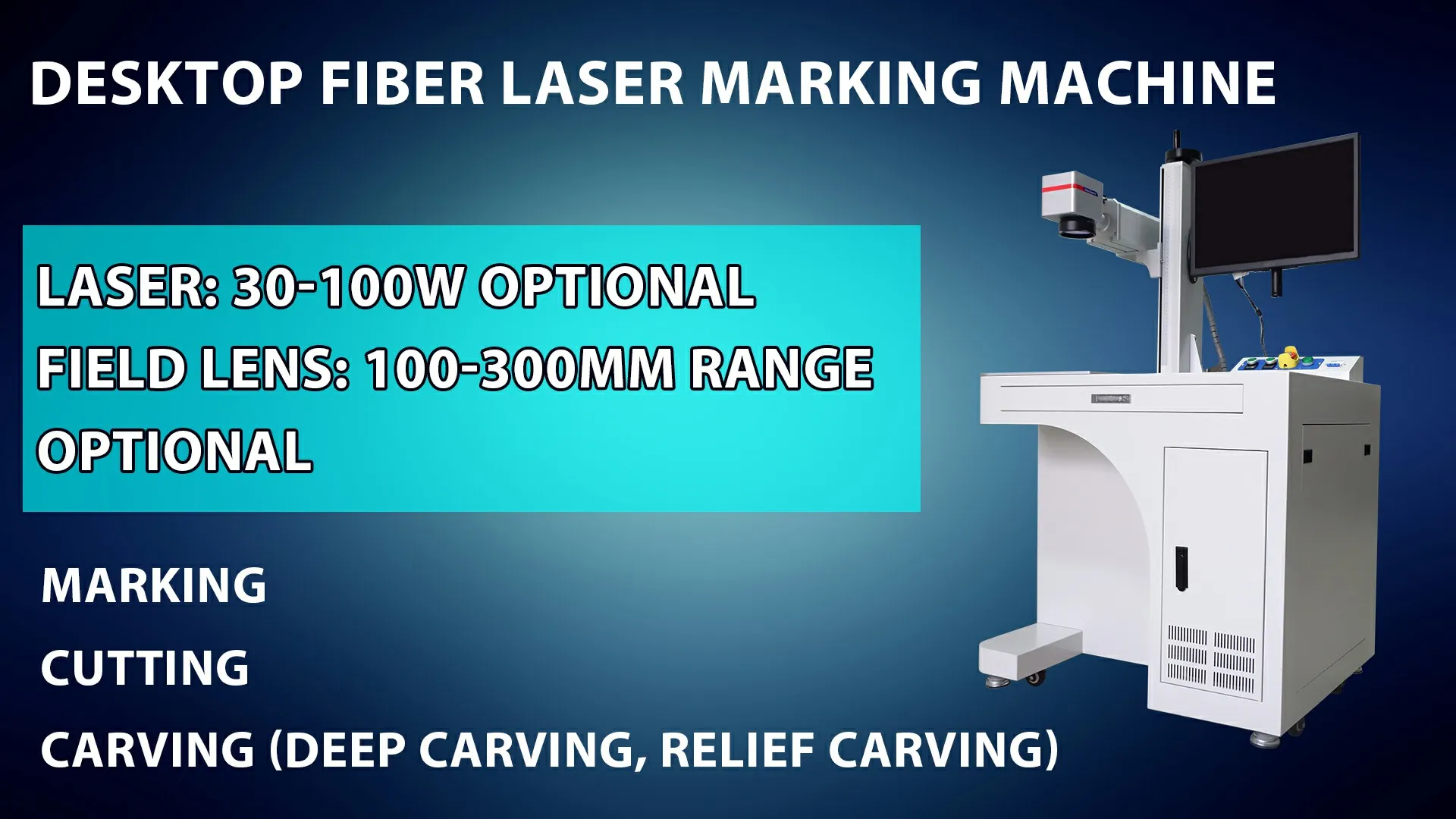

Desktop Fiber Laser Marker Advantages

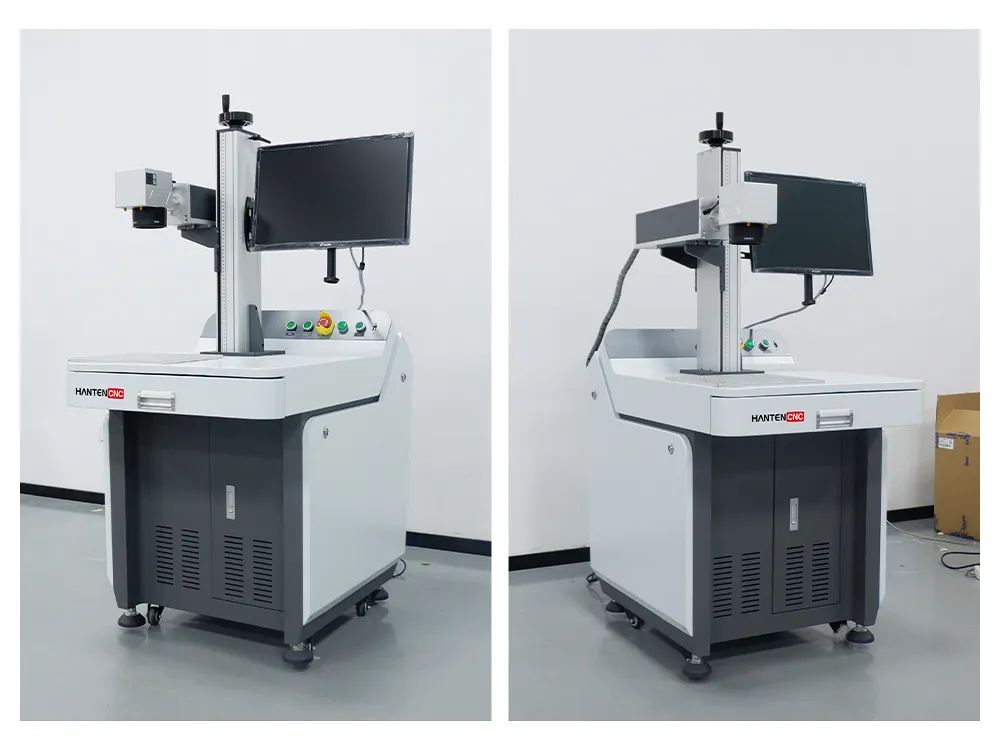

- Desktop design, humanized console, and marking process are more stable.

- Double red light focus means more accurate marking positioning.

- The desktop fiber laser marker has excellent performance and stable energy output to ensure the marking effect.

- The laser beams are finer, and the marking effect is more exquisite.

- The marking fixture can be designed according to the customer’s product, so the marking efficiency is higher and faster.

- Easy and quick installation, USB connected with computer easily.

- Desktop fiber laser marker has no consumables and does not require maintenance.

Desktop Fiber Laser Marker Applications

Our desktop fiber laser marker is widely used in circuit chips, electronic components, communication products, jewellery, food packaging industries, etc. It can mark metal (stainless steel, aluminum, alloy, brass, silver, gold, titanium, iron) and some non-metal materials, such as automotive parts, hardware and tools, aerospace components, integrated circuit chips, computer accessories, watches, home appliances, wire and cable and many other areas of patterns and text marking. The high-power laser marking machine can also cut thin metals, such as stainless steel, aluminium, alloy, brass, silver, gold, and titanium.

Desktop Fiber Laser Marker Demonstration Video

Desktop Fiber Laser Marker Display

Component Details Display of Desktop Fiber Laser Marker

Desktop Fiber Laser Marker Dimensions

Desktop Fiber Laser Marker Parameters

| Model | HTF20 | HTF30 | HTF50 | HTF60 | HTF100 |

| Supply Voltage | 110V/220V、

50/60Hz |

110V/220V、

50/60Hz |

110V/220V、

50/60Hz |

110V/220V、

50/60Hz |

110V/220V、

50/60Hz |

| Overall Power Consumption | 460W | 490W | 550W | 580W | 700W |

| Cooling Method | Air-cooled | Air-cooled | Air-cooled | Air-cooled | Air-cooled |

| Machine Dimensions | 600*775*1430mm | 600*775*1430mm | 600*775*1430mm | 600*775*1430mm | 600*775*1430mm |

| Machine Weight | About 70Kg | About 70Kg | About 70Kg | About 70Kg | About 70Kg |

OPTICAL PARAMETERS |

|||||

| Output Power | 20W | 30W | 50W | 60W | 100W |

| Galvo Head | RC 1001 | RC 1001 | RC 1001 | RC 1001 | RC 1001 |

| Laser Source | JPT/MAX/RAYCUS | JPT/MAX/RAYCUS | JPT/MAX/RAYCUS | JPT/MAX/RAYCUS | JPT/MAX/RAYCUS |

| Maximum Pulse Energy | 0.8mJ | 0.8mJ | 1.25mJ | 1.5mJ | 1.5mJ |

| Frequency Adjustable Range | 1-600kHz | 1-600kHz | 1-600kHz | 1-4000kHz | 1-4000kHz |

| Laser Wavelength | 1064nm | 1064nm | 1064nm | 1064nm | 1064nm |

| Beam Diameter | 7±0.5mm | 7±0.5mm | 7±0.5mm | 7±0.5mm | 7±0.5mm |

| Marking Area | 100*100mm-300*300mm | 100*100mm-300*300mm | 100*100mm-300*300mm | 100*100mm-300*300mm | 100*100mm-300*300mm |

| Power Adjustment Range(%) | 0-100% | 0-100% | 0-100% | 0-100% | 0-100% |

| Fiber Cable Length | 3m | 3m | 3m | 3m | 3m |

| System Software | EZCAD2 | EZCAD2 | EZCAD2 | EZCAD2 | EZCAD2 |

Desktop Fiber Laser Marker Features

RC1001 Galvo Head

The RC1001 galvanometer is compact and weighs only 900g. It adopts a high-performance scanning motor and internationally leading optical sensing technology to achieve high-precision positioning and fast marking.

Our Calvo head has good linearity, small drift, high resolution, high repeat positioning accuracy, strong anti-interference ability, and very stable and reliable performance.

Control Panel

The laser power button can be used to control the standby and working states of the laser, ensuring quick activation of the laser when needed and improving work efficiency.

The power button of the ammeter provides real-time current monitoring, helping operators maintain the optimal working state of the laser, timely detect and solve potential problems, and ensure the marking effect and equipment reliability.

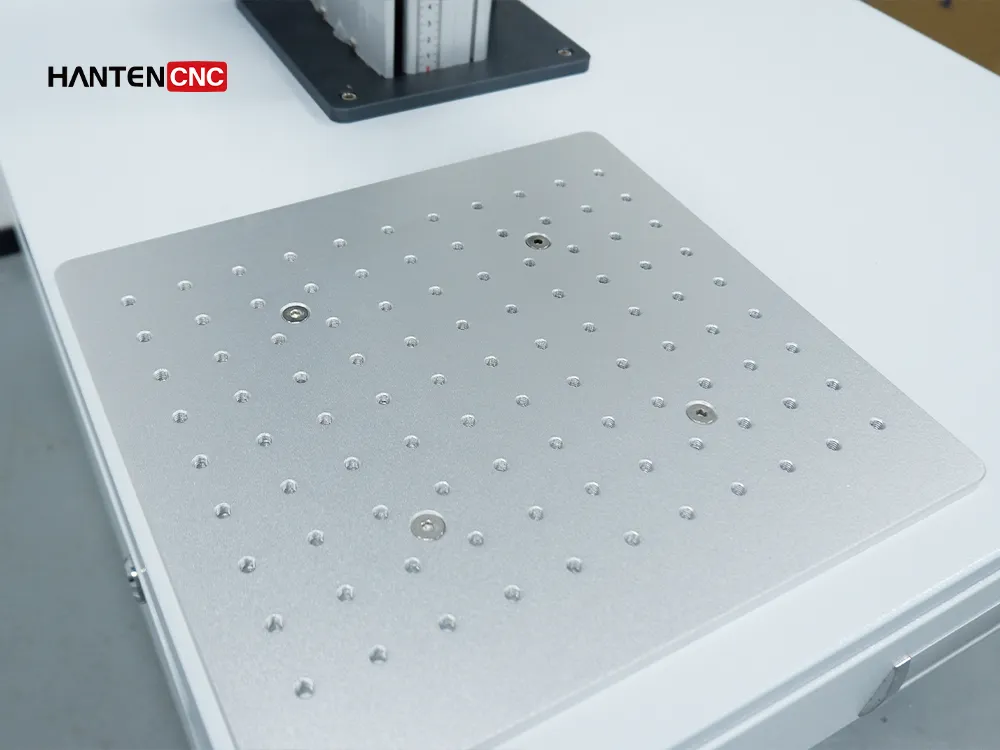

Operation Table

Our desktop fiber laser marking machine uses aluminum plate as the worktable. Aluminium is not easily corroded, can maintain stability in various working environments, is not easy to rust, and extends the service life of the worktable.

The worktable comes with positioning holes, enabling you to fasten multiple workpieces and mark them securely. The positioning holes can also be used as heat dissipation holes, ensuring precision marking.

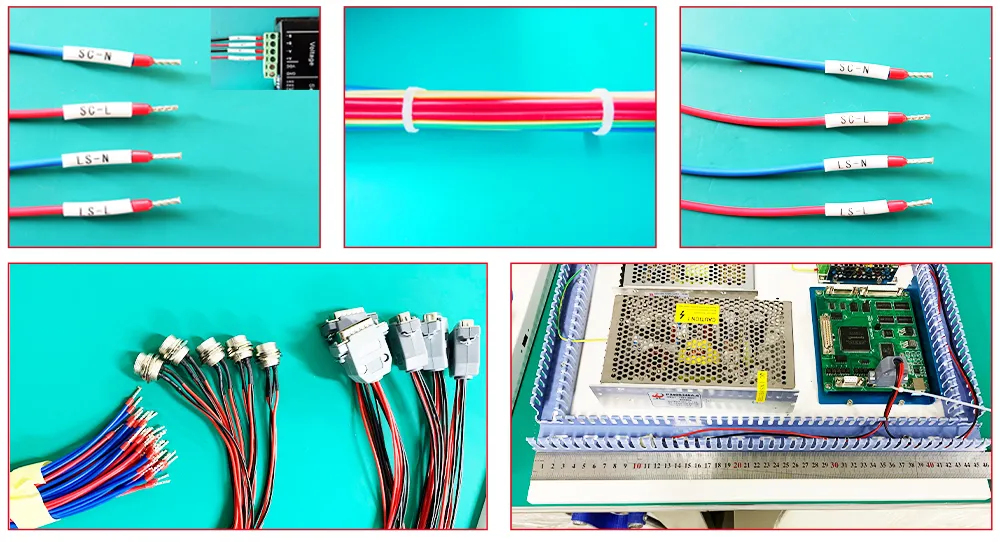

Well-organized Internal Wiring

HANTENCNC’s desktop fiber laser marker has well-organized internal wiring that minimizes the risk of electrical shorts or malfunctions, ensuring smooth and reliable operation. Secondly, neatly arranged internal wiring also makes maintenance easier, helping technicians to identify and address any issues that may arise more easily.

Other Optional Desktop Fiber Laser Marker

Desktop Fiber Laser Marker Sample Display

Configuration Comparison: HANTENCNC vs. Other Factories

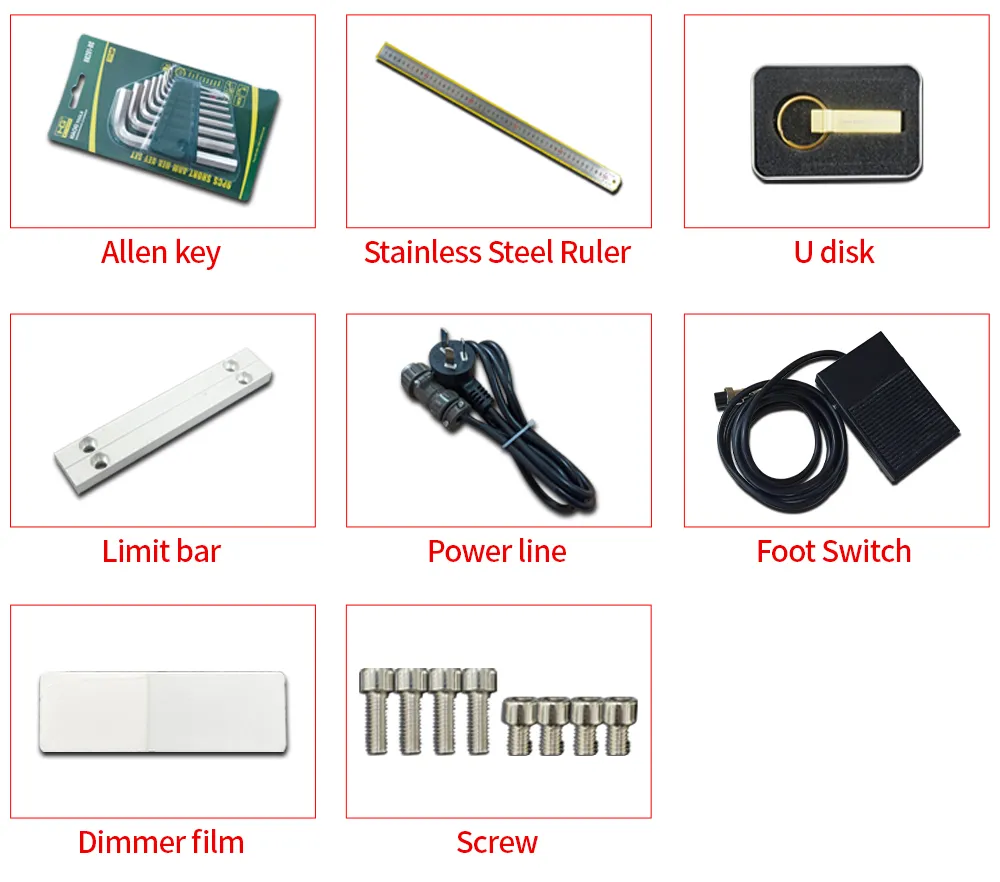

Included Accessories of Desktop Fiber Laser Marker

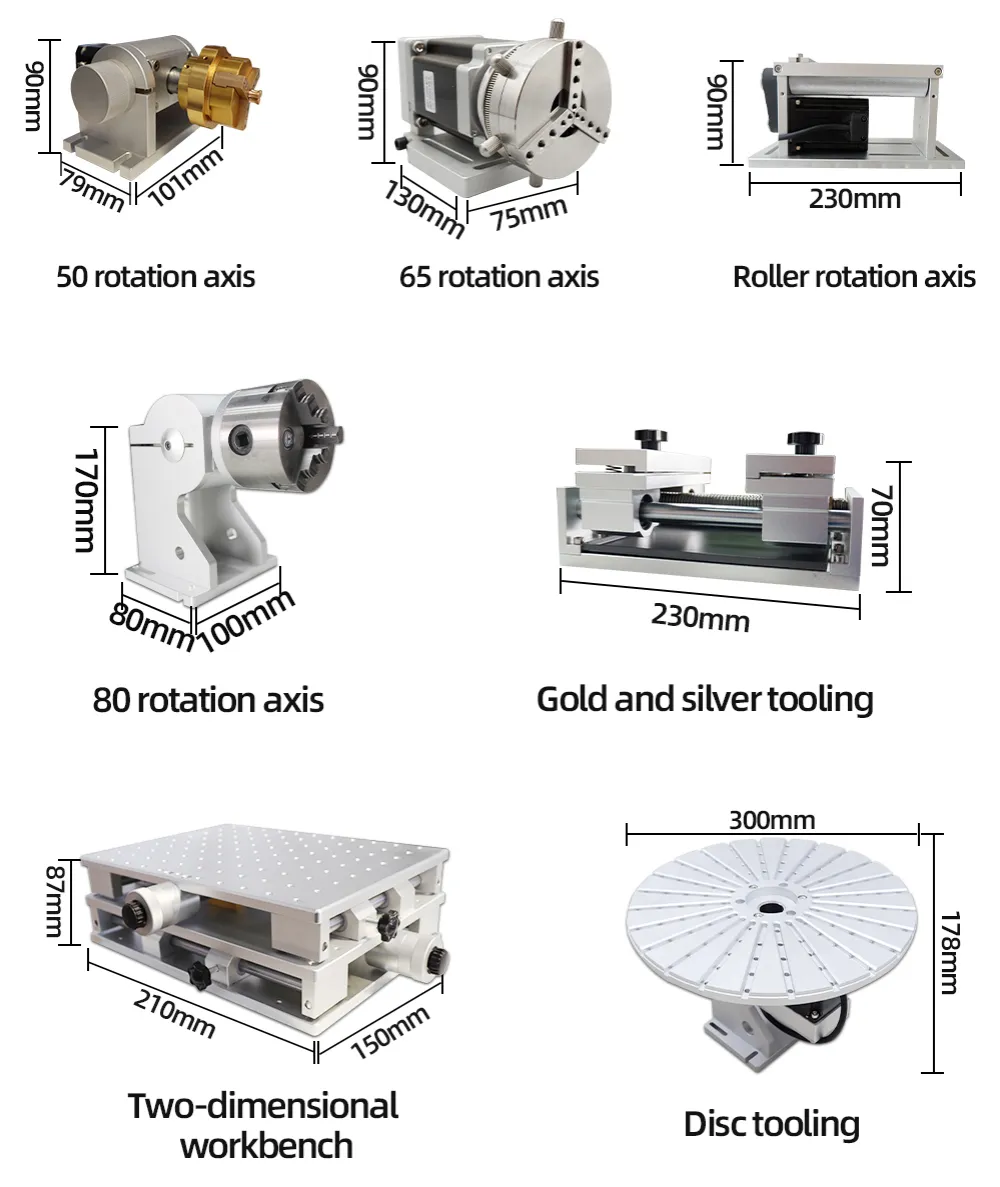

Desktop Fiber Laser Marker Accessory Selection

Customer Visits

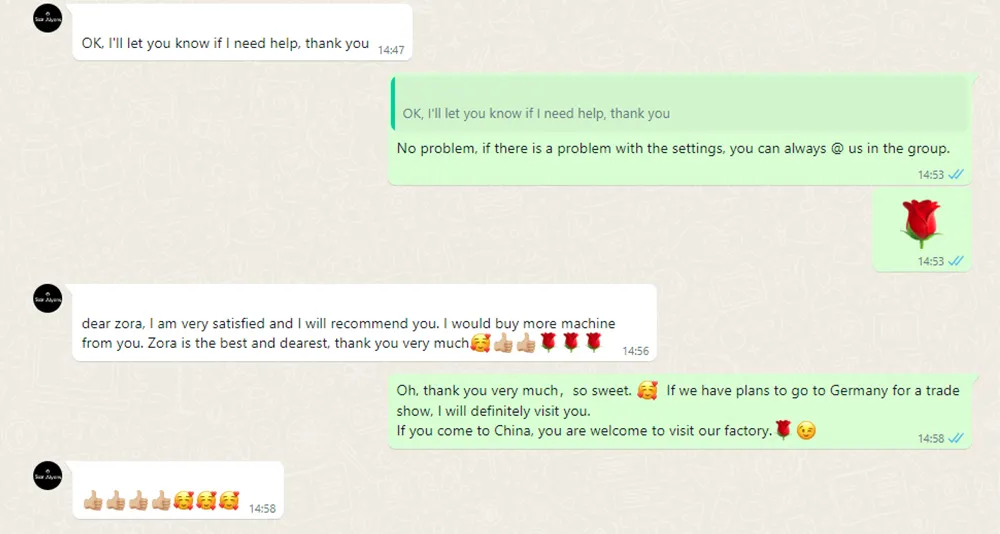

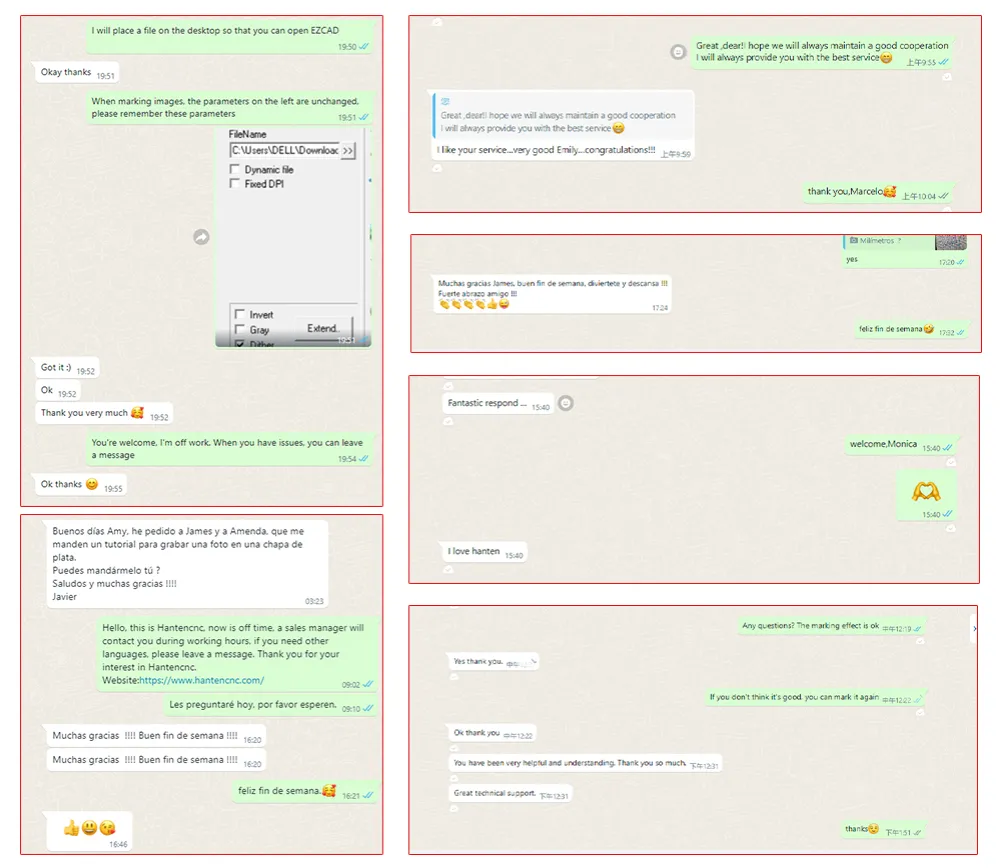

Customer Reviews

Qualification Certifications

HANTENCNC Partnerships