Demonstration Video

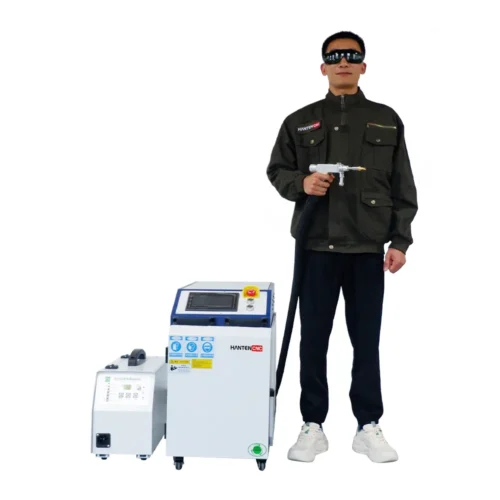

1500W 2000W Laser Welding Machine For Mold Display

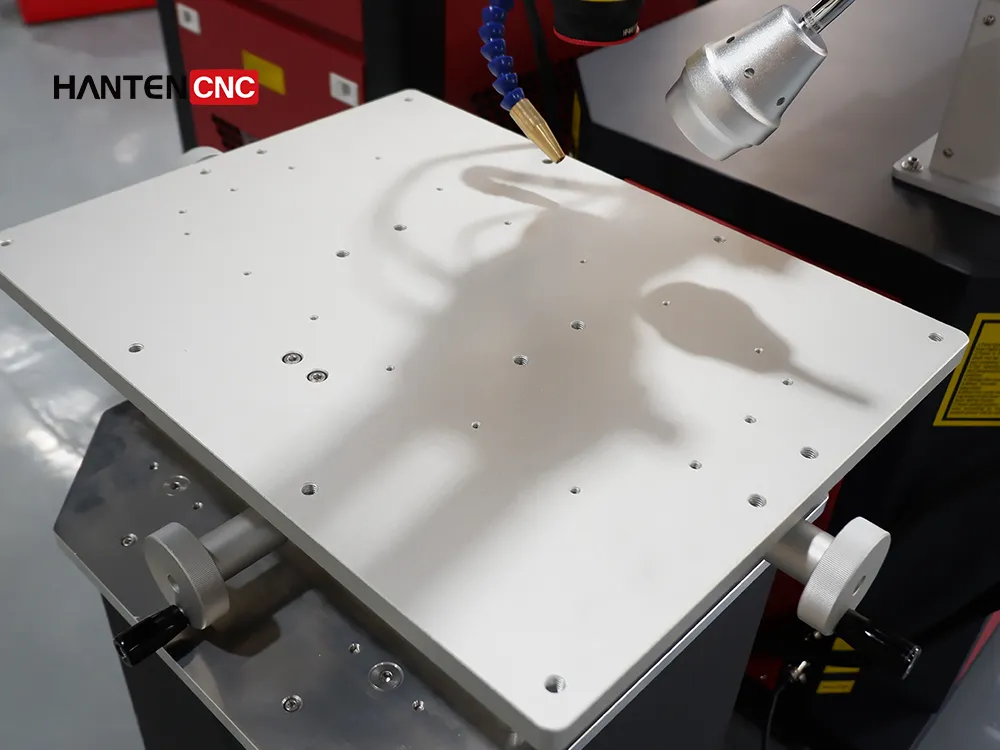

Fiber Laser Welding Machine For Mold Details

Component Detail Display of Mold Laser Welding Machine

1500W 2000W Laser Welding Machine For Mold Parameter

| Machine power | 1500W/2000W |

|---|---|

| Laser wavelength | 1064mm |

| Fiber length | 10M/12M/15M/Maximum20M |

| Output power | 1500W/2000W |

| Overall Power Consumption | 7400W/8900W |

| Maximum Oscillation Speed | 20000mm/s |

| Spot adjustment range | 0.2-2mm/0.3-3mm |

| Laser frequency | 1-20HZ/1-30HZ |

| Cooling system | 1.5P/3P |

| Aiming and positioning | CCD or microscope |

| Host welder dimensions and weight | 174*74*144mm/245kg |

| Water Chiller dimensions and weight | 84*65*120mm/108kg |

Advantages of Laser Mold Welding Machine

-

Fine welding:

Mold laser welding machines can achieve high-precision and fine welding, helping to repair small and complex mold parts.

-

Small heat-affected zone:

The laser produces a relatively small heat-affected zone, which helps to reduce thermal deformation and material deterioration.

-

Partial repair:

The welding area can be precisely controlled to achieve local repair of damaged molds without affecting other parts.

-

Adaptable to a variety of materials:

The laser has good adaptability to a variety of metal materials, so it can be used to repair different types of molds.

-

High energy density:

The high-energy-density pulsed laser can penetrate the material and generate sufficient heat in the welding area, making it suitable for repair work that requires weld depth.

-

Quick fix:

Mold laser welding machines usually have high welding speeds and can complete mold repair work in a relatively short time and improve production efficiency.

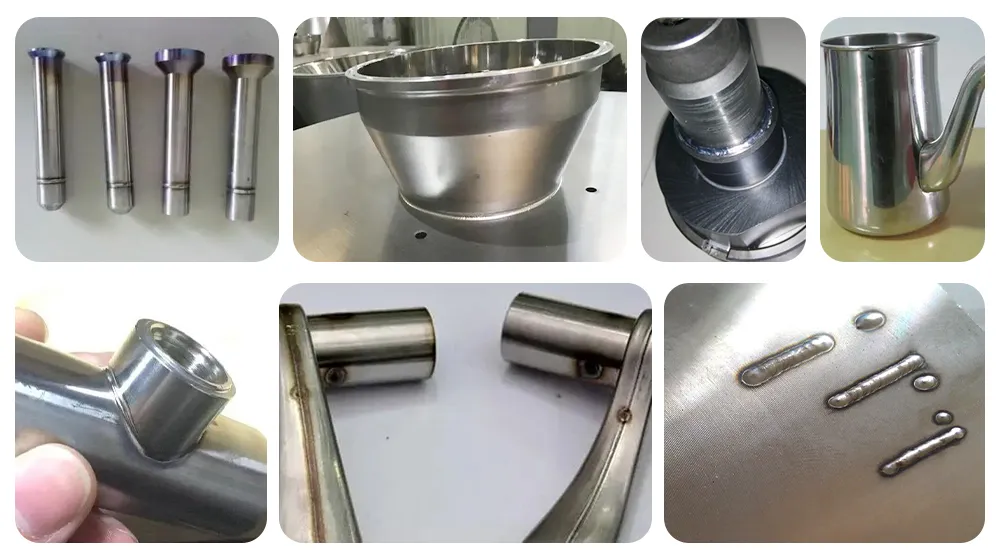

Welding Results Display

Customer Visits

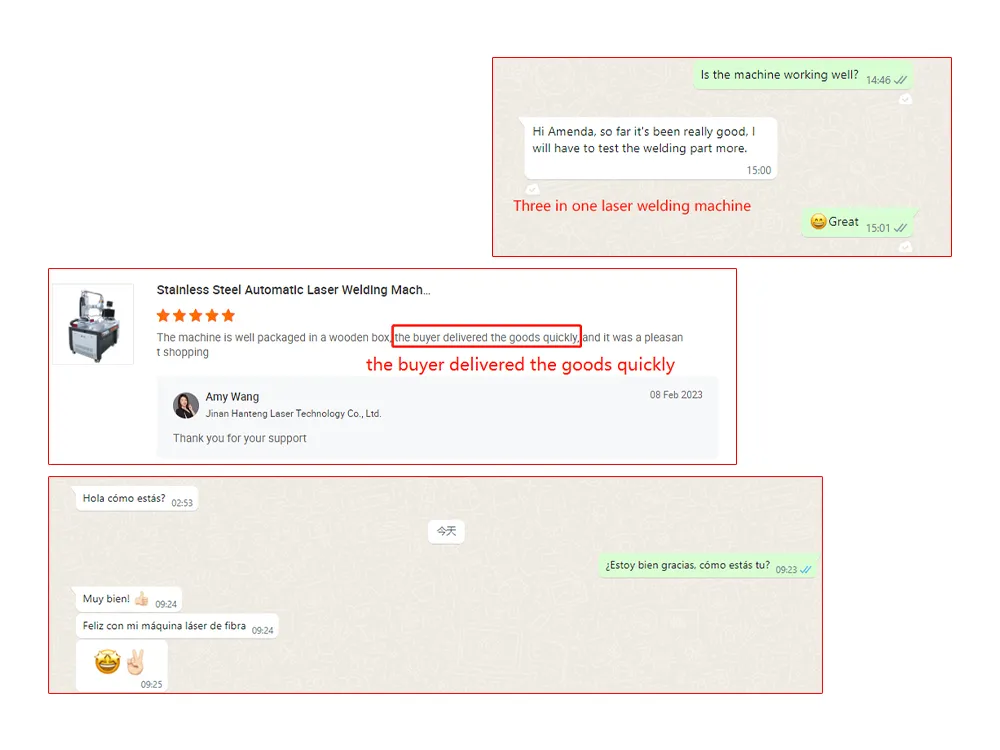

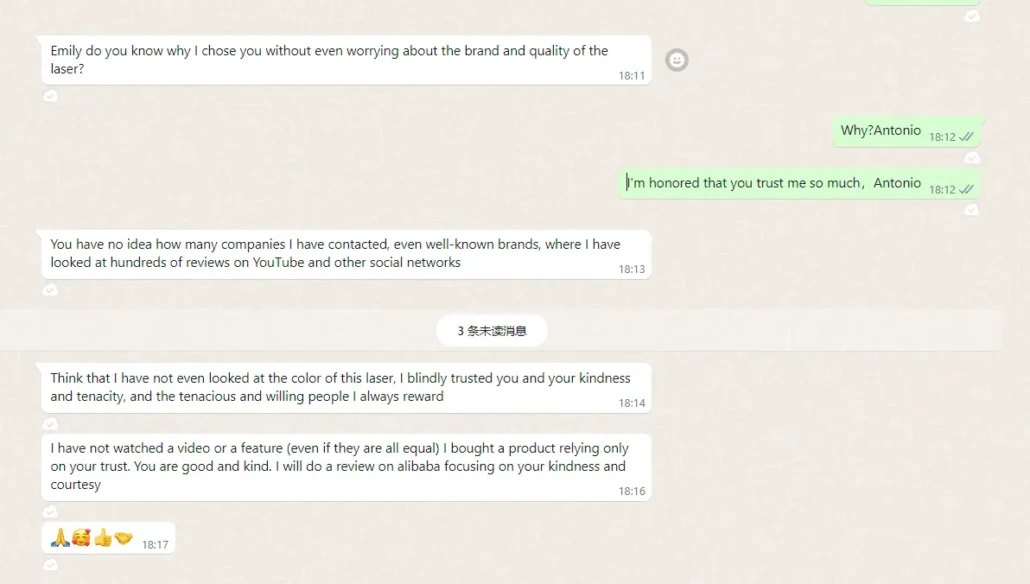

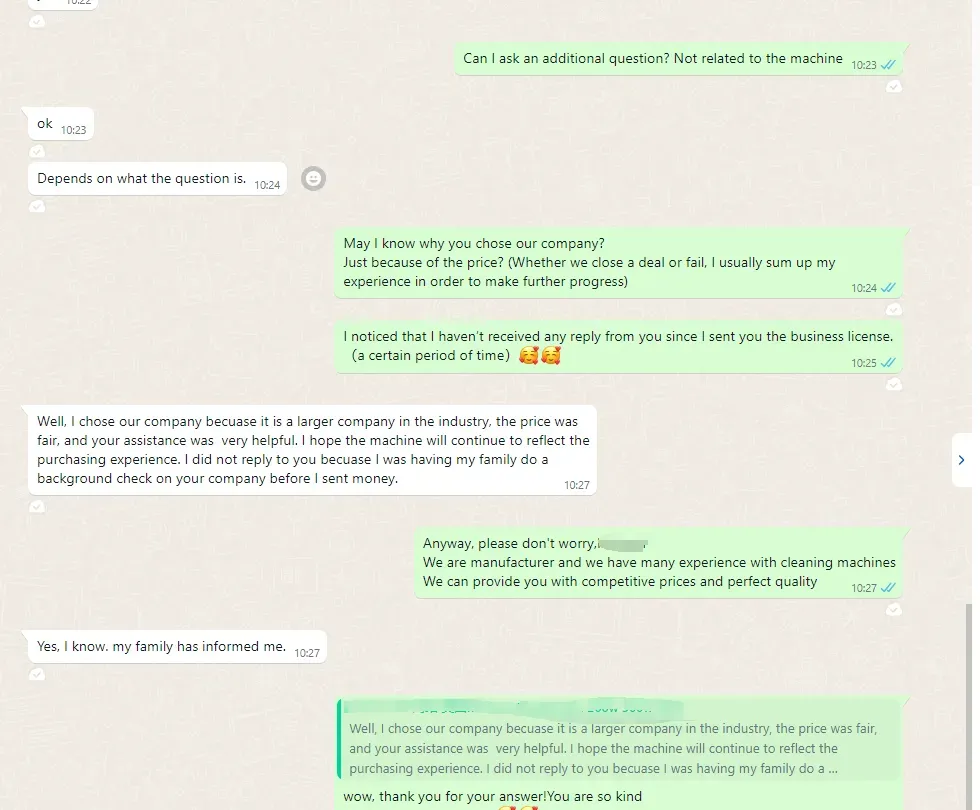

Customer Reviews