Welding is a technique for joining two metal pieces using heat and pressure. There are several ways to produce heat. Thus, different types of welding machines appear in the metal industry. A Laser welding machine is among the most popular technologies of the twentieth century.

Why is laser welding the most popular in today’s world? In one sentence, a laser welding machine is fast, clean, and the most accurate welder. You might already know its advantages or want to choose this technology for your project. However, you may not know how to use or maintain it. Then, this article is for you.

The article outlines the fundamental concepts of laser welding machines. It highlights the general procedure for operating a laser welder machine and explains the necessary pre-and post-processing jobs to prolong the machine’s lifespan. Overall, we will cover everything from set-up to maintenance. Follow these steps to ensure a smooth welding process.

Understanding Laser Welding Machine

As said, there are several ways to create heat to melt and join metal. You could use electricity, friction, or more modern technology like lasers. A laser welding machine uses a concentrated laser beam to melt and fuse metals.

Why do people choose laser beam welders instead of other conventional machines? Laser welding uses highly concentrated laser beams. Thus, it doesn’t need to affect unnecessary parts. If you observe other techniques, you will find that they produce a wide HAZ area. Indeed, this is oversensitive for delicate components.

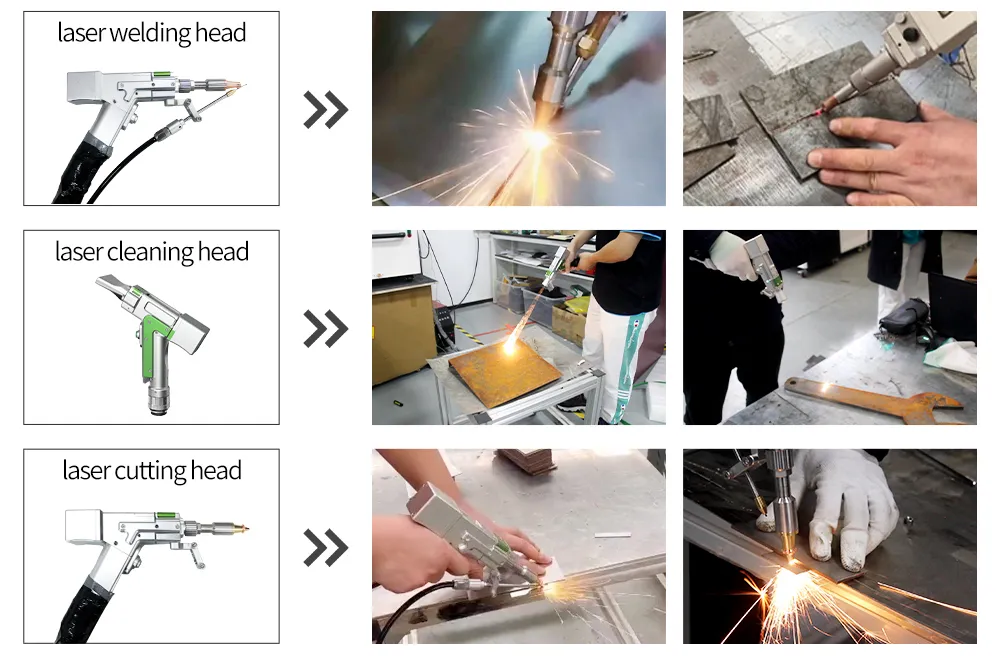

Besides, the laser welding method can be versatile. Since it uses lasers, you can use the same machine for other metal fabrication tasks, like cutting, engraving, or cleaning. It depends on your specific project needs.

A laser welding machine typically has five parts. (1) The laser source produces the laser beam. It may be of various types: CO2, fiber, or Nd::YAG laser. Fiber lasers are typically used for precision welding. CO2 lasers are ideal for thicker materials. However, the Nd::YAG laser welder is typical for micro, spot, and seam welding.

(2) The beam delivery system directs the laser to the workpiece. (3) The worktable holds the material in place. (4) The cooling system prevents overheating. (5) Finally, the control panel adjusts welding settings.

Getting Started with Laser Welding Machine

Are you ready to use your laser welding machine? Wait a while and consider the pre-processing steps. Did you forget about the safety and proper calibration of your device? Yes, these two steps are crucial for every laser welding task.

Ensure Safety First!

The laser beam welder creates a highly focused laser beam to melt and fuse metal. So, indeed, if this laser comes in contact with your skin, it may burn the place it touches. You must be careful, especially when you are dealing with reflective metals.

(1) Wear laser safety glasses to protect your eyes.

(2) Wear gloves and protective clothing to prevent burns.

(3) Ensure the workspace is well-ventilated to remove fumes.

(4) Keep a fire extinguisher near your working place.

(5) Above all, follow all machine-specific guidelines.

Set-up the Machine

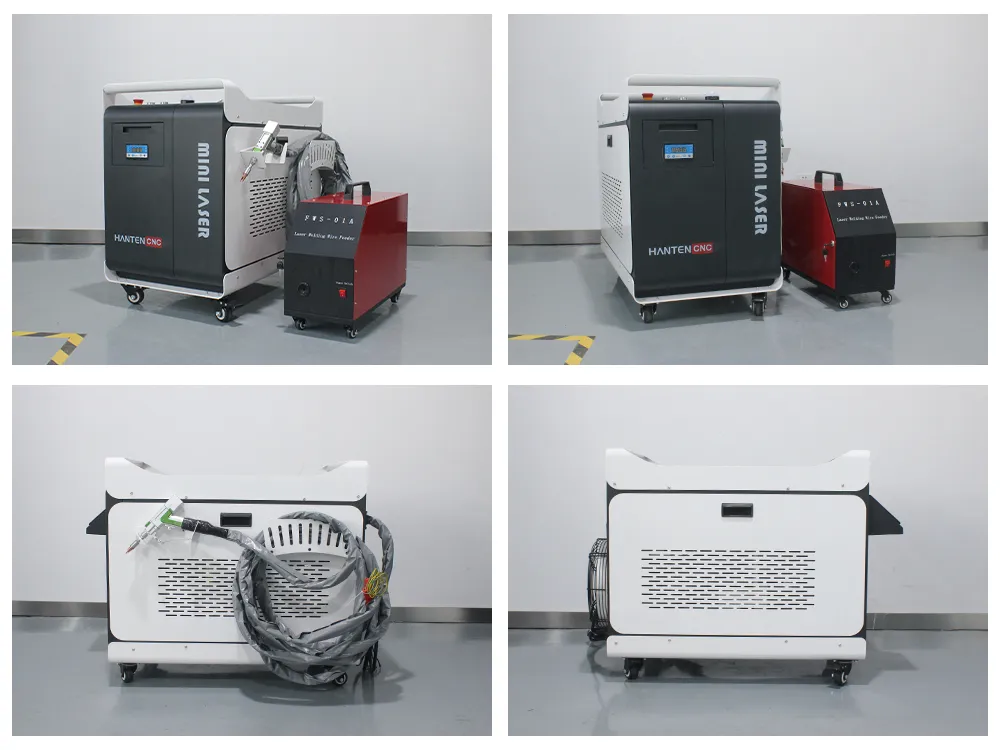

There are two types of typical handheld laser welding machines: with and without a wire feeder. The most common one is usually the one with the wire feeder. Jewelry, battery production, and delicate component welding may not require a wire feeder.

Whatever the type is, they usually come in a box with disassembled parts. Don’t worry! The central controller unit and the wire feeder typically come in correctly assembled. You must assemble the laser gun based on your appropriate project. Also, you must connect the optical cable with the laser gun and the machine. Next, properly install the wire feeder with the laser gun and the wire feeder machine. You might find other parts as well; all you need to do is follow the proper guidelines from the manufacturer.

Once you have installed all necessary parts, calibrate the laser settings and wire feeder connections. A few laser welding machines may come with shielding gases, which you can check if required.

Step By Step Process of Operating a Laser Welding Machine

Before operating your laser welding machine, you must calibrate the device correctly. You have already checked the wire feeder connection, laser gun, and cooling system. Also, make sure that you have the proper safety gear.

Step #1 Prepare your workpiece

You must be careful with the metal parts, not only the laser welding machine. Is it clean enough for laser welding? Note that the contamination can weaken the weld seam. Dust and debris interfere with the metal welding joints. So, clean your metal part before the primary process.

Next, place the workpiece on a stable surface. You can also use a fixture to keep it steady during welding. Since you are dealing with two metal parts, ensure they are correctly aligned.

Step #2 Adjust the laser parameters

Now, come to the laser welding display. Find settings, and choose the desired settings language. In HantenCNC, there are 20+ languages. So, these machines are straightforward to use, and people from any country can easily set up the device.

Set the appropriate laser power, pulse duration, and frequency. Note that you must consider various factors to choose the correct settings. In this case, you can get help from the manufacturers. At HantenCNC, we always provide laser settings for different metals of different grades. So you don’t have to worry about calculating or finding the appropriate laser settings.

Step #3 Perform and Observe the Actual Welding Process

Once everything is ready, start the welding machine and monitor the process. If you are a beginner, you can first test the laser settings on a scrap piece to ensure you are dealing with the correct laser parameters.

You must ensure the welding speed and beam intensity are consistent during laser machine welding. This will provide a strong and smooth weld. Also, always stay focused and observe the weld pool formation.

Step #4 Clean Up the residue

Finally, once the welding is complete, check for imperfections. Clean off any remaining residue, such as slag or oxidation. In this case, you can use a brush or air blast. If necessary, you can also polish the welded area.

How to Maintain your Laser welder for Long Lasting Operations

The laser welding machine is an efficient and precise method for joining metals. However, to get the best result, you must be careful, especially regarding safety measures and the proper operation of the device. There’s a saying: A craftsman is only as good as his tools if he knows how to use them safely. The same thing applies to laser welding as well.

Using Recommended Settings

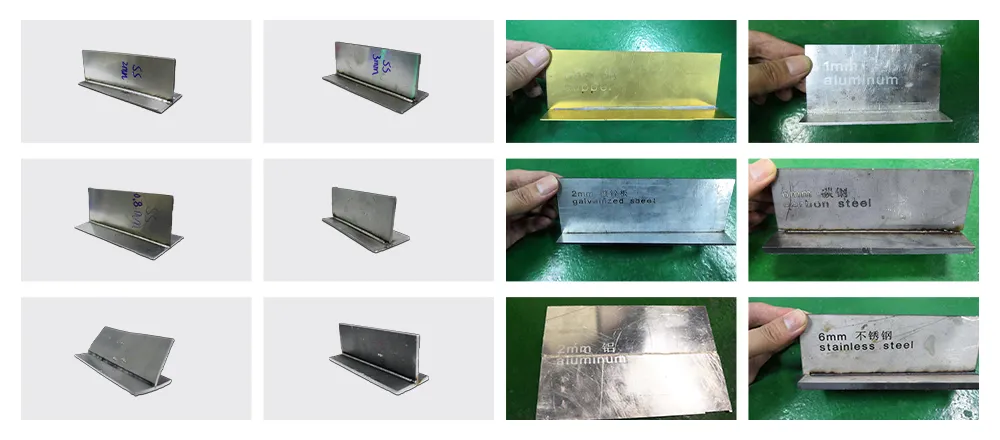

The laser welding setting is not the same for all metals. The main reason is their diverse properties. Each metal behaves differently with laser beams. Three metal properties are critical in this case: thermal conductivity, reflectivity, and melting point.

Aluminum is one of the most popular metals people use every day. This metal has a very high thermal conductivity. It can quickly dissipate heat when you direct laser beams on it. In this case, you must apply relatively higher laser power to counteract this behavior. Higher laser power typically reduces the melting time and ensures deep penetration. Incorrect laser power may create weak or incomplete welds.

Steel, on the other hand, has lower thermal conductivity. It absorbs heat quickly and effectively, so using moderate power settings with a steady welding speed is OK. Note that stainless steel is also a reflective metal. So, there’s a possibility that some lasers might reflect when doing laser welding. Therefore, you must adjust the laser settings to prevent energy loss.

Similarly, copper is a highly reflective and conductive metal. Titanium needs more precise control over heat input. Otherwise, it may oxidize and create contaminations. Nickel Alloys need more stable settings to prevent cracking or porosity. Nickel is widely used in many aerospace and industrial applications.

You will realize the importance of following the recommended laser settings. This will ensure that your weld seam is strong and free of contamination.

Upkeep & Parts Replacement

Of course, you want a long-lasting device. To achieve this, you must properly maintain your laser welding machine. In this case, regular maintenance and parts replacement is crucial. For a laser welding machine, you must focus on four factors.

- Check the lenses and optics. Did you clean them regularly or periodically? Dust and debris on lenses can distort the laser beam. Do not use regular clothes; instead, use specialized wipes and solutions.

- Laser welding machines produce a certain amount of heat. If your machine fails to dissipate this heat properly, your laser welder may not perform as expected. So, always check the cooling system.

- To avoid contamination, some laser welder uses shielding gases. In such cases, you must ensure that the flow rate of the gas is set correctly. If you find something unusual, change the part or refill the gas before using it.

- Also, replace worn-out nozzles, filters, and optics. Do not use spare parts that the manufacturer does not recommend.

Using Expert Hands

Laser welding is tricky compared to laser cutting or engraving processes, especially handheld ones. You must know the exact location of the welding and the timing of moving the gun. In such cases, expert hands can produce the desired result. However, it is not that difficult to learn laser welding. You can quickly master it after a couple of projects.

Final Words!

This article covers everything from understanding and setting up laser welding equipment to using it securely. It also highlights four essential points about maintaining it. If you have any questions, contact our customer support team. You are always welcome to ask any inquiries.