The 100W jewelry laser welding machine developed by HANTENCNC is mainly used in the gold and silver industry; the jewelry includes bracelets, rings, necklaces, earrings, pendants, and stainless steel jewelry.

Due to its unique advantages, jewelry laser welding machines are successfully used in the processing and welding of the jewelry industry, as well as the welding of micro and small-sized components.

The jewelry laser welding machine is a special equipment designed for repairing small holes or flaws on jewelry surfaces and performing perfect spot welding.

During the welding process, the surface of the jewelry is heated, and the heat is gradually conducted to the inside of the material and diffuses. By controlling the parameters of the laser, such as the width, energy, peak power, and repetition frequency, the jewelry melts and forms a specific molten pool; the jewelry laser welding machine can produce precise, clean welds with minimal thermal distortion.

100W Jewelry Laser Welding Machine

100W Jewelry Laser Welding Machine Details

100W Jewelry Laser Welding Machine Demonstration Video

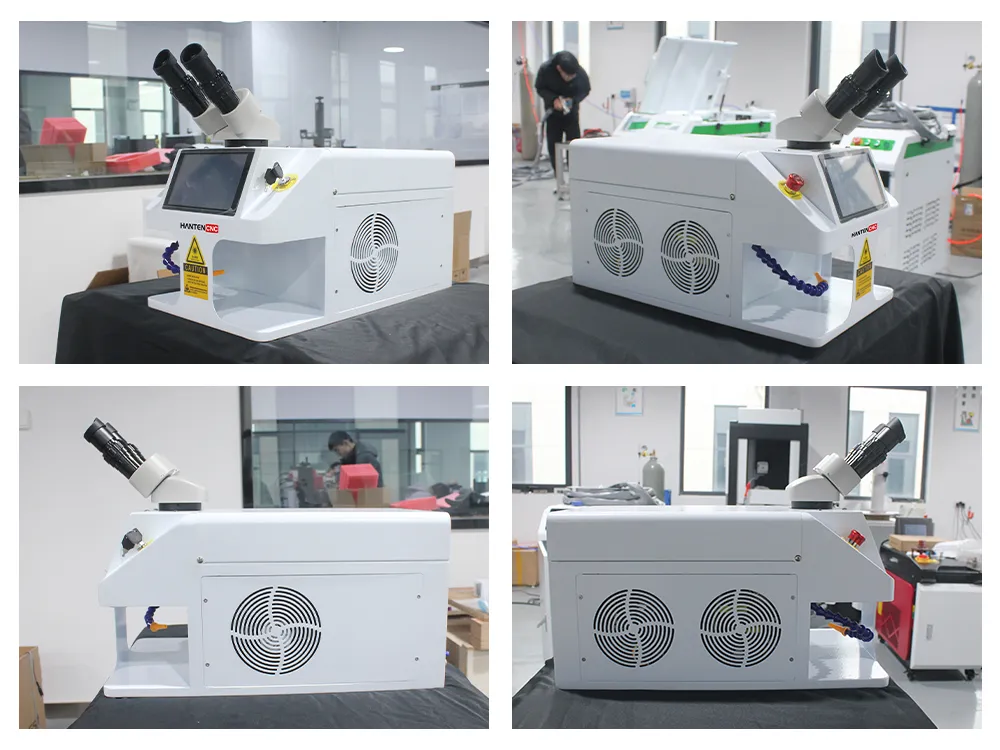

100W Desktop Jewelry Laser Welding Machine Display

Component Detail Display of 100W Jewelry Laser Welder

Showcasing Welded Samples Using Jewelry Laser Welding Machine

Features of HANTENCNC's jewelry laser welding machine:

1. Adjustable Parameters

According to the specific welding requirement, the parameters of the 100W jewelry laser welding machine can be adjusted to achieve the required welding effect, such as energy, pulse width, frequency, spot diameter, etc.

2. Automatic Light Shielding

The 100W jewelry laser welding machine is equipped with an automatic shading device to protect the operator’s eyes from laser radiation.

3. Continuous Operation and Stability

For operators who need to weld a large number of jewelry, the 100W jewelry laser welding machine can operate continuously for 24 hours and maintain stable working performance.The machine exhibits stable performance, maintaining reliability and precision throughout the welding process.

4. High Speed & High Efficiency:

The laser beam allows for simultaneous multi-beam processing. it enhances welding speed significantly, which can enable users to weld the jewelry efficiently and effectively in a short time with high quality.

5. Focusing Capability and Applicability Range

The jewelry laser welding machine can focus the laser beam on a small area, making it suitable for welding small and closely spaced components, facilitating high-speed automated welding and precision machining.

6. Extensive Applicability

The jewelry laser welding machine excels in welding high-melting-point, refractory, and difficult-to-weld metals such as titanium and aluminum alloys, exhibiting excellent welding results. This versatility allows for the efficient handling of complex welding requirements.

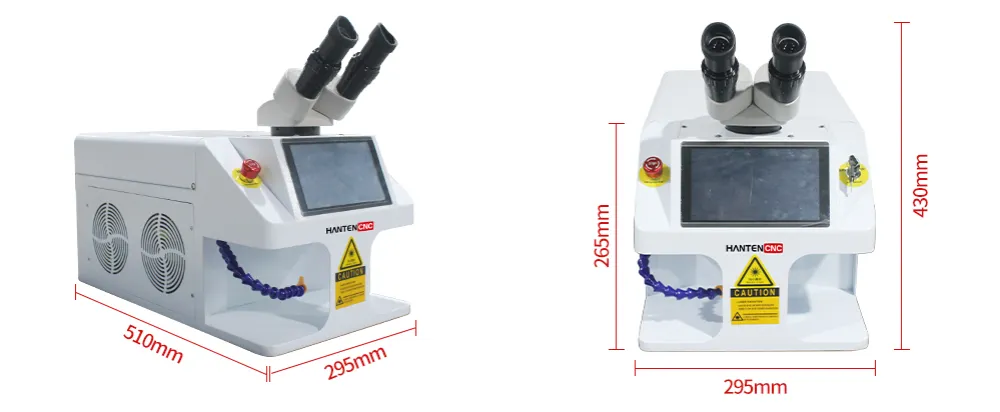

100W Jewelry Laser Welding Machine Dimensions

100W Jewelry Laser Welding Machine Parameter

| Model | HTW100 |

|---|---|

| Maximum laser power | 100W |

| Laser wavelength | 1064mm |

| Laser cavity | ceramic |

| Rated power | 2KW |

| Frequency | 1–20HZ |

| Current adjustment | 1-150A |

| Spot adjustment | 0.1–3mm |

| Spot diameter | 0.3–2mm |

| Cooling system | water cooling |

| Observation system | CCD and microscope |

| Equipment voltage | AC220V 50/60HZ |

| Dimensions | 650*360*560mm |

| Net weight | 26kg |

| Gross weight | 40kg |

Product Details

Microscope

The microscope on a jewelry laser welding machine can help us observe the small details and welding points during the welding process, the microscope provides a better view of the specific points being welded, which ensures the welding process is more precise and flexible, as the user is able to see finer details and make adjustments accordingly. The microscope ensures high accuracy during the jewelry welding process.

Surround Light

The ring light on the jewelry laser welding machine is primarily used to provide additional illumination, illuminating the welding area. This helps welding operators to see the welding points and details more clearly, enhancing the accuracy and quality of the welding process.

Display Screen

The display screen of the jewelry laser welding machine plays a crucial role in the welding process. It allows for the adjustment of welding settings and provides access to relevant information such as parameters, status, and real-time feedback.

Jewelry Laser Welding Machine Certificates

Customer Visits

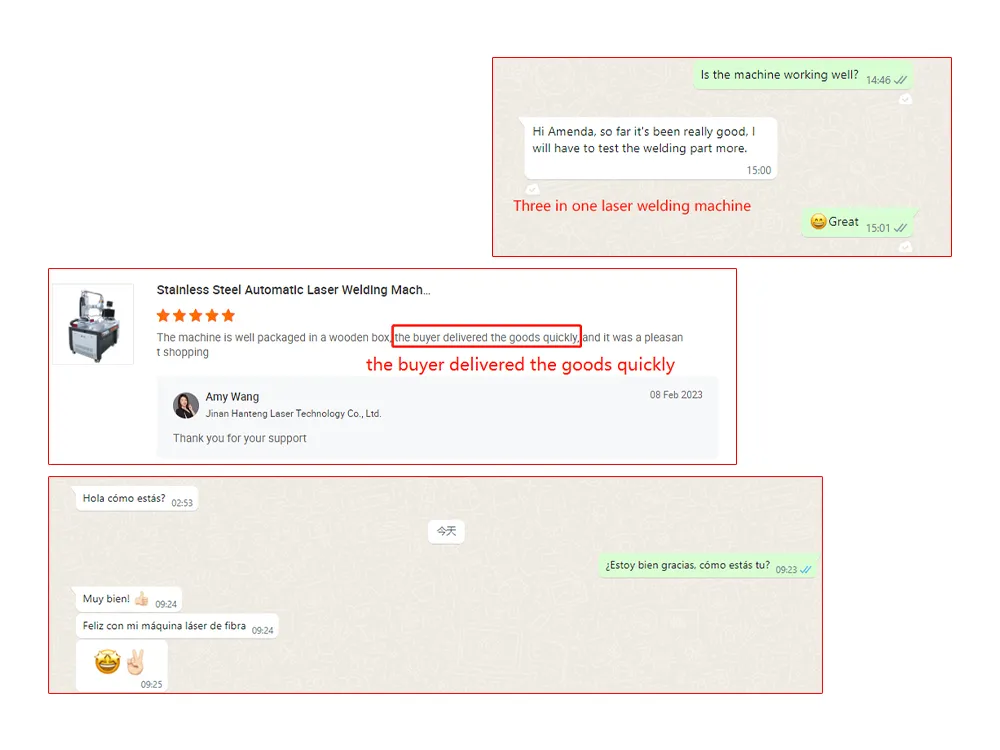

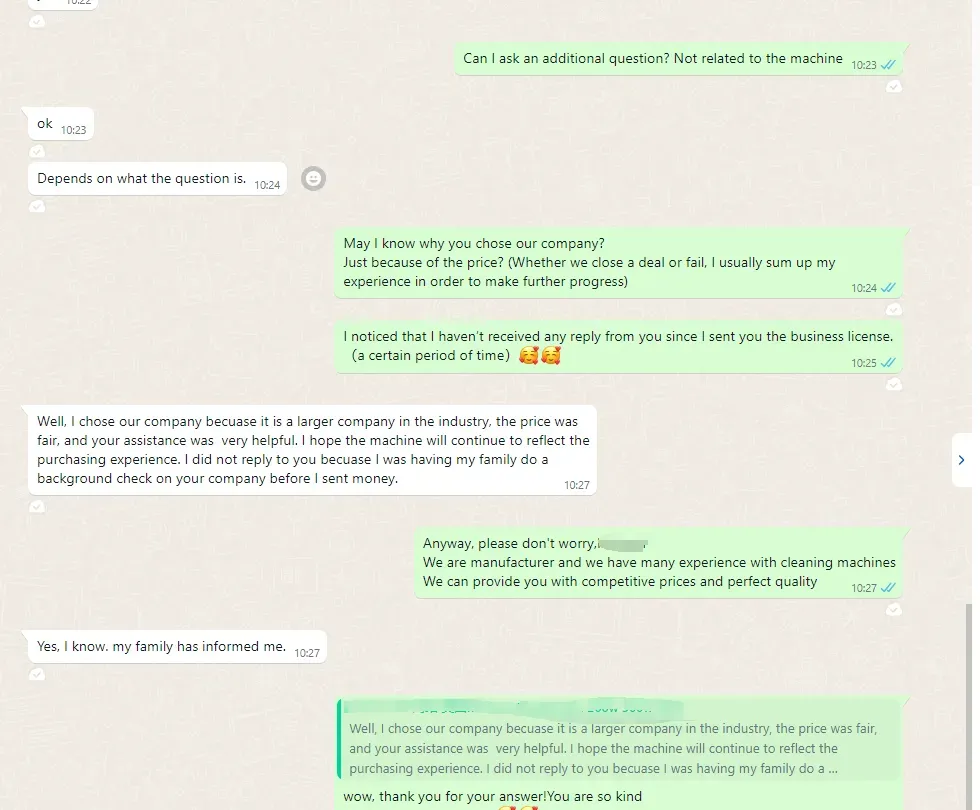

Customer Reviews