Industrial cleaning is a critical link in corporate production chains, but traditional methods like chemical cleaning, sandblasting, and ultrasonic cleaning entail costs far beyond the obvious equipment purchase and labor expenses. Studies show that hidden costs account for 30%-40% of total operational costs, including inefficient manpower, compliance fines, equipment downtime losses, and more.

This article deeply analyzes these hidden burdens and reveals how high-power pulsed laser cleaning machines become the ultimate solution for enterprises to reduce costs and enhance efficiency.

Why 500W Laser Cleaning Machines Are the Smart Choice for Modern Industry?

1. Labor Costs: The Hidden Drain on Productivity

Traditional cleaning methods inherently rely on substantial manual labor. Take chemical cleaning as an example: workers must handle hazardous solvents, manually apply and rinse surfaces, processes that require not only professional training and protective gear but also consume significant time. A case study shows that cleaning a single metal mold with chemical solvents takes 4 hours of labor; including wages, safety protection, and waste disposal costs, the single-station cleaning cost is approximately €80. Another common method, sandblasting, while slightly faster, also depends on manpower: operators must maneuver heavy equipment and frequently adjust pressure parameters, leading to inconsistent results—removing rust alone takes an average of 3 hours per work piece.

2. Compliance Risks: The Overlooked Environmental Regulations

As global environmental standards tighten (e.g., the EU’s revised Industrial Emissions Directive, California’s Proposition 65), the compliance risks of chemical cleaning pose significant financial and reputational hazards. Traditional industrial cleaning generates toxic waste, including volatile organic compounds (VOC) and heavy metal wastewater, which are costly to treat. Non-compliance can result in fines of at least 3% of annual revenue, plus the risk of production halts for rectification. Additionally, maintaining compliance often requires installing expensive filtration systems or hiring third-party auditors, increasing operational costs by 15%-20%.

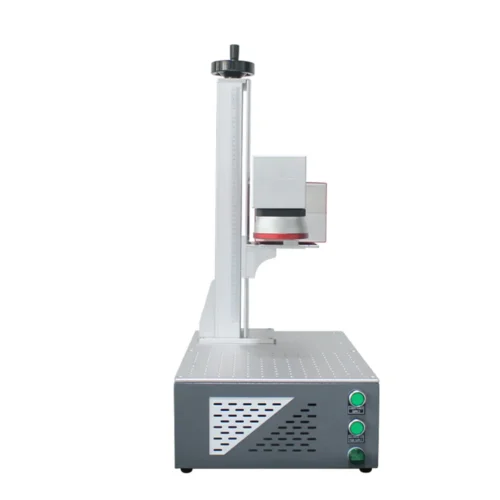

Pulsed laser cleaning technology fundamentally transforms this landscape. By using high-energy laser pulses to vaporize or strip contaminants, it eliminates the need for chemical solvents, thereby eradicating VOC emissions and waste disposal requirements. The HANTENCNC Seagull III 500W pulsed laser cleaning machine holds CE/FDA certifications and features a unique four-dimensional safety protection system, with universal voltage (110-220V) and frequency (50-60Hz) compatibility. The cleaning head is equipped with an automatic distance-measuring sensor (automatically locking laser emission when no work piece is detected), further enhancing safety, reducing work injury risks and insurance costs, and ensuring compliance in strict markets like Germany and Japan. This technology also future-proofs against evolving safety regulations, avoiding hidden costs from equipment retrofits or re-certifications.

More critically, inefficiency leads to normalized overtime. Statistics show that the annual cost of ineffective overtime in manufacturing due to low cleaning efficiency increases by 12%. Prolonged overtime not only reduces employee health but also raises the risk of work-related injuries (e.g., mechanical operation errors).

In a global manufacturing sector facing skilled labor shortages, high-power pulsed laser cleaning machines significantly reduce labor demand.

For instance, the HANTENCNC Seagull3 laser cleaning machine, with high pulse energy and 500W output power, can clean 15㎡ of 20μm-thick paint or rust per hour—internal test data show this efficiency is 2x that of 200W multimode lasers and 4x that of 100W single-mode lasers. Its intuitive touchscreen interface supports multilingual operation and a preset process library, allowing even untrained operators to adjust parameters in seconds.

The ergonomic handheld cleaning head weighs only 1.5kg, paired with a shoulder strap design to prevent fatigue during long-term use and ensure sustained high efficiency. For a small factory cleaning 30 metal work pieces daily, switching to laser cleaning can save over 100 labor hours monthly, cutting labor costs by over $20,000 annually.

3. Equipment Downtime Losses: Every Minute Costs Money

Equipment downtime eats into manufacturers’ profits every second. Traditional cleaning often requires disassembling machinery, transporting components to cleaning areas, and waiting for drying or curing, with a single cycle causing production stoppages of 8-12 hours. For example, downtime from sandblasting jet engine components has severely impacted production efficiency, leading to losses from assembly line delays and overtime costs for urgent repairs.

High-power pulsed laser cleaning machines use non-contact precision stripping technology to avoid substrate damage and extend equipment lifespan. They support in-situ cleaning, meaning equipment can be cleaned without full disassembly, reducing downtime by 70%. The HANTENCNC Seagull3 features a rugged frame design and built-in spring shock absorption system, ensuring stable operation in high-vibration environments like steel plants, automotive repair shops, and metal processing facilities. Its synchronized cabinet and laser heat dissipation holes, paired with an advanced cooling system, prevent overheating in high-temperature settings. With a fast startup design (warm-up time <30 seconds), it supports 24/7 continuous operation. For a plastic mold factory, this translates to adding over a dozen production days annually, generating nearly $100,000 in extra revenue.

4. Why Does the HANTENCNC 500W Seagull3 Stand Out?

Beyond cost advantages, this equipment boasts technological leadership:

Design Details

Touchscreen with acrylic protection to guard against damage and dust, extending equipment lifespan.

Handheld cleaning head with 2mm steel wire (40kg load-bearing) to prevent fiber optic breakage.

Fire-retardant fabric and fiber protection spring accessories for fire resistance and bending tolerance.

Precision Cleaning

Controllable pulse width ensures zero substrate damage, making it suitable for high-precision scenarios like precision machining and cultural relic restoration.

Portability and Flexibility

Weighing just 50kg with a compact design and dual-wheel structure, it easily navigates tight spaces—ideal for on-site maintenance in aviation repair shops and ship ports.

Long-Term ROI

1-year warranty, low maintenance costs, and no need for filter replacements or chemical storage, offering durability far exceeding traditional equipment. In contrast, chemical cleaning systems incur over $10,000 annually in safety inspections and waste audit fees.

5. Launch Your Efficient Cleaning Revolution Today

Choosing a 500W pulsed laser cleaning machine is not just a technological upgrade but a strategic investment in your enterprise’s future.

LIMITED TIME OFFER

First 50 orders receive free extended warranty and customized cleaning parameter services!

Contact us to schedule a free sample test!