Articulated Arm Mold Laser Welding Machine | 1000W 1500W

HANTENCNC’s mold laser welding machine is suitable for repairing and welding precision machine components, as well as welding various metal structural parts and gold or silver jewelry.

Laser welding is a new type of welding method that creates deep and narrow welds, keeping surrounding areas cool and minimizing distortion. By controlling parameters such as the width, energy, peak power, and repetition frequency of the laser pulse, HANTENCNC’s mold laser welding machine can realize spot welding, butt welding, stacking welding and seal welding, etc. It’s fast, produces smooth welds, and usually does not need extra finishing.

Advantages of the HANTENCNC’s mold laser welding machine:

- Consumable-free: No bulbs, maintenance-free.

- Lower average power consumption: Approximately 5.6 kWh per hour at full power.

- Wide fusion range: Effective fusion: stainless steel 0.1-1.2mm, stable laser, no deviation.

- Equipped with a specialized dual-temperature control water chiller, ensuring stability for prolonged, high-power operations.

- Lens equipped with a water cooling system for prolonged high-power operations, providing better lens protection.

- Deep welding capability ensures stronger and more thorough fusion, free of pores or dross, resulting in aesthetically pleasing repair traces.

- Laser head easily rotates 90 degrees and moves forward or backward, facilitating welding on any side.

- Compact design: Smaller footprint for convenient on-site welding services.

Mold Laser Welding Machine Parameters

| Machine model | HTW1000 / HTW1500 |

|---|---|

| Laser power | 1000W/1500W |

| The maximum laser power | 1500W |

| Laser wavelength | 1080±10 nm |

| Motion mode | Continuous, pulsed |

| Fiber Length | 10M/12M/15M/Maximum20M |

| Maximum oscillation speed | 20000mm/s |

| Laser welding depth | ≤3.0 mm (depending on material) |

| Fiber core diameter | 50 μm |

| Fiber wire length | >8 m |

| Beam splitting mode | Precision energy spectroscopy or high-speed time spectroscopy |

| Light output mode | QCW/PWM/CW |

| Aiming and positioning system | Microscope |

| Rated power | 5.6 KW |

| Cooling method | Water cooling (dual temperature and dual control) |

| Electricity requirement | 220V±10% 50Hz/40A |

| Main machine size/net weight | L 960×W 550×H 680mm / 120 KG |

| Table size/net weight | L 610×W 410×H 580mm / 55 KG |

| Boom size/net weight | L 1600×W 1070×H 1680mm / 120 KG |

Advantages of Laser Welding Machine for Mold

- High Precision: Laser welding technology excels in achieving superior precision. It enables precise welding even on intricate details and complex shapes of molds. This precision ensures accurate and consistent welds, resulting in high-quality joints.

- Low Heat Input: Laser welding minimizes heat input during the welding process, reducing the size of the heat-affected zone on the mold. The low heat input can maintain the mold’s stability in shape and dimensions.

- Fine Control: Laser welding technology allows for highly precise control over welding parameters such as laser power, welding speed, and focal length. Fine-tuning these parameters ensures optimized welding results, meeting specific requirements in mold manufacturing.

- Non-contact: Laser welding operates as a non-contact method, eliminating the need for direct contact with the mold surface, which eliminates issues related to mechanical stress and wear, which are common in traditional welding methods. The absence of contact also prevents wear and contamination caused by friction between the welding tip and the mold surface.

- Fast Speed: Laser welding is an efficient method with fast welding speeds, which is an ideal solution for mass-producing molds or high-throughput manufacturing processes.

Articulated Arm Mold Laser Welding Machine Demonstration Video

Component Detail Display of Mold Laser Welding Machine

Microscope Operating System

The microscope monitors operations and employs the latest automatic shading system to prevent eye irritation during work hours.

CCD System

CCD system (camera system) is utilized for monitoring. Besides the operator’s view through the microscope, non-operators can observe the entire welding process on the camera monitoring system’s display screen.

Ceramic Concentrator

HANTENCNC develops and produces mold laser welding machines that use imported ceramic concentrators. These concentrators are corrosion-resistant and high-temperature-resistant, offering a cavity life of 8-10 years and a xenon lamp lifespan exceeding 8 million times.

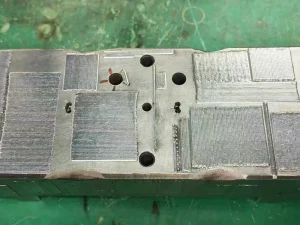

Mold Laser Welding Machine Sample Display

Customer Case: 1500W Mold Laser Welding Machine in Saudi Arabia

Customer Reviews

Customer Visits

HANTENCNC Partnerships

HANTENCNC Services

HANTENCNC offers a 2-year warranty for the laser source and a 1-year warranty for the whole machine, sample testing, OEM customization, remote guidance, and lifelong after-sales support.