The articulated arm laser welding machine solves one of the biggest challenges in mold repair: large molds no longer need to be disassembled. Instead, the machine can be moved directly next to the mold, and the extendable arm accurately positions the laser head to perform on-site repair.

Since disassembling large molds can take anywhere from several hours to several days, this solution significantly reduces downtime, saving time and labor.

In addition to mold repair, the machine is also suitable for efficient welding of various metal and alloy parts, including hardware products, precision mechanical components, and automotive parts.

Thanks to the high flexibility of the articulated arm and its intelligent configuration, this machine delivers higher welding efficiency, greater process adaptability, and improved weld quality compared to traditional methods—making it ideal for complex industrial welding tasks.

Laser Welding Machine for Large Mold Repair Features

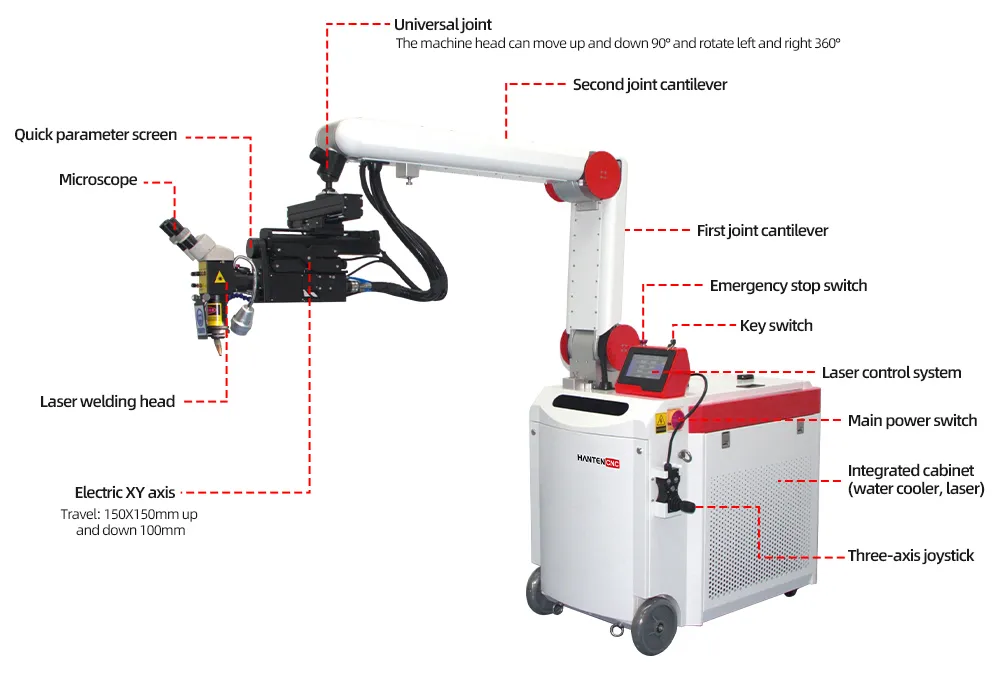

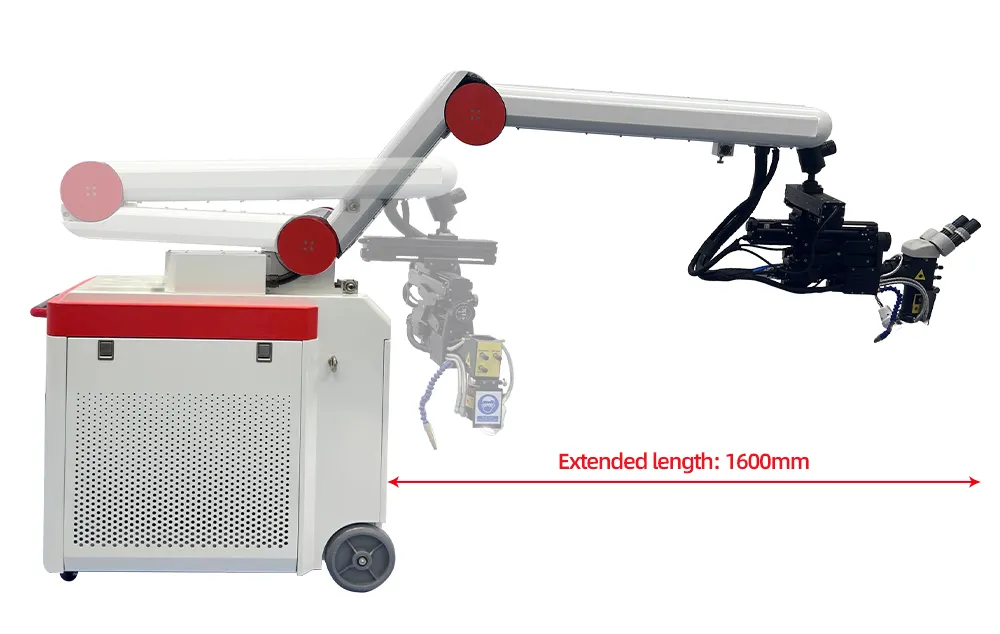

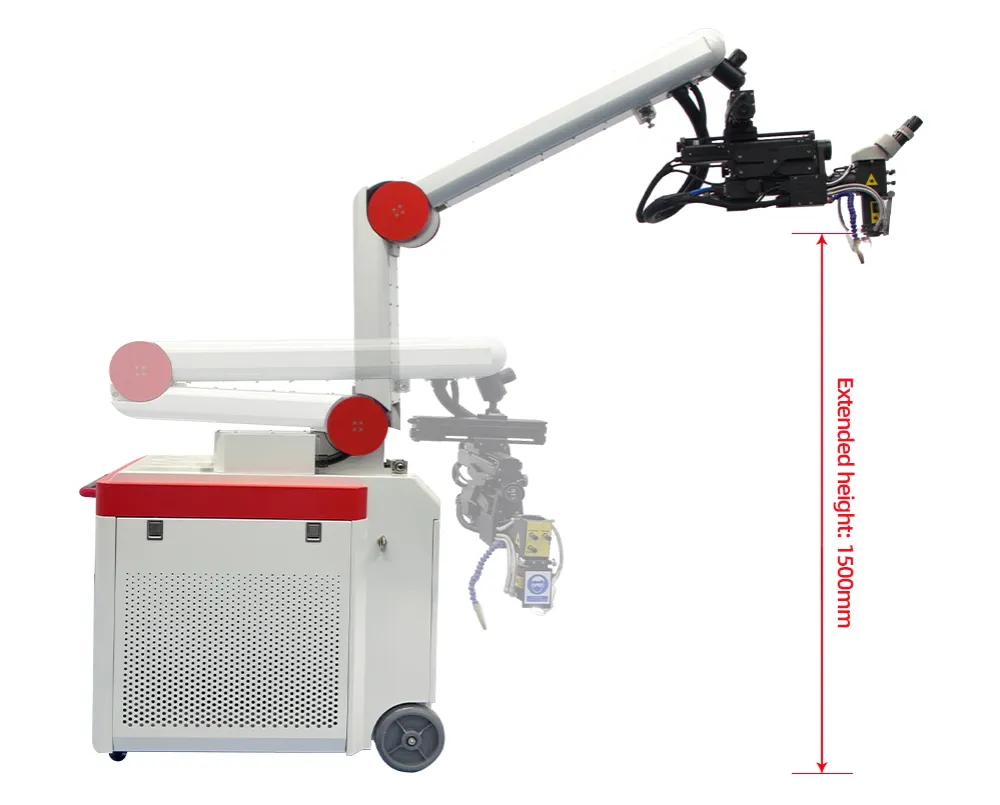

1. Full 360° Rotating Cantilever Arm

No Blind Spots: 360° rotation + extended reach eliminates dead zones.

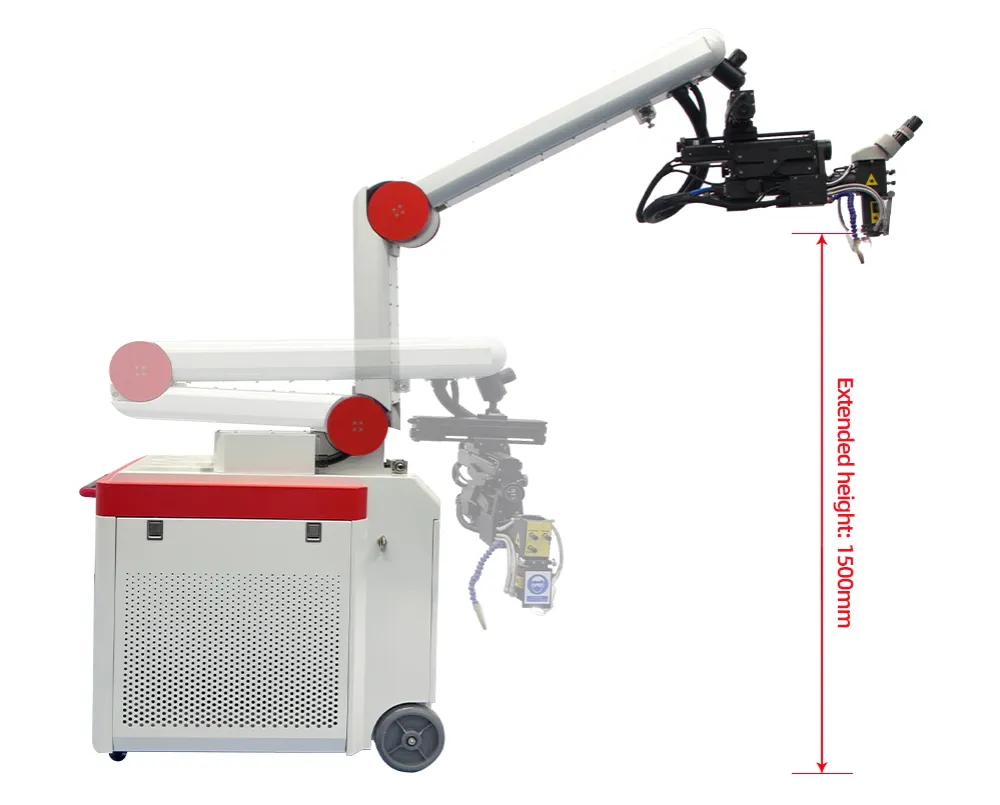

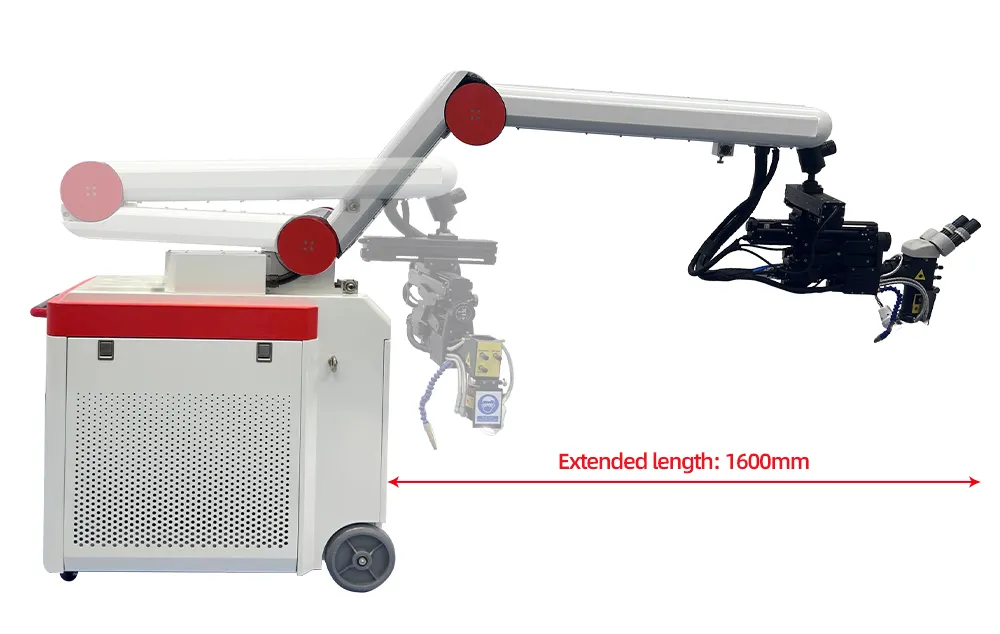

Handles Both Large and Small Workpieces: From small precision welds (200mm area) to large-part applications (1600mm reach+1500mm lift).

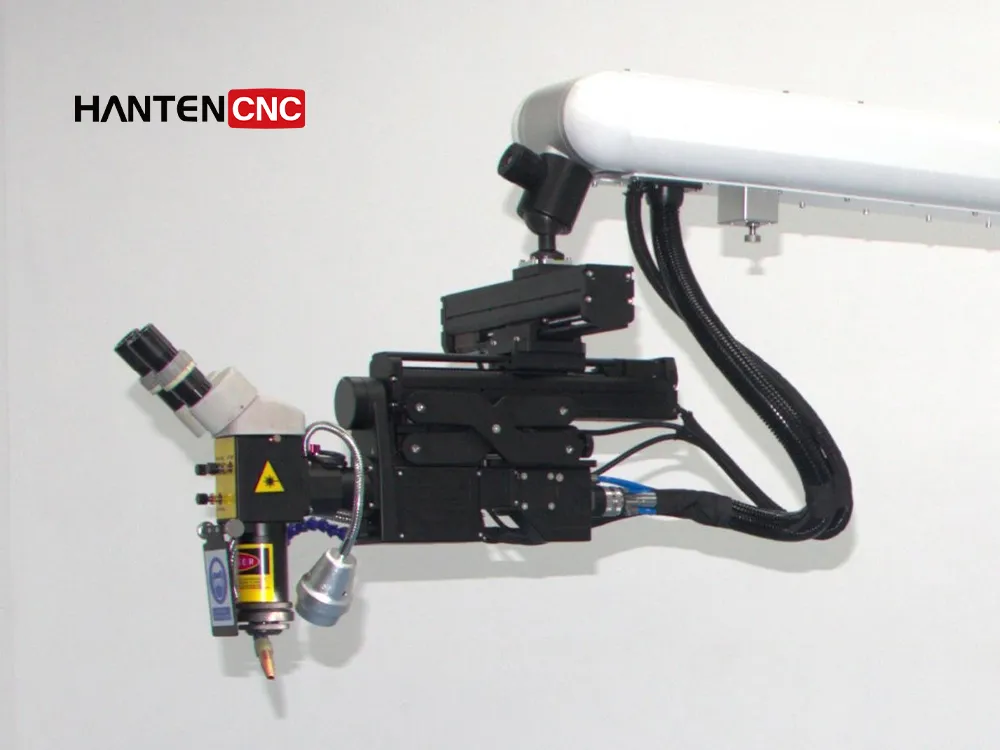

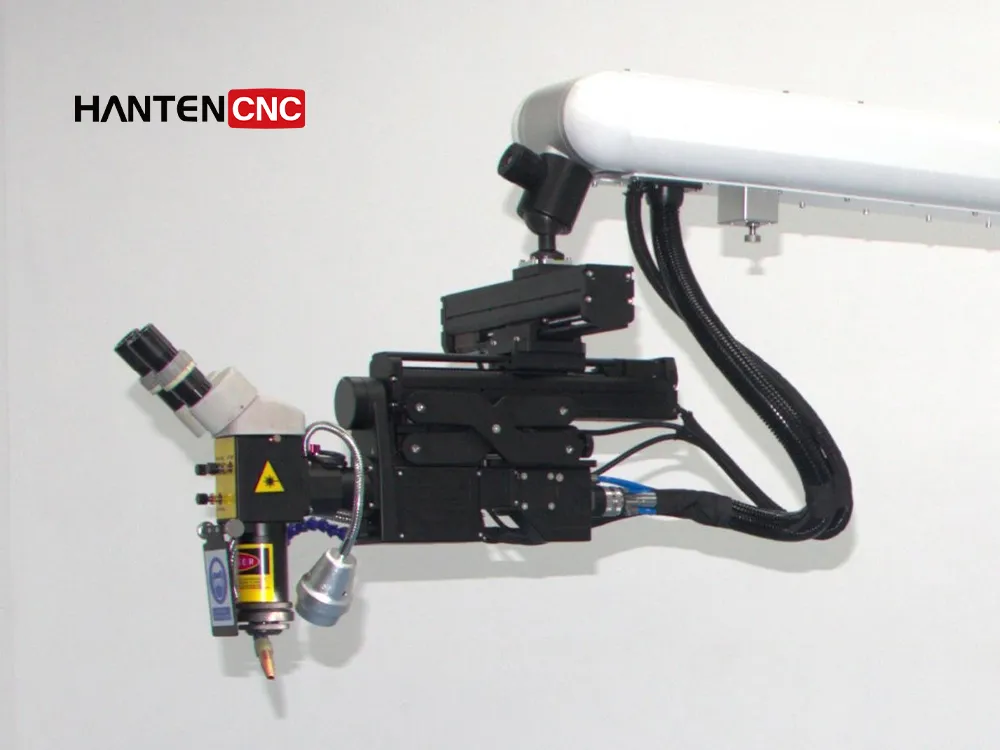

Precision Vision System:Built-in microscope + optional camera for pinpoint accuracy

2. High Efficiency and Stability – Ideal for Long-Term Operation

The articulated arm laser welding machine offers two laser source options: 150W/300W QCW pulsed laser and 1500W continuous laser.

Both equipped with a built-in industrial chiller, with the help of the built-in chiller, it ensures stable laser output, significantly improving welding efficiency and overall productivity.

150W/300W QCW Pulsed Laser:

The pulsed output allows precise control of heat input, minimizing the risk of mold deformation. It is ideal for accurate welding and repair of large molds.

1500W Continuous Laser:

Unlike pulsed lasers, the continuous laser enables long-duration, uninterrupted welding, making it suitable for repairing large mold cavities, welding thick metal parts, and batch production.

3. Flexible for Complex Welding Tasks

Designed with an articulated arm and omnidirectional wheels, the system offers exceptional mobility and flexibility.

With a 3-axis joystick and a 180° rotatable welding head, it enables multi-angle welding on complex surfaces—such as side walls or curved areas—without the need to disassemble large molds. Simply move the machine next to the workpiece for precise on-site repair.

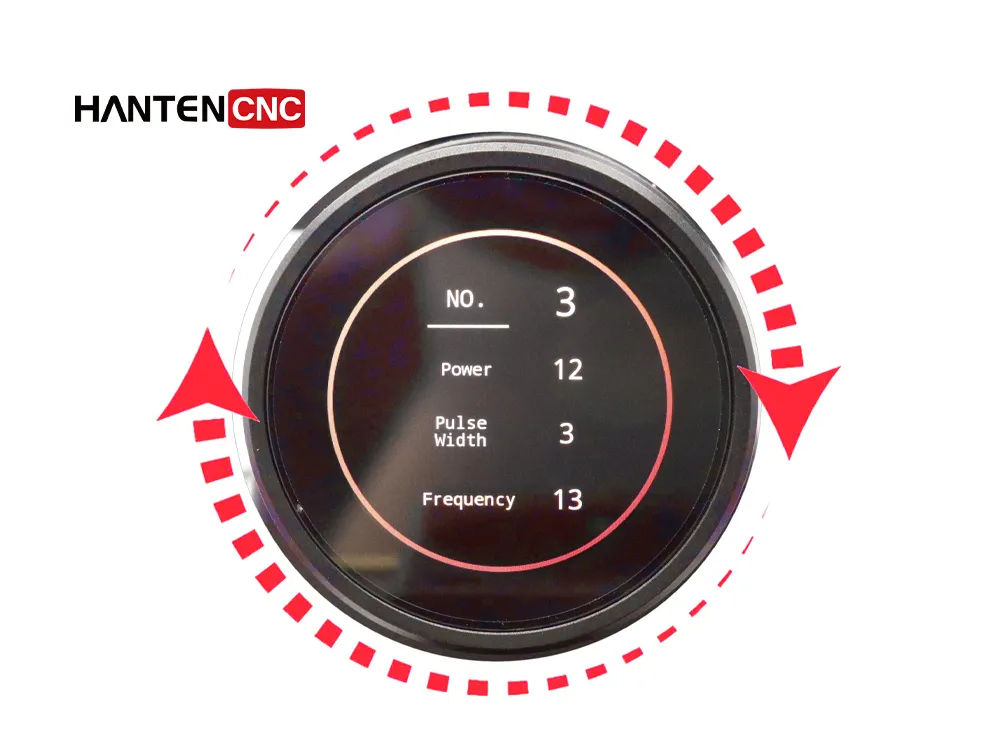

4. Quick-Adjust Rotary Control Panel

Equipped with a user-friendly rotary control screen that allows for one-touch adjustment of key parameters such as power and speed.

Supports various materials, including steel, copper, and different alloys, making it easy to switch between tasks.

5. Integrated Gas Shielding System

Built-in argon gas protection ensures that the weld area remains oxidation-free during the welding process.

This maintains the natural appearance of the material and ensures high-quality welds.

6. Optional Dual-Axis Swing Welding Head

The standard configuration includes a single-axis swing laser welding head, ideal for flat surfaces or simple curves.

Single-axis swing laser welding head: It is suitable for straightforward welding jobs.

Dual-axis swing laser welding head (Optional): It is suitable for welding on 3D surfaces, at multiple angles, or on highly reflective materials. The dual-swing laser welding head greatly improves weld quality and yield rate.

7. Optimized Operational Cost

This laser welding machine allows for on-site repairs without the need to disassemble large molds, resulting in significant time savings of hours or even days.

By minimizing machine downtime, it proves to be especially beneficial for high-value components in industries like automotive and aerospace.

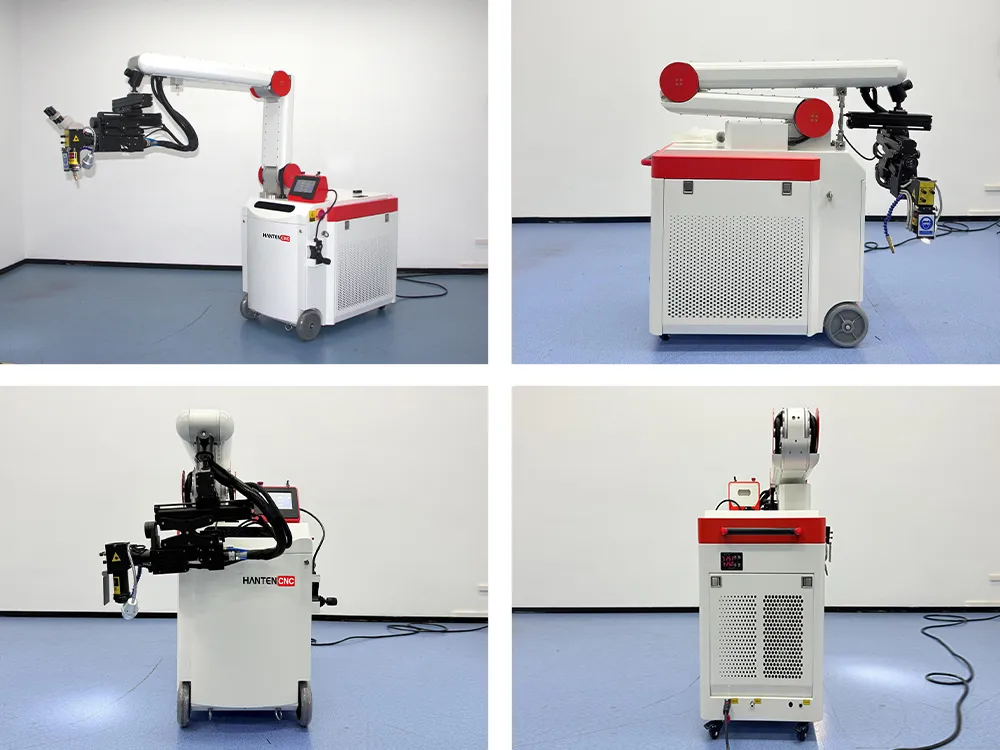

Laser Welding Machine for Large Mold Repair Machine Display

Laser Welding Machine for Large Mold Repair Components

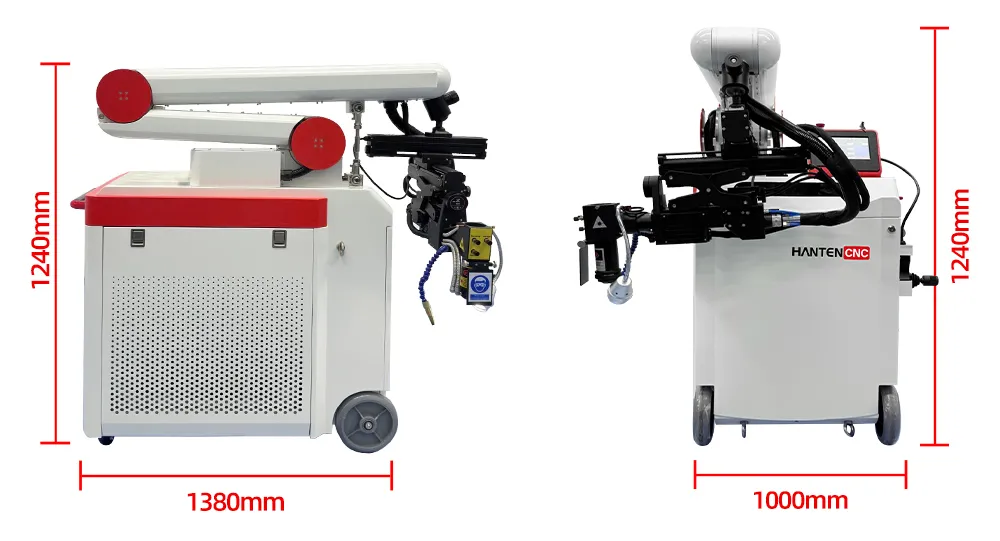

Laser Welding Machine for Large Mold Repair Dimensions

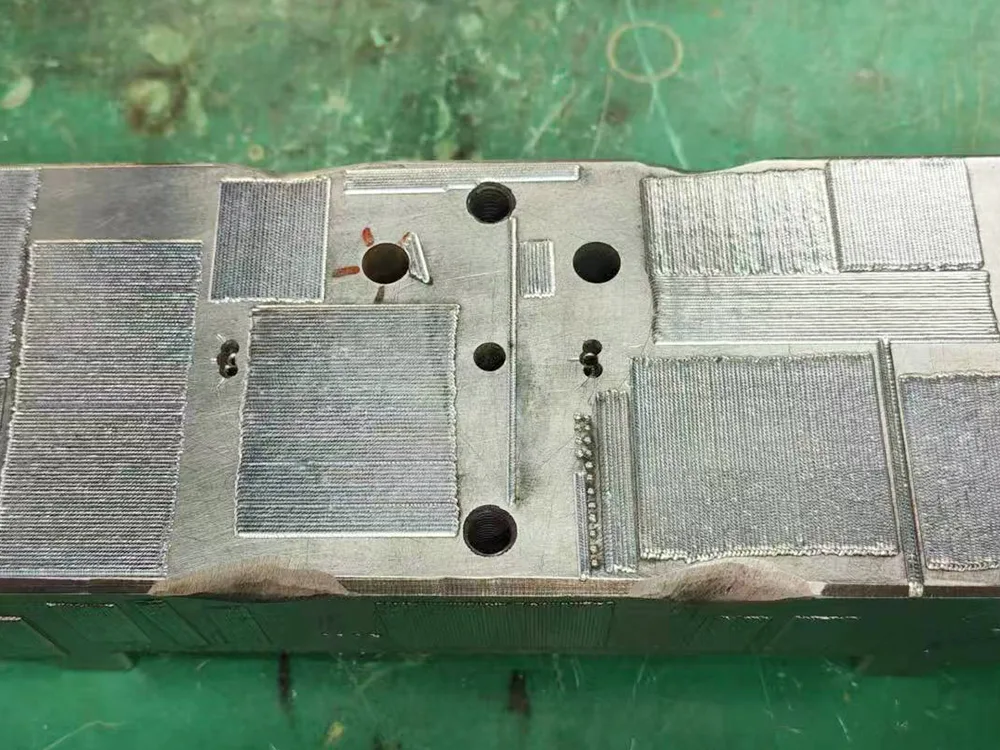

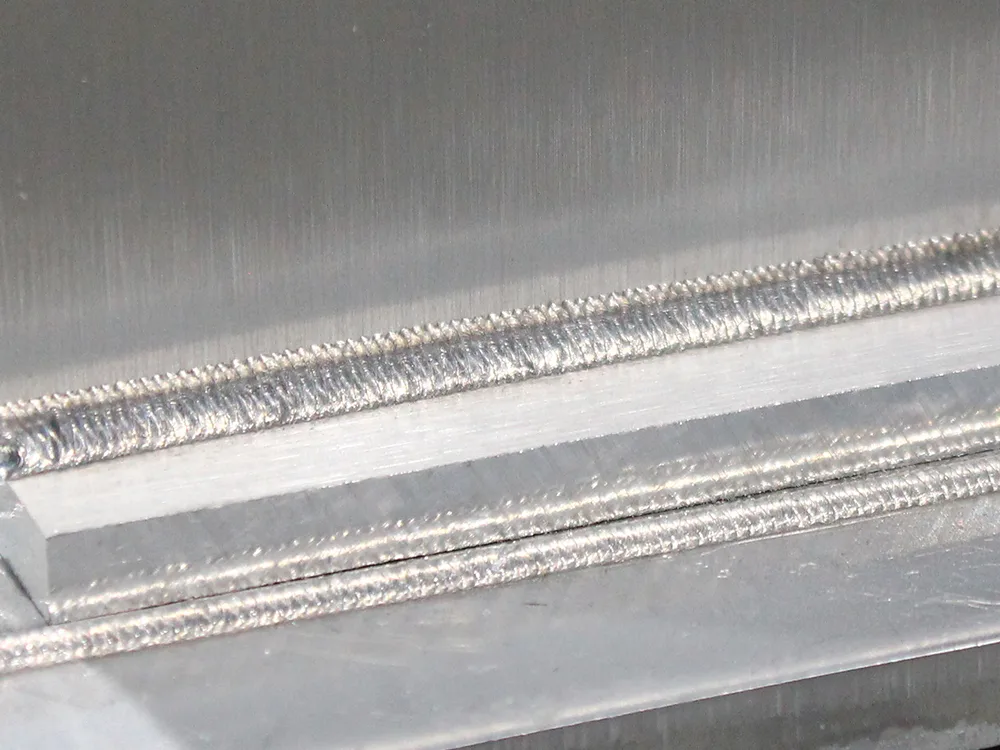

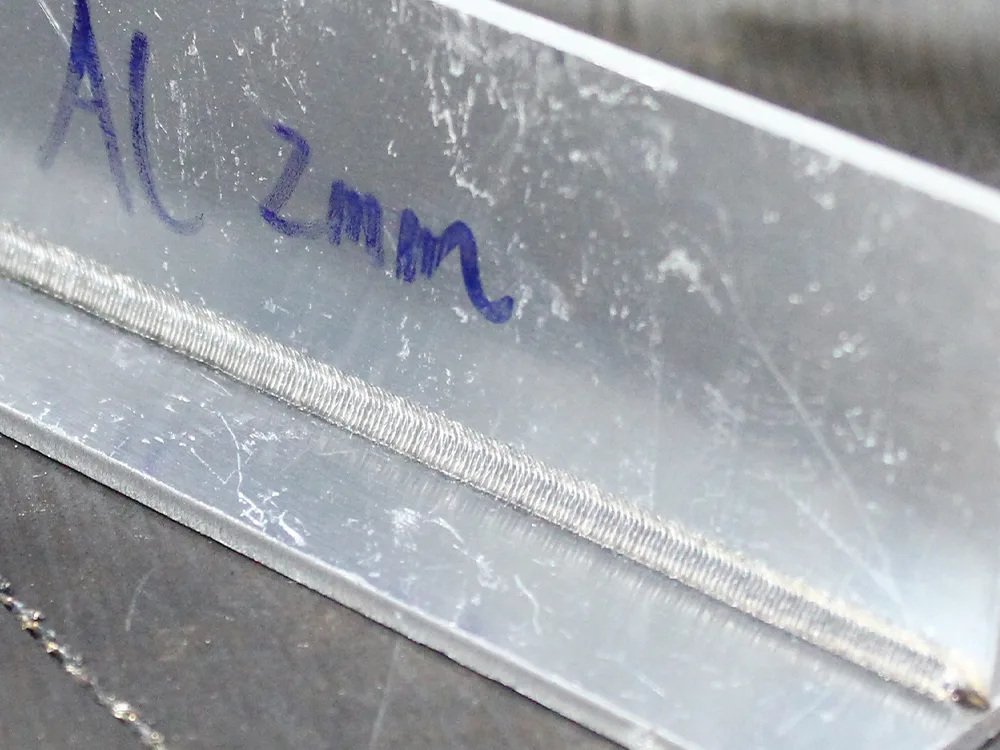

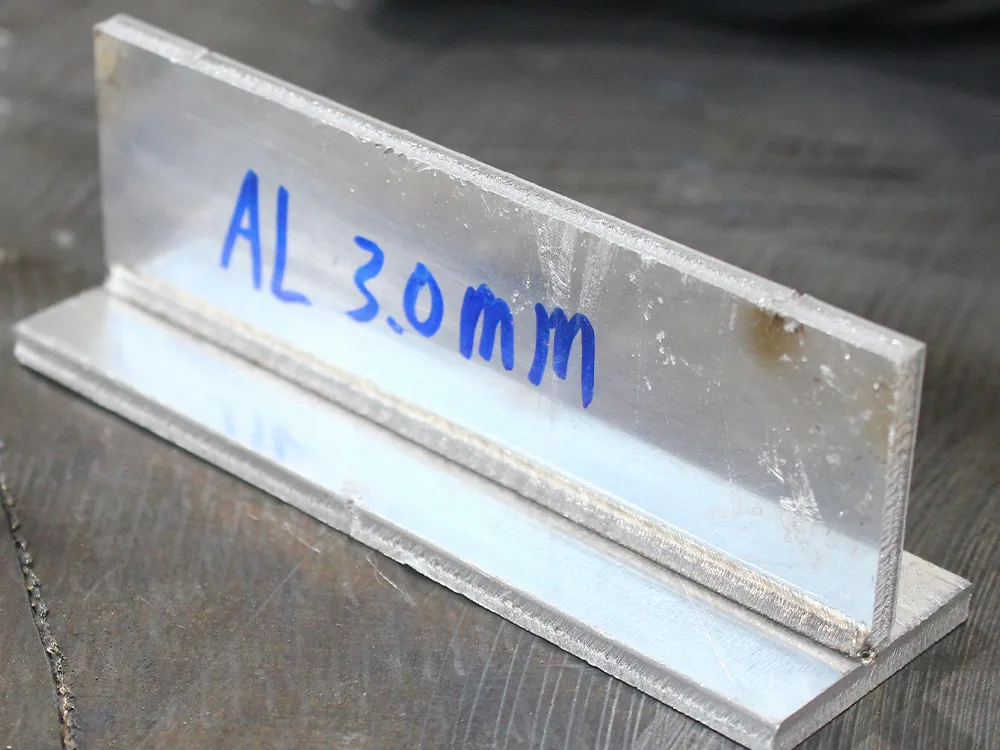

Precision Mould Welding Samples Using QCW Laser

This process uses a QCW (Quasi-Continuous Wave) laser to weld molds with high precision.

The QCW laser delivers powerful, controlled bursts of energy, ensuring that the weld is clean and strong. This is perfect for repairing or joining molds used in manufacturing, where accuracy is critical.

QCW lasers can focus on very small areas, which results in a smooth, high-quality finish that meets the exact specifications needed for the mold.

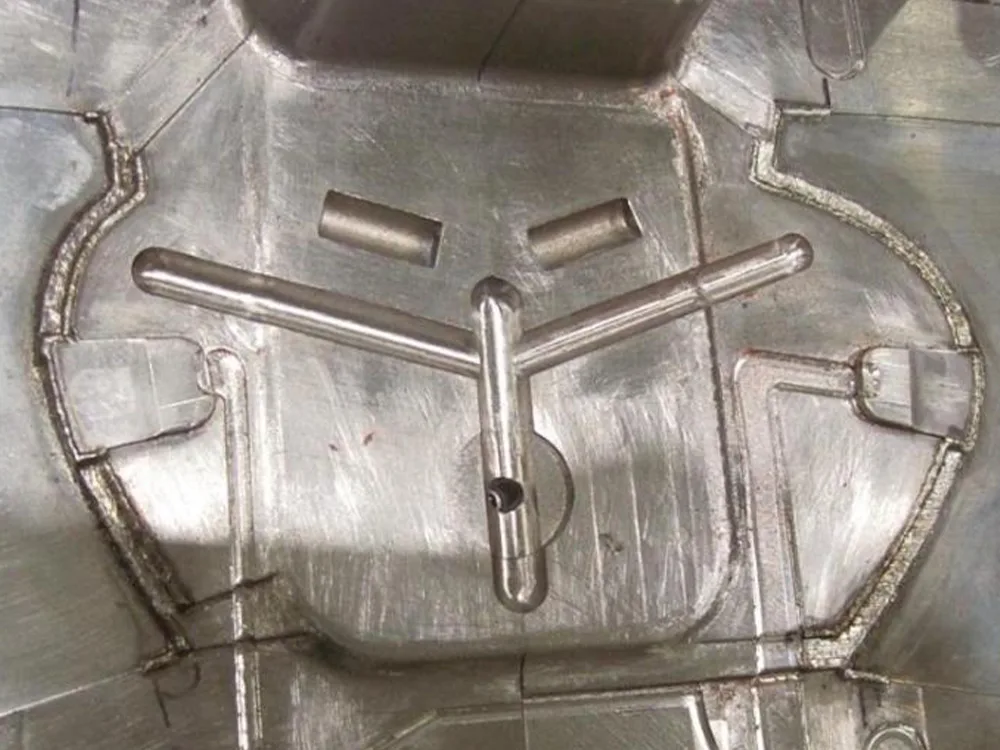

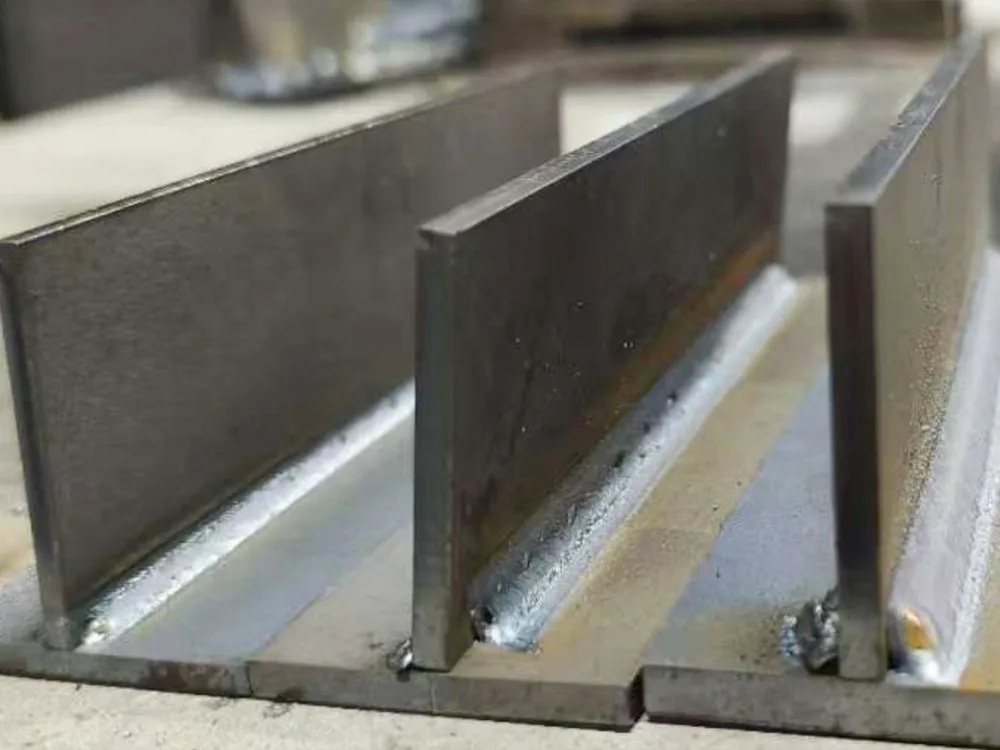

Precision Welding Samples Using 1500W Continuous Laser

The 1500W Continuous Laser is a high-power laser used for welding metal parts with great accuracy.

The continuous laser works by emitting a constant, steady beam of light, which melts the metal to create a strong, durable weld.

The 1500W power ensures that even thicker materials can be welded quickly and effectively.

The 1500W continous laser welding is perfect for industries that require strong and precise welds, such as automotive, aerospace, and heavy machinery manufacturing.

Arm-type Laser Welding Machine Parameters

| Model | HTW200 | HTW300 | HTW1500 |

|---|---|---|---|

| Laser Type | QCW laser (Quasi Continuous Wave) | QCW laser (Quasi Continuous Wave) | Continuous laser |

| Max Laser Power | 150W | 300W | 1500W |

| Rated Power Consumption | 2.5KW | 3KW | 7KW |

| Power Supply | 220V ±5V 50Hz / 60A | 220V ±5V 50Hz / 60A | 220V ±5V 50Hz / 60A |

| Laser Wavelength | 1080 ± 10nm | 1080 ± 10nm | 1080 ± 10nm |

| Laser Fiber Length | 10M | 10M | 10M |

| Laser Frequency | 1–30Hz | 1–30Hz | 1–25Hz |

| Pulse Width | 1–20ms | 1–20ms | 1–60ms |

| Spot Size Range | 0.2–3mm | 0.2–5mm | 0.2–5mm |

| Cooling Method | Water Chiller | Water Chiller | Water Chiller |

| Chiller Power | 0.4P | 0.4P | 0.4P |

| Microscope & Vision System | Microscope / CCD Camera(Optional) | Microscope / CCD Camera(Optional) | Microscope / CCD Camera(Optional) |

| Cantilever Arm | 360° continuous rotation for flexible multi-angle operation | 360° continuous rotation for flexible multi-angle operation | 360° continuous rotation for flexible multi-angle operation |

| Working Area (X-Y-Z) | 200 × 200 × 100 mm | 200 × 200 × 100 mm | 200 × 200 × 100 mm |

| Articulated arm extension height/Vertical Extension | 1500 mm | 1500 mm | 1500 mm |

| Articulated arm extension length / Horizontal Reach | 1600 mm | 1600 mm | 1600 mm |

| Machine Dimensions | 1380 × 1000 × 1240mm | 1380 × 1000 × 1240mm | 1380 × 1000 × 1240mm |

| Machine Weight | 295kg (including water chiller) | 295kg (including water chiller) | 295kg (including water chiller) |

Customer Visits

Laser Welder Machine Certificates

HANTENCNC owns trademark registration certificates, utility patent certificates, software copyright certificates, etc.

HANTENCNC’s laser welder machines are CE and FDA-certified, ensuring high quality and safety.

You can trust HANTENCNC and HANTENCNC’s laser welding machines, which are backed by these certificates.

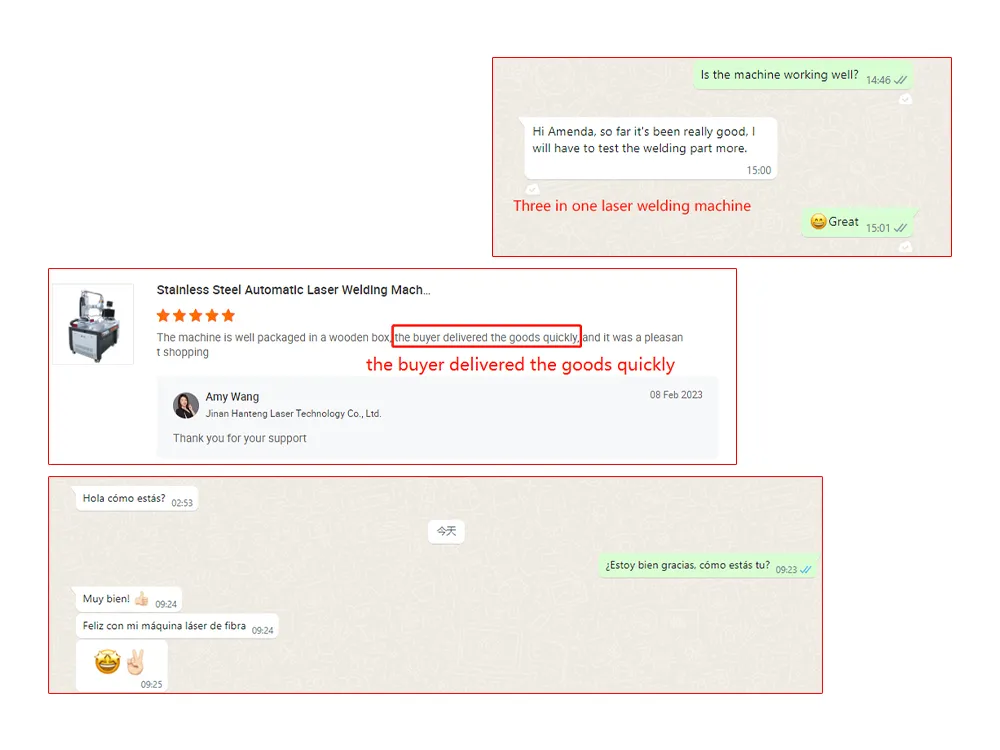

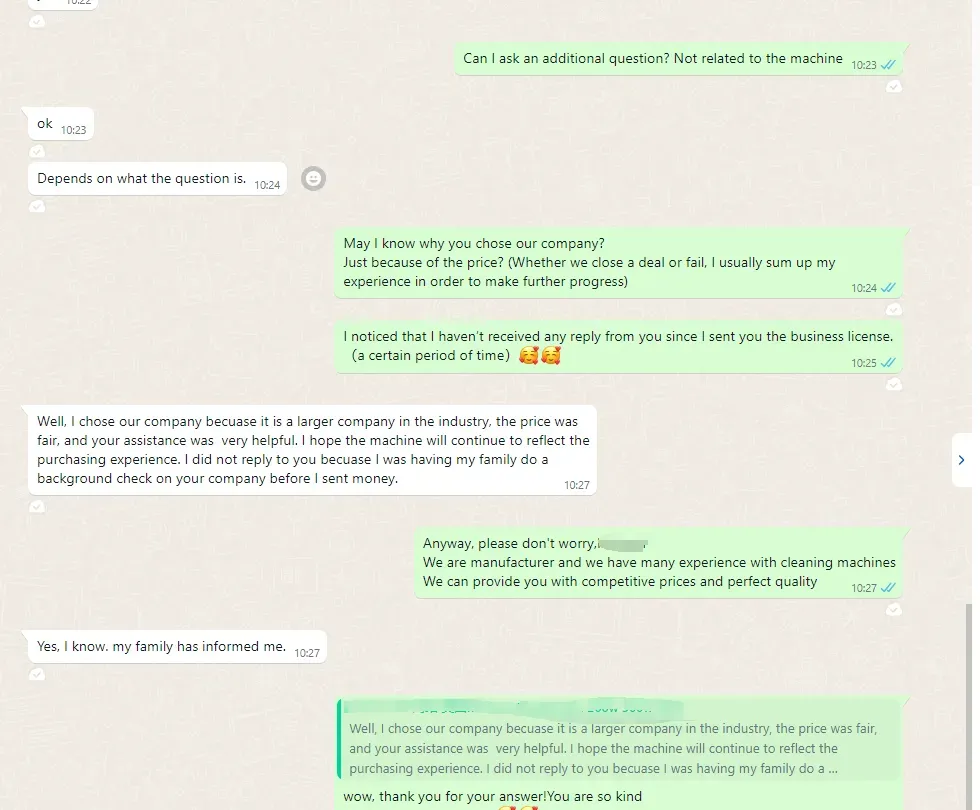

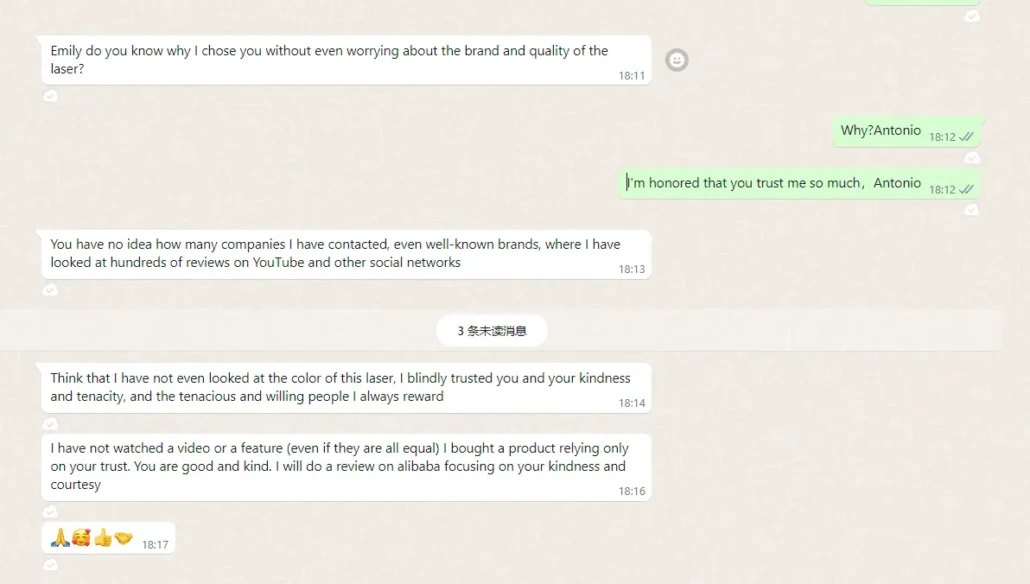

Customer Reviews

HANTENCNC Partnerships

Our Service

HANTENCNC provides free sample testing, a 2-year warranty for the laser source, a 1-year warranty for the whole machine, and ODM services.