Aluminum is lightweight, corrosion-resistant, and durable. It is, therefore, a versatile and widely used material in various industries. Laser technology has proven to be an efficient and precise method for marking aluminum. Laser marking offers high-quality, permanent markings on aluminum surfaces without compromising the integrity of the material. This article will explore the process of laser marking on aluminum. We will also discuss the necessary steps and considerations for achieving optimal results.

How to Mark Aluminum With a Laser

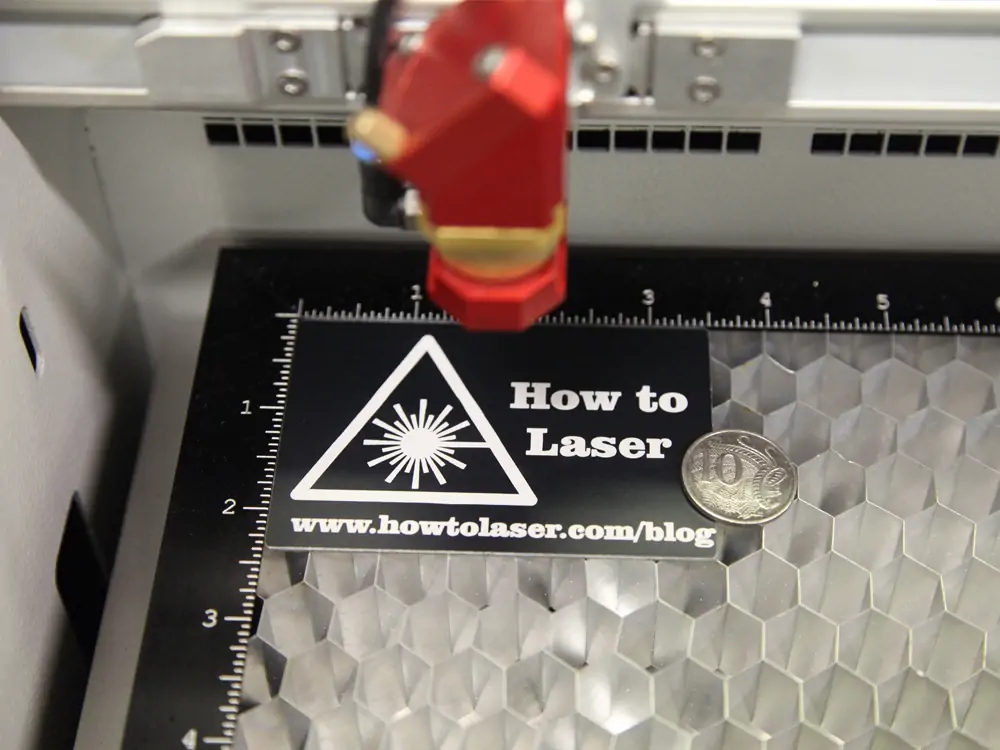

Selecting The Right Laser Aluminum Marker

Choosing a laser aluminum marker suitable for laser marking aluminum is crucial. These CO2 lasers should be usable for this purpose. Because they provide excellent results on aluminum surfaces. They operate at a wavelength of 10.6 micrometers, which absorbs aluminum, enabling precise and efficient marking.

Preparing The Aluminum Surface

To achieve optimal laser marking results, proper surface preparation is essential. Follow these steps to prepare the aluminum surface for laser marking:

Clean The Surface

Remove any dirt, dust, or oils from the aluminum surface using a mild detergent or alcohol. Ensures that the laser interacts with the material and minimizes any potential interference.

Dry The Surface

Adjusting Laser Parameters

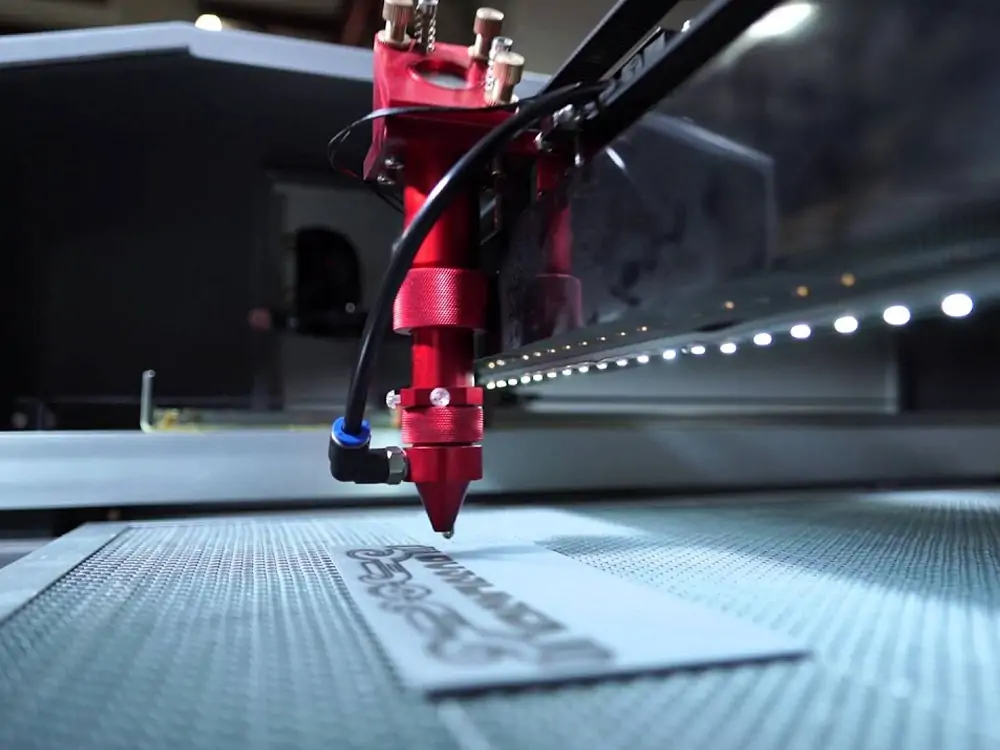

The laser parameters must be properly adjusted to achieve the desired marking results. Laser power, speed, Frequency, and focus should be considered.

Laser Power

The laser power determines the depth and visibility of the marking. Higher power settings generally result in deeper markings. But be cautious to stay within the material’s limitations. As excessive power can cause damage. Laser safety goggles should comply with the appropriate safety standards and be able to block the specific wavelength of the laser being used. It’s important to note that more than regular safety goggles or glasses are needed for laser protection. Because they may not protect against laser radiation. When selecting laser safety goggles, consider the following:

Marking Speed

The marking speed affects the quality and precision of the mark. Finding the optimal balance between speed and quality is crucial. Test different rates to determine the ideal setting for your specific application.

Frequency

Frequency refers to the number of laser pulses delivered per second. Adjusting the Frequency can influence the mark’s appearance. Including its contrast and readability. Experiment with different frequencies to achieve the desired effect.

Focus

Proper focusing of the laser beam is crucial for achieving precise markings. Adjust the focal length to ensure the laser beam is tightly focused on the aluminum surface. Adjusting will enhance the clarity and definition of the mark.

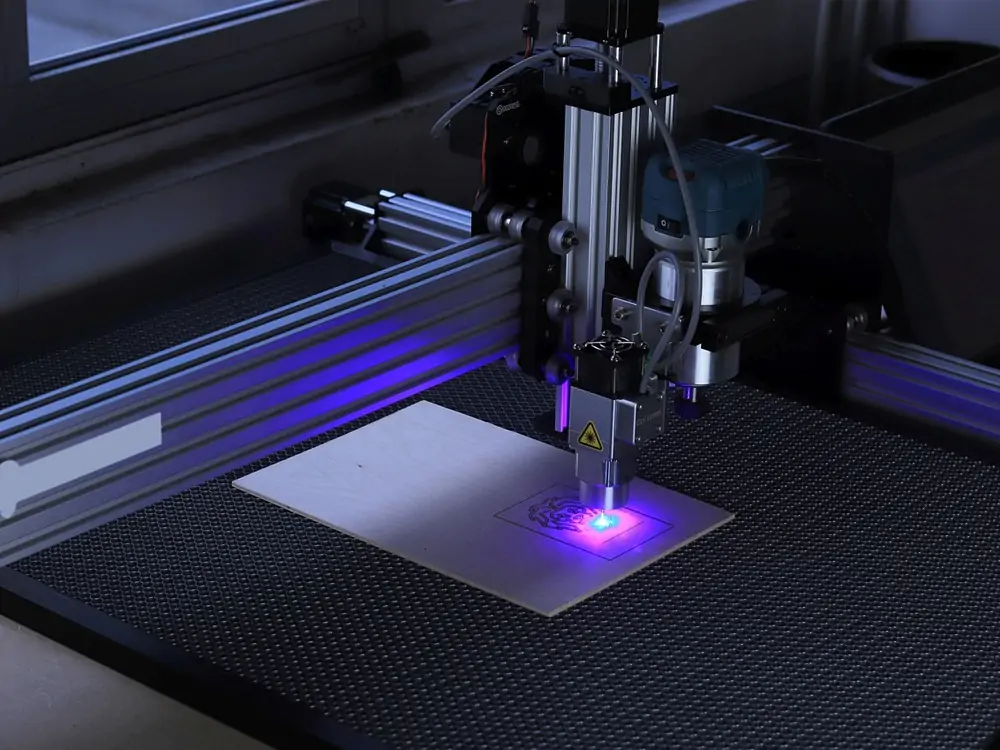

Implementing Laser Marking Techniques

When laser marking aluminum, several techniques can be employed to achieve different effects or meet specific requirements. The most common methods include:

Surface Annealing

This technique uses a laser to heat the aluminum surface without vaporizing it. By applying controlled heat, the surface oxidizes, resulting in a contrasting mark. Surface annealing is ideal for creating dark, permanent markings on aluminum.

Surface Etching

Etching removes a thin aluminum surface layer, creating a visible and durable mark. By adjusting the laser power and speed, you can control the depth and width of the etched area. Surface etching is commonly used for creating logos, serial numbers, or barcodes.

Color Marking

Specific laser systems can produce color marks on aluminum surfaces. This technique relies on altering the oxide layer formed during laser marking. Various colors can be achieved by manipulating laser parameters and controlling the oxide layer thickness. Color marking is often used for aesthetic or branding purposes.

Focus

Proper focusing of the laser beam is crucial for achieving precise laser marking aluminum. Adjust the focal length to ensure the laser beam is tightly focused on the aluminum surface. Adjusting will enhance the clarity and definition of the mark.

Safety Precautions

Working with lasers requires strict adherence to safety guidelines to protect both the operator and the equipment. Here are some essential safety precautions to consider when laser marking aluminum:

Eye Protection

Laser beams can cause permanent eye damage, so wearing appropriate laser safety goggles is crucial. The goggles should be designed for the laser wavelength and provide enough protection. Ensure that all individuals near the laser marking process wear appropriate eye protection.

Ventilation

Laser marking aluminum processes can produce fumes or gases. It depends on the type of aluminum being marked. Ensure proper ventilation in the workspace. It can reduce the inhalation of potentially harmful substances. Use fume extraction systems or local exhaust ventilation to remove any airborne contaminants.

Fire Safety

Aluminum is highly reflective, and laser marking can generate heat. Ensure your workspace has appropriate fire prevention measures. These include fire extinguishers, fire-resistant materials, and proper emergency protocols. Keep flammable materials away from the laser marking area.

Operator Training

Proper training and certification are essential for anyone operating a laser marking system. Operators should be knowledgeable about laser safety protocols, emergency procedures, and equipment handling. Regular training and refresher courses should be conducted to ensure ongoing safety awareness.

Material Compatibility

Different alloys and aluminum coatings may respond differently to laser marking. So, test compatibility before marking to determine the correct laser parameters for your aluminum material. Material specificity will help prevent any unexpected reactions or damage to the material.

Maintenance And Inspection

Regular maintenance and inspection are necessary to ensure its safe and efficient operation. Follow the manufacturer’s guidelines for maintenance procedures. These include cleaning, alignment checks, and replacing worn-out parts. Any malfunctioning equipment should be promptly repaired or replaced.

Restricted Access

Restrict access to the laser marking area to authorized personnel only. Mark the location and implement safety protocols. It can prevent unauthorized individuals from entering the workspace during operation. This exercise will cut the risk of accidents or exposure to laser radiation.

Emergency Preparedness

Have a well-defined emergency plan. These include evacuation routes, emergency shutdown procedures, and communication protocols. Ensure that all operators are familiar with these procedures and conduct regular drills. It can practice response to potential emergencies.

Laser marking on aluminum should always be performed cautiously and adhere to safety guidelines. Consulting with laser marking professionals or experts can provide further insights and recommendations for your application.

Conclusion

In conclusion, laser marking aluminum is a reliable and efficient method. It can achieve high-quality and permanent markings on aluminum surfaces. Choose a suitable laser marking machine, prepare the aluminum surface, adjust the laser parameters, and install the correct marking technique. You can get the best results for your specific application. But safety must be focused on throughout the entire process. They ensure proper eye protection, ventilation, fire safety measures, and operator training. They are essential to prevent accidents and maintain a safe working environment. Regular maintenance and inspections, restricted access, and emergency preparedness can further contribute to a safe and efficient operation.

Following these guidelines and considering the specific requirements of your laser marking aluminum project. Then, you can use laser technology to create precise and appealing markings. Laser marking on aluminum opens up a world of possibilities for various industries. These include automotive, aerospace, electronics, and more. With the right approach and safety precautions, laser marking on aluminum can benefit your business. It will provide long-lasting and professional markings that meet your needs.