Battery Laser Welding Machine for Lithium-ion Batteries Introduction

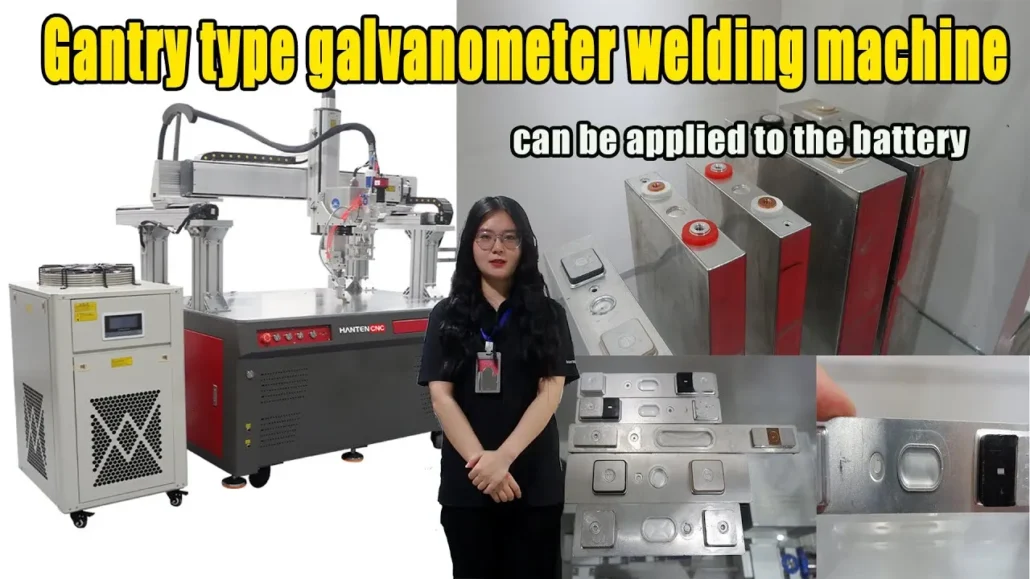

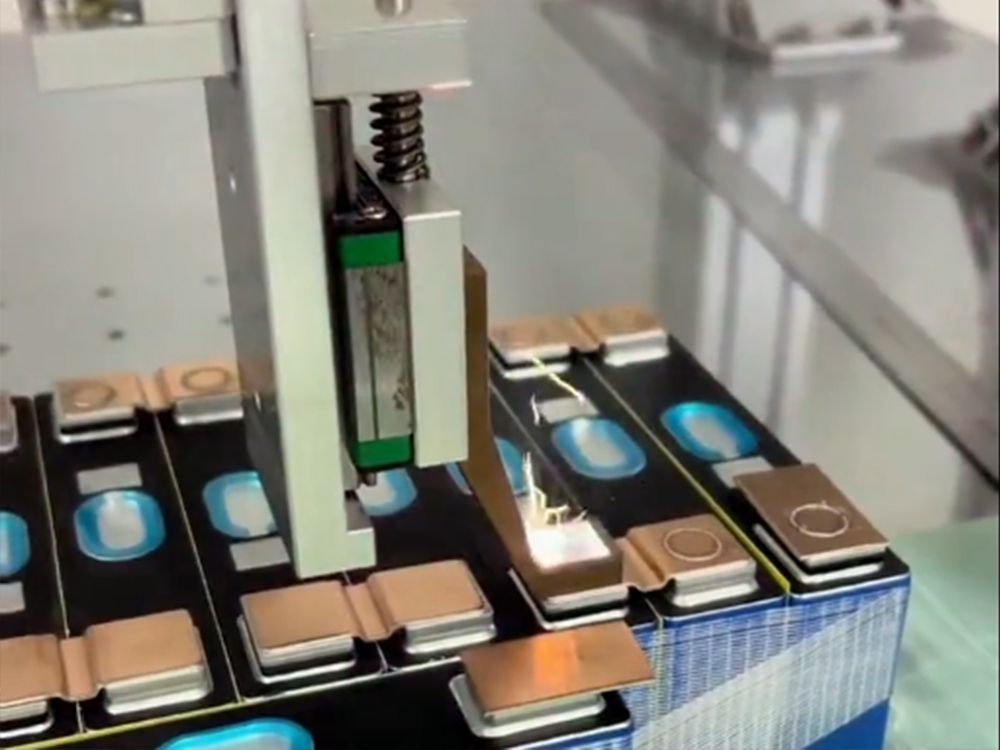

HANTENCNC’s 1500W, 2000W, and 3000W Gantry battery laser welding machine for lithium ion batteries is designed for high-precision spot welding of lithium-ion battery tabs and components.

Equipped with an advanced industrial computer, industrial dual-temperature water chiller, and dual temperature control, the battery laser welding machine meets the highest industrial standards for lithium-ion battery welding.

In addition, equipped with a CCD camera, HANTENCNC’s software, and an industrial computer, our battery laser welding machine can realize real-time monitoring during welding.

The battery laser welding machine’s air-blowing system can blow off residue or dust while welding and keep the welding area clean to ensure a reliable, consistent welding operation.

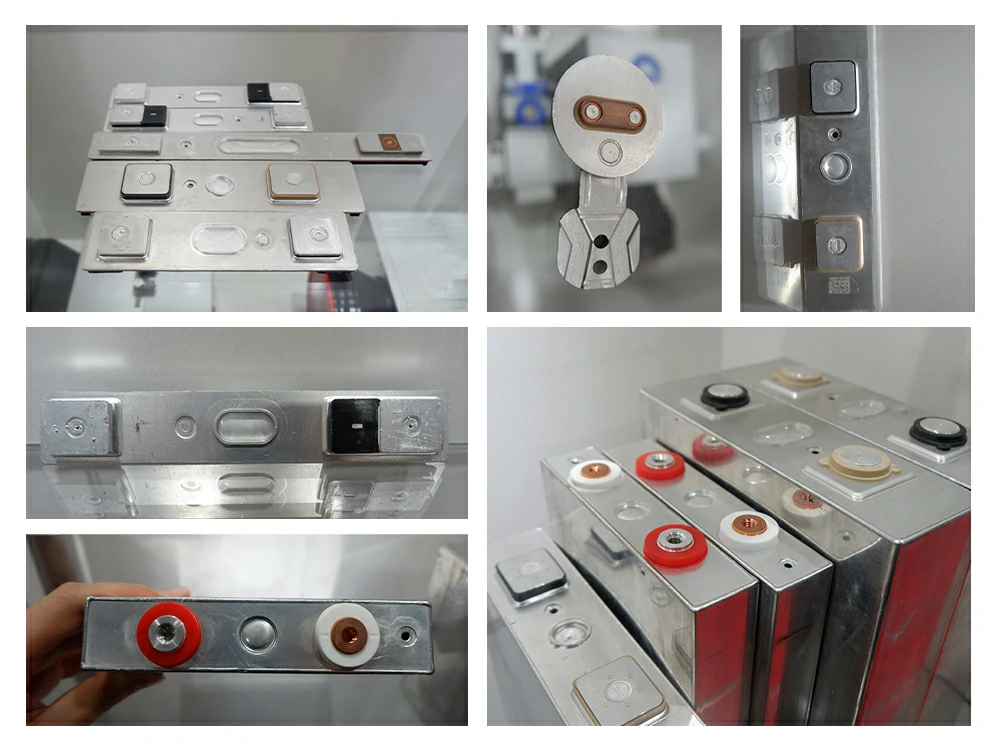

HANTENCNC’s battery laser welding machine for lithium ion batteries has added a fixture for welding batteries, which can be customized according to your needs.

The main application of HANTENCNC’s laser welding machine for lithium ion batteries includes the following: lithium battery cells welding, electronic equipment welding, and hardware accessories welding, etc.

Battery Laser Welding Machine Introduction Video

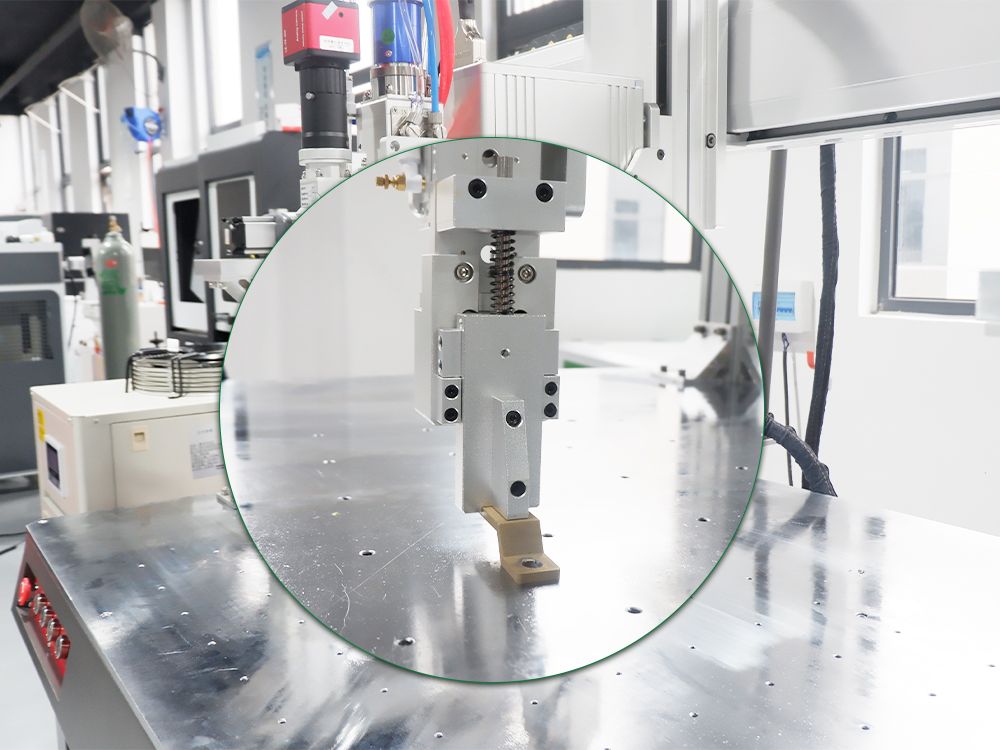

Gantry Li-ion Battery Laser Welder Details

Gantry Battery Laser Welding Machine Parameters

| Model | HTW1500/HTW2000/HTW3000 |

|---|---|

| Power | 1500w/2000w/3000w |

| Working voltage | 220V, Single Phase/380V, Three Phase |

| Fiber Length | 10M/12M/15M/Maximum20M |

| Maximum Oscillation Speed | 20000mm/s |

| Frequency | 5kHz |

| Wavelength | 1064nm |

| Solder joint size | 0.2-3.0mm |

| Protective gas | N2 gas |

|

XYZ-Axis Movement range |

1000x600x600x300/400mm |

| Camera | CCD camera |

| Cooling method | Dual-temperature water chiller |

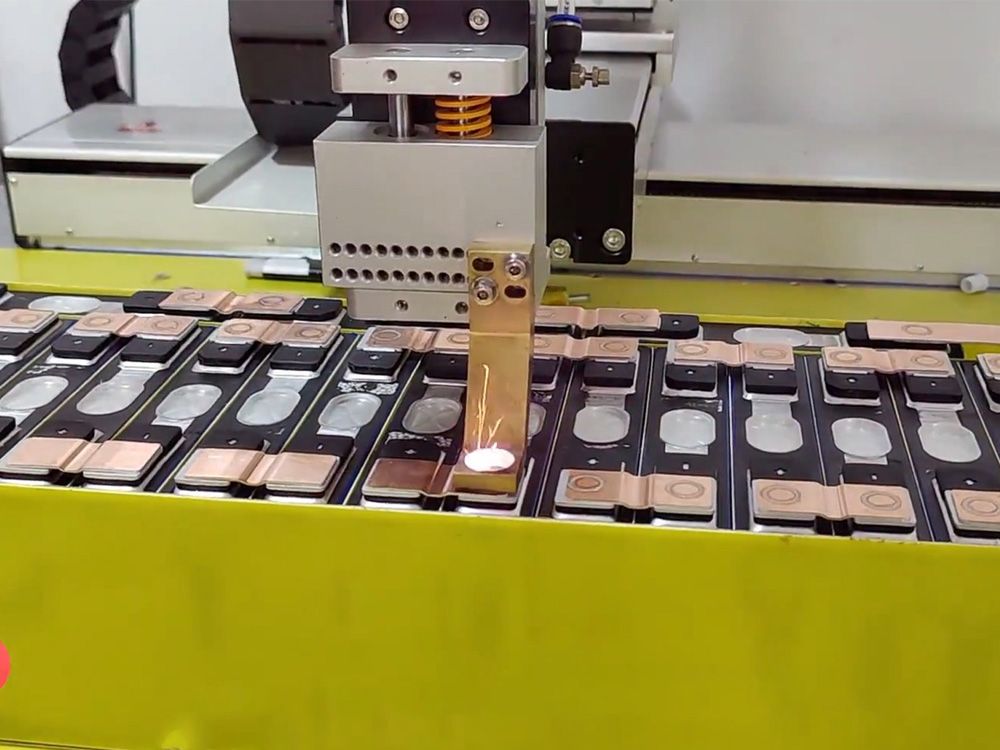

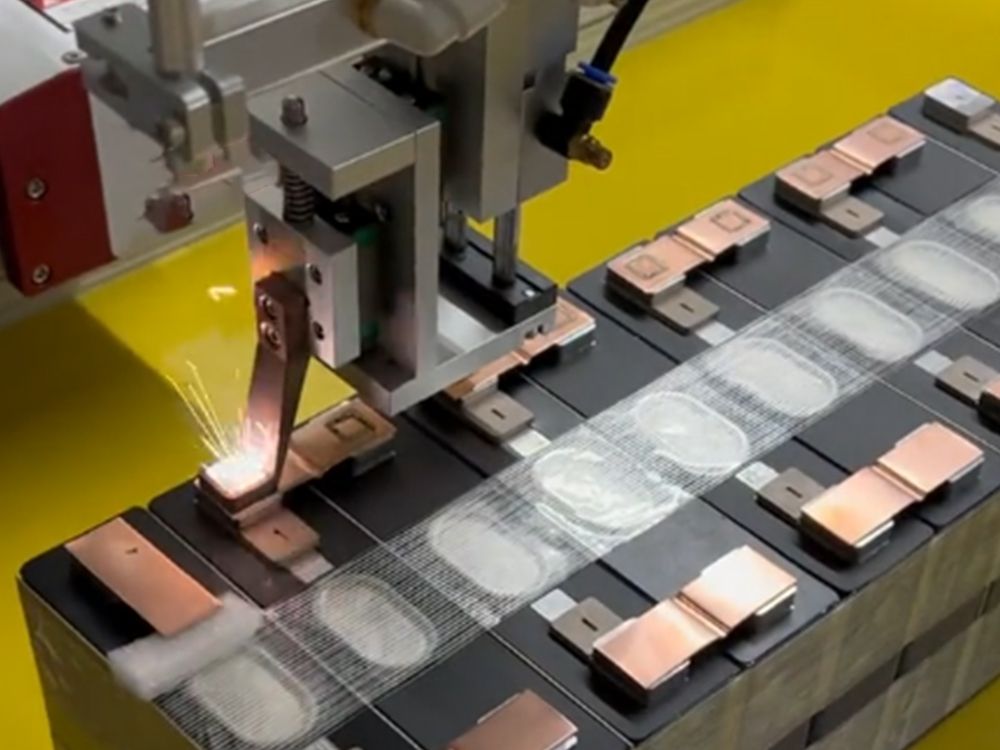

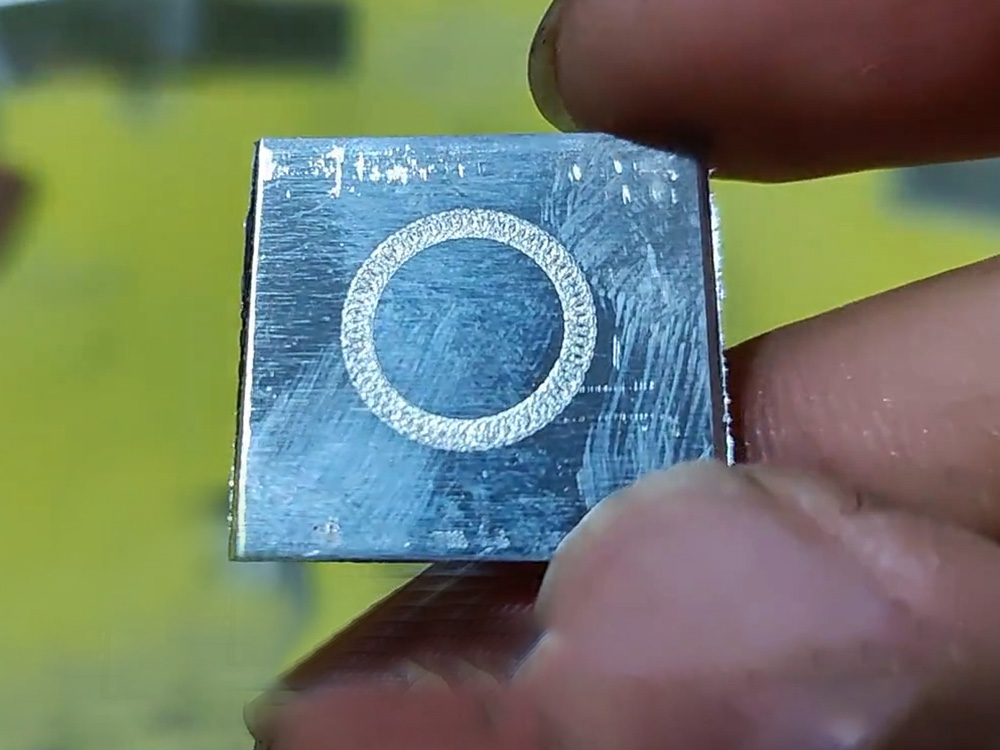

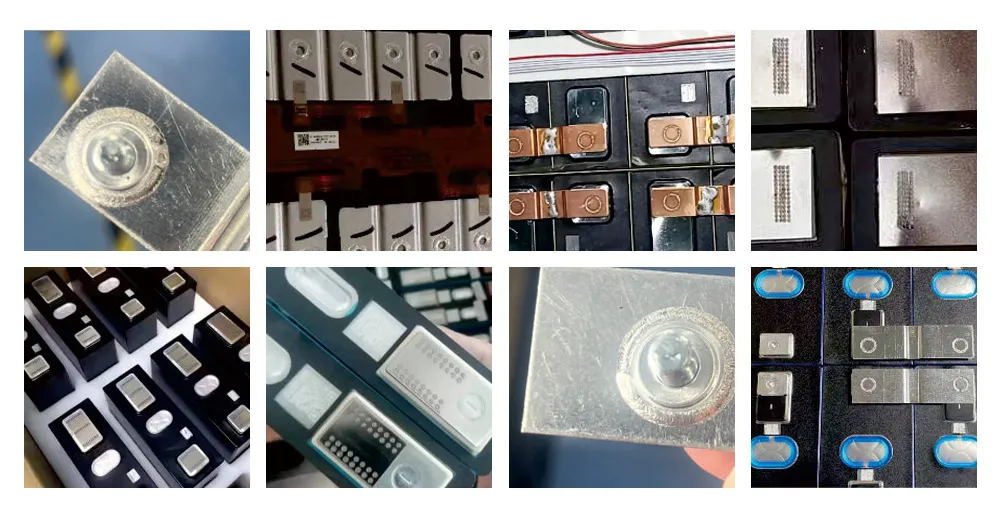

Battery Laser Welding Examples

Battery Laser Welder Advantages

High-precision Welding

Laser welding technology can achieve very high precision and control. It can precisely weld tiny battery components, ensuring welding quality and stability.

Fast Welding Speed

Laser welding is very fast and can complete the welding process in a short time. This is important for the mass production of battery components, increasing production efficiency and capacity.

No Need For External Auxiliary Materials

Laser welding is a non-contact welding technique that does not require additional welding materials. Such as welding wire or flux. This simplifies the production process and reduces material costs.

No Direct Contact With The Welded Parts

Laser welding is performed by heat transfer without direct contact with the welded parts. This means that mechanical damage or deformation is avoided, and the integrity of the welded part is maintained.

High-Strength Welding

Laser welding provides a high-strength welded connection. The weld strength is higher than traditional welding methods. This is critical to the reliability and durability of battery components.

Small Heat-affected Zone

The heat input during laser welding is very small, and there is almost no heat-affected zone. This means that the material surrounding the weld is not overheated or damaged, helping to maintain the properties of the welded part.

Flexibility

The laser welding battery machines can be programmed and adjusted. It is suitable for welding battery components of different sizes, shapes, and materials. This flexibility makes it suitable for diverse production needs.

Application of Battery Laser Welding Machine

- Battery Pack Welding: The large battery pack is the main power source for electric and hybrid vehicles. Battery laser welding machines can be used to weld the connection between cells or modules of a battery pack. It can ensure efficient current transfer and structural strength.

- Battery Cover Welding: Battery packs are usually sealed with a metal cover to ensure safety and prevent leakage of the battery’s internal components. Laser welding battery machines can weld the sealed connection between the battery cover and the case.

- Battery Terminal Soldering: The battery pack must be connected to the vehicle’s electric system or other external power source. Battery laser welding machines can weld contacts between battery terminals and wires or connectors. So it can ensure reliable, current transfer.

- Battery Heat Sink Soldering: High-performance battery packs often require heat sinks to control temperature and improve heat dissipation. Laser welding battery machines can weld heat sinks to battery pack internal components for efficient heat transfer.

Difference between Gantry and Stack Battery Laser Welding Machine

The Difference Between Gantry and Stack Laser Welding Machine

Tutorial Videos on HANTENCNC's Gantry Laser Welding Machine

Software Demonstration Tutorial Video on HANTENCNC’s battery laser welding machine

Drawing and Filling Weld Graphics Tutorial Video on HANTENCNC’s battery laser welding machines

Customer Visits

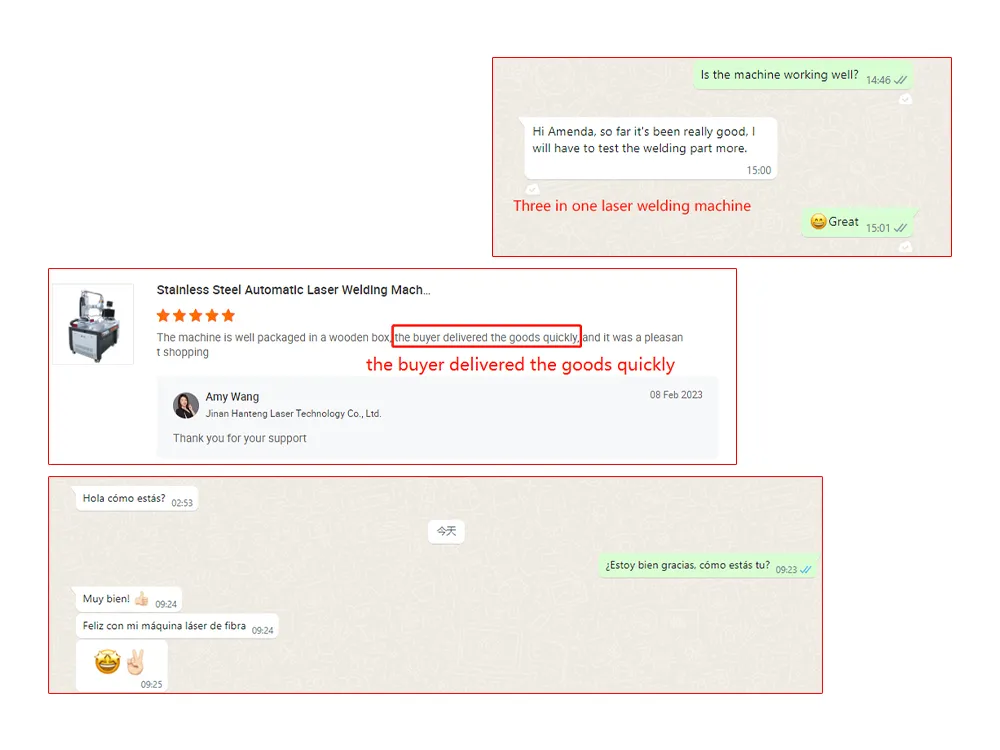

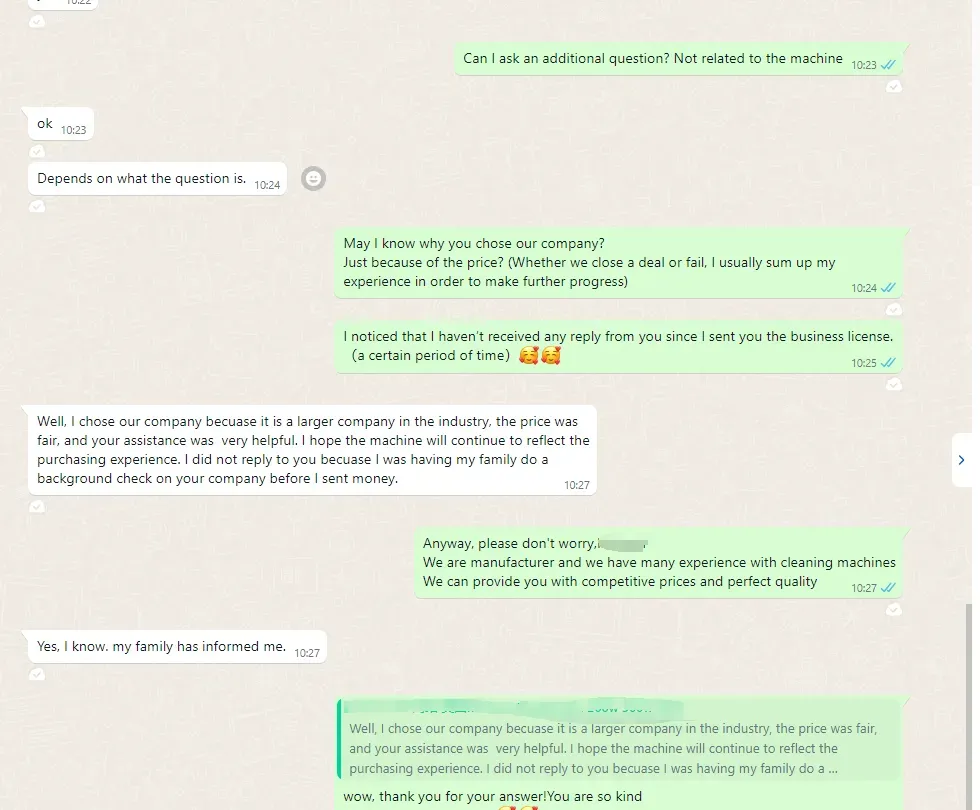

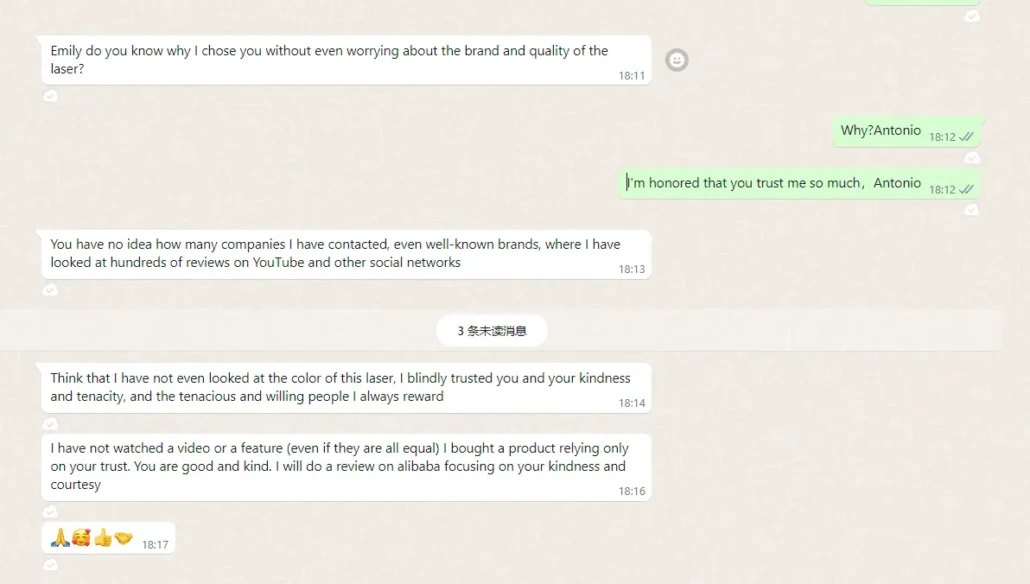

Customer Reviews

HANTENCNC Partnerships

HantenCNC Service

HANTENCNC’s lithium battery laser welding machines are CE and FDA-certified. We offer a 2-year warranty for the laser source and a 1-year warranty for the whole machine, sample testing, OEM customization, remote guidance, and lifelong after-sales support.