Advantages Of CO2 Glass Laser Marking Machine

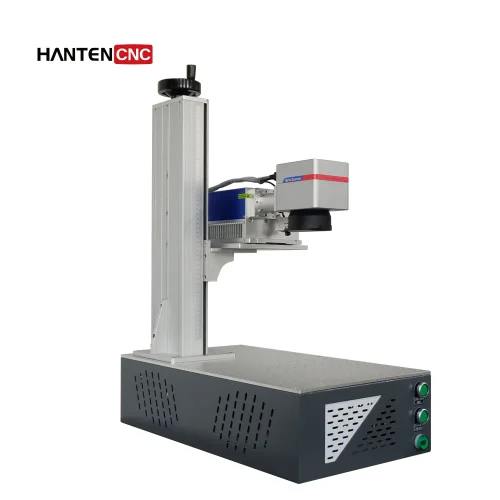

- The CO2 glass tube laser marking machine has a high-power output of 100W and can complete complex and precise marking tasks in a short period of time.

- The 3D dynamic focus control technology significantly improves the accuracy and efficiency of marking, achieving a marking area of 600 * 600mm.

- The galvanometer adopts FEELTEK high-speed dynamic module, ensuring fast response and stable operation.

- Using glass tube laser, it has low cost and is easy to replace, with good cooling effect and stable performance, suitable for long-term continuous operation.

CO2 Glass Laser Marking Machine Display

CO2 Glass Laser Marking Machine Component

CO2 Glass Laser Marking Machine Parameters

| Model | THCS-100 |

| Power | 100W |

| Power stability rate | ±4% |

| Laser source | Davi |

| Galvanometer | 3D FWWLTEK |

| Wavelength | 10.6μm |

| Marking area | 600*600mm adjustable |

| Beam quality | M2﹤1.2 |

| Beam diameter (1/e²) | 2.5 |

| Operating frequenc (KHZ) | 0-100% |

| Input voltage/current | 48V/30A |

| Maximum thermal load | 1400W |

| Cooling method | Water cooling |

Details Description Of CO2 Glass Laser Marking Machine

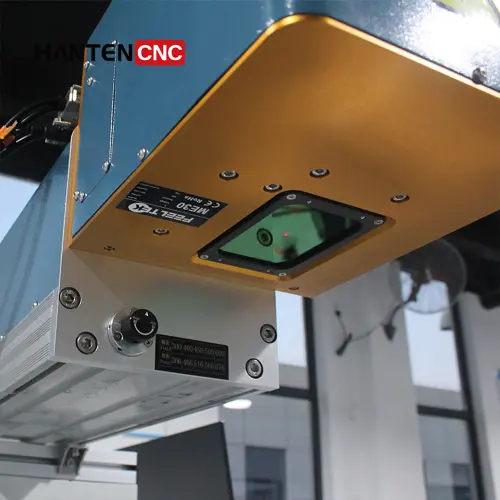

3D Dynamic Focusing System

The 3D FEELTEK galvanometer system typically supports three-axis control (X, Y, Z), enabling precise laser positioning and processing in three-dimensional space.

It adopts dynamic focusing control technology to adjust the focus position in real time, and can perform distortion free marking on large surfaces, 3D surfaces, steps, cones, slopes, and other objects.

Computer Display Screen

The CO2 glass laser marking machine adopts a side mounted computer display screen, which optimizes the spatial layout of the equipment and avoids the problem of occupying additional space.

Through the computer display screen, you can monitor the process of laser marking in real time and adjust parameters in real-time, providing an intuitive user interface, making the operation simpler and more intuitive.

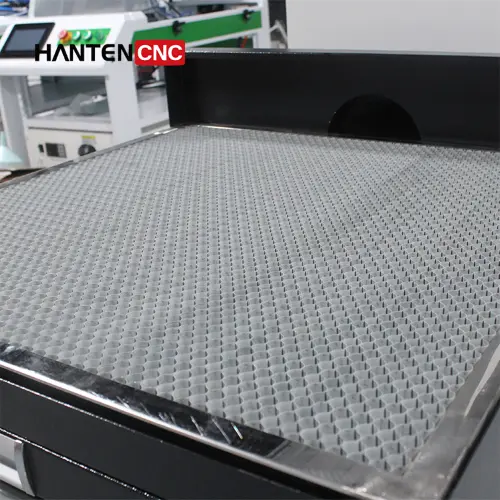

Adjustable Workbench Height

Our glass laser marking machine can adjust the height of the workbench, which can flexibly adapt to different sizes and shapes of workpieces, and meet diverse marking needs.

You can adjust the workbench to the appropriate height according to your needs, improve work comfort and satisfaction, and reduce the fatigue of long-term work.

Water-cooling System

Our glass laser marking machine adopts a water-cooled system. Compared with an air-cooled system, the water-cooled system usually operates quieter and provides precise and stable temperature control, helping to maintain the quality and consistency of the laser beam.

Water cooling systems are usually enclosed to prevent external dust and pollutants from entering the cooling circuit, protecting the cleanliness and safety of the laser and cooling system.

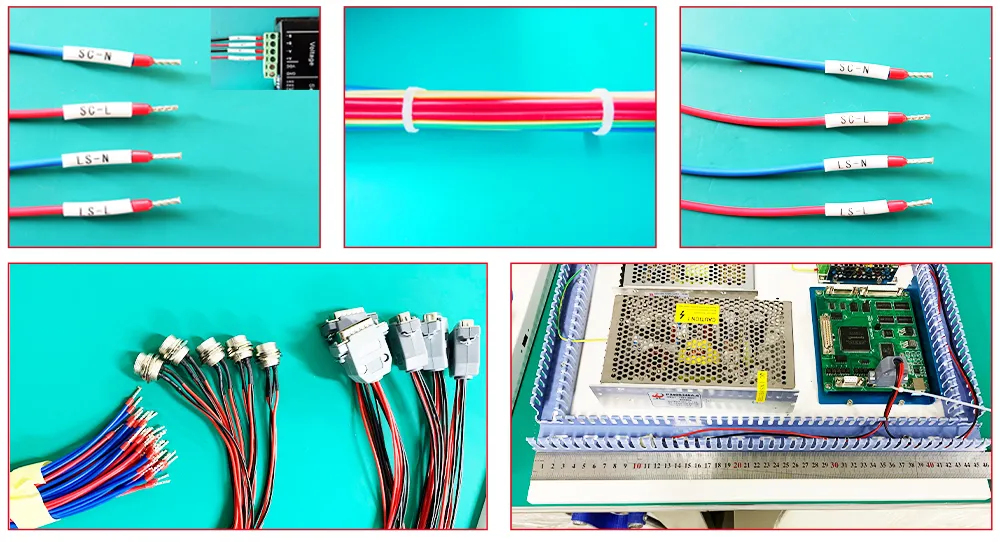

Well-organized Internal Wiring

Our glass tube laser marking machine has clear internal circuit markings and orderly arrangement, which not only prevents circuit interference and short circuits, but also facilitates maintenance.

CO2 Glass Laser Marking Machine Sample Display

Our glass tube laser marking machine adopts CO2 laser processing technology, which can accurately and quickly mark materials such as fibers, fabrics, crystals, acrylic, ceramics, plastics, metals, etc.

Customer Visits

Customer Reviews

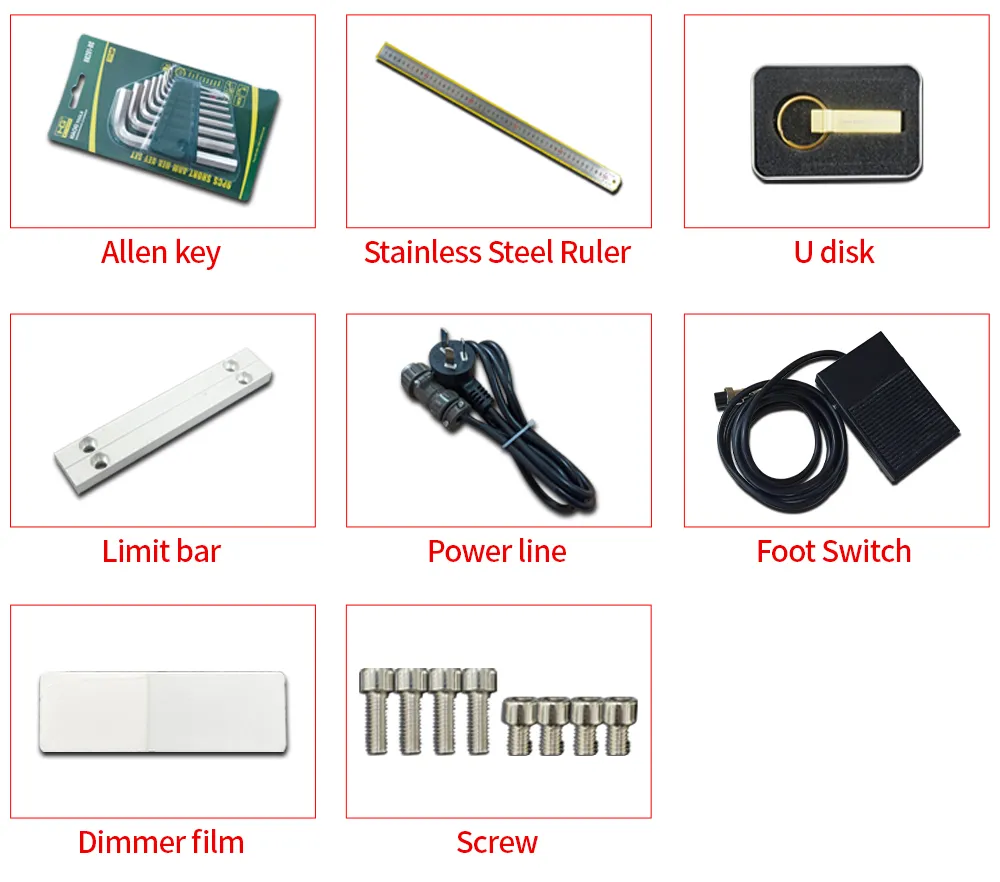

CO2 Glass Laser Marking Machine Included Accessories

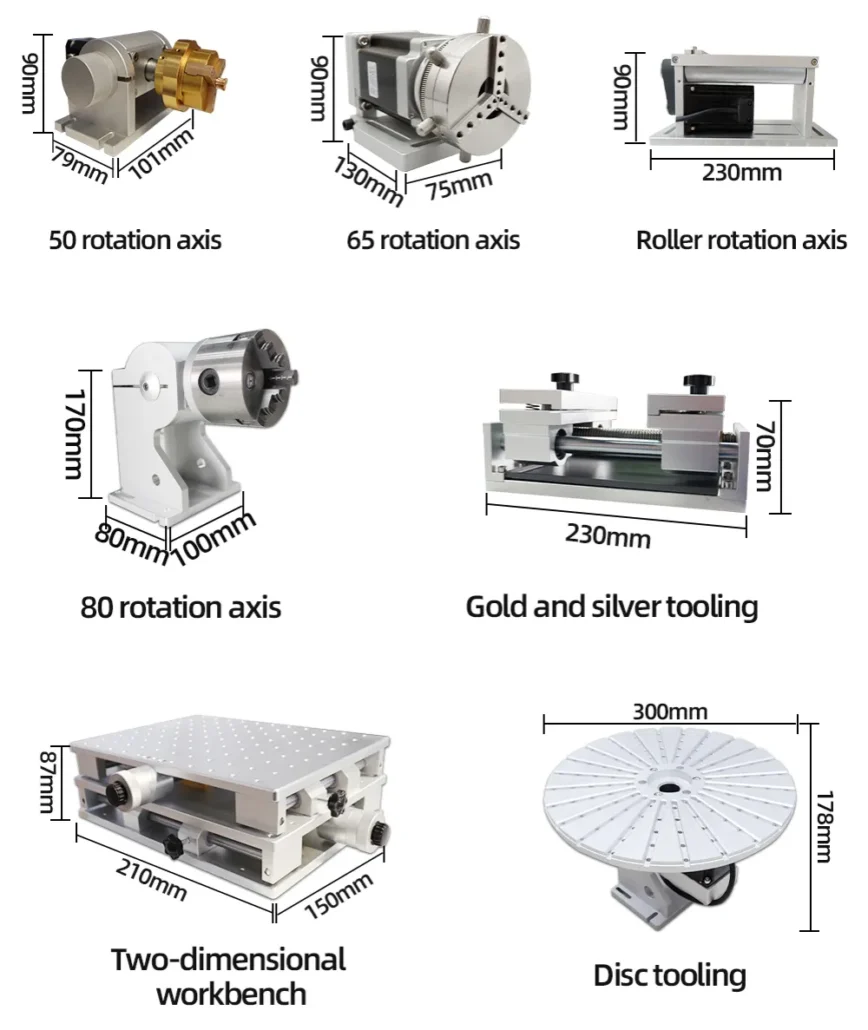

CO2 Glass Laser Marking Machine Accessory Selection

Qualification Certifications

HANTENCNC Partnerships