In industrial laser systems, two prominent technologies have emerged as significant contenders. Fiber lasers and CO2 lasers. These laser technologies are used in various industries for cutting, welding, engraving, and marking. Fiber and CO2 lasers offer unique advantages and are suitable for specific use cases. This article will delve into the key differences between fiber laser vs CO2. We will also explore their working principles, characteristics, and applications. Wish can help you choose your specific laser needs.

Understanding Fiber Lasers

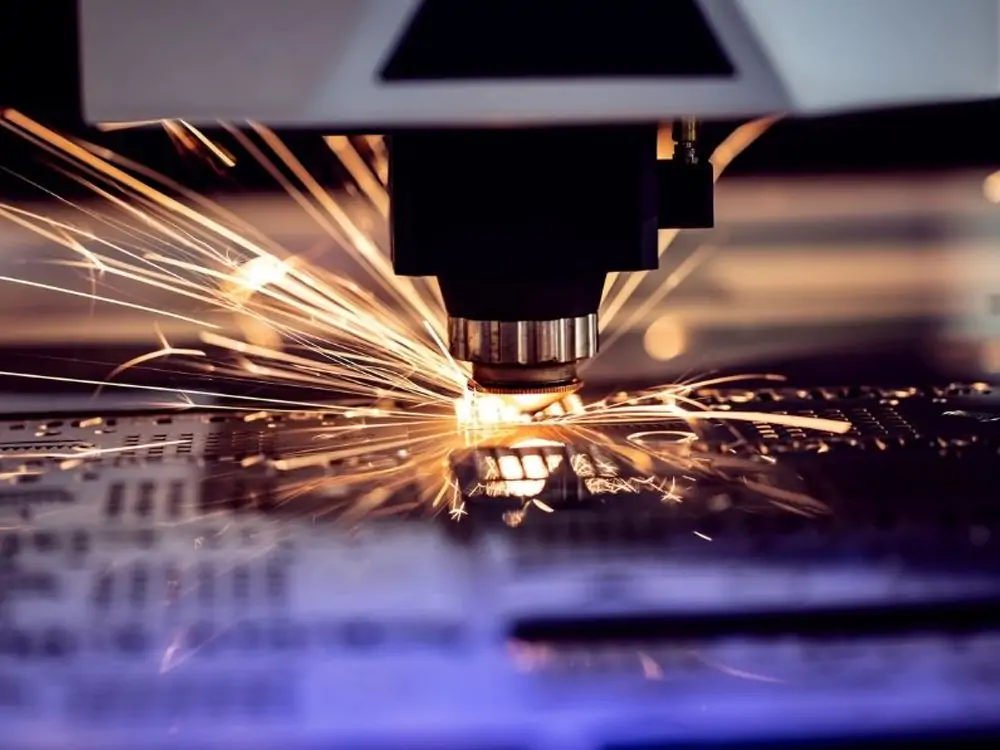

Fiber lasers are solid-state lasers that use optical fibers as the gain medium. They generate a laser beam by pumping a diode laser into an optical fiber. Optical fibers amplify light by stimulated emission. The amplified light is then focused and emitted through an output coupler, resulting in a high-power laser beam. Fiber lasers operate at a wavelength of 1,064 nanometers (nm).

Advantages of Fiber Lasers

High Efficiency

Fiber lasers are efficient in converting electrical power into laser light. They can achieve higher wall-plug efficiencies compared to some other types of lasers. This efficiency results in lower power consumption and operating costs.

Superior Beam Quality

Fiber lasers produce a high-quality laser beam with a slight focus spot size and excellent beam profile. This beam quality enables finer and more precise laser cutting, welding, and marking. It makes fiber lasers ideal for applications that need high accuracy.

Compact Design

Fiber lasers are compact and lightweight compared to CO2 lasers. It will make integrating them into existing manufacturing systems or robotic setups easier. Fiber laser machines have a small footprint and a flexible fiber optic delivery system. It also makes them suitable for applications with tight spaces or complex geometries.

Maintenance And Longevity

Fiber lasers have a longer operational lifetime than CO2 lasers due to the absence of gas discharge tubes. They need minimal maintenance. It increases uptime and reduces downtime for industrial processes.

Applications of Fiber Lasers

Fiber lasers find applications across various industries, including:

Metal Processing

Fiber lasers are widely used for cutting and welding metals like stainless steel, aluminum, and titanium. Their high beam quality and power density allow for precise and efficient metalworking. It makes them invaluable in the automotive, aerospace, and manufacturing industries.

Medical

Fiber lasers are used in medical applications like laser surgery, dermatology, and ophthalmology. Their high precision and versatility enable minimally invasive procedures and delicate tissue ablation.

Electronics

Fiber lasers are employed in the electronics industry for PCB drilling and micro-machining. Their ability to be precise and accurate is critical to modern electronics manufacturing.

Aerospace And Defense

Fiber lasers play a crucial role in aerospace and defense applications. They are used for cutting and drilling intricate components in aircraft manufacturing. These include turbine blades, fuel nozzles, and fuselage panels. Fiber lasers are also employed in defense applications. Such as laser-based target designation, range finding, and directed energy weapons.

Photovoltaic Industry

Fiber lasers are employed in the manufacturing of solar cells and photovoltaic modules. They are used for scribing and dicing processes to create precise patterns and separate solar cells from wafers. Fiber lasers offer high speed, accuracy, and cost-effectiveness in producing solar panels.

Marking And Engraving

Fiber laser machines are ideal for marking and engraving applications on various materials. These include metals, plastics, ceramics, and composites. Fiber laser machines have excellent beam quality and high precision. So it can create detailed and permanent marks with perfect contrast and readability. It makes them valuable in the automotive, electronics, medical devices, and jewelry industries.

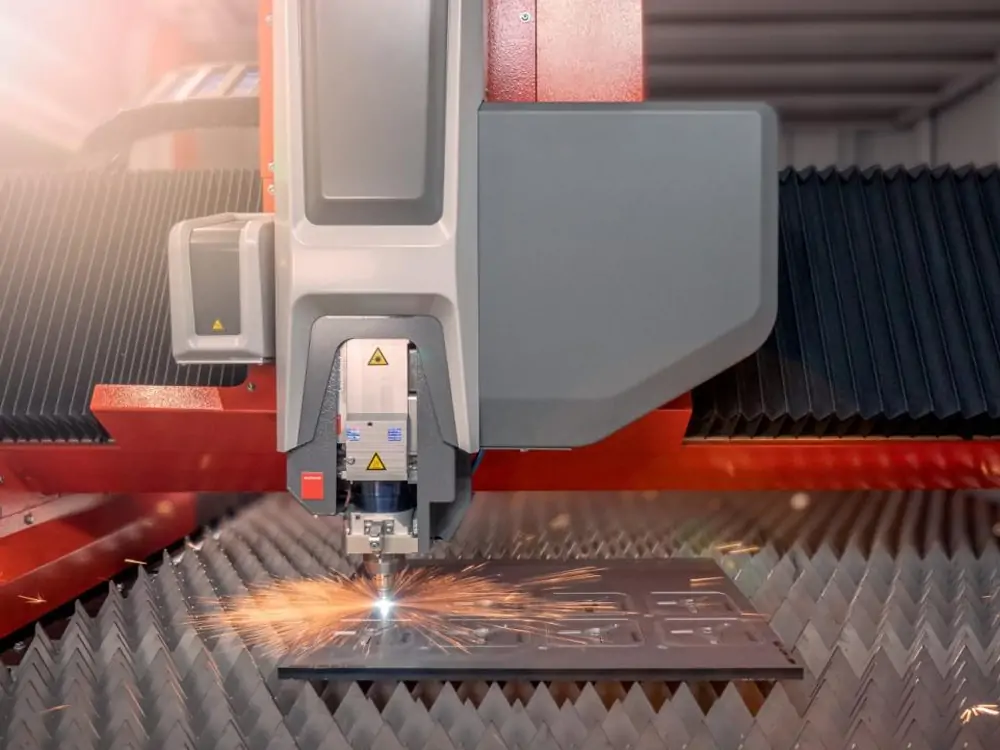

Understanding CO2 Lasers

CO2 lasers, also known as carbon dioxide lasers, are gas lasers widely used in industrial applications. CO2 lasers operate based on the principle of stimulated emission. The active medium in a CO2 laser is a mixture of carbon dioxide (CO2), nitrogen (N2), and helium (He) gases. When an electric discharge passes through this gas mixture, it energizes the CO2 molecules. It causes them to reach higher energy levels. As the molecules return to their lower energy states, they emit photons in the infrared range. Specifically at 10,600 nanometers (nm).

Advantages of CO2 Lasers

High Power

CO2 lasers can deliver high power outputs, ranging from a few watts to kilowatts. This high power makes them suitable for applications that need intense heat. Such as cutting thick metals or engraving deep markings.

Versatility

CO2 lasers can process various materials, including wood, plastic, glass, textiles, and leather. Their long wavelength allows excellent absorption in non-metallic materials. It makes them well-suited for engraving, etching, and surface treatments.

Cost-Effectiveness

CO2 laser machines offer cost advantages for specific applications. Especially about initial buy costs. They are usually less expensive than fiber lasers. It is cheaper for enterprises with particular requirements and budget constraints.

Continuous Wave Mode

CO2 lasers operate in continuous wave mode. It means they can deliver a constant laser beam for extended periods without interruption. This feature makes them suitable for applications that need steady and continuous laser power. Such as large-scale industrial cutting or engraving processes.

High Power Output

CO2 lasers can deliver high power outputs, ranging from a few watts to kilowatts. This high power makes them particularly suitable for applications that need intense heat. Such as cutting thick metals or engraving deep markings. The ability to generate high power enables efficient and rapid processing of materials.

Established Technology

CO2 lasers have been used for many years and have established a solid reputation in the industry. They have undergone extensive development and refinement, resulting in reliable and mature technology. Reliability combined with expertise makes CO2 lasers the trusted choice for many applications.

CO2 lasers offer several advantages. These make them a preferred choice for various industrial applications. Their high power output, versatility in material processing, cost-effectiveness, continuous wave operation, and established technology contribute to their popularity. When choosing between CO2 lasers and other laser technologies, it is essential to consider specific considerations. Such as application requirements, material compatibility, accuracy needs, and budget constraints. By understanding these factors, businesses can choose the laser system that best meets their needs. It can help you achieve the best possible results in your manufacturing process.

Applications of CO2 Lasers

CO2 laser machines find applications in various industries, including:

Industrial Cutting And Welding

The high power and versatility of CO2 lasers have made them popular in the automotive, shipbuilding, and construction industries. It is widely used in cutting and welding applications. They can efficiently cut through thick metal sheets and provide excellent weld quality.

Engraving And Marking

CO2 lasers are widely used for engraving and marking various materials. These include wood, acrylic, glass, and paper. Their long wavelength allows for deep engraving and precise marking. It makes them valuable in signage, packaging, and personalized products.

Textile And Apparel Industry

CO2 lasers are used in textile and clothing manufacturing. It can cut intricate patterns and create intricately designed fabrics. CO2 laser machines provide precise control and high-speed processing, increasing industry productivity.

Comparison And Choosing the Right Laser Technology

When it comes to choosing between fiber laser vs CO2 laser, several factors need to be considered based on the specific application requirements:

Material Compatibility

Consider the type of materials you need to process. While fiber and CO2 lasers offer versatility, fiber lasers excel in metal processing. CO2 laser machines are better suited for non-metallic materials.

Precision And Accuracy

Fiber lasers are preferred due to their superior beam quality if your application demands high precision and fine detail. CO2 lasers are better suited for applications where slight imperfections are acceptable.

Power And Speed

If you need high-power output or fast processing speeds, CO2 lasers may be the better option. They can deliver higher wattages and have a longer wavelength. So, they are more suitable for specific industrial applications.

Initial And Operating Costs

Conclusion

In conclusion, fiber and CO2 lasers have their place in the world of laser technologies. Choosing the right one depends on the specific needs of your application. Fiber lasers are known for their high efficiency, superior beam quality, and high precision. CO2 lasers offer high power, versatility in non-metallic materials, cost-effectiveness, and continuous wave operation. When deciding, evaluating factors is crucial. Such as material compatibility, precision requirements, power, speed needs, and initial and operating costs. By carefully considering these factors, you can make an informed choice that meets your requirements and goals.

Fiber and CO2 lasers have advantages and can deliver exceptional results in their respective domains. Understanding and matching your needs with the laser technology that best suits your requirements is critical. With the right laser system, you can enhance productivity, improve quality, and drive innovation in your industrial processes.