Hello everyone, this is Hanteng Jiguang Technology Co., Ltd. We are a professional laser equipment manufacturer. main production:Laser welding machine.Laser cleaning machine.Laser cutting machine.Marking machine: fiber laser marking machine. Carbon dioxide marking machine. UV laser marking machine.Laser equipment such as ultraviolet printers.

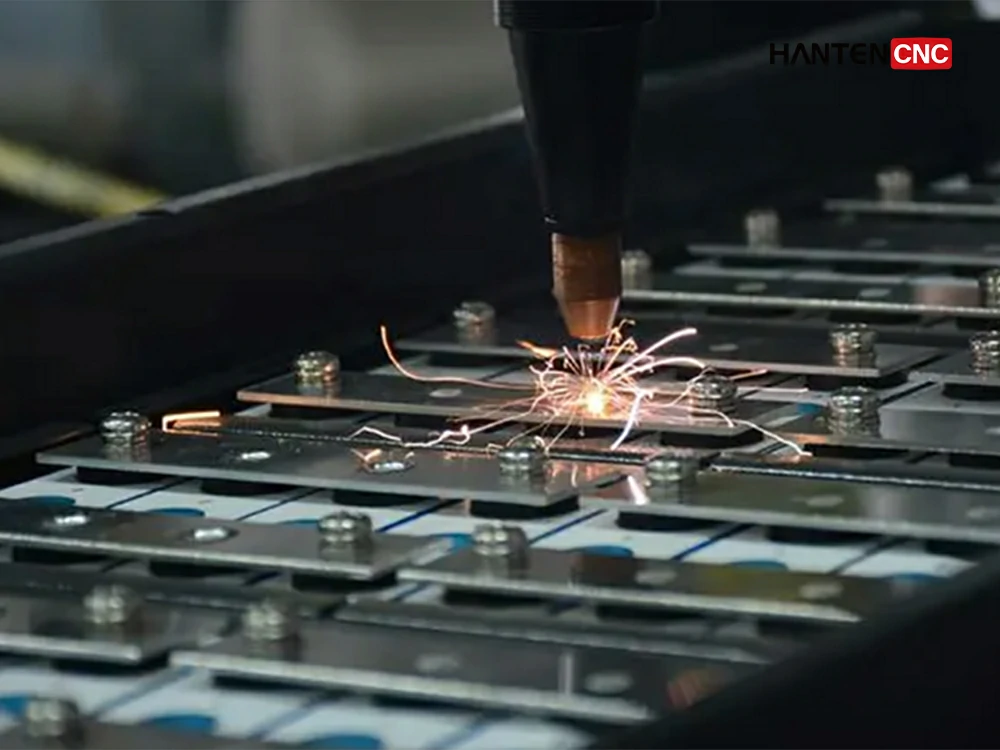

Today I will introduce to you our most popular machine: platform fiber laser welding machine.

Let me briefly introduce the machine first: platform fiber laser welding machine. It uses a new generation of fiber laser light source. Equipped with single pendulum or double pendulum welding joints. It has the advantages of simple and easy operation and beautiful and non-damaging welds. At the same time, it also has the advantages of fast welding speed, high efficiency, no consumables and no pollution. High-quality results can be achieved in welding metal materials such as stainless steel plates, iron plates, and galvanized plates.

HANTENCNC laser welding machine structure

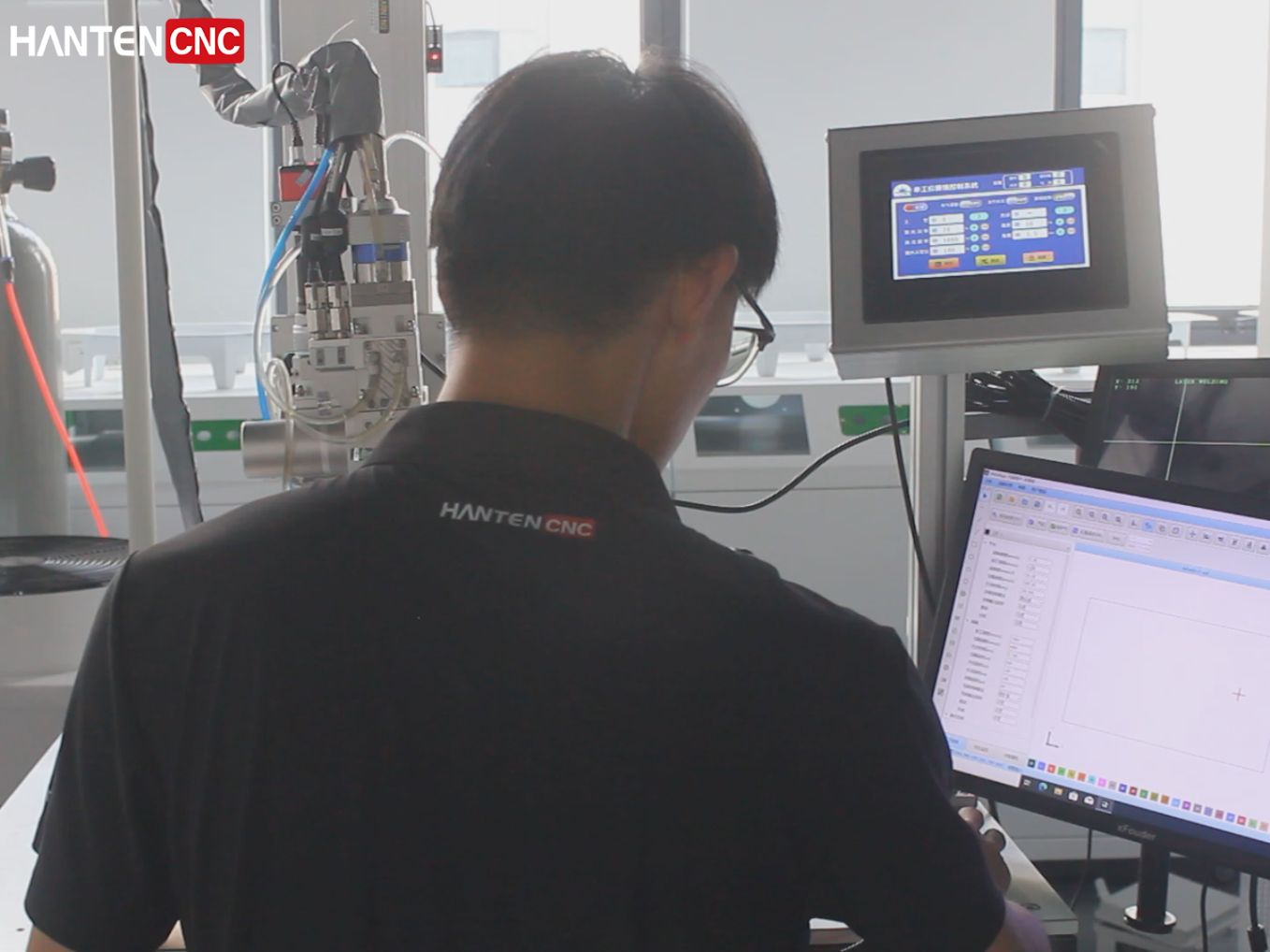

The platform fiber laser welding machine produced by HANTENCNC is equipped with a standard independent three-dimensional automatic mobile worktable. An optional swivel clamp is also available. It can realize two-dimensional automatic laser welding. It can monitor the system using a microscope and red light. Equipped with external water cooling system.

- The laser system includes: laser light source and laser power supply. There are also main components such as laser control card, welding head, and optical path.

- Cooling system: Since the laser welding machine works at high power, it generates high-energy heat. So the cooling system can cool the laser. The power of the chiller equipped with different power is different.

- Workbench cabinet: The worktop is a metal platen. Space on the desk can include stands for monitors and measuring instruments. It is small in size, and the table layout can be customized according to user requirements. For example, it can be installed with manual lifting accessories and so on. The workbench refers to the laser welding automatic workbench. Also called the motor system. The table makes the laser beam move according to the specific requirements and welding trajectory to realize automatic welding. It can be said that the workbench is the core component of the fiber optic platform laser welding machine. It mainly controls the welding action. Relatively speaking, the motion control of the worktable is to program the motion through NC programming. In order to control the program, the workbench can move as required.

- Screen observation system: This machine is equipped with a screen observation detection system. It can observe and detect the welding effect and running track of the laser spot welding seam at any time.

- Increase the automation equipment system. The platform fiber laser welding machine can be used with three-axis and four-axis linkage worktables. There are also manipulators and cantilever worktables to achieve precise welding motion trajectory control. And it can choose different working track ranges.

- Optional servo wire feeder is mainly used for workpieces with large welding gaps. The wire feeder feeds the wire smoothly. Cooperating with the welding head can realize the perfect welding of precision workpieces with large weld seams.

The application industry of HANTENCNC platform laser welding machine

Platform laser welding machine is a high-precision, high-efficiency welding equipment. It is widely used in many industries. The following are some application industries that purchase HANTENC CNC equipment:

- Automobile manufacturing industry: it can be used for welding of automobile body. Includes welding of doors, roof and cabin. It guarantees welding quality and strength. In addition, this platform laser welding machine can also be used for welding of automotive engine parts. Such as cylinder head, crankshaft, etc.

- Electronic industry: platform laser welding machine can be used for welding electronic components. Examples include circuit boards and connectors, and batteries. Because the platform laser welding machine has the characteristics of high precision and high speed. Welding quality and stability can be guaranteed.

- Machinery manufacturing industry: platform laser welding machines can be used to weld metal parts. Such as machine tools and ships, and aircraft welding. The platform laser welding machine can realize welding of complex shapes and fine structures. Greatly improved welding quality and production efficiency.

- Medical device industry: platform laser welding machine can be used for welding of medical devices. Such as surgical instruments and artificial joints, and dental instruments. The platform laser welding machine can realize the precision welding of tiny instruments. It ensures the quality and safety of the equipment.

- Aerospace industry: It can be used for welding of spacecraft. Such as rocket engines and spacecraft casings. Because the platform laser welding machine has the characteristics of high energy density and fast speed. It enables deep welding of spacecraft materials. Ensure welding quality and strength.

- Photoelectric industry: platform laser welding machine can also be used for optical fiber welding. Such as fiber optic connectors, fiber optic couplers, etc. Precision welding of optical fibers can be realized. It also ensures the transmission efficiency and stability of the optical fiber.

To sum up, the application industry of HANTENNCNC platform laser welding machine is very wide. Not only the industries described above can be applied. The high precision and high efficiency of the platform laser welding machine make it play an important role.

Model features and advantages of HANTENCNC platform laser welding machine

- The weld seam after welding by HANTENCNC platform welding machine is smooth and beautiful. There is no deformation when welding workpieces. It has the characteristics of no welding scar. And the welding is firm to reduce the subsequent grinding process. It greatly saves time and cost.

- The operation of the HANTENCNC platform welding machine is simple. Only need simple training to operate. Beautiful products can be welded without professional welders. No technical requirements, general workers can operate. And the operation is simple and easy to understand. We have professional engineer training. It only takes 20 minutes to master the use of the machine proficiently.

- The welding head of the fiber optic platform welding machine. It has a variety of welding welding modes. Its spot width can be adjusted, and its welding tolerance is strong. The platform laser welding machine produced by HANTENCNC not only welds firmly. Moreover, raw materials are saved, and the welded parts will not be disconnected after the engineer’s test.

- The welding speed of the HANTENCNC platform welding machine is fast. It is 2-10 times faster than traditional welding, and one machine can save at least several welding workers a year. It’s more efficient and faster. Create higher benefits for your company’s production.

- The welding consumables of the HANTENCNC platform welding machine are less. It has a long service life. It can ensure safer and more environmentally friendly during use.

- Compared with traditional hand-held laser welding. The HANTENCNC platform welding machine has a higher degree of customization and automation. It can not only be equipped with various configurations. It can also make different fixtures for different workpieces of customers to improve efficiency.

- The HANTENCNC platform welding machine can weld various non-standard customized products. It can realize mass production and assembly line production.

- The HANTENCNC platform welding machine equipment adopts a combination of a special welding head and a three-axis servo motor. It has higher precision, enables seam tracking and multi-angle welding.

Common after-sales problems of platform laser welding machines

The staff of HANTENCNC received a lot of feedback from fans in the backstage of Youtube. It is said that after buying another platform laser welding machine, there is no after-sales service. Failure to find a seller leads to delays in production and increases costs. Today, the engineers of HANTENCNC have summarized some common after-sales problems of platform laser welding machines for you. You can take a look:

- Equipment failure: After a long period of use, the platform laser welding machine may experience some failures. Such as laser damage and circuit failure. At this time, it is necessary to contact the manufacturer or after-sales service personnel for maintenance in time.

- Parts replacement: The parts used in the platform laser welding machine may be worn or damaged after long-term use and need to be replaced. Common parts that need to be replaced include lasers, optical fibers, and lenses. Users can contact the manufacturer to purchase original parts for replacement. Or ask the after-sales service personnel to replace it.

- Parameter adjustment: During use, it may be necessary to adjust parameters according to different welding requirements. Some users are not familiar with the operation method or how to adjust the parameters. If you have purchased our equipment, you can consult HANTENCNC after-sales service personnel at any time. We will provide professional free guidance.

- Operation training: For some newly purchased platform laser welding machines, users may not be familiar with the operation method. They need training. Our after-sales service personnel can guide online. Teach users how to operate the equipment correctly. Avoid problems caused by operating errors.

- Maintenance: Platform laser welding machine is a precision equipment. It requires regular maintenance to ensure the normal operation of the equipment. HANTENCNC’s after-sales service personnel can provide suggestions and guidance for maintenance. Help our users extend the life of their equipment.

- Safety issues: Safety issues need to be paid attention to during the use of the platform laser welding machine. Avoid accidents. The after-sales service of HANTENCNC will provide our customers with safe operation guidance. Teach users how to use equipment properly. And provide the necessary safety protection equipment.

- Fault diagnosis: If our users encounter problems that cannot be solved, they can ask after-sales service personnel to carry out fault diagnosis. Our after-sales service can determine the cause of the failure by checking the equipment and testing parameters. We will provide customers with corresponding solutions.

In short, there may be various after-sales problems during the use of platform laser welding machines. Just choose a good manufacturer, especially a company integrating industry and trade like HANTENCNC. You don’t have to worry about after-sales issues anymore. We will provide corresponding technical support and solutions to ensure the normal use of the equipment.

The above is a brief introduction to some working principles, advantages and structures of the HANTENCNC platform welding machine. For laser welding machines, we also have more models and equipment. Such as handheld laser welding machines and laser spot welding machines. There are also different models such as laser jewelry welding machines.