New 20W/30W/50W Handheld Laser Marking Machine

This handheld laser marking machine supports handheld operation for flexible and convenient use. The entire unit weighs only 8KG and features an ergonomic design with an 8-inch tempered capacitive touchscreen.

The laser marking machine offers one-click startup, a standard power interface, and a detachable battery, enabling effortless extended operation.

It supports the marking of text, patterns, QR codes, barcodes, and Excel files. It is compatible with PLT, JPG, DXF, BMP, and other vector and image formats to meet diverse marking needs.

It can be applied to a wide range of materials, including iron, copper, aluminum, stainless steel, various metals, coated paper, painted glass, plastic, and painted wood. It is certified by CE, FCC, FDA, RoHS, and other authoritative standards.

With technical upgrades based on the original model, this handheld laser marker delivers enhanced performance at a more affordable price. Equipped with a high-capacity battery, efficient cooling system, and high-precision optical module, it ensures stable full-power output without heat buildup, significantly improving productivity.

Powered by an 8-core Linux system and a user-friendly interface, it streamlines operation and efficiently handles various marking tasks. An emergency stop switch is also included for enhanced safety. Regardless of your industry, if you require marking, this machine will exceed your expectations and deliver outstanding results.

Ultra-Portable Design

Weighing just 8kg with an 8-inch intuitive touchscreen and ergonomic grip, this marker delivers comfortable, user-friendly operation wherever your work takes you.

Power Supply Options: Plug-in vs. Battery-Powered Models

Our handheld laser marking machines offer flexible power supply options, including a removable battery-powered version and a standard plug-in version, to meet the needs of various working environments.

🔌 Plug-in Handheld Laser Marker Version

The standard plug-in model is ideal for fixed locations such as workshops, providing stable and reliable plug-and-play operation.

🔋 Removable Battery Laser Marker Version

The battery-powered model features a removable lithium battery, making it particularly suitable for mobile applications or outdoor use and ensuring continuous and efficient performance.

The battery version not only supports battery power but can also be plugged in, allowing for dual power modes. Users can switch between power sources according to their actual needs.

It supports marking while charging, eliminating the need to wait for the battery to recharge and greatly improving work efficiency—making it a reliable solution for both daily marking needs and challenging on-site applications.

Whether for long-duration continuous operation or emergency marking tasks, the battery-powered handheld laser marking machine delivers convenient, stable, and efficient marking performance.

Battery Performance:

Charging Time: About 3 hours to full charge (supports fast charging).

Continuous Runtime: 3-4 hours per charge (varies by usage intensity).

Field Use Tip: Carry a spare battery for all-day operation in outdoor.

Note: Cold environments may reduce battery efficiency.

Dual-Safety Laser Activation

In addition to the basic laser switch button, this handheld laser marking machine is also equipped with an optical distance sensor. There is a white spacer at the bottom of the device. The laser will only be triggered when the spacer comes into contact with the punching material. Even if the laser switch is pressed, the laser will not be activated when the marking material is not in contact.

This design greatly reduces the risk of accidental triggering to the operator and complies with the safety standards of the laser marking machine industry.

Double-Layer Coated Galvanometer Lenses

Our galvanometer lenses employ a double-layer coating process, whereas other brands typically use a single-layer coating.

The double-layer coating not only resists high temperatures and withstands high-power laser energy, but also the high-precision coating reduces light scattering on the lens surface, minimizes power loss, and ensures a more concentrated and effective laser beam.

Optional Accessories (Sold Separately)

Want to take your laser marking to the next level?

When you’re tackling big jobs, the Extension Roller Kit lets you mark large surfaces in one smooth motion – no repositioning needed.

The Cooling Fan System keeps your workspace spotless by zapping away dust on the fly.

Our heavy-duty desktop stand provides rock-solid stability for precision work.

Extension Roller Kit

Enables smooth large-area marking.

Cooling Fan System

Efficient dust removal for cleaner operation.

Desktop Stand

Heavy-duty aluminum base for stable, hands-free marking.

22 Languages Supported

This handheld laser marker supports 22 major languages – from English and Spanish to Arabic and Chinese – making it truly global-ready. The intuitive multilingual interface ensures operators worldwide can use it comfortably right out of the box.

No more confusing menus or translation headaches – just straightforward operation in the language you know best. It’s smart localization that makes high-tech laser marking accessible to everyone, everywhere.

- Arabic (العربية)

- Bengali (বাংলা)

- Czech (Čeština)

- German (Deutsch)

- Greek (Ελληνικά)

- English

- Spanish (Español)

- Persian (فارسی)

- French (Français)

- Hungarian (Magyar)

- Italian (Italiano)

- Japanese (日本語)

- Korean (한국어)

- Dutch (Nederlands)

- Polish (Polski)

- Portuguese (Português)

- Russian (Русский)

- Thai (ไทย)

- Turkish (Türkçe)

- Vietnamese (Tiếng Việt)

- Simplified Chinese (中文简体)

- Traditional Chinese (中文繁體)

20W/30W/50W Handheld Laser Marking Machine Introduction Video

20W/30W/50W Handheld Laser Marking Machine Components

20W/30W/50W Handheld Laser Marking Machine Dimensions

Front View

Side View

20W vs 30W vs 50W – How to Choose the Right Wattage?

20W – For Everyday Marking Tasks

The 20W handheld laser marker is ideal for users with basic marking needs; it is perfect for marking serial numbers, barcodes, logos, and QR codes on metal and certain plastics. It’s energy-efficient, lightweight, and easy to handle—great for small-scale production, light-duty tasks, or mobile applications.

30W – The All-Rounder

The 30W handheld laser marker can handle a broader range of materials and provide faster marking speeds. It’s well-suited for most general-purpose tasks in workshops, factories, or on-site jobs—whether you’re marking tools, equipment, nameplates, or components.

50W – For Deep or High-Speed Marking

The 50W handheld laser marking machine is designed for more demanding applications, delivering deeper engraving and higher throughput.

Suppose you need to mark harder metals, deeper layers, or achieve faster cycle times in a high-volume production environment. In that case, the 50W model offers the performance you need without compromising mobility.

20W/30W/50W Handheld Laser Marking Machine Parameters

| Model | HTF20 | HTF30 | HTF50 |

|---|---|---|---|

| Laser Wavelength | 1064mm | 1064mm | 1064mm |

| Laser Frequency | 30-60kHz | 40-60kHz | 50-80kHz |

| Power Voltage | 110V/220V | 110V/220V | 110V/220V |

| Power Frequency | 50-60Hz | 50-60Hz | 50-60Hz |

| Total Power Consumption | ≤200W | ≤200W | ≤250W |

| Output Power | 20W | 30W | 50W |

| Marking Area | 70*70mm、100*100mm | 70*70mm、100*100mm | 70*70mm、100*100mm |

| Marking Speed | ≤7000mm/s | ≤7000mm/s | ≤7000mm/s |

| Marking Line Width | 0.03mm | 0.03mm | 0.03mm |

| Minimum Character Size | 0.15mm | 0.15mm | 0.15mm |

| Cooling Method | Air-cooled | Air-cooled | Air-cooled |

| Repeat Positioning Accuracy | 0.01mm | 0.01mm | 0.01mm |

| Supported Image Formats | BMP、DXF、HPGL、JPEG、PLT | BMP、DXF、HPGL、JPEG、PLT | BMP、DXF、HPGL、JPEG、PLT |

| Net Weight | 6-6.8KG | 6-6.8KG | 8-8.8KG |

| Package Dimensions | 525*423*310mm | 525*423*310mm | 525*423*310mm |

| Package Weight | 9-9.8KG | 9-9.8KG | 11.5KG-12.5KG |

Details of Optional Accessories (Available at Additional Cost)

This handheld portable marking machine has different accessories for you to choose from: desktop stand, cooling fan system, magnetic base and extended roller kit.

You can flexibly select and combine these accessories according to your specific needs to maximize the performance and efficiency of the marking machine, ensuring that tasks can be completed with ease in various application scenarios.

Desktop Stand (Sold Separately)

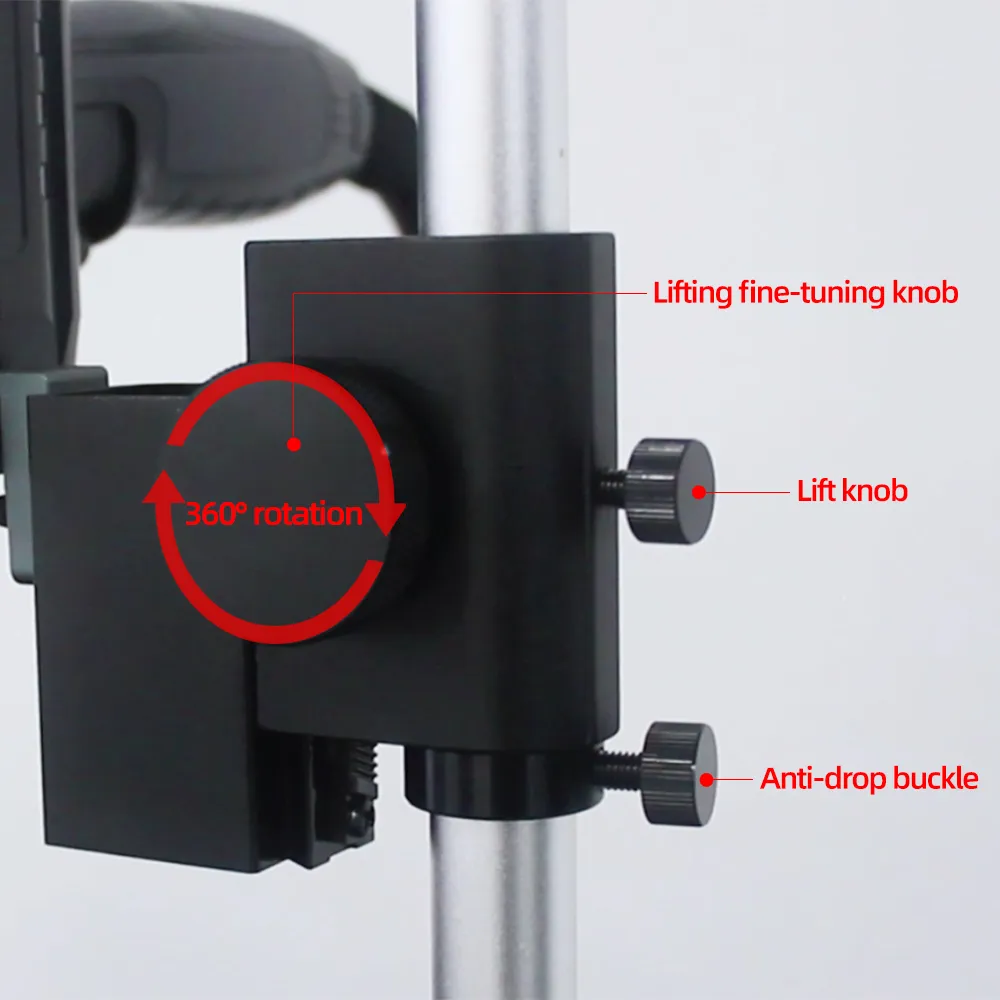

Focusing adjustment Function

The small desktop stand equipped with this handheld laser marking machine allows for precise focus adjustment. This feature allows you to calibrate the laser marking focal distance quickly.

Positioning Function

Adopting dual red light positioning technology, when the two red dots are focused and overlap, the focal distance calibration is completed, and you can start laser marking.

Structural Advantages

The stand features a complete aluminum alloy large-format base, ensuring a sturdy and long-lasting structure.

The extra-long column design supports different height adjustments, making it suitable for various materials and marking scenarios.

There is a small knob on the side of the stand, which is a liftable calibration knob. It can be used to adjust the focal distance up and down to achieve rough positioning and help you find the approximate marking focal distance.

There is a large circular knob on the stand, achieving precise focus calibration. It can be used to fine-tune the focal distance up and down for accurate positioning.

Cooling Fan System (Sold Separately)

Improve Marking Accuracy

During the marking process, dust and particles will be generated when the laser acts on the surface of the material. Adding a cooling fan to the focal length positioning cover can quickly blow away the particles generated during the marking process, thereby keeping the working area clean and effectively improving the marking effect, making the marking more delicate and clear.

Protect the Field Lens

The dust and particles generated during the laser marking process are easy to adhere to the field lens. Long-term accumulation will reduce the transmittance of the lens, affect the quality of marking, and accelerate the wear rate of the lens. The configuration of the fan can reduce the accumulation of these particles on the lens surface, thereby effectively protecting the field lens, extending its service life, and reducing maintenance costs.

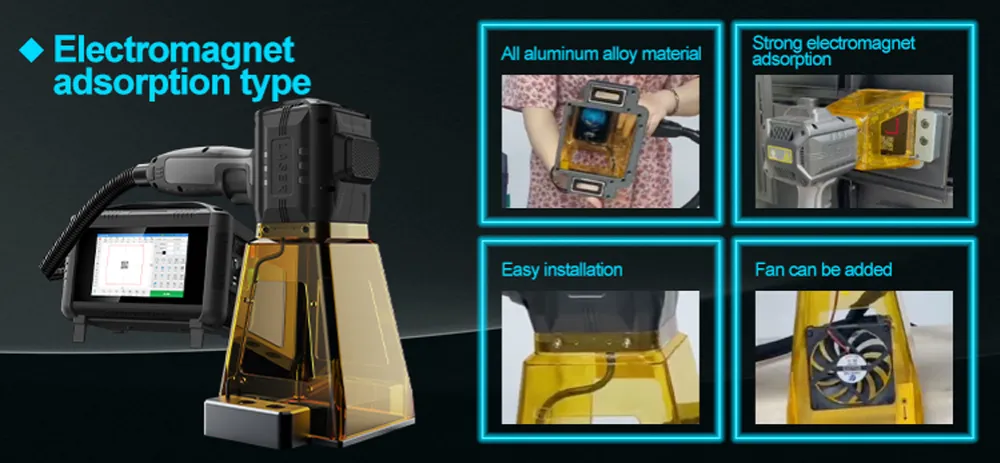

Magnetic Base(Sold Separately)

The magnetic base is made of all-aluminum alloy material, which is lightweight, corrosion-resistant, moderately strong, not easy to deform or damage, ensuring the durability of the equipment in various environments.

It features an electromagnetic adsorption design, capable of generating a magnetic suction force of up to 80 kg. Whether it is horizontal marking or vertical marking material, the adsorption is very firm. This accessory ensures the stability of the equipment during the marking process, preventing displacement or sliding.

The installation of a magnetic base is very simple, with no complicated fixing steps or additional tools required.

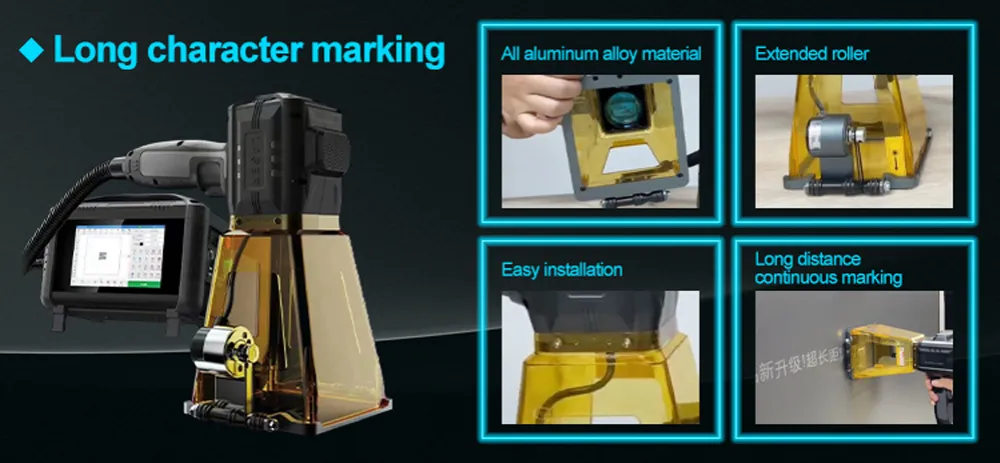

Extension Roller Kit(Sold Separately)

The design of the extended roller enables long-distance continuous marking, making it suitable for marking large areas or long strips of materials. After the roller is extended, the mobile marking is smoother, reducing the instability of manual operation. Therefore, the marking lines are more uniform and clear, greatly improving the marking quality.

Equipped with an extended roller, it can effectively improve work efficiency and reduce the time required for repeated position adjustments. Traditional marking methods require frequent pauses to adjust the marking position, but the design of the extended roller does not require this. Therefore, the error is smaller, the time consumption is less, and the marking efficiency is higher.

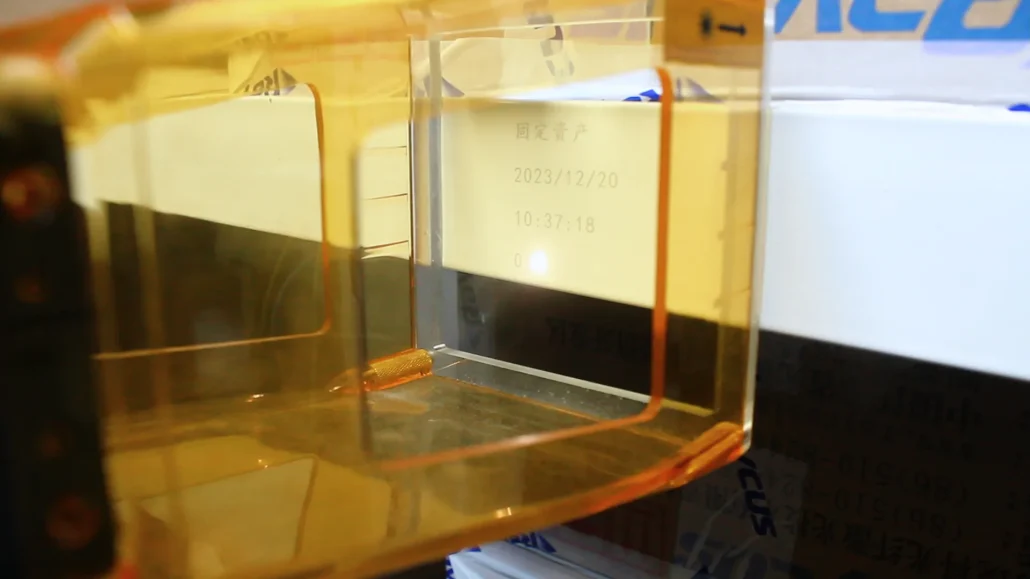

20W/30W/50W Handheld Laser Marking Samples

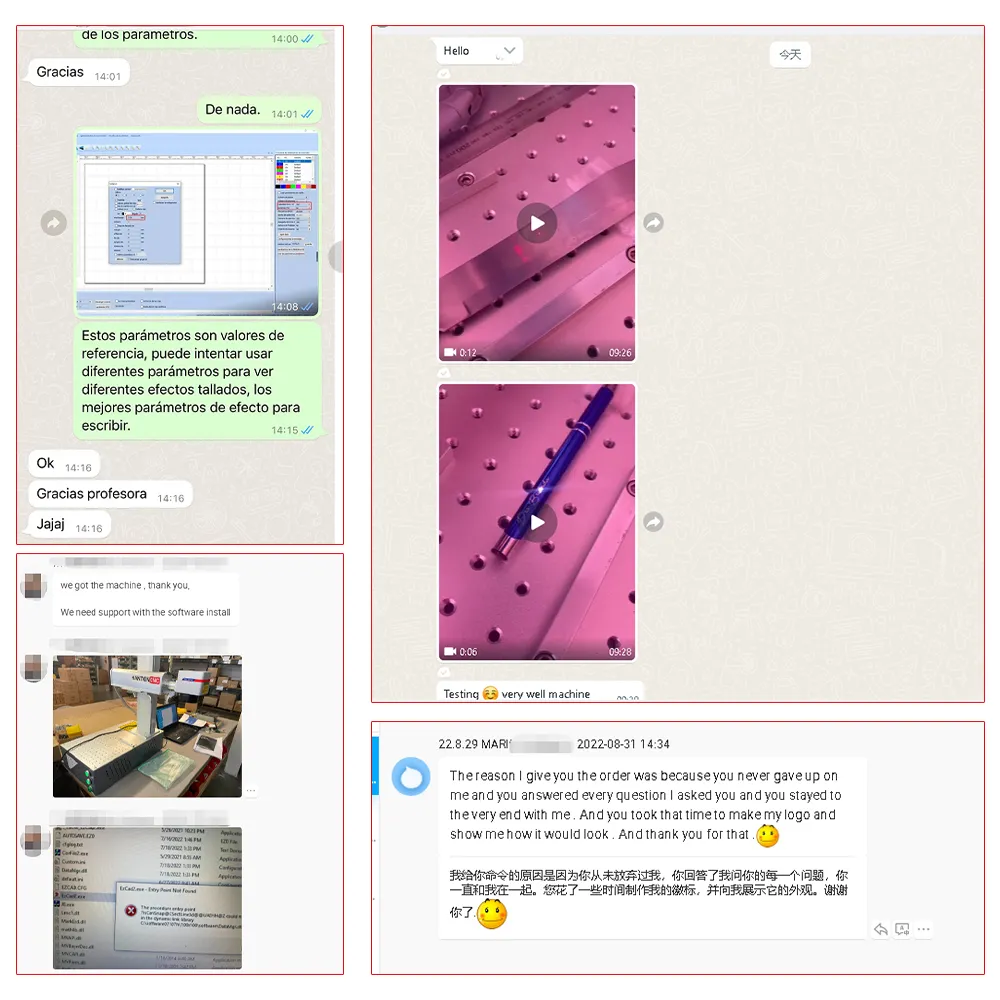

Customer On-site Demonstration

Customer Visits

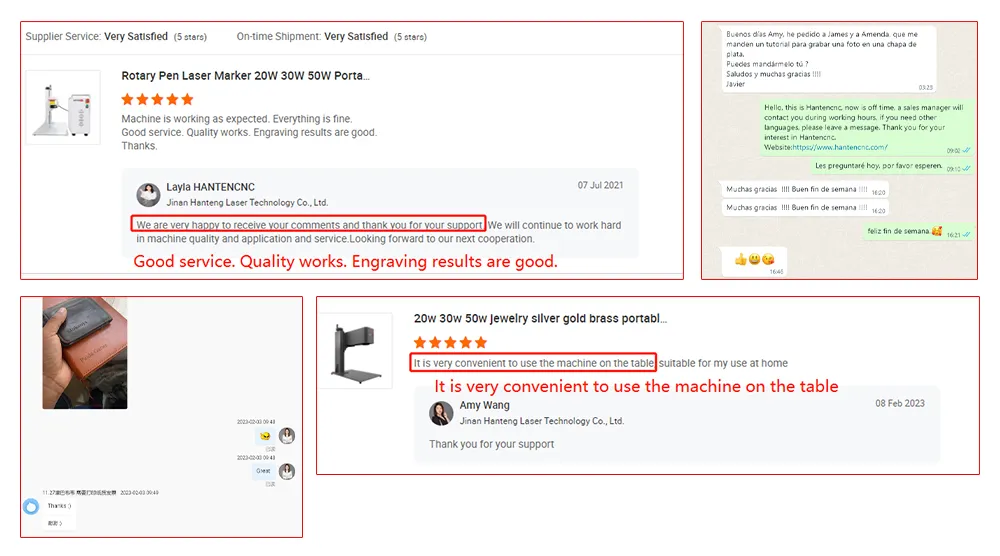

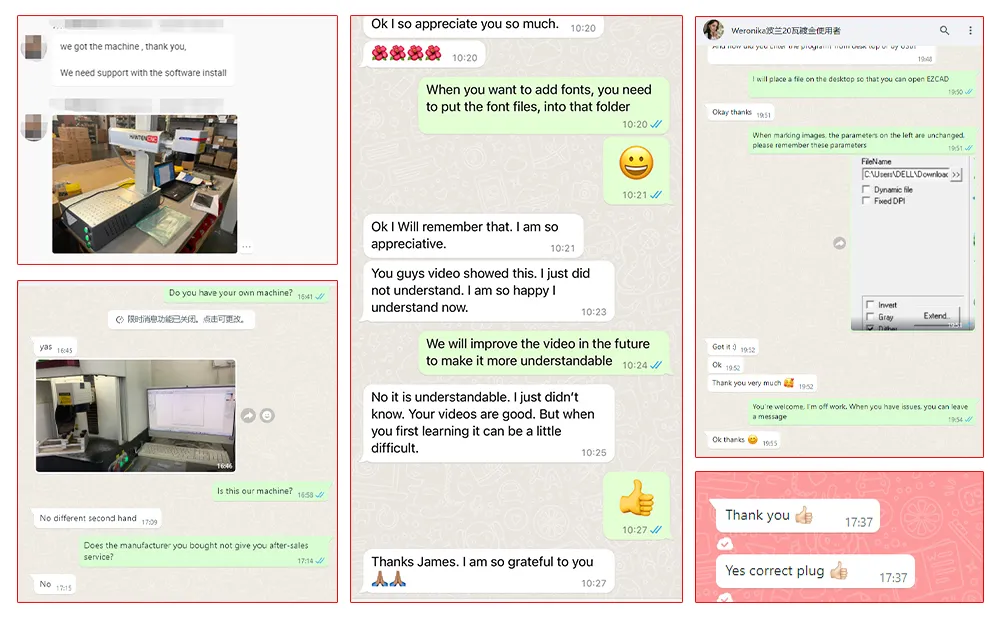

Customer Reviews

HANTENCNC Partnerships

HantenCNC Service

HANTENCNC provides full support services:

Before purchase, we provide free sample testing.

After purchase, we offer a two-year laser warranty and a one-year machine warranty.

We respond quickly to all inquiries, ensuring timely support.