Laser technology is playing an increasingly important role in modern society. As an essential application of laser technology, fiber laser plays a vital role in some fields. These include communication, medical treatment, and industrial manufacturing. There are many different types of fiber lasers on the market. Choosing a product that suits their needs has become a headache for many.

This article introduces fiber laser machines’ fundamental principles, technical characteristics, and selection points. You may be a beginner curious about fiber laser technology or a professional looking for the latest application trends. This article will provide comprehensive and in-depth knowledge. Choosing a suitable fiber laser is a challenging task. But by reading through this article, you will be able to make more rational decisions.

Basic Principle of Fiber Lasers

A fiber laser machine is a device that uses fiber as an amplification medium to amplify laser signals. Its basic working principle involves the laser amplification process and the feedback mechanism of light. The following is the basic principle of fiber laser machines.

1. Stimulated Radiation Amplification

Laser amplification is achieved by stimulated radiation. In the optical fiber, specific excited state active substances are called activators. It is usually a rare earth ion. Such as ytterbium, neodymium, erbium. When external energy is injected into the activator, the electrons of the activator are excited to a high energy level. When an electron at a high energy level is excited by an incident photon, it can produce a new photon of the same frequency and phase as the incident photon by the mechanism of stimulated radiation. It amplifies the laser signal.

2. Optical Feedback Mechanism

To generate laser amplification, fiber lasers need a feedback mechanism. So, it is easy to amplify the laser signal many times in the fiber. It is usually done by placing optical mirrors or gratings at either end of the fiber. This optical cavity can propagate the laser signal back and forth in the laser amplification medium. It will result in continuous enhancement of the laser signal. One of the mirrors is translucent, allowing some laser photons to escape. It is the output of the laser.

3. Laser Production

When the photons emitted by the electrons in the activator are reflected and amplified several times through the optical cavity, they will reach a high enough energy and coherence. It creates a laser beam. This laser beam escapes through the translucent mirror and becomes the laser’s output.

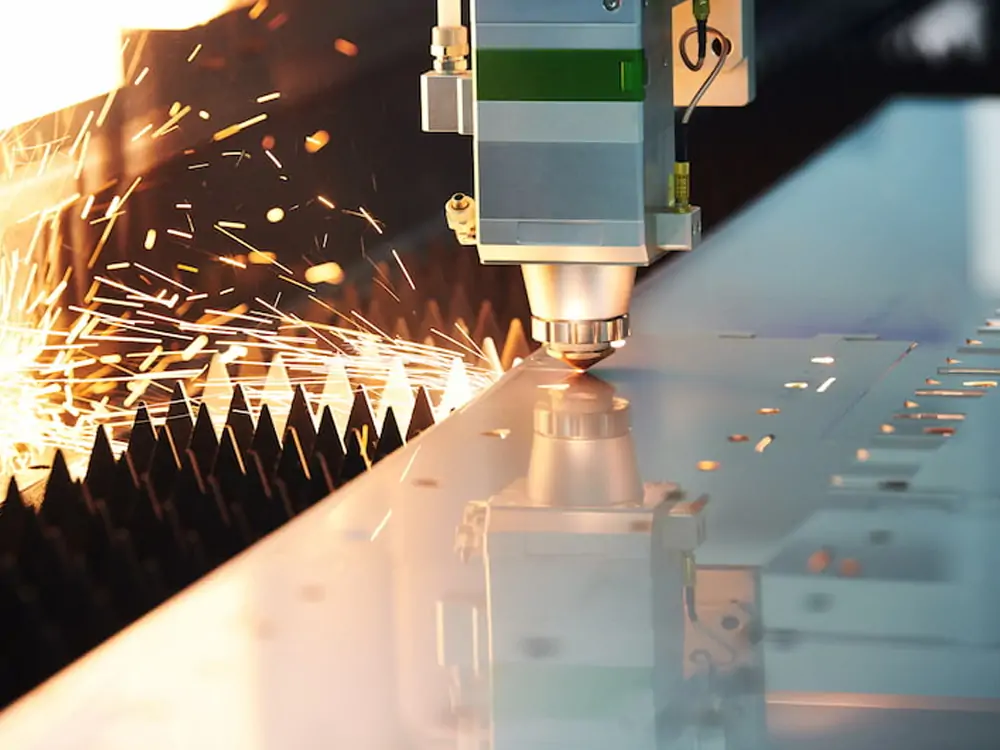

Fiber Laser Machine Features

Fiber laser machines are widely used in many applications. Its characteristics make it a popular type of laser. The following are some of the main features of fiber lasers.

1. Small Size And Compactness

Fiber lasers are designed to maximize fiber optics’ small size and flexibility. So it can make very compact devices. It makes them suitable for limited-space applications while facilitating integration into complex systems.

2. High Beam Quality

Beam propagation in optical fibers is limited by waveguide guidance. Therefore, the beam of a fiber laser machine usually has high quality and coherence. It can be focused on more minor points and is suitable for precision machining and imaging applications.

3. Stability And Reliability

The structure of the fiber laser machine is simple, and no complex optical components need to be positioned and calibrated. It makes them generally stable and reliable over long periods.

4. High Efficiency

Fiber lasers usually have high electro-optical conversion efficiency. It can convert the input electrical energy into a laser output, reducing energy waste.

5. Wavelength Diversity

Fiber lasers in different wavelength ranges can be manufactured by selecting appropriate activators and doping materials. It gives them flexibility in medical, communications, and scientific research applications.

6. Anti-interference Property

The beam in a fiber laser travels through the fiber and is less disturbed by the external environment. Such as mechanical vibration and electromagnetic interference. It helps maintain high output stability.

7. Long-distance Transmission

Because of the low transmission loss of fiber, fiber lasers can be used for long-distance laser signal transmission. Such as in communications and sensing applications.

8. Flexible Output Power Regulation

By controlling the input current or other parameters, the output power of the fiber laser can be easily adjusted. It can meet the requirements of different applications.

What Should You Consider When Buying A Fiber Laser Machine

Choosing the suitable fiber laser involves considering several factors. These ensure that you select the right machine for your application. Here are some guiding steps to help you choose a suitable fiber laser.

Define Application Requirements

- Identify your application area. Such as material processing, medical treatment, communications, scientific research, etc.

- Determine the primary use of the laser, such as cutting, welding, marking, etc.

- Specify the desired laser output wavelength, power range, and beam quality.

Consider Performance Parameters

- Output power: Determine the required output power range according to the application’s needs.

- Wavelength range: Select the wavelength range suitable for the application. It is usually based on material characteristics or transmission requirements.

- Beam quality: Select the laser with the correct beam quality according to the accuracy requirements.

Reliability And Stability

- Consider the reliability and long-term stability of the laser. Especially for applications that need continuous operation.

- Check the reliability data and warranty policies provided by the manufacturer. Learn about the life expectancy and stability of lasers.

Cost And Budget

- Filter laser options that meet the expected performance based on the budget range.

- Consider not only buy costs but also operating costs, maintenance costs, and additional equipment costs.

Technical Support And After-sales Service

- Choose a manufacturer or supplier with a good reputation and reliable technical support.

- Understand after-sales service policies, including repairs, upgrades, and replacements.

User Reviews And Experience Sharing

- Search online for relevant user reviews and experience sharing to learn about other users’ experiences.

- Consult channels such as professional forums, social media, and trade shows.

Considering the above factors, choose the fiber laser that suits your needs. The final choice should result from balancing performance, reliability, cost, and application requirements. If you need more specific advice, it is recommended that you consult the laser manufacturer.

Conclusion

When choosing a suitable fiber laser, it is essential to consider some factors. Such as application requirements, performance parameters, cost, and reliability. The right choice can provide a solid foundation for the project’s successful implementation and efficient operation.

Each fiber laser has advantages and limitations. This article will help you find the best solution. By weighing all these factors, you can choose the best for your performance, reliability, and cost-effectiveness. It can bring success and progress to your project.