Among the many successful cases of HANTENCNC, many customers are very satisfied with the cleaning effect of our laser wood stripping machine.

This article first introduces the functions of laser wood stripping machines, and then focuses on some successful cases of HANTENCNC laser wood stripping.

In the article, some pictures of the actual laser wood stripping cleaning effects of customers who have purchased laser wood stripping machines are shown to give you an intuitive understanding of the laser cleaning of paint on wood.

If you are looking for an efficient and non-destructive laser wood stripping solution, you may wish to learn about HANTENCNC’s laser cleaning technology.

1. What is a Laser Wood Stripping Machine?

A laser wood stripping machine is a tool that uses laser technology to remove contaminants, such as paint, oil, dirt, or coatings, from wooden surfaces without damaging the underlying wood.

Compared to traditional cleaning methods, like sandblasting, chemical cleaning, or mechanical scrubbing, laser wood stripping is a non-abrasive, eco-friendly alternative method.

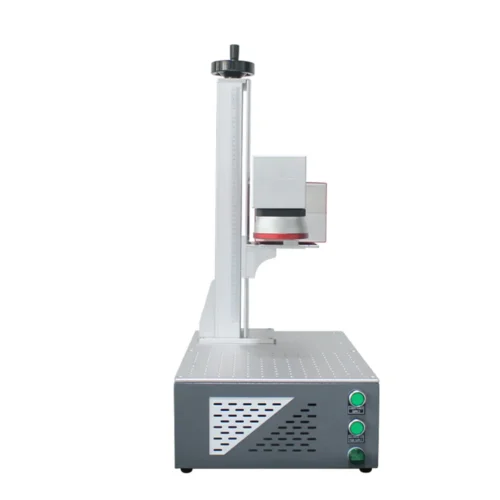

The following are the three most popular laser cleaning machines from HANTENCNC that are very suitable for wood stripping, with pictures as follows:

2. How Does a Laser Wood Stripping Machine Work?

A laser wood stripping machine works by using a focused laser beam to remove coatings such as paint, varnish, or resin from wooden surfaces without damaging the underlying wood. Here’s a step-by-step breakdown of how it works:

The laser wood stripping machine emits high-energy laser pulses, usually from a pulse fiber laser , which are directed at the wood surface.

The paint or coating absorbs the laser energy much more than the bare wood. This causes rapid heating of the coating layer.

The absorbed laser energy causes the coating to vaporize, crack, or lift off from the surface in a process called laser ablation.

Because the laser is finely controlled and delivers energy in very short bursts, nanoseconds or milliseconds, the heat does not penetrate deeply into the wood, avoiding burning or charring.

So the laser wood stripping machine is an ideal tool for stripping paint from wooden, They offer precise and eco-friendly cleaning without damaging the base materials.

It is widely used in applications such as furniture restoration, antique and artwork conservation, building renovation, boat and yacht maintenance and wood product manufacturing.

Advantages of Laser Wood Stripping Machine

The advantages of laser wood stripping machine are following:

✔ Non-contact process (no surface damage)

✔ Eco-friendly (no chemicals or media blasting waste)

✔ Precision cleaning (works on complex shapes)

✔ Low operating costs (minimal consumables)

✔ Safe for delicate materials

3. Types of Laser Wood Stripping Machine

There are mainly two types of laser wood stripping machines: pulse laser stripper and continuous laser stripper. Each has different characteristics and applications. Below is a detailed list of these two types of pros, cons, and typical uses.

Pulse Laser Stripper operates like a precision sniper; it uses short, controlled bursts to remove contaminants layer by layer safely without damaging the underlying base.

It is ideal for delicate applications, such as cultural relic restoration, precision component cleaning, and electronics maintenance; it is particularly suitable for stripping paint from wooden surfaces.

While continuous laser stripper operates like rapid-fire sweepers, they provide constant beam output for efficient large-area cleaning. It is best for industrial-scale projects, such as ship hull preparation, pipeline maintenance , and heavy equipment refurbishment.

HANTENCNC’s Pulse and Continuous Laser Cleaning Machines

The following two product categories are HANTENCNC’s Pulse laser cleaning machines and Continuous Laser Cleaning Machines:

4. Does the Laser Wood Stripping Machine Really Work?

Does the laser wood stripping machine really work?

The short answer is yes — and here’s why.

Over the past few years, HANTENCNC has delivered laser wood stripping machines to a wide range of customers across industries like furniture renovation, building restoration, flooring maintenance, and more. The real-world results show consistent, repeatable, and safe paint removal from wooden surfaces — without damaging the wood grain underneath.

Let’s take a closer look at how it performs across different applications:

4.1 Real Cleaning Cases

4.1.1 1000W 15mJ Laser Cleaning on a Spiral Wooden Staircase

The customer used a 1000W pulse laser cleaning machine to remove the paint on the surface of the wooden spiral staircase. After cleaning, the wood texture appeared naturally, and the surface was flat and intact, making it easy to repaint or process later.

4.1.2 300w 5mJ SEAGULL2 laser wood stripping effect on furniture

In this case, the customer used a 300W SEAGULL2 handheld pulse laser cleaning machine to successfully remove the thick paint layer on the surface of solid wood furniture. The image shows a clear comparison between before and after cleaning, and the effect is remarkable.

4.1.3 300w 5mJ SEAGULL2 laser wood stripping effect on Stairs and Floors

When cleaning wooden stair treads, the laser can accurately peel off old paint and preserve the original appearance of the wood, which is particularly suitable for old house renovation projects.

4.1.4 300w 5mJ SEAGULL2 Wood Floor Paint Stripping

SEAGULL2 shows the advantages of high efficiency and low heat-affected zones when cleaning solid wood floors.

Because it is a pulse laser cleaning machine, it is suitable for high-end floor renovation. It can be processed on-site without disassembly.

4.1.5 500W Water-Cooled Laser Wood Stripping Machine for Door Cleaning

The 500W water-cooled laser wood stripping machine from HANTENCNC is perfect for removing thick, large-area paint layers. It can run 24/7 without overheating, ensuring smooth operation. Compared to a 200W laser wood stripping machine, the 500W laser cleaning machine offers over 3x faster paint removal—with no damage, no consumables, and easy operation, no special skills required.

Here’s a real demo of the 500W water-cooled laser wood stripping machine in action for wooden door cleaning.

Our customer feedback confirms that HANTENCNC’s 500W laser stripper delivers high efficiency, effortless operation, and flawless paint removal—making it the ideal tool for furniture refurbishment and maintenance.

4.2 Which Coatings Can Be Effectively Removed from Wood by Laser?

Paints are generally divided into two main categories: water-based and oil-based paints.

Water-based paints are easier to remove with laser cleaning. They offer good cleaning results with minimal damage to the wood substrate.

For oil-based paints, coatings such as metallic paints and epoxy paints can also be effectively removed.

Other types of oil-based coatings may require testing to evaluate compatibility with laser cleaning.

When the coating thickness is less than 300 μm, laser cleaning is usually very effective.

If the coating is thicker than 300 μm, it can still be removed through multiple cleaning passes, though there may be slight damage to the wood surface.

4.3 Can All Paints Be Removed from Wood by a Laser Wood Stripping Machine?

Can all paints be removed from wood with a laser? The answer is no, not all of the paints can be removed from wood by a laser wood stripping machine.

After many experiments on wood paint removal by HANTENCNC, the following wood coatings are difficult to remove by laser cleaning: Epoxy Coatings, Polyurethane Coatings, Baked Enamel or Powder Coatings, 2K Paints and High-gloss Varnish / UV Coating. The specific reasons are as follows:

Epoxy Coatings, which are commonly used in industrial furniture or floors, have extremely strong adhesion; it is difficult for lasers to completely vaporize or peel them off.

Polyurethane Coatings, which are commonly found in furniture and floors, have excellent heat resistance and wear resistance and are not easily decomposed by lasers.

Other wood coatings that are difficult to remove by cleaning include Baked Enamel and Powder Coatings. These types of paints are more tightly bonded to wood after high-temperature curing, and are difficult to effectively remove with ordinary power lasers.

In addition, 2K Paints, which are particularly difficult to remove, contain a two-component system of curing agent, have high hardness and strong adhesion, and are particularly difficult to remove.

There are also High-gloss Varnish / UV Coatings. These high-gloss finish coatings resist laser absorption, and laser energy is easily reflected, so the effect is not obvious.

5. Conclusion

Through the analysis of the working principle, advantages, classification and multiple real cases of laser wood paint strippers in this article, we can clearly see that:

The laser wood paint stripper is indeed an efficient, environmentally friendly and non-destructive cleaning tool.

It performs particularly well in the fields of furniture renovation, floor maintenance, and cultural relics restoration, and is especially suitable for removing water-based or thin layers of oily coatings.

Of course, not all types of coatings are suitable for laser cleaning. For surfaces with high adhesion or high reflectivity such as epoxy, polyurethane, 2K paint, and high-gloss UV coatings, it is still necessary to evaluate whether it is suitable for laser cleaning, or to use other auxiliary processes to achieve better results.

If you are looking for a solution that does not damage the wood and can efficiently remove paint, laser wood paint stripping technology is undoubtedly worth considering.

6. About HANTENCNC

HANTENCNC is a leading industrial laser equipment manufacturer in China, focusing on the research, development, production, and sales of laser cleaning machines, laser marking machines, laser welding machines, and other equipment. Since its establishment, we have always adhered to the concept of “making industrial lasers simpler and more reliable” and have continued to provide global customers with high-performance, easy-to-operate, and high-stability laser equipment solutions.

We have an independent R&D team, professional technical support, and an international service system. Whether you are engaged in automobile manufacturing, metal processing, furniture renovation, or cultural relics restoration, we can provide you with efficient, environmentally friendly, and customized laser cleaning solutions.

At present, HANTENCNC’s products have been exported to more than 60 countries and regions, including Europe, America, Southeast Asia, and the Middle East, and they have won wide recognition and good reputations from users.

Welcome to visit our official website or contact us for more product details, video demonstrations, and free testing services.