HANTENCNC’s handheld 3-in-1 laser welding machines combine laser welding, laser cleaning, and laser cutting functions into one machine. They can adapt to various work scenarios, saving cost and space while allowing for quick switching between different functions, significantly improving work efficiency.

Laser Welding Function:

Our 3-in-1 laser welding machines use a high-power laser beam to achieve firm, smooth and beautiful welding results in a fast welding speed.

They are suitable for welding a variety of metal materials, including stainless steel, carbon steel, aluminum alloy, etc., greatly improving production efficiency.

Laser Cutting Function:

The 3-in-1 laser welding machines can also be used for the precise cutting of thin metal materials.

This laser cutting function is mainly used for cutting thin metal sheets within 2-3mm thickness.

Laser Cleaning Function:

This cleaning function is particularly suitable for pre-welding surface cleaning, helping to keep the workpiece clean before welding.

Also, the cleaning function enables the machine to efficiently and precisely remove rust, oil, paint, and coating from materials without causing any damage, ensuring a solid, beautiful, satisfactory weld.

3 in 1 Laser Welding Machine Display

3 in 1 Laser Welding Machine Components

3 in 1 Laser Welding Machine: Welding, Cleaning & Cutting

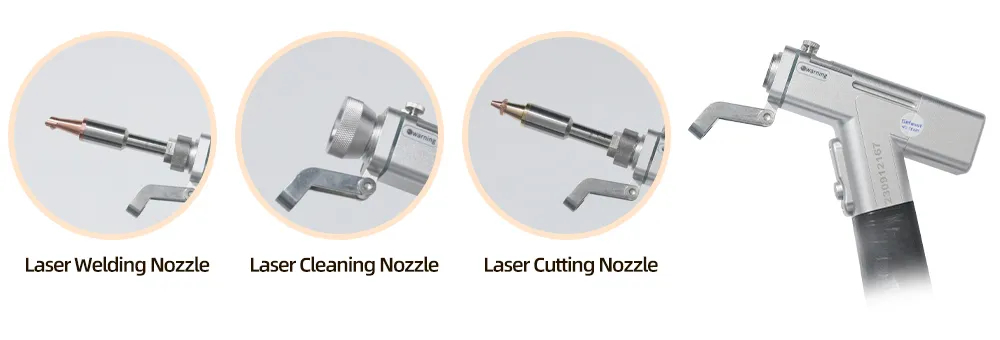

The 3-in-1 laser welding machines are designed to perform three different functions such as welding, cleaning, and cutting. These functions require different nozzles to perform.

They feature 3 different nozzles to fulfill different functions.

3 in 1 Laser Welding Machine Dimensions

3 in 1 Laser Welding Machine Features

3-in-1 Laser Welding Gun Advantages

The 3-in-1 laser welding gun supports handheld continuous welding, spot welding, cutting and cleaning functions. The control system has 19 built-in languages, and there are 6 additional languages available.

The welding gun body adopts an integrated design to ensure high welding strength, no deformation, high penetration, and better stability of welding effect.

The focusing mirror and protective mirror are designed as drawers, and the collimating mirror is integrated with the QBH. The installation or replacement of the focusing mirror and protective mirror is like a drawer, which can be easily pulled out or pushed in, making replacement more convenient.

The welding gun body is equipped with a fault indicator light, which realizes real-time monitoring of the built-in temperature, and an independently developed safety detection system: when the air pressure, the temperature of the protective mirror is too high, and the laser fails, it will flash a warning.

Our 3 in 1 laser welding machines are equipped with Raycus lasers, which are well-known for their high stability and long service life, ensuring the reliable operation of the equipment in long-term work and reducing maintenance and replacement costs.

Handheld Design

Our 3-in-1 laser welding machines adopt a handheld design, their handheld design makes them flexible, portable, and precisely controlled, making them suitable for a variety of applications, including welding complex shapes and on-site welding tasks.

Handheld Laser Welder Parameters

| Model | HTW1500 | HTW2000 | HTW3000 |

|---|---|---|---|

| Laser source | Raycus | Raycus | Raycus |

| Laser power | 1500W | 2000W | 3000W |

| Power Adjustment Range | 0-1500W | 0-2000W | 0-3000W |

| Operational Voltage | 220V Single Phase | 220V Single Phase | 380V Three Phase |

| Laser wavelength | 1080nm | 1080nm | 1080nm |

| Fiber length | 10M/12M/15M/Maximum20M | 10M/12M/15M/Maximum20M | 10M/12M/15M/Maximum20M |

| Operating Mode | Continuous Welding | Continuous Welding | Continuous Welding |

| Maximum Oscillation Speed | 20000mm/s | 20000mm/s | 20000mm/s |

| Operating System | Handheld Welding System | Handheld Welding System | Handheld Welding System |

| Cooling System | Water-cooled | Water-cooled | Water-cooled |

| Working environment temperature range | 10-40℃ | 10-40℃ | 10-40℃ |

| Humidity range Operating environment | < 70% non-condensing | < 70% non-condensing | < 70% non-condensing |

| Welding gap requirements | ≤0.5mm | ≤0.5mm | ≤0.5mm |

| Laser welding machine dimensions | 860*410*700mm | 860*410*700mm | 1140*530*1040mm |

| Single wire feeder dimensions | 570*250*400mm | 570*250*400mm | 570*250*400mm |

| Welder Machine Weight | 109.2kg | 109.2kg | 109.2kg |

| Laser Welding Gun Weight | 0.75kg | 0.75kg | 0.75kg |

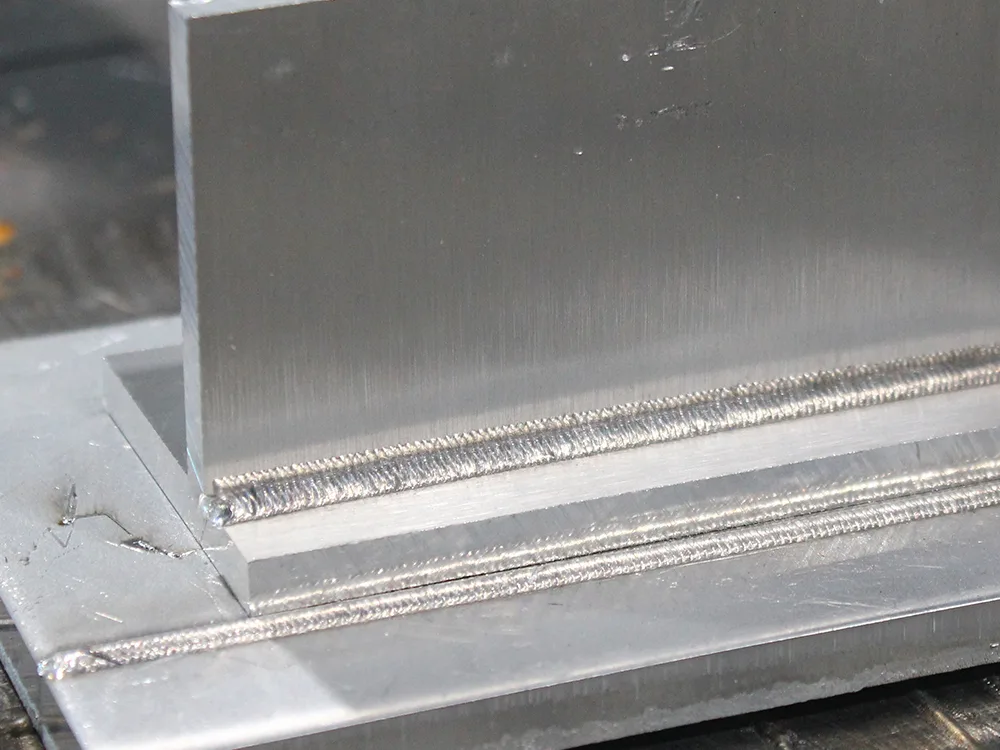

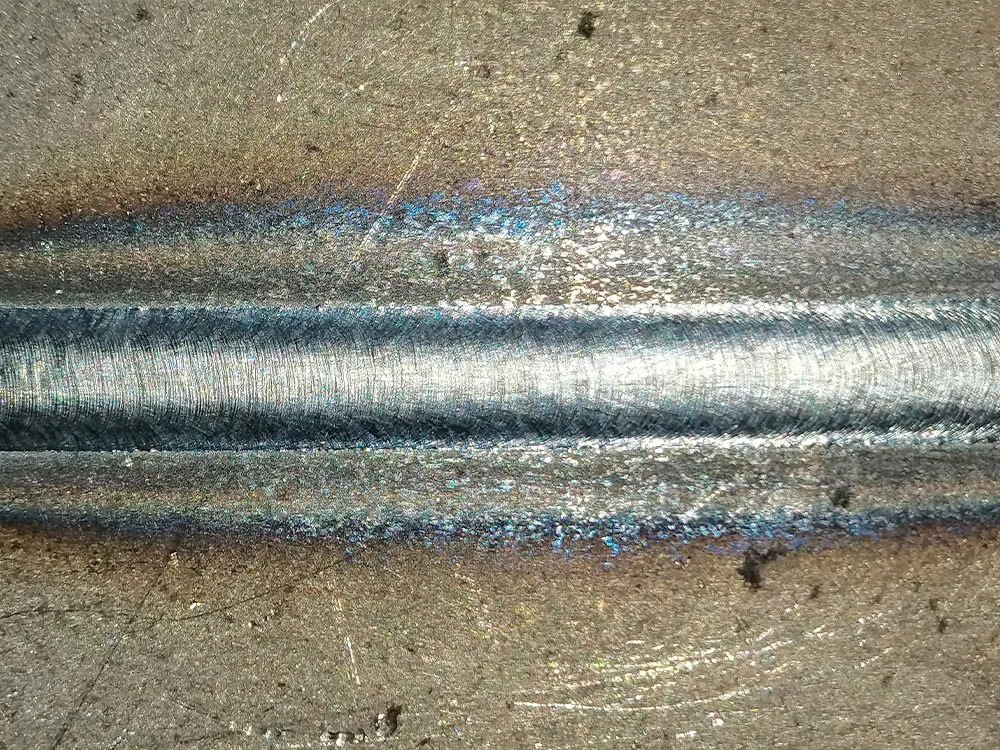

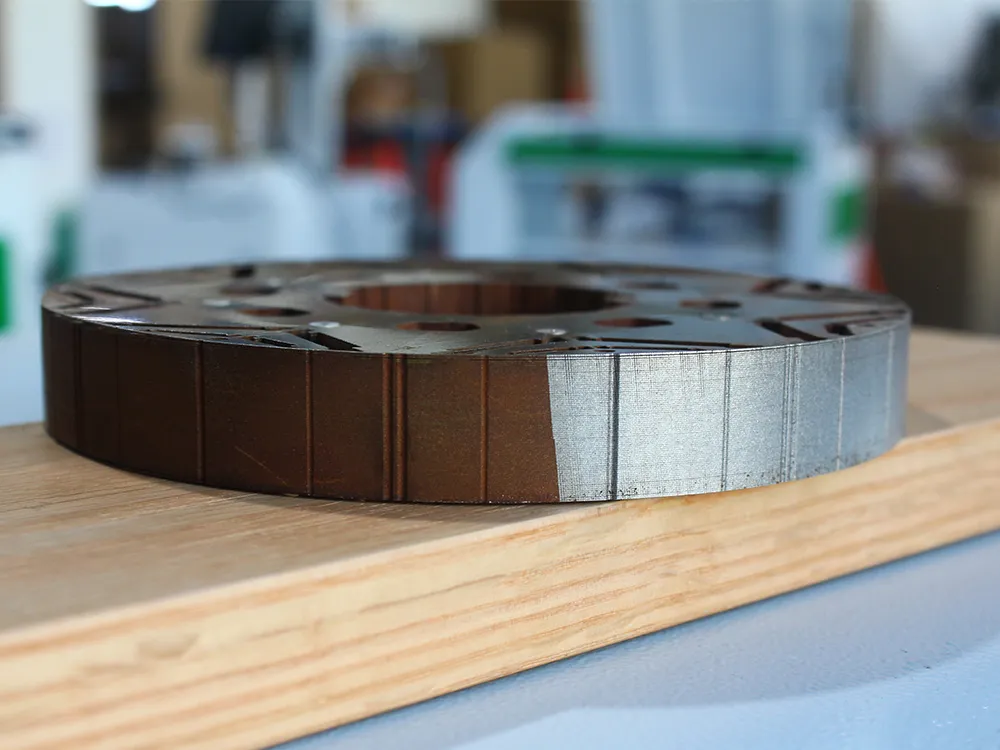

Laser Welding Samples

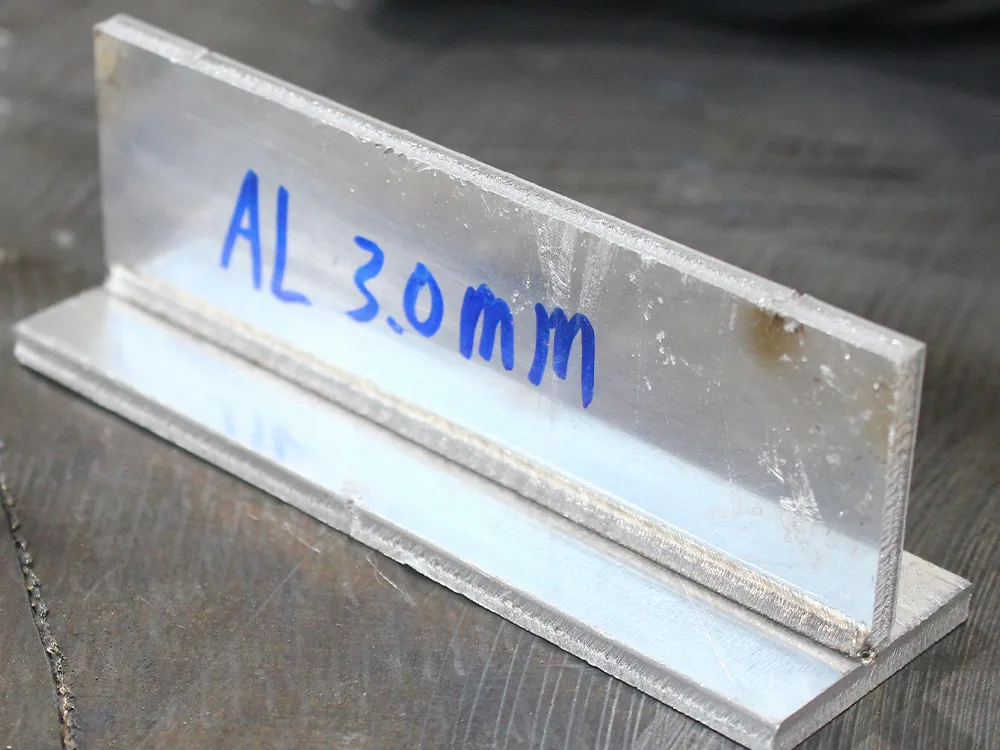

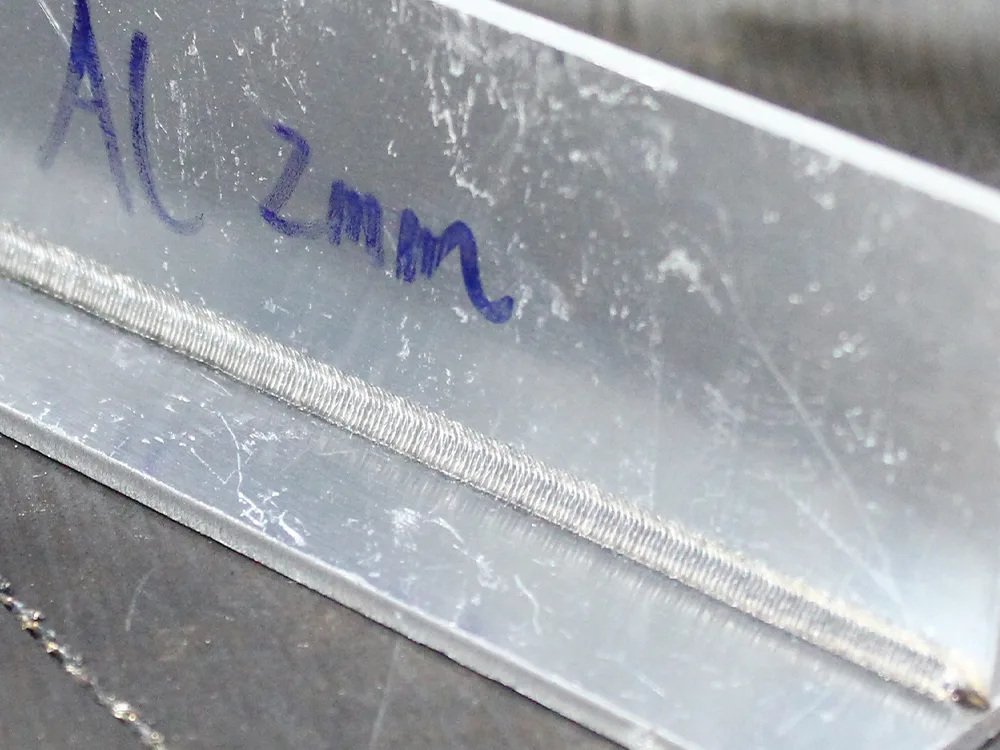

The 1500W to 3000W 3-in-1 laser welding machine has powerful welding functions and is suitable for efficient welding of a variety of metal materials, including stainless steel, carbon steel, aluminum alloy, etc. It uses a high-power laser beam to achieve deep melting welding, with a firm, smooth and beautiful weld, fast welding speed, and greatly improved production efficiency.

It supports multiple welding modes and can weld workpieces of different shapes and thicknesses below 6mm. It is particularly suitable for sheet metal processing, home appliance manufacturing, automotive industry and other fields.

The handheld design makes it easy to use and flexible, so it can handle complex or hard-to-reach welding areas. Laser welding gives strong heat and precise control, so the metal is less affected by heat. This means less deformation, better welding quality, and less need for grinding afterward.

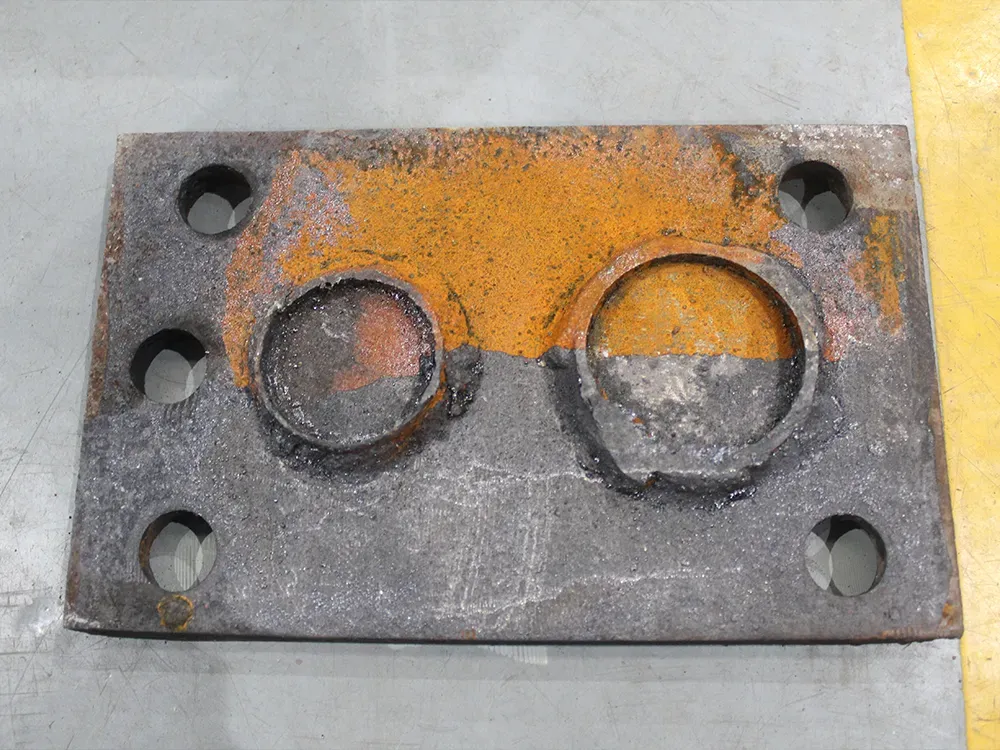

Laser Cleaning Samples

Before welding, the 3-in-1 laser welding machine can be used to clean rust, oxide layers, and oil stains from the metal surface.

These functions help ensure better welding quality.

The maximum cleaning width depends on the focal length of the focusing lens.

The maximum cleaning widths of focusing lens with focal lengths of 150mm, 400mm, and 800mm are 30mm, 60mm, and 120mm respectively.

You can choose different lenses based on your cleaning needs—shorter focal lengths for precise work and longer ones for wider coverage.

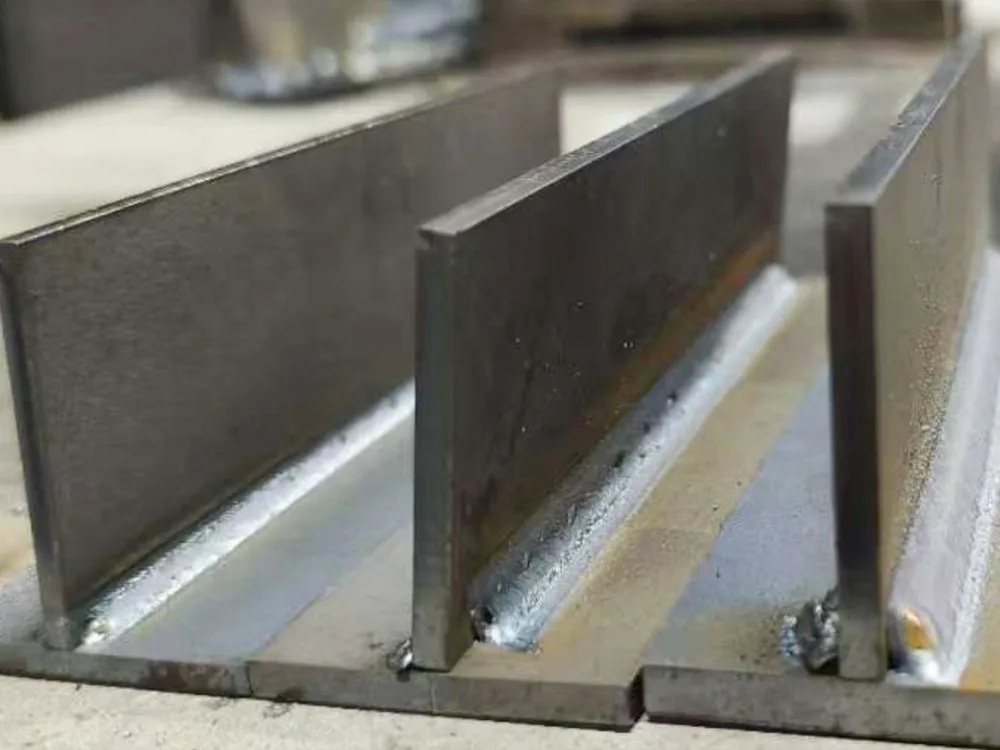

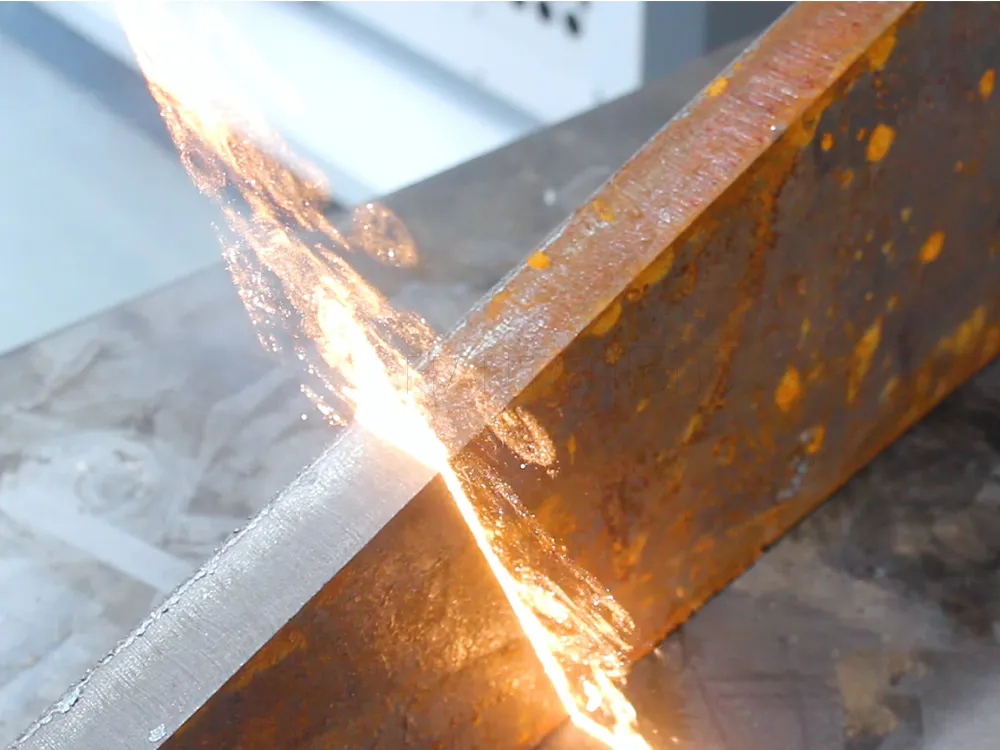

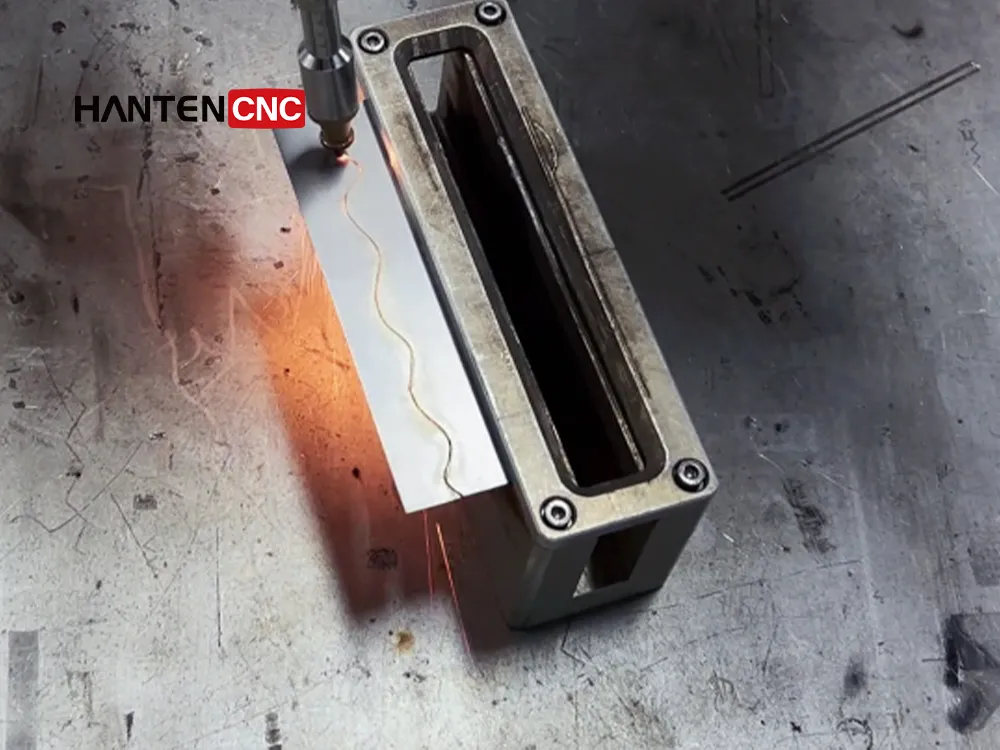

Laser Cutting Samples

The cutting function of the 3-in-1 laser welding machine is designed for cutting metal sheets within 2-3 mm, and can efficiently complete the precise cutting of thin metals.

Since the 3-in-1 laser welding machine is designed for both welding and cleaning, we’ve adjusted the cutting power to better suit thin sheet metal rather than thick or heavy materials.

If you need to cut thicker metal materials, we recommend that you use a high-power laser cutting machine to ensure a stronger cutting effect.

Customer Visits

Qualification Certification

HANTENCNC owns trademark registration certificates, utility patent certificates, software copyright certificates, etc.

HANTENCNC’s laser welding machines are CE and FDA-certified, ensuring high quality and safety.

You can trust HANTENCNC and HANTENCNC’s fiber laser welding machines backed by these certificates.

HANTENCNC Partnerships

HANTENCNC Service

HANTENCNC provides free sample testing, a 2-year warranty for the laser source, a 1-year warranty for the whole machine, and ODM services.