HANTENCNC offers 300W laser rust removal machines, ideal for removing rust, graffiti, and oxidation layers from metal, buildings, car repairs, and more. Our handheld laser rust removers are known for their high cleaning efficiency, ease of use, and system stability.

Our laser rust removal machines are equipped with handheld laser cleaning heads and universal wheels, which allow operators to move the machines and easily target specific areas for cleaning.

Our handheld laser rust removers adopt a water-cooling design, ensuring our laser rust removal machines can maintain stability and reliability during long working hours. This cooling method is usually more efficient.

300W Laser Rust Removal Demonstration Video

300W Laser Rust Removal Features

Built-in Water Cooling Unit

Display of Operating Interface

HANTENCNC’s pulse laser rust removal machines have 9 cleaning modes and can show a live-time status. You can adjust the settings for various cleaning needs.

Our pulse handheld laser rust removers will provide error message notifications, making it easy to control and manage the laser rust removal machines.

300W Laser Rust removal Machine Display

300W Laser Rust Removal Machine Dimensions

Cleaning Gun of 300W Laser Rust Removal Machine

Composition of Laser Cleaning Gun

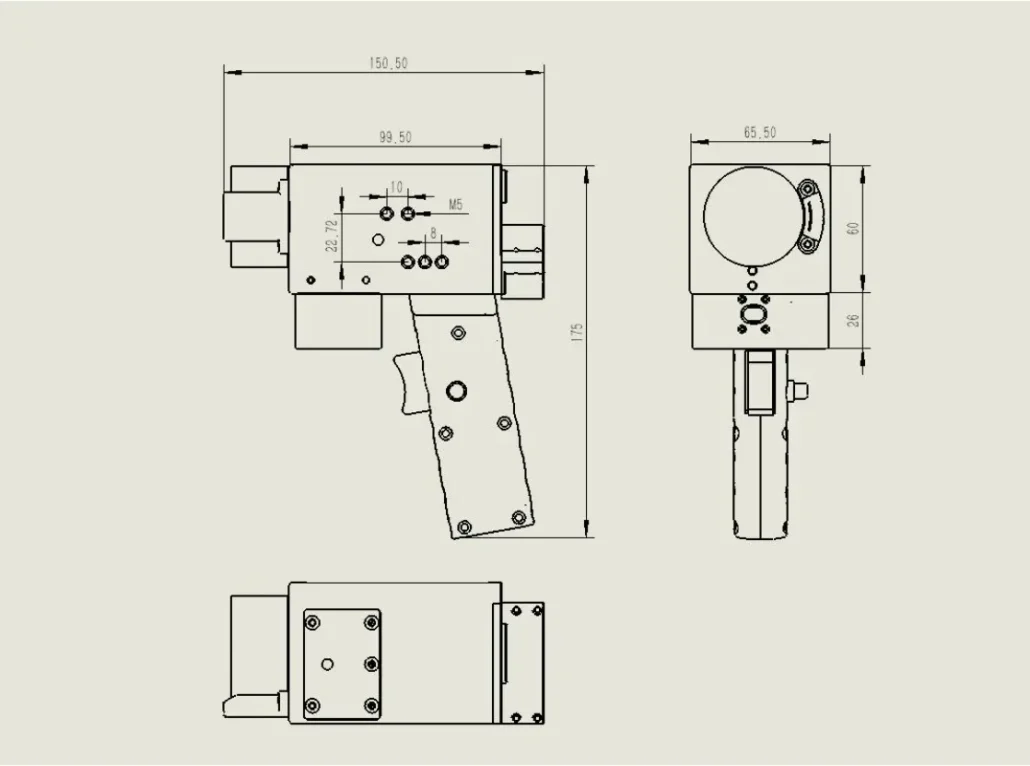

Dimensions of Laser Cleaning Gun

Professional Laser Cleaning Design

An optical scanner with high transmittance and large depth of field, suitable for long-term operation in high-power laser cleaning.

High-performance laser galvanometer with fast scanning speed and high precision, combined with professional control software, meets the needs of various cleaning applications.

Lightweight Cleaning Head Structure Design

1. Portable design:

The cleaning gun is compact and easy to carry, and its comfortable grip makes it easy to use.

2. Lightweight design:

The weight of the cleaning gun is less than 1.25kg, so you can use the laser cleaning gun for a long time effortlessly.

3. Dust-proof sealing design:

The external light path is sealed with a dust-proof design, effectively preventing the entry of dust generated during cleaning.

4. Front-end blowing dust curtain design:

The front-end blowing dust curtain design effectively protects the mirror from dust or oil pollution in the air.

5. Anti-interference design:

The cleaning head’s anti-interference ability is improved through measures such as signal reinforcement, signal shielding layer, galvanometer encapsulation, and metal shielding shell design.

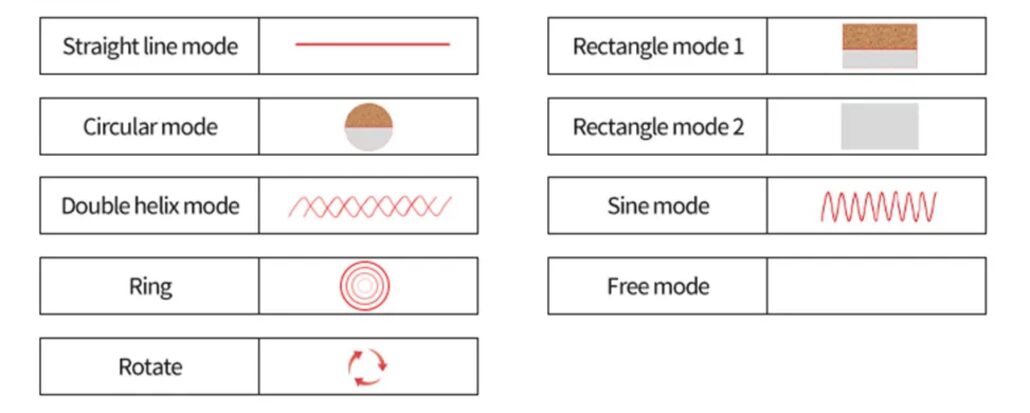

9 Cleaning Modes for Laser Rust removal

HANTENCNC’s 300w laser rust removal supports 9 cleaning modes to cater to various materials and cleaning tasks.

- Straight Line Mode

- Rectangular Mode 1

- Rectangular Mode 2

- Circular Mode

- Sinusoidal Mode

- Spiral Mode

- Free Mode

- Ring Mode

- Rotation Mode

You can switch these modes by clicking on the “Scanning Mode” option on the interface.

Some cleaning modes are gentler, suitable for materials with higher surface requirements, and can reduce or eliminate traces after cleaning. Some cleaning modes are more powerful and ideal for removing stubborn dirt or coatings.

Choosing the right cleaning modes ensures minimal traces and enhances the appearance and quality of the product, which is especially crucial in industries like automotive manufacturing, aerospace, electronics, and more.

16 Supported Languages for the Laser Rust Removal

HANTENCNC’s laser rust removal currently supports Chinese, Traditional Chinese, English, Russian, Japanese, Spanish, German, Korean, French, Polish and 16 other languages.

You can easily switch between these language options directly on the handheld laser rust remover’s interface. We also provide customized language services if you require any other languages.

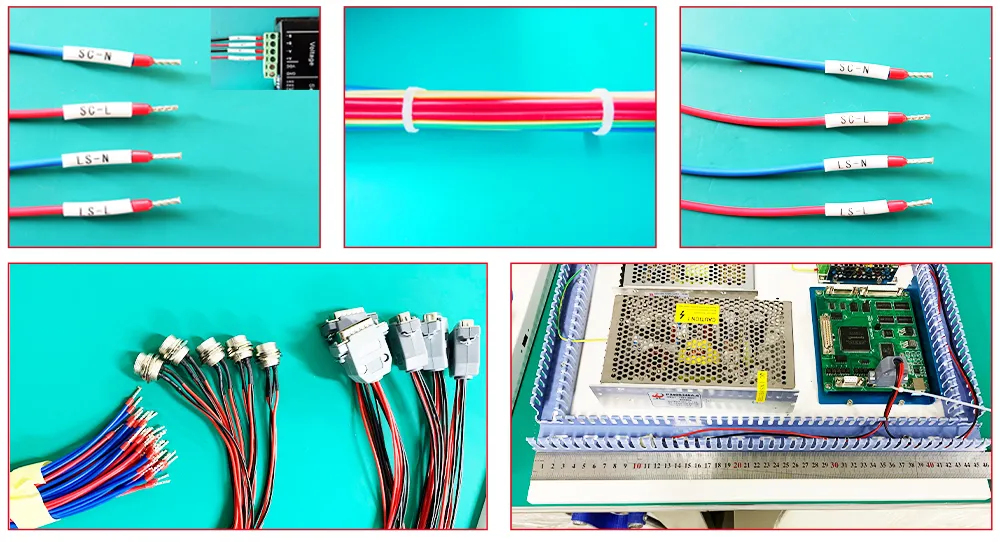

Well-organized Internal Wiring

Neat internal wiring reduces the risk of cable entanglement and friction, reduces the probability of short circuits and electrical failures, and thus enhances the safety of equipment.

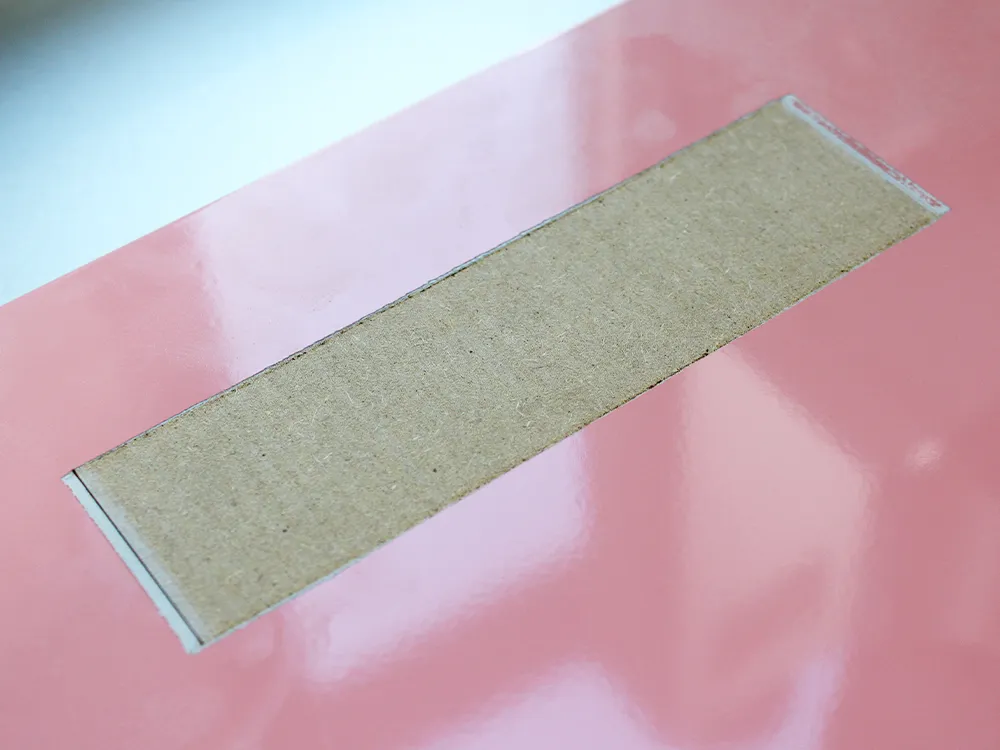

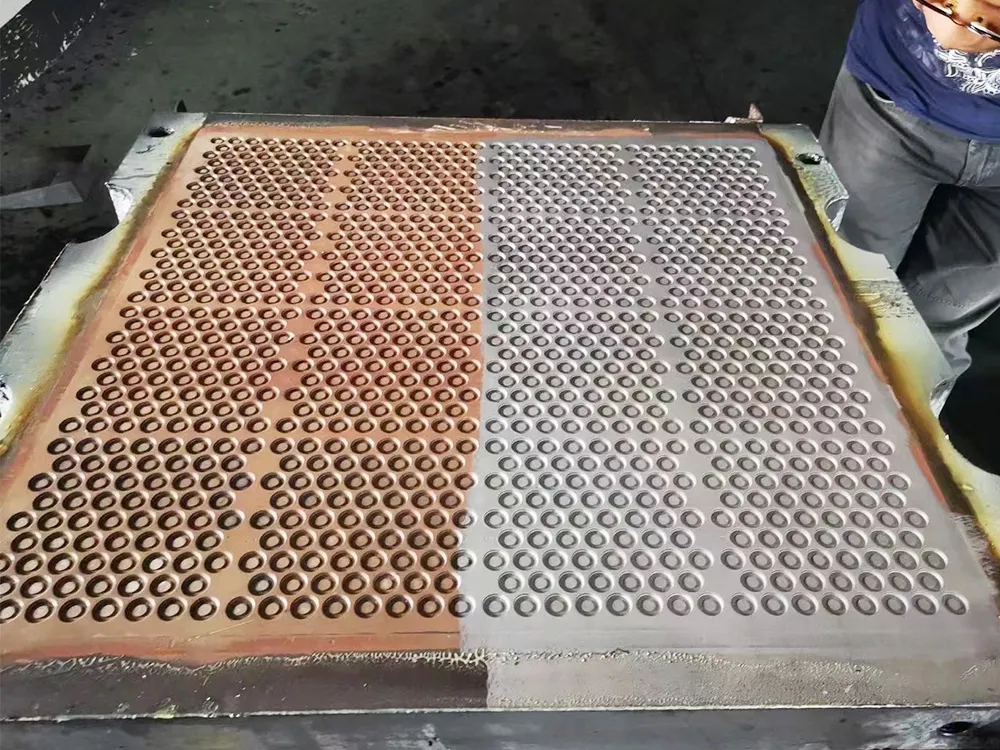

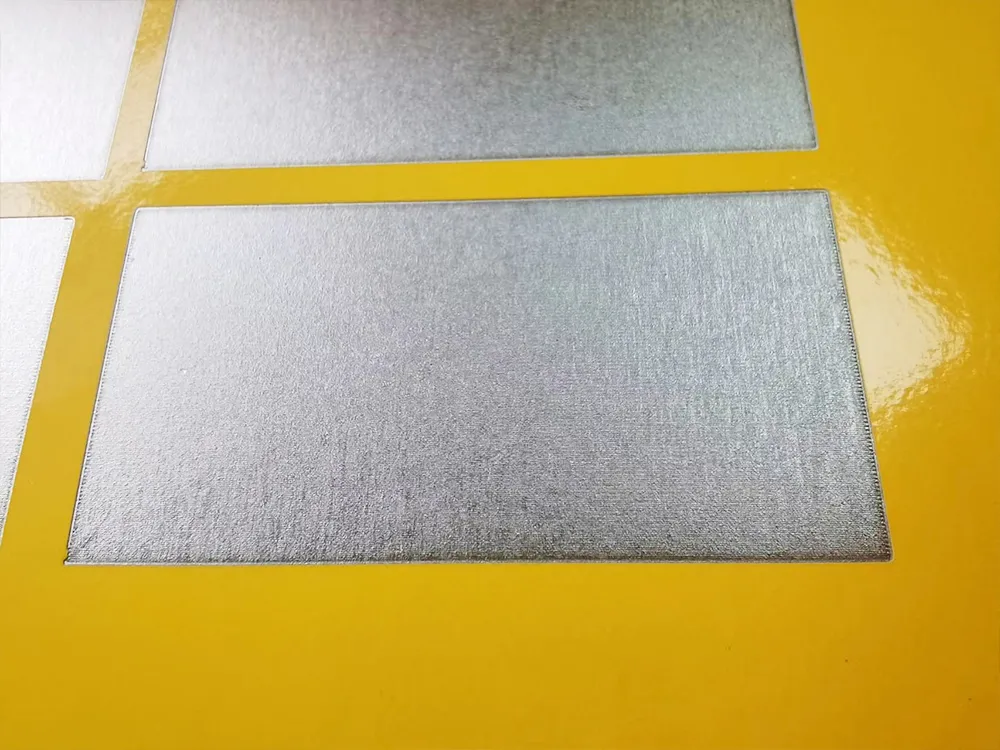

Laser Rust Removers' CLeaning Effects: Before vs. After

Parameters of 300W Laser Rust Removal Machine

Handheld Laser Rust Remover Parameters |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | HTCM300 | |||||||||||

| Laser power | 300W | |||||||||||

| Working Voltage | 110/220V 50/60 HZ | |||||||||||

| Laser Working Mode | Pulse | |||||||||||

| Laser Source | JPT | |||||||||||

| Average Laser Power | >300W | |||||||||||

| Power Instability | <5% | |||||||||||

| Maximum Pulse Energy | 15mJ | |||||||||||

| Pulse Width | 2-500ns | |||||||||||

| Cooling Method | Water Cooling | |||||||||||

| Power Regulation Range(%) | 0-100( Gradient Adjustable) | |||||||||||

| Repeat Frequency(kHz) | 1-4000(Gradient Adjustable) | |||||||||||

| Fiber Cable Length | 5m | |||||||||||

| Cleaning Head Weight (including isolator) | <1.5Kg | |||||||||||

| Working Environment Humidity | ≤80% | |||||||||||

| Working Environment Temperature | 10℃~40℃ | |||||||||||

| Machine Dimensions (Length, width and height) | About 950mm*400mm*710mm | |||||||||||

| Machine Weight | About 80Kg | |||||||||||

Laser Cleaning Head Parameters |

||||||||||||

| Cleaning Head Weight | Less Than 1.25Kg | |||||||||||

| Scanning Width | 0-145mm Optional | |||||||||||

| Scanning Frequency | Not Less Than 300Hz | |||||||||||

| Maximum Scan Line Speed | About 30m/s | |||||||||||

| Maximum Scanning Speed | 20000mm/s | |||||||||||

| Light Transmittance | ≥98% | |||||||||||

| Laser Power Adjustment | 10%-100% | |||||||||||

| Focal Length | Standard configuration 210mm (160mm/254mm/330mm/420mm optional) | |||||||||||

| Incident Spot Diameter | ≤10mm | |||||||||||

| Cable Length | Standard configuration of 10m | |||||||||||

Customer Visits

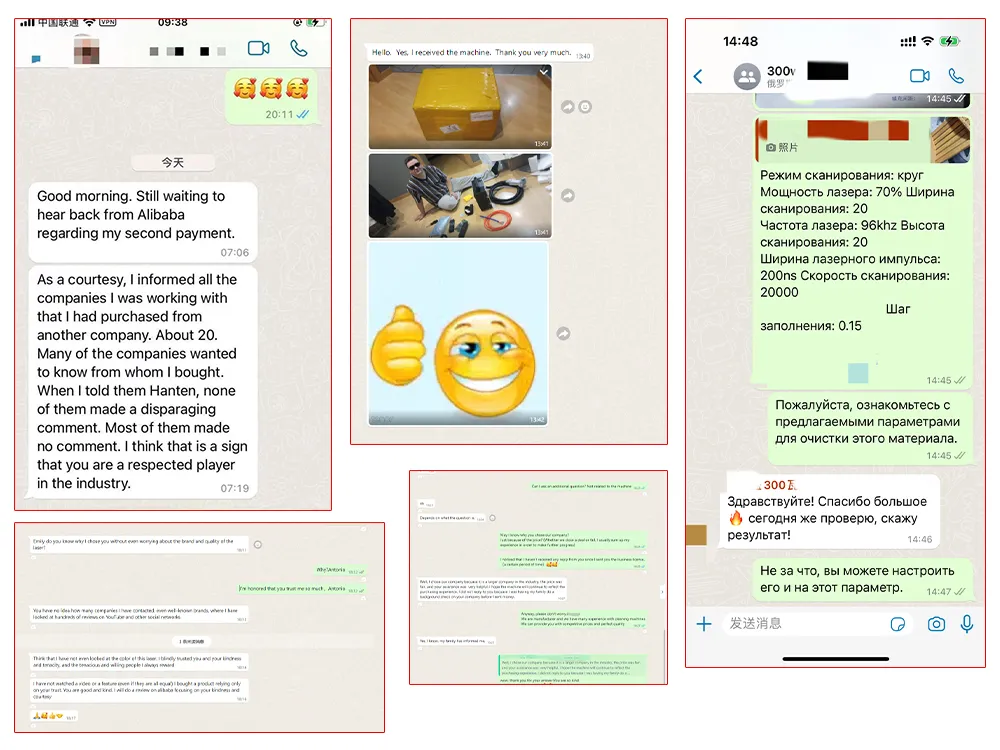

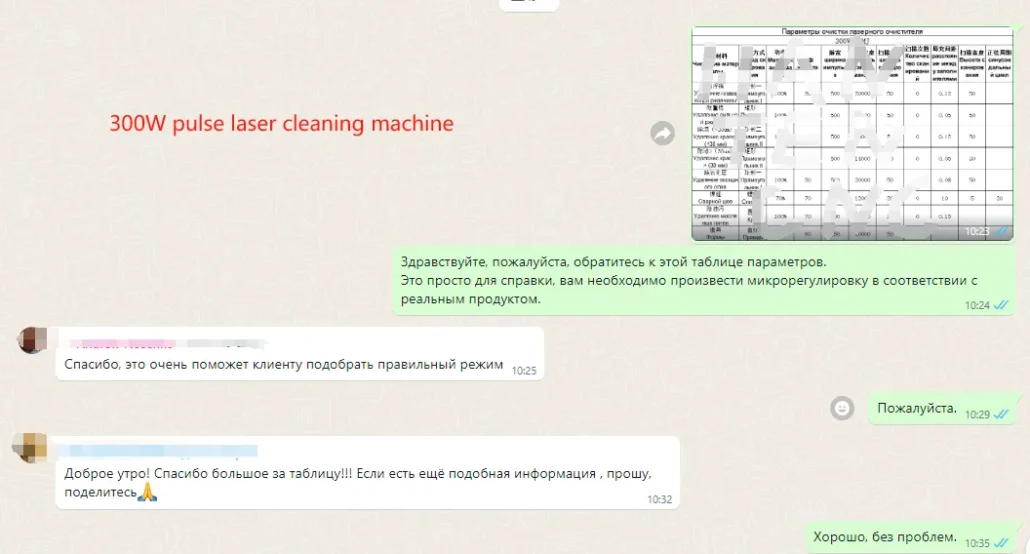

Customer Reviews

Quality Certificate