Foreword

In the mid-18th century, Western countries took the lead in starting the first industrial revolution. Since then, mankind has entered a new industrial age. With the development of the times, the application of science and technology rises. In order to meet the needs of production, human beings have gradually transformed from manual carving to industrialized mass production. Sculpting tools are gradually upgraded.

In 1958, American scientists accidentally discovered a phenomenon in an experiment. They found that when the inner light (knife and cloth), that is, light hits the back, the emitted light hits the rare earth crystal. They found that the two became one, reflecting fresh and cold glares and shadows, gathered together forever. This discovery became known as “The Principle of the Laser”.

Two years later, a laboratory in California developed the first laser in human history. Its wavelength is 0.6943um. Since then it has been widely used in production. In July of the same year, Maiman developed the first laser machine.

With the continuous development of technology, in today’s era, laser marking machines have emerged as the times require.

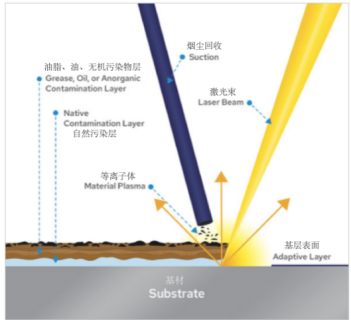

Laser Marking Machine Principle

The laser marking machine irradiates the surface of the material through the laser beam. The laser causes the evaporation of the surface material to expose the deep material, thus completing the marking. Due to the high heat of the laser beam. The materials on the surface of the material are thermally expanded and peeled off to expose the deep layer materials. Finally, the material shows the pattern and text to be etched, as well as various graphics such as barcodes.

Classification of Laser Marking Machines

With the development of technology, the types of laser marking machines are gradually increasing. According to the classification of lasers, laser marking machines can be divided into the following categories:

- Fiber laser marking machine

- MOPA fiber laser marking machine

- CO2 laser marking machine

- UV laser marking machine, etc.

Among them, the fiber laser marking machine can be divided into:

- 3D fiber laser marking machine

- 2D fiber laser marking machine

CO2 laser marking machines and UV laser marking machines can be divided into:

- Air-cooled laser marking machine

- Water-cooled laser marking machine

Machine introduction

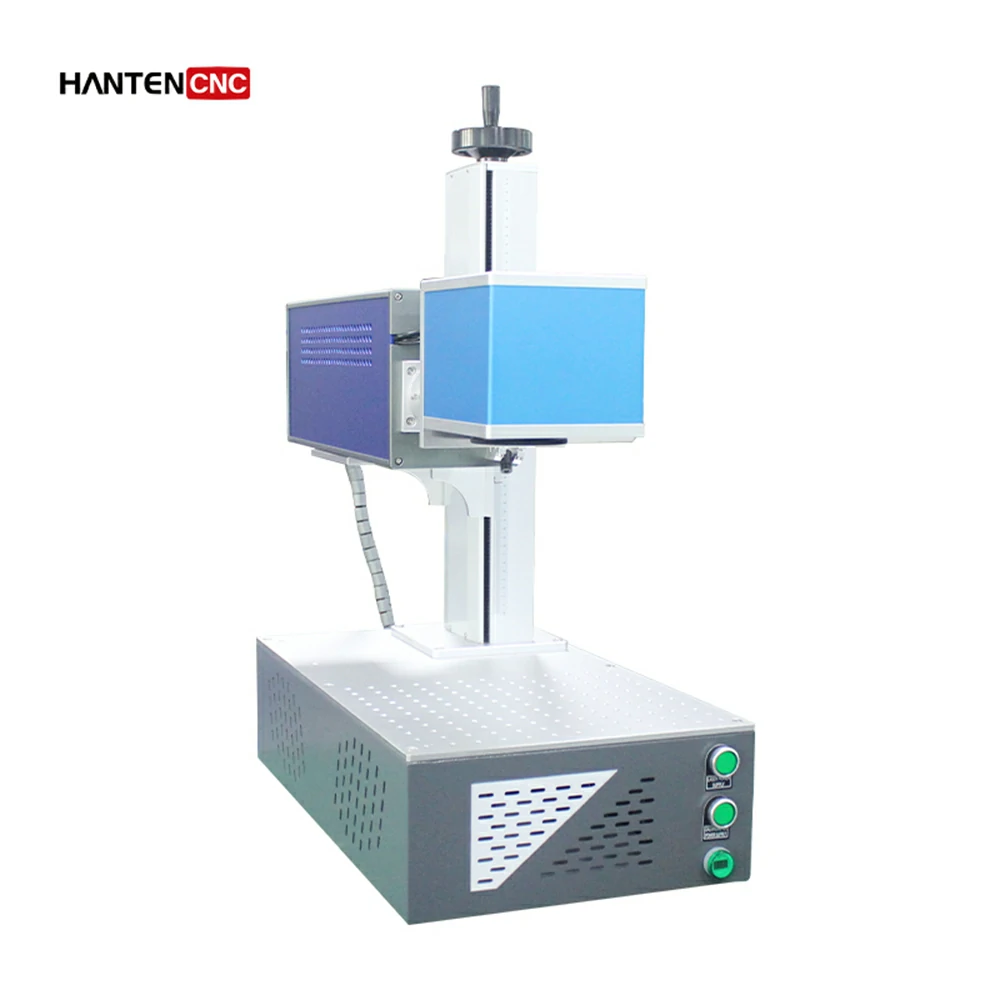

Usually the laser marking machine is mainly composed of a rotating lifting shaft, a vibrating mirror, a field mirror, a laser, a board, a column, a workbench, and a control switch.

There are different classifications of laser marking machines. Laser wavelengths are also different. The materials used also vary. Choose a suitable marking machine to mark beautiful patterns. So as to achieve the best marking effect.

Fiber laser marking machine

The wavelength of fiber laser marking machine is 1064nm. It is made by using ytterbium-doped double-clad fiber as the laser medium. This enables high-power fiber lasers to obtain beam output close to the diffraction limit. A fiber laser is used for the output of the basement membrane. The focused spot diameter is 10 microns. Then the computer controls the high-speed scanning galvanometer to deflect and change the optical path of the laser beam. Thus realizing automatic marking.

The power of common fiber laser marking machines is divided into 20W, 30W, 50W, 60W, 80W, and 100W. The application range of the machine is very wide, it can mark on all metals and some non-metals. For example, it is used for cutting and engraving metal pendants such as gold and silver. There are also metal crafts processing. Non-metallic materials are mainly used in some plastics such as ABS and PVC. As well as painted wood and leather etc.

In addition, fiber optic marking machines can also be divided into: MOPA series fiber laser marking machines according to different lasers.

Ordinary fiber laser marking machines use Q-switched lasers. The MOPA fiber laser marking machine uses a special MOPA laser. So what is the difference between MOPA lasers and ordinary Q-switched lasers?

Simply put, the pulse width and frequency of MOPA fiber lasers are independently adjustable. The pulse width affects the processing accuracy of the machine. The pulse width is narrower. The heat affected zone is smaller. The higher the accuracy of machine marking. The size of the frequency represents the processing efficiency of the machine. MOPA fiber lasers have a wider repetition rate range. Its repetition rate can reach MHz high-frequency output. High repetition rate means high processing efficiency. And MOPA can still maintain high peak power characteristics under high repetition frequency conditions.

In addition, the most obvious difference between MOPA and ordinary marking machines is that MOPA can print color patterns on metal materials. For example, marking colorful LOGO on the surface of stainless steel. MOPA laser marking machine can meet the needs of customers for color marking.

The marking dimension of the widely used fiber laser marking machine is 2D marking. 3D laser marking is a laser surface depression processing method. The requirements for 3D marking on the surface flatness of the processed object have been greatly reduced. The machinable effects are more colorful. More creative processing techniques emerged as the times require.

3D fiber laser marking machine is simple and easy to use. It is suitable for three-dimensional product engraving with large arc and high drop, fast and efficient. It can also cope with various stepped surfaces. Indiscriminate marking of various shapes can also be realized. And the 3D laser marking machine can operate stably in harsh environments.

Fiber laser marking machine

3D laser marking machine

CO2 laser marking machine

The wavelength of CO2 laser marking machine is 10640nm, which is 10.64um. It is a laser vibrating mirror marking machine using CO2 gas as the working medium.

CO2 laser marking machine is divided into radio frequency tube laser and glass tube laser. At present, RF tube CO2 laser marking machines are more widely used in the market. The advantage of RF tubes compared to glass tube lasers is that they have a lifetime of 20,000 hours. Its advantage is that the inflatable body can be returned to the factory for maintenance beyond the service life. Can achieve the effect of continuous use. The service life of the glass tube is only 6000 hours. After the service life is exceeded, the machine cannot be used. New glass tubes need to be replaced, requiring higher costs. Compared with the two, the cost performance of RF tube lasers is higher than that of glass tube lasers.

The cooling methods of RF tube CO2 laser marking machine are divided into air cooling and water cooling. Common CO2 laser marking machines have powers of 30W, 40W, and 60W. It is worth noting that although the composition of the CO2 laser marking machine and the fiber laser marking machine are the same, the models are similar. But their field mirrors, vibrating mirrors, and lasers are not universal.

CO2 laser marking machine is used in various non-metallic materials and some metal products. For example, common bamboo and wood products, paper, acrylic, leather, glass, ceramics, rubber and so on. Widely used in pharmaceutical packaging, food packaging, beverage packaging, plastics and other industries.

Metal tube CO2 laser marking machine

Portable CO2 laser marking machine

UV laser marking machine

The wavelength of the UV laser marking machine is 355nm. Since the UV laser is a cold laser, the thermal effect is very small. The wavelength of 355nm determines that the ultraviolet focused spot is extremely small. It can reduce the mechanical deformation of the material to a large extent and has little influence of processing heat. Therefore, the UV laser marking machine can perform ultra-fine marking and special material marking.

The power of UV laser marking machine is mainly divided into 3W, 5W, 10W, 15W. Cooling methods include air cooling and water cooling. It is mainly used in 3C electronic products and lamps. Food packaging and wire. There are also leather and wine glass industries, etc. Application materials include plastic and PVC, as well as glass. It can meet the needs of fine marking applications.

Portable UV Laser Marking Machine

Flying Laser Laser Marking Machine

With the development of science and technology and the transformation of production and lifestyle. Laser marking machines are more widely used in production and life. Laser marking machines are of great help to improve production efficiency and save production time. HANTENCNC has been engaged in laser equipment manufacturing for 18 years. The laser marking machines produced by us are sold all over the world. It has received wide acclaim. “Customer-oriented, we live for quality.” Not just our slogan. We will serve our customers wholeheartedly. Provide high-quality laser marking machines and high-quality services.