Our UV laser marking machine has a compact design that saves space, making it ideal for work environments with limited room. Gainlaser lasers deliver high-precision beams while reducing energy consumption, perfect for precision marking applications.

This UV laser marking machine is perfect for marking various materials, including glass, ceramics, plastics, etc. And it is very suitable for engraving DIY customized patterns on leaves or marking other anniversary gift!

Laser UV Marking Machine Video Presentation

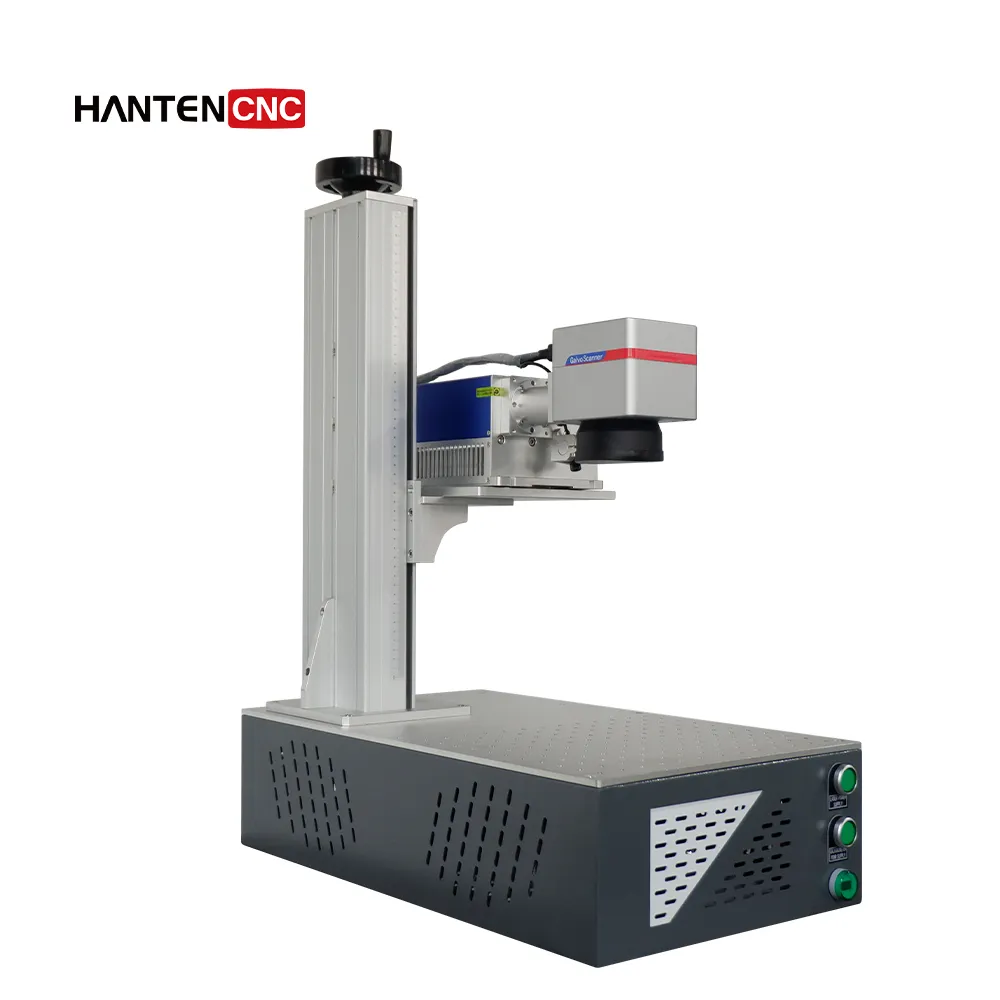

Laser UV Marking Machine Display

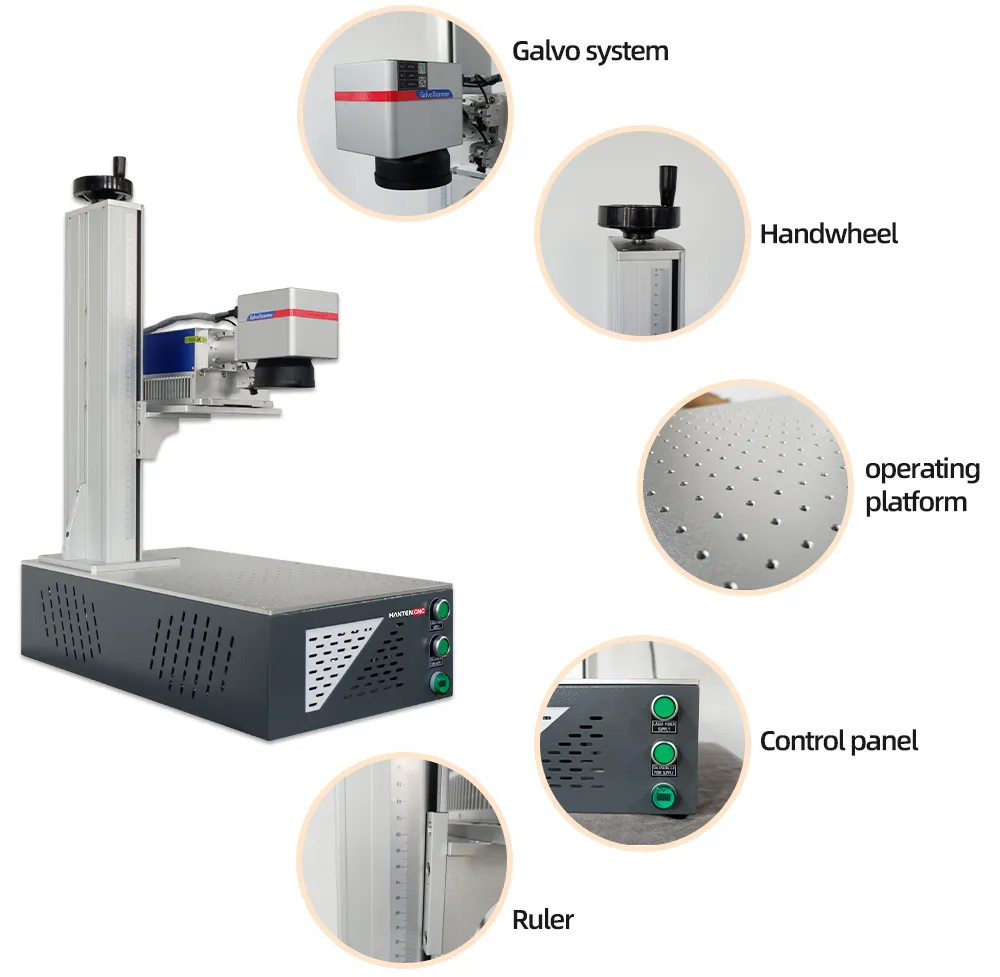

Component of Laser UV Marking Machine

Dimension of Laser UV Marking Machine

Laser UV Marking Machine Parameters

| Model | HTU-3 | HTU-5 |

| Net weight | 40kg | 40kg |

| Machine size | 800*350*650mm | 800*350*650mm |

| Cooling | Air cooling | Air cooling |

Laser Parameters |

||

| Laser source | Gainlaser | Gainlaser |

| Power | 3W | 5W |

| Marking area | 100mm-200mm | 100mm-200mm |

| Laser wavelength | 355nm | 355nm |

| Average power | >3W@30kHz | >5W@40kHz |

| Beam Quality | M²<1.2 | M²<1.2 |

| Frequency range | 1-150kHz | 1-150kHz |

| Spot diameter | 0.7±0.1mm | 0.8±0.1mm |

| Beam circularity | >90% | >90% |

| Marking speed | ≤7000mm/s | ≤7000mm/s |

| Electricity demand | 220V(110V)/50Hz(60Hz) | 220V(110V)/50Hz(60Hz) |

Details About Laser UV Marking Machine

RC1001 Galvanometer

The RC1001 galvanometer has fast response speed and high precision, ensuring that the marking pattern is clear.

It is highly durable, uses high-quality materials and precision manufacturing processes. In addition, the RC1001 galvanometer shows excellent stability during high-frequency operation, reduces errors, and has low power consumption, improving the energy efficiency of the entire laser marking system.

Air-cooling System

The air-cooling system of the UV laser marking machine shows significant advantages in resisting changes in external temperature.

First, there is no need to rely on additional cooling equipment. Secondly, the air-cooling system responds quickly. Even in high or low temperature environments, it can still maintain the optimal operating temperature of the laser and extend the service life of the equipment.

Lifting Column

The lifting column of this UV laser marking machine provides a flexible height adjustment function, which can be quickly adjusted according to the size of different workpieces to ensure that the laser focus is always in the best position, thereby improving marking accuracy.

The design is stable, reducing errors caused by vibration or instability. In addition, the adjustment process is simple and convenient, and it can be easily operated, which improves work efficiency and production flexibility.

UV Laser Marking Samples Display

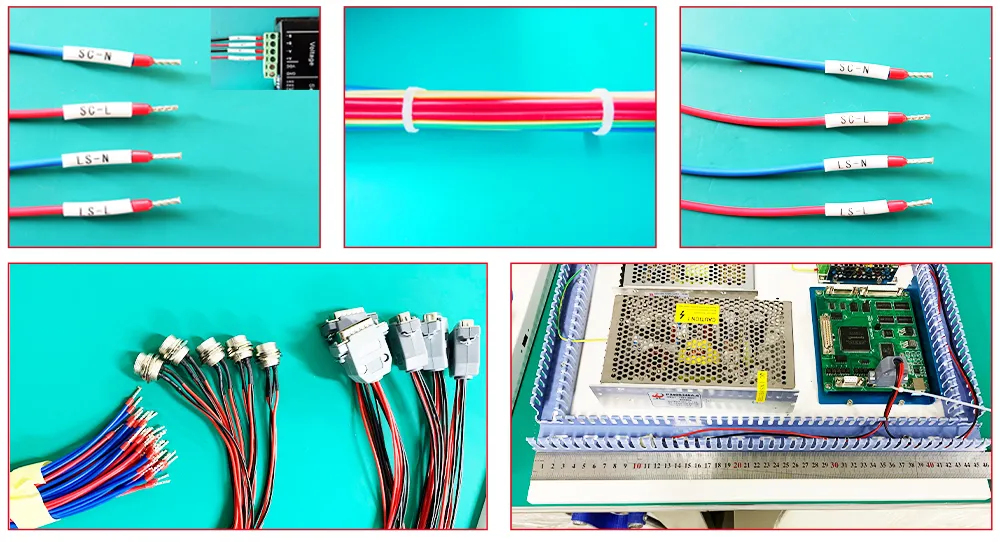

Well-organized Internal Wiring

Clearly marked circuits can effectively prevent misoperation, reduce the risk of connecting wrong or reversed wires, and thus protect equipment and your safety.

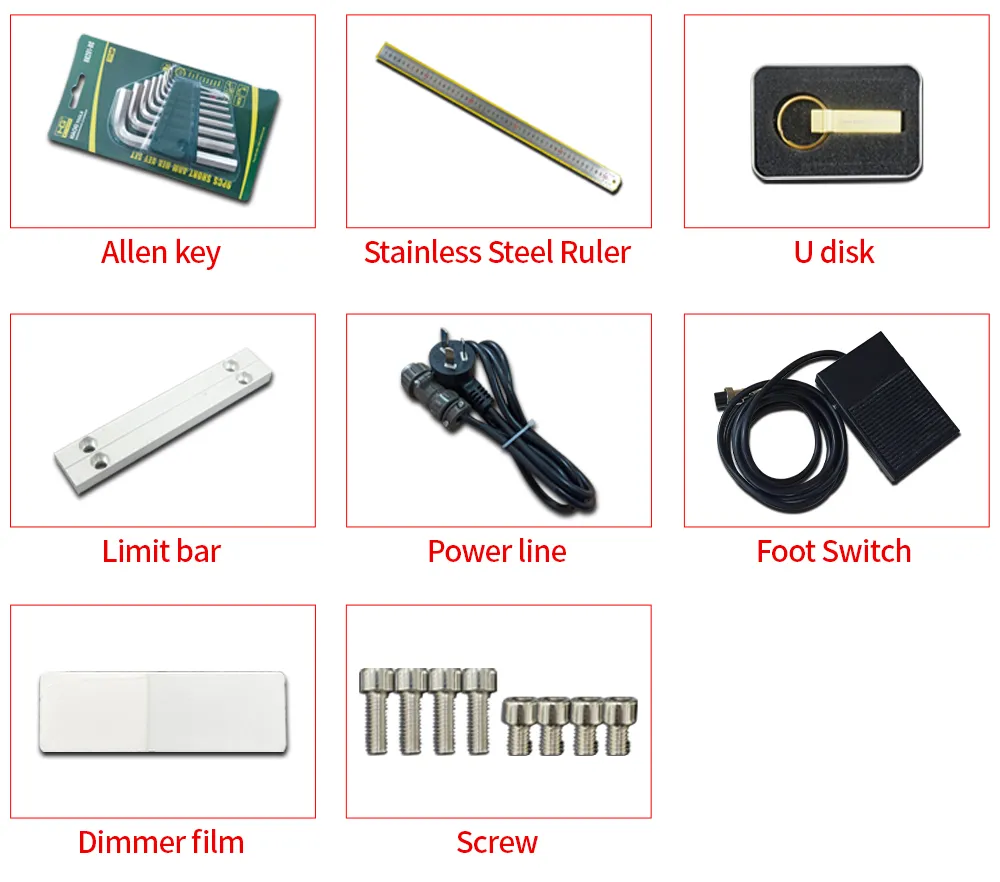

Included Accessories of Laser UV Marking Machine

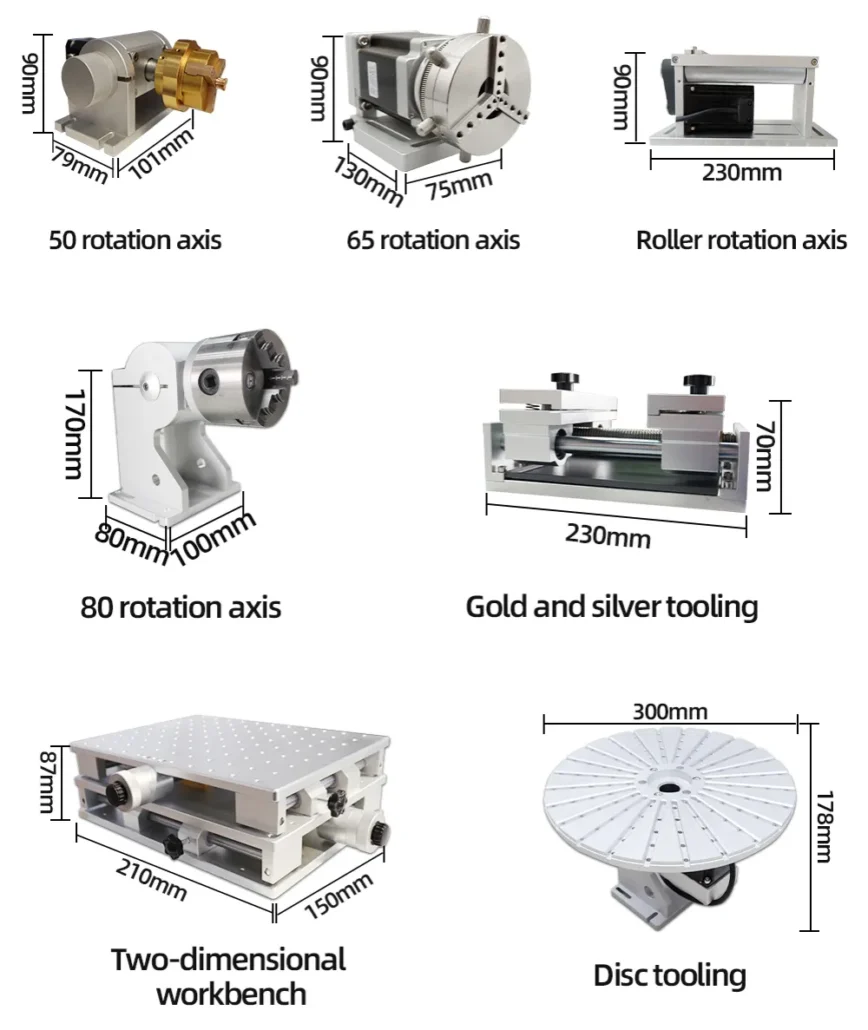

Laser UV Marking Machine Accessory Selection

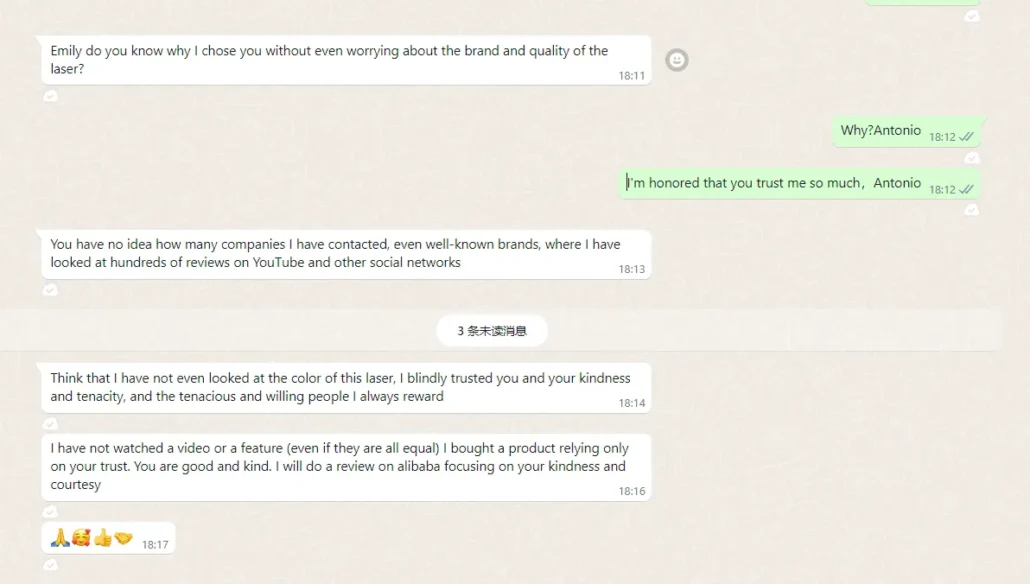

Customer Reviews

Customer Visits

Qualification Certifications

HANTENCNC Partnerships