Pulse laser cleaning allows precise control of pulse energy, minimizing thermal impact on the substrate. This reduces the risk of damage to delicate surfaces and ensures high-precision cleaning, especially on complex materials.

By releasing concentrated energy in short pulses, our 300W pulse laser stripper with a maximum pulse energy of 15mJ is ideal for quickly removing thick oxide layers, thick paint, rust, oil stains, graffiti and other industrial pollutants without causing any damage to the material’s surface.

Our 300W pulse laser stripper has advantages of minimize thermal impact on the substrate, high cleaning efficiency, environmentally friendly, precise control, strong adaptability, low maintenance costs, and long service life and enhanced safety.

Our pulse laser stripper tool can remove rust, paint, coatings, oxides, dirt, and other contaminants from metal, floor,wall, stone, ceramics surfaces. HANTENCNC’s laser derusting machines are widely used in automotive manufacturing, aerospace, ship maintenance, metal processing, construction, and cultural heritage preservation industries.

300W Laser Derusting Machine Demonstration Video

300W Pulse Laser Derusting Machine Display

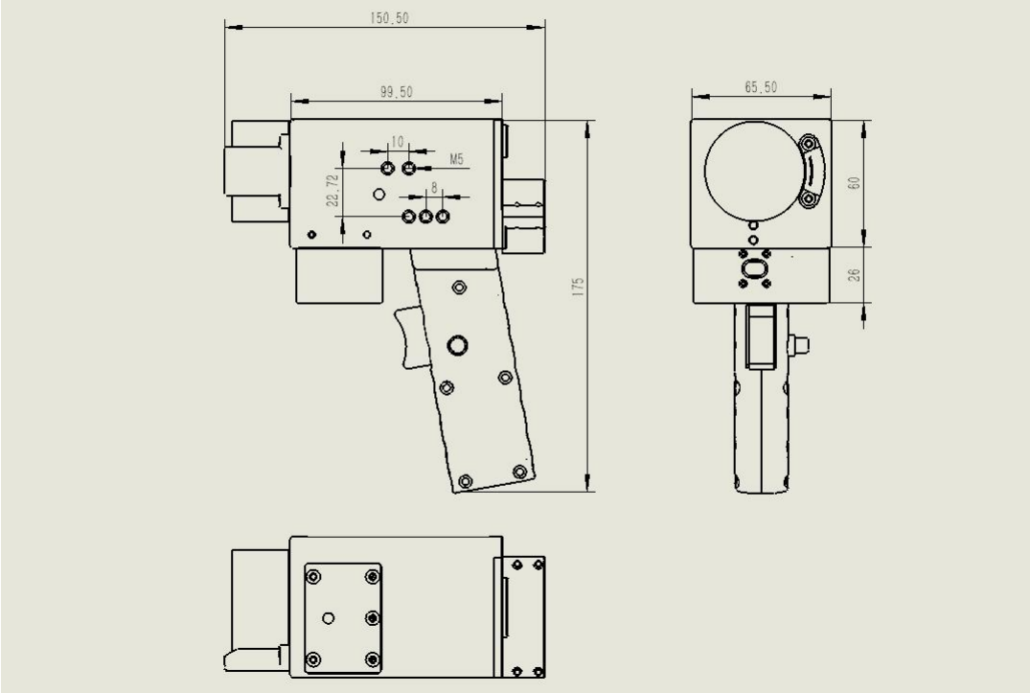

Multimode Pulse Laser Derusting Machine Dimensions

Pulse Laser Cleaning Gun Composition and Dimensions

Pulse Laser Cleaning Machine Introduction

Non-contact pulse industries laser cleaning

The 300w pulse laser cleaning machine is a newly designed product. This product uses non-contact cleaning, which can effectively degrease, rust, stain and paint the base material. It can be applied to metal, stainless steel and other materials.

Pulse industries laser stripper machine details

This laser derusting machine is a self-developed pulse laser cleaning machine. The chassis is green and white, making it look more high-end. This product has the three primary characteristics of being lightweight, pushable, and safe, making it more convenient for laser cleaning operations.

Portable Laser Cleaning Gun Details

Our 300W laser cleaning gun has fast scanning speed and high accuracy, meeting various cleaning needs.

Equipped with front-end control screen and focal length display screen, capable of measuring focal length and achieving high-precision cleaning.

Portable Design:

The paint removal laser gun is compact and portable, with a weight of less than 1.25kg.

Dust Sealing Design:

Prevents dust from entering the cleaning gun.

Anti Interference Design:

Ensure stable operation of the laser cleaning gun in various complex environments and improve equipment reliability.

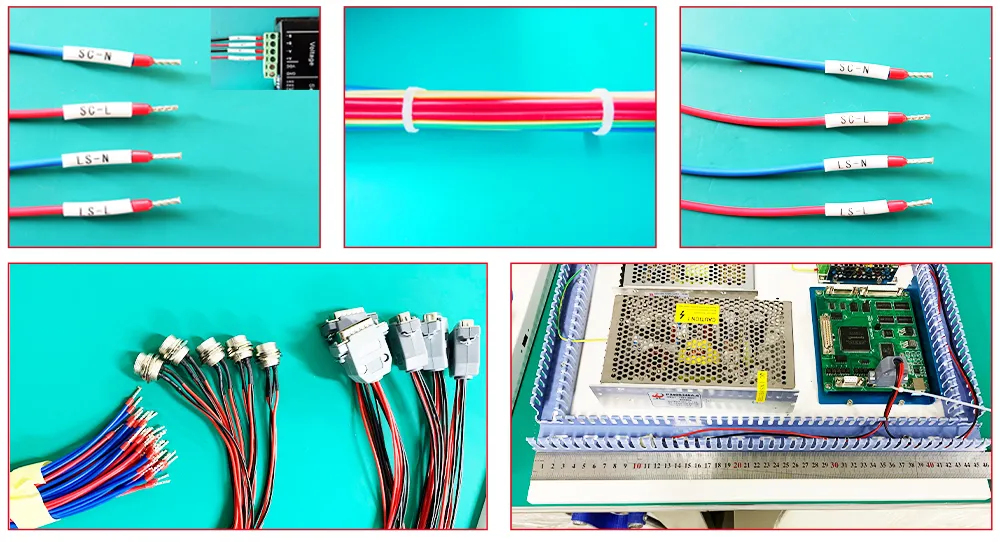

Clasp-Style Cable Protection Sleeve — Flame Retardant

We use clasp-style cable protection sleeves to protect the fiber optics and cables during operation. They are made of flame-retardant PVC and POM materials, and they have passed SGS certification.

These cable protection sleeves can provide exceptional cable protection in high-temperature and complex working environments.

Pulse Laser Derusting Machine Details

-

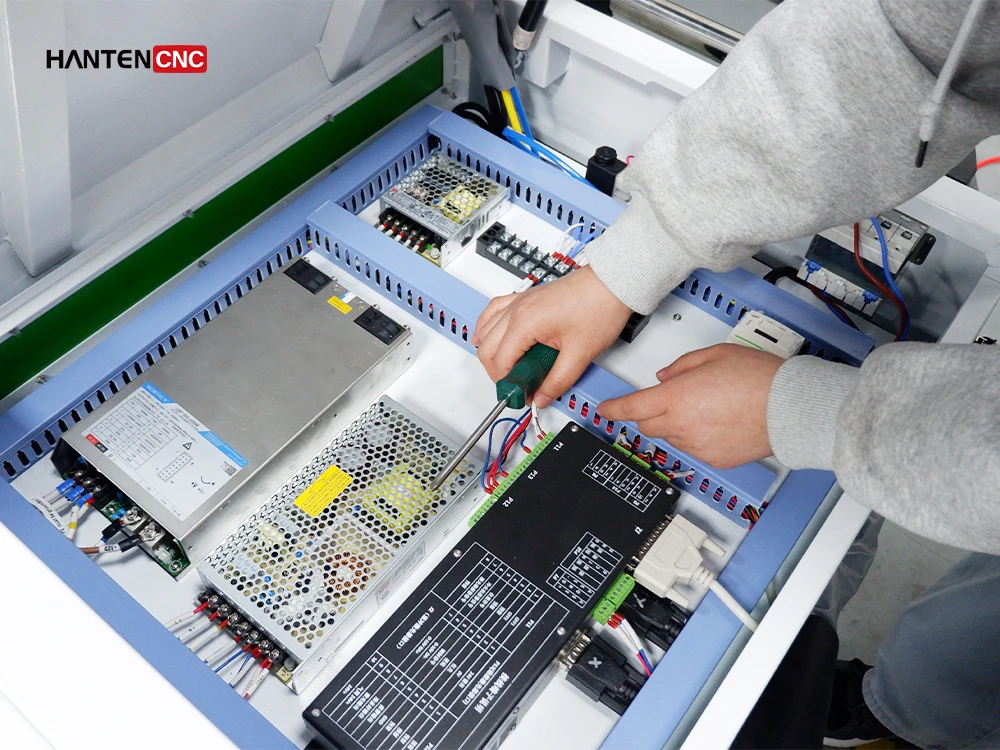

Circuit Line

The machine is neat and uniform, with a concise and clear circuit line panel.

-

Water Chiller

The constant temperature of the water cooling system controls the heat generated by the laser cleaning system. It can better protect laser equipment to function correctly.

-

Display And Switches

The machine is capable of multifunctional display. It is equipped with a one-button start switch for easy use. The machine’s cleaning system is stable and efficient.

Laser Derusting Machine Application Fields

The laser derusting machine is a high-tech product. It has the advantages of high efficiency, environmental protection, no pollution, and low energy consumption. It is widely used in manufacturing, maintenance, moulding, the restoration of cultural relics, the stone industry, and other fields.

Manufacturing

Laser cleaner machine is mainly used for cleaning metal surfaces. Parts of cars, planes and railways are cleaned during manufacturing. Laser cleaning can effectively remove the rust, oxide layer, oil stains, and other elements that form on the metal surface. Traditional cleaning methods can cause damage to the substrate surface. Laser cleaning machines can quickly, efficiently and non-destructively clean metal surfaces.

Maintenance Industry

Cleaning laser machines are mainly used for equipment, tools, parts, etc. For example, mechanical equipment, aviation equipment, electronic equipment, etc. During equipment maintenance, corrosion, rust, and other contaminants often appear on the surface. Using conventional cleaning may wear down the surface of the equipment. The substrate is not damaged during laser cleaning. It is safety, environmental protection, and high efficiency.

Mold Industry

Contaminants such as oil stains and welding slag are often attached to the surface of the mould. These pollutants will affect the life of the mould and the use effect. Laser derusting machines can effectively avoid mould surface wear and reduce mould accuracy and other problems.

Heritage Restoration

Laser cleaners can help restore ancient artefacts with paint, stains, or other contaminants, such as stone carvings, steles, pottery, and metalware. Traditional cleaning methods may cause secondary damage to cultural relics. The laser cleaning machine can accurately control the energy and position of cleaning to avoid damage to cultural relics. In addition, the laser cleaning machine can also clean some difficult-to-clean parts, such as small sculptures or complex three-dimensional structures.

Stone Industry

Laser cleaning machines can clean building materials such as marble, granite, and concrete. Laser cleaning machines can clean large areas of stone more quickly. It can also avoid using chemical cleaning agents to pollute the environment. In addition, the laser cleaning machine can accurately control the depth and intensity of cleaning. It can prevent damage to the stone surface.

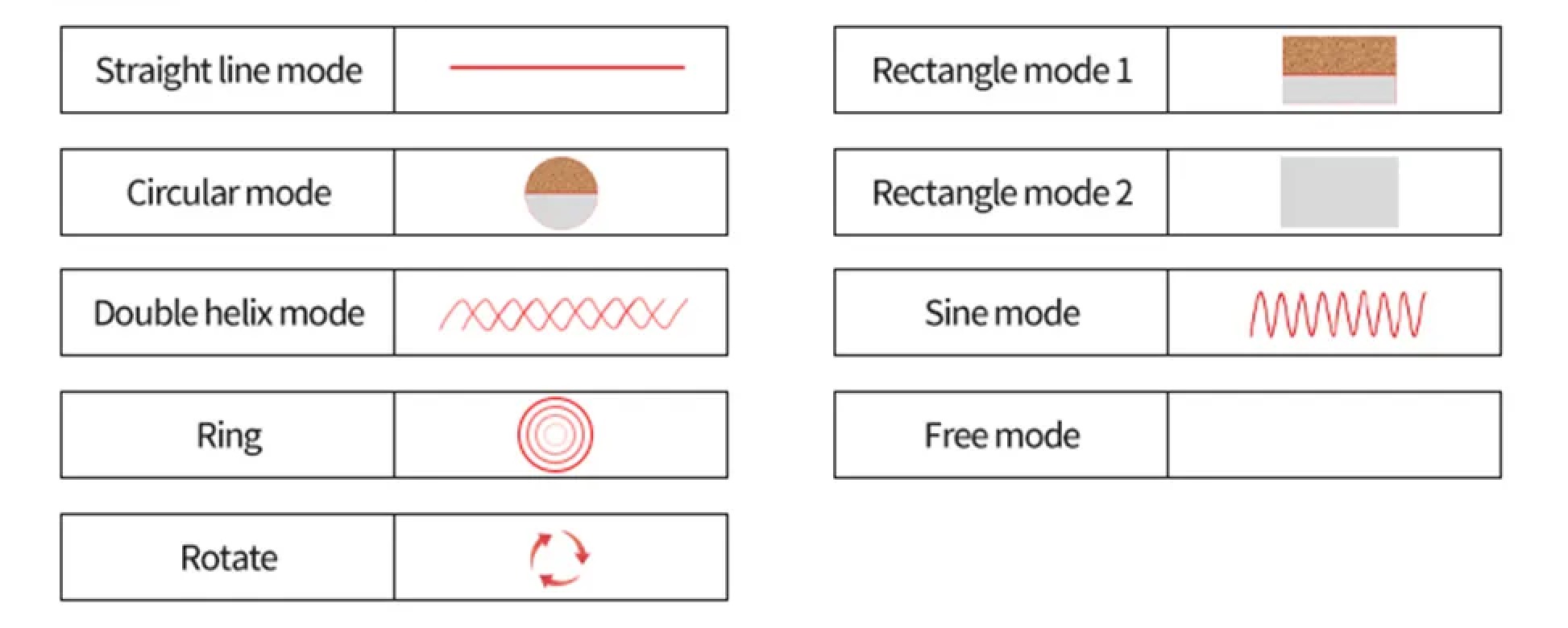

9 Cleaning Modes for Laser Derusting Machine

The operation interface of the HANTENCNC laser derusting machine offers 9 cleaning modes:

- Straight Line Mode

- Rectangular Mode 1

- Rectangular Mode 2

- Circular Mode

- Sinusoidal Mode

- Spiral Mode

- Free Mode

- Ring Mode

- Rotation Mode

You can switch between these derusting modes by clicking on the “Scanning Mode” option on the interface.

16 Supported Languages for Laser Derusting Machine

HANTENCNC’s 300W laser derusting machine currently supports Chinese, Traditional Chinese, English, Russian, Japanese, Spanish, German, Korean, French, Polish and 16 other languages.

You can easily switch between these language options directly on the laser stripper’s interface. If you require any other languages, we also provide customized language services.

Well-organized Internal Wiring

Organized internal wiring makes the positions of cables and connectors clear and easy for maintenance personnel to quickly locate and solve problems, reducing repair time and costs.

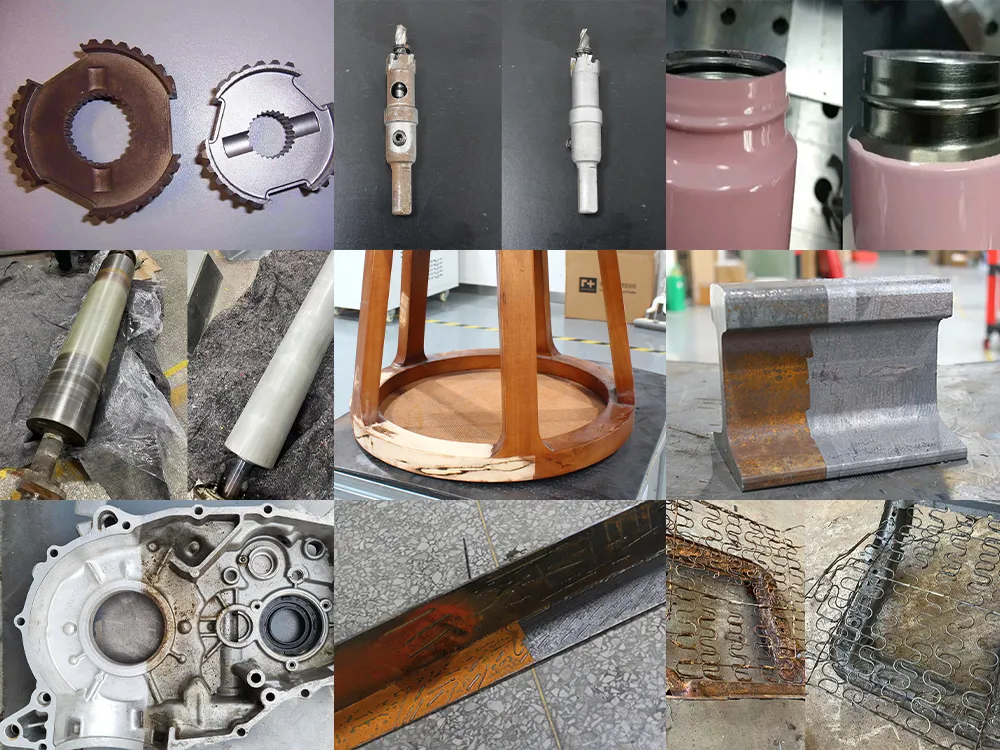

Pulse Laser Derusting Machine Cleaning Effects: Before vs. After

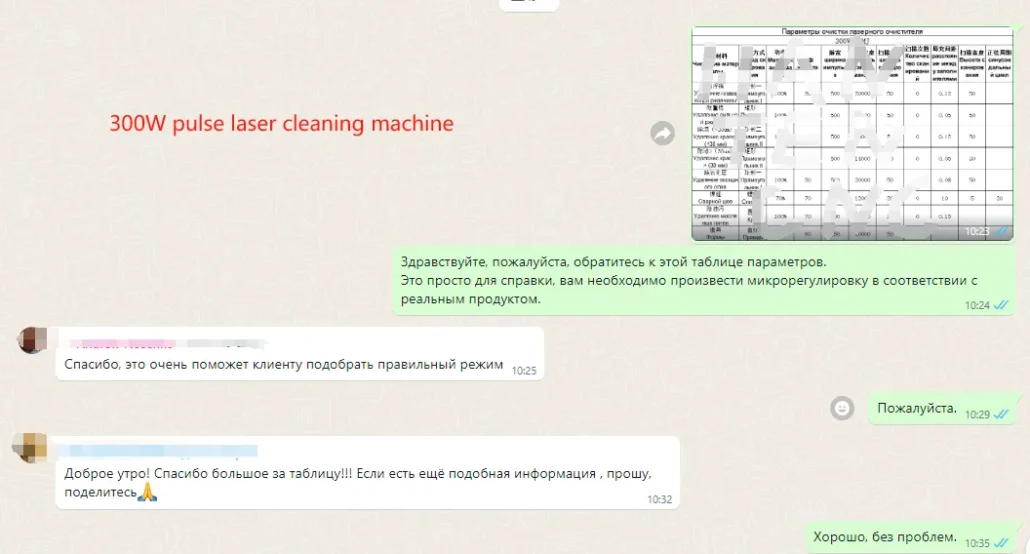

Laser Derusting Machine Parameters

| Laser power | HTCM300 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Voltage | 110/220V 50/60 HZ | |||||||||||

| Laser Working Mode | Pulse | |||||||||||

| Average Laser Power | ≥300W | |||||||||||

| Power Instability | <5% | |||||||||||

| Maximum Pulse Energy | 15mJ | |||||||||||

| Pulse Width | 2-500ns | |||||||||||

| Cooling Method | Water Cooling | |||||||||||

| Power Regulation Range(%) | 0-100( Gradient Adjustable) | |||||||||||

| Repeat Frequency(kHz) | 1-4000(Gradient Adjustable) | |||||||||||

| Fiber Cable Length | 5m | |||||||||||

| Cleaning Head Weight (including isolator) | <1.5Kg | |||||||||||

| Working Environment Humidity | ≤80% | |||||||||||

| Working Environment Temperature | 10℃~40℃ | |||||||||||

Laser Cleaning Head Parameters |

||||||||||||

| Cleaning Head Weight | <1.25Kg | |||||||||||

| Scanning Width | 0mm-145mm Optional | |||||||||||

| Scanning Frequency | Not Less Than 300Hz | |||||||||||

| Maximum Scan Line Speed | About 30m/s | |||||||||||

| Maximum Scanning Speed | 20000mm/s | |||||||||||

| Field Lens Focal Length | 210mm(160mm/254mm/330/420mm Optional) | |||||||||||

| Light Transmittance | ≥98% | |||||||||||

| Laser Power Adjustment | 10%-100% | |||||||||||

| Incident Spot Diameter | ≤10mm | |||||||||||

| Cable Length | Standard configuration of 10m | |||||||||||

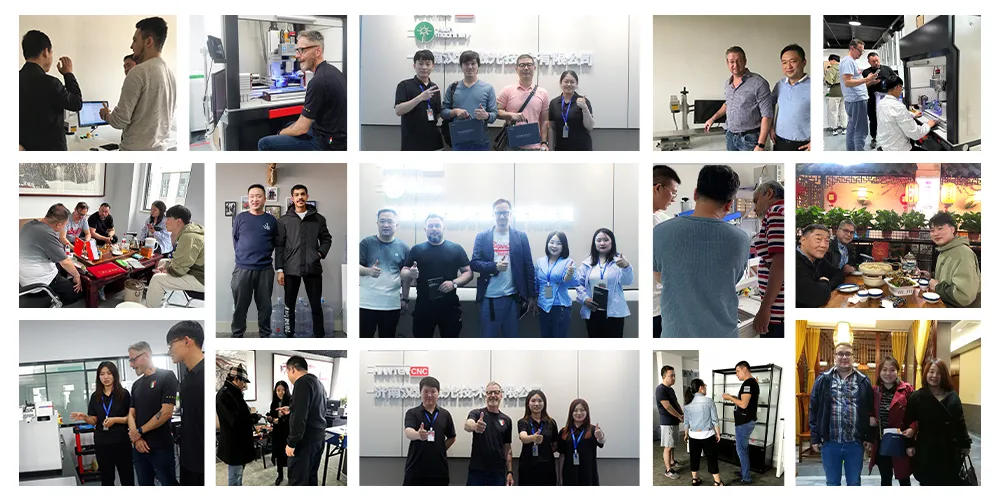

Customer Visits

Customer Reviews