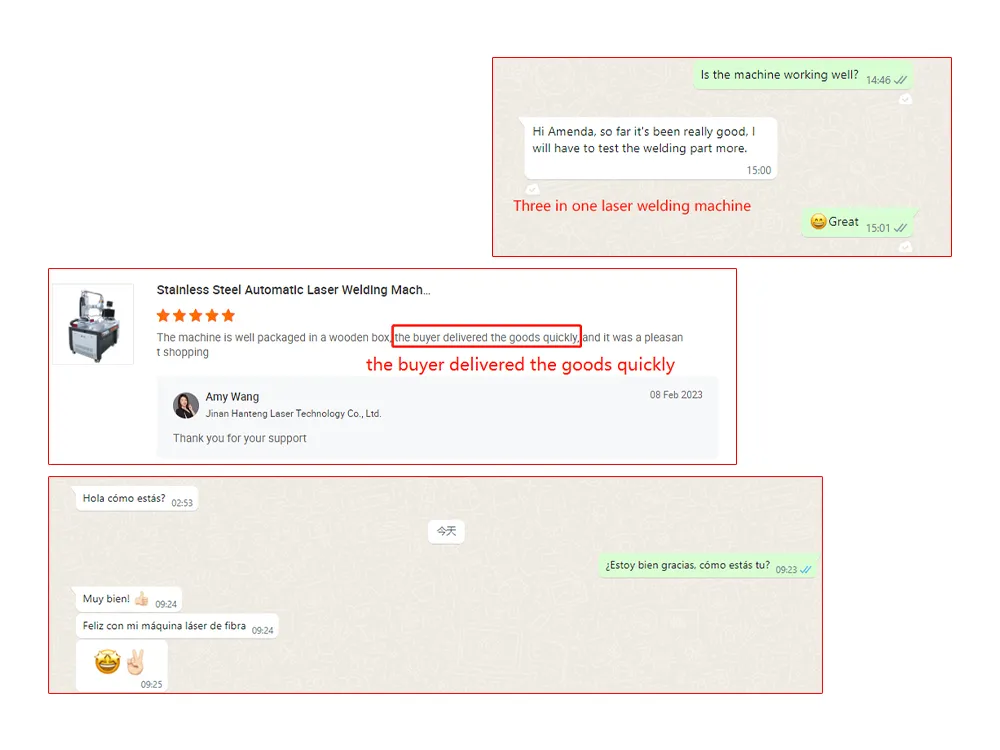

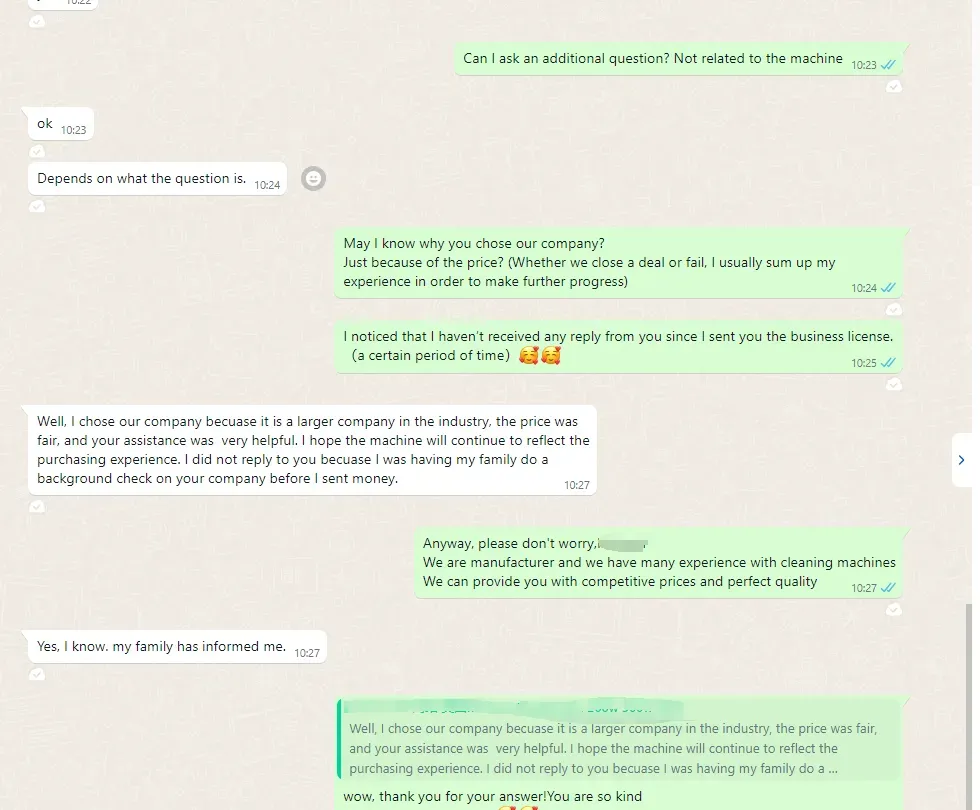

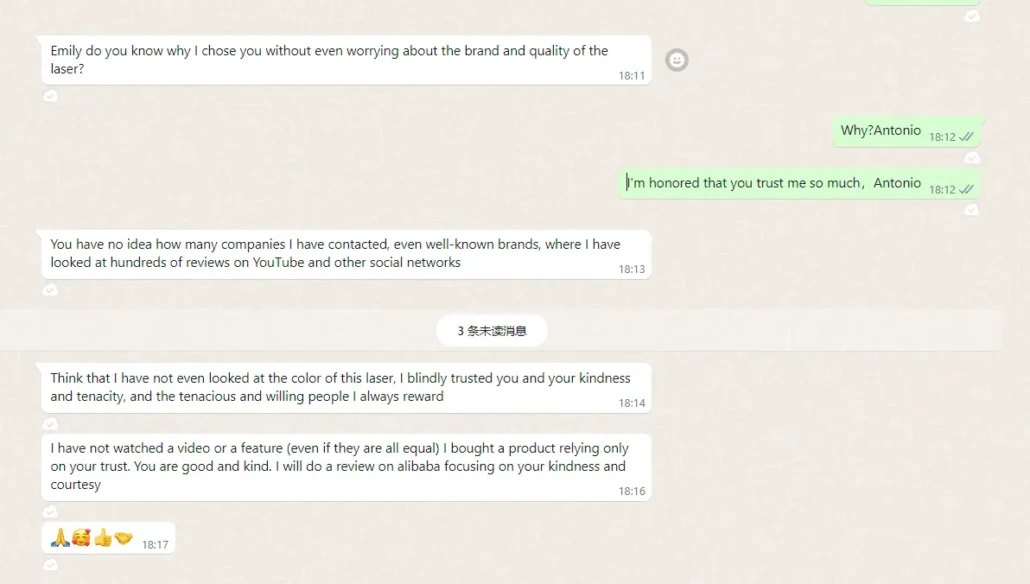

Customer Reviews