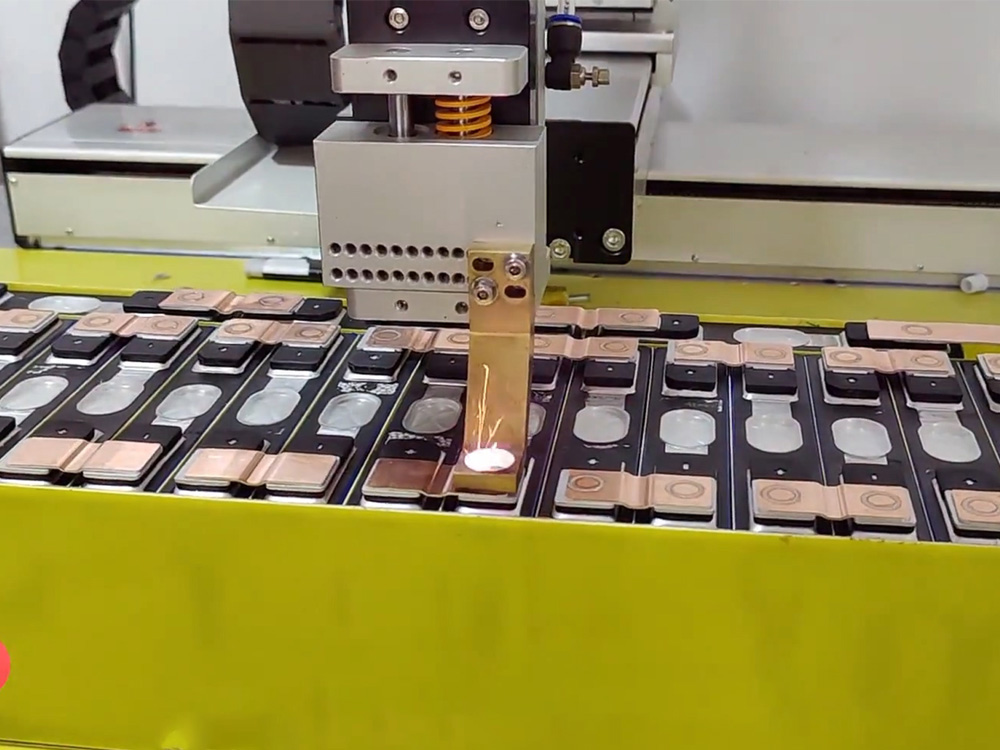

With the continuous development of modern technology. Lithium battery has gradually become one of the representatives of new energy. It is increasingly widely used in various fields. In the production process of lithium batteries. Laser welding technology has become an essential link. Lithium battery laser welding machine has the characteristics of high efficiency and precision….

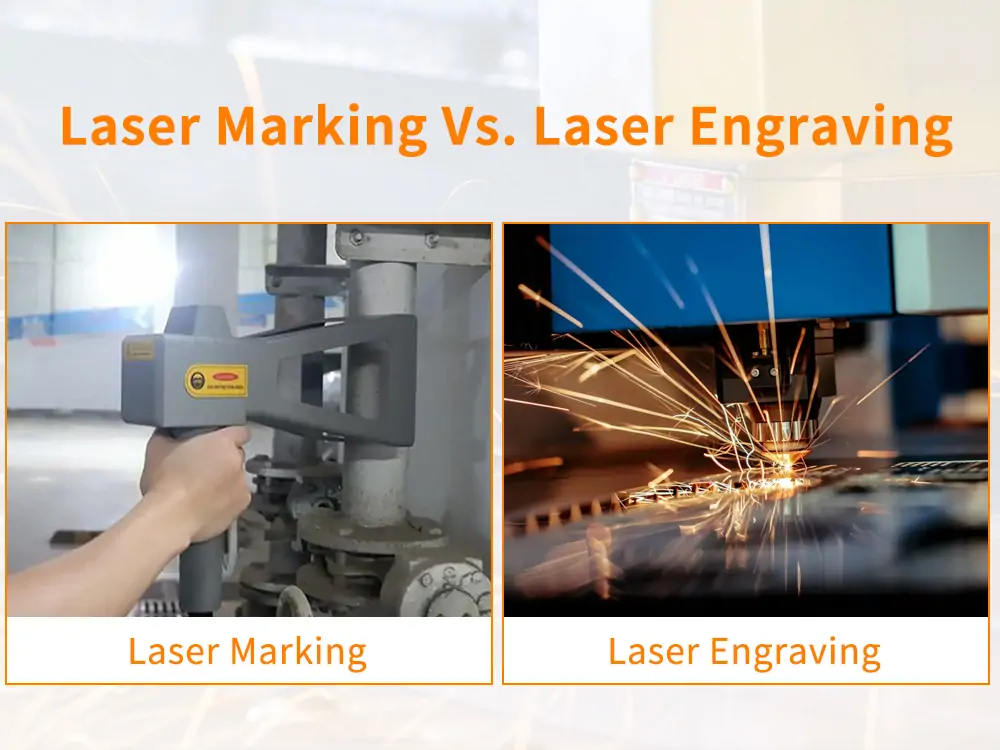

Laser technology has become a widespread method for creating durable marks or patterns on materials. In this field, laser marking and laser engraving are two standard methods. They play an essential role in many different applications. For industrial manufacturing or personal customization, laser marking and engraving provide precise, efficient, and durable marking solutions. Both techniques…

Before learning more about laser welding. Let’s first understand some of its basic principles. Laser welding is a method that uses a laser as a heat source. Melts part or the entire cross-section of a workpiece. And solidify under certain conditions to form an organic welding method. The principle is to use the laser beam…

Laser technology is playing an increasingly important role in modern society. As an essential application of laser technology, fiber laser plays a vital role in some fields. These include communication, medical treatment, and industrial manufacturing. There are many different types of fiber lasers on the market. Choosing a product that suits their needs has become…

In modern industrial manufacturing, laser engraving has become a vital technology. Laser marker machines are essential in some fields. Such as metal processing, plastic manufacturing, medical devices, and electronics industries. Choosing a reliable laser marking machine manufacturer is necessary. It will bring the best engraving results and quality. This article will introduce the world’s top…

The 500-watt handheld laser cleaning machine is the latest laser cleaning tool launched by HANTENCNC. Hereinafter referred to as HTCM-500. Compared with traditional cleaning methods, the advantages of HTCM-500 are very obvious. Will be mentioned below. HTCM-500 is widely used in various industries. It has the characteristics of precise positioning, so it can meet the…

In the mid-18th century, Western countries took the lead in starting the first industrial revolution. Since then, mankind has entered a new industrial age. With the development of the times, the application of science and technology rises. In order to meet the needs of production, human beings have gradually transformed from manual carving to industrialized…

With the continuous advancement of science and technology, laser cleaning technology has been widely used in various industries. Laser cleaning machines have unique advantages as efficient, environmentally friendly, non-contact cleaning tools. It has been valued and favored by enterprises and institutions worldwide. However, among the many laser cleaning machine manufacturers, which are the best in…

Hello everyone, this is Hanteng Jiguang Technology Co., Ltd. We are a professional laser equipment manufacturer. main production:Laser welding machine.Laser cleaning machine.Laser cutting machine.Marking machine: fiber laser marking machine. Carbon dioxide marking machine. UV laser marking machine.Laser equipment such as ultraviolet printers.Today I will introduce to you our most popular machine: platform fiber laser welding…

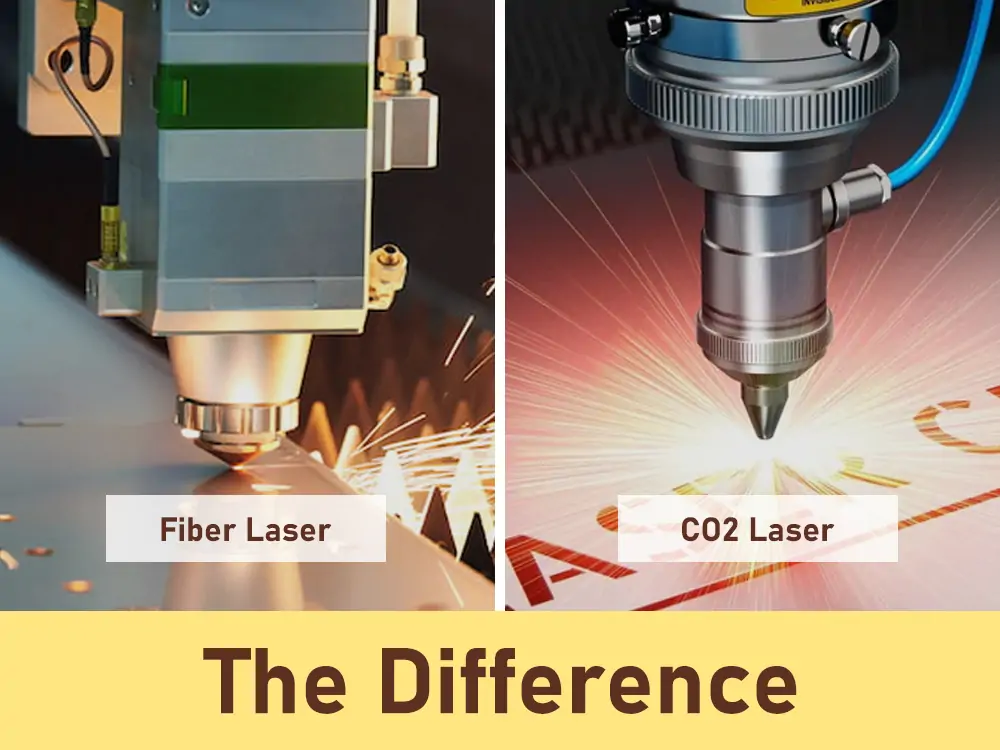

In industrial laser systems, two prominent technologies have emerged as significant contenders. Fiber lasers and CO2 lasers. These laser technologies are used in various industries for cutting, welding, engraving, and marking. Fiber and CO2 lasers offer unique advantages and are suitable for specific use cases. This article will delve into the key differences between fiber…