Continuous laser cleaning machines are powerful tools used in various industries for precise and efficient cleaning. Proper operation is crucial to ensure safety and achieve optimal results. This guide will walk you through the step-by-step process of operating your continuous laser cleaning machine, from initial setup to starting the cleaning process. 1. Add Water to…

The art of engraving metal has come a long way. In ancient times, people used hammers and chisels. However, in today’s world, human civilizations are more advanced and capable of doing work faster. Modern tools are quick, accurate, and very easy to use. A laser marking machine for metal is one of the most popular…

Laser cleaning is one of the most potent and effective ways of cleaning things. It is often used in automobiles, aerospace, electronics, and industrial applications. However, these cleaning tools have safety risks. You must follow the proper laser safety precautions to ensure a safe cleaning process. This article covers the most important safety rules when…

Welding is a technique for joining two metal pieces using heat and pressure. There are several ways to produce heat. Thus, different types of welding machines appear in the metal industry. A Laser welding machine is among the most popular technologies of the twentieth century. Why is laser welding the most popular in today’s world?…

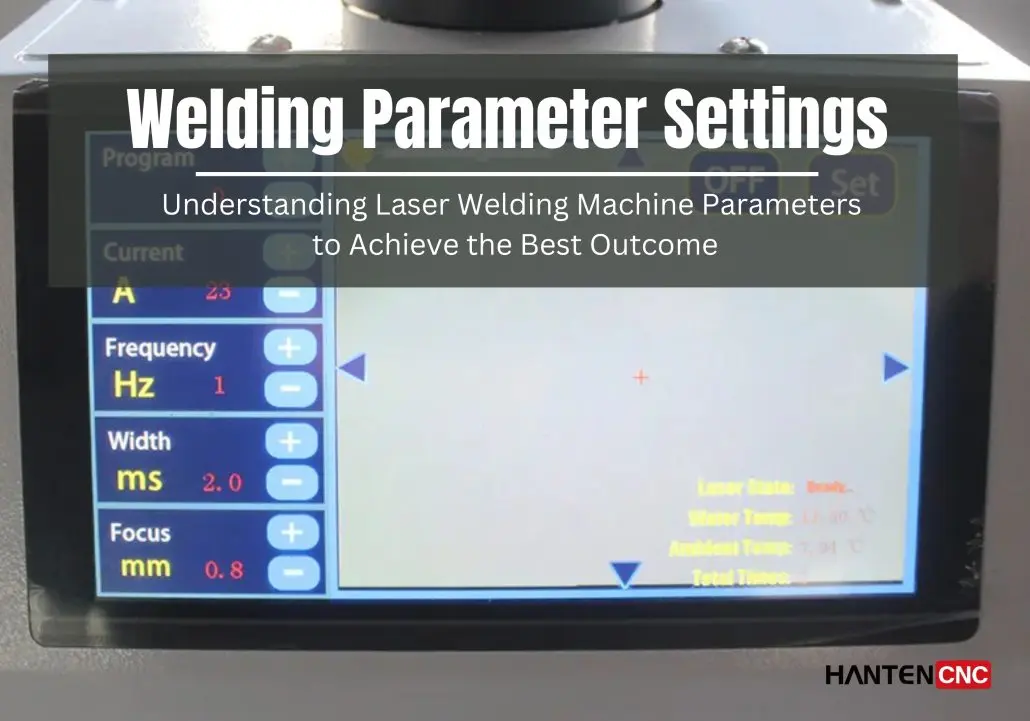

You all are more or less familiar with the welding process. It typically joins two metal parts. This joining process can be achieved through various methods. Laser welding is one of the most common techniques here. Indeed, it is the fastest and most accurate method of welding. However, you must appropriately set the laser welding…

In 2025, laser welding has become one of the most demanding technologies in the world. It is replacing many old ways of welding. It works quickly, correctly, and very well for any business. From car parts to household items, laser welding is the best option. However, most people don’t understand the cost of a laser…

Screen Printing and Laser marking are both widely used in today’s world. However, the exact use may vary depending on their suitability. Each method has its unique advantages and limitations. In this article, you will learn more about their differences and know which suits your project better.

We paint many things around us. Most of them are daily products. Paints typically add color and protect surfaces from scratches, from cars to furniture. Because of this, you can get a durable lifespan of the product. However, there are times when you must remove it. You may need to do it for restoration or…

Continuous and pulse laser cleaning machines are two laser types of laser cleaner. This article will introduce pulse laser cleaning machines and continuous laser cleaning machines around their working principles, laser characteristics, and specific applications. At the same time, the differences between the two will also be analyzed in depth. At the end of the…

Laser marking is the best and fastest way to make marks on things. It doesn’t even touch the object. Unlike other methods, laser marking is much more reliable and safe. This “UV laser VS Fiber Laser Marking Machine” guides you in learning more about UV and fiber lasers. This article mainly discusses the similarities and differences…