Laser cleaning is one of the most potent and effective ways of cleaning things. It is often used in automobiles, aerospace, electronics, and industrial applications. However, these cleaning tools have safety risks. You must follow the proper laser safety precautions to ensure a safe cleaning process. This article covers the most important safety rules when you use a laser cleaning machine.

What Precautions Should Be Taken During Laser Cleaning?

There are various types of laser safety precautions. By following these precautions, you can ensure a safe and efficient working environment.

1. Personal Protective Equipment (PPE)

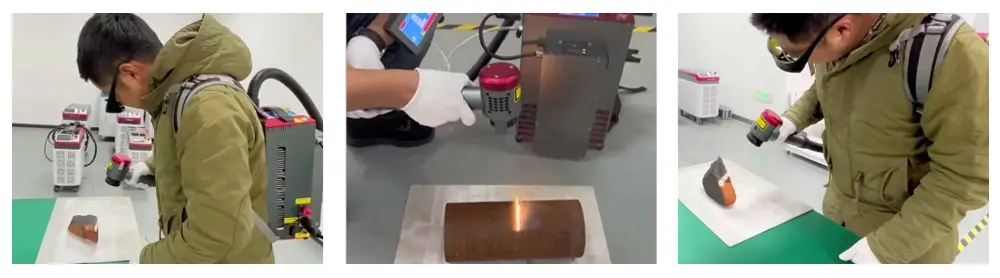

Laser rays can hurt people very badly. Therefore, you must wear safety goggles to protect your eyes from high-power laser blasts.

Gloves and safety clothes can prevent burns from laser rays. This clothing can save you from heat when you deal with high-power lasers. Although most laser cleaners nowadays are easy to use and very safe, you can work with them even with bare hands. However, we always recommend that you wear safety gear before every operation.

2. Laser Safety Information

You must focus on controlling parameters, warning signs, and laser barriers or enclosures when considering laser safety measures.

A laser cleaning machine has various signs marked on it. You must understand what the marking denotes. Therefore, getting training on how to use lasers safely is essential.

Most laser cleaners use class 4 lasers, which can burn your skin if you don’t handle them properly. If you are dealing with high-power laser cleaning, ensure the safety enclosure.

3. Safe Working Place, Ventilation, and Air Filtration

You must ensure that your working place is neat and clean. It is always recommended that trained staff do laser cleaning. However, most laser cleaners nowadays are very easy to use. Even people with no knowledge about lasers can do the cleaning. However, pay attention to your expertise when dealing with high-power laser cleaning.

Moreover, to avoid accidents, the floor in your working area should not have anything that creates obstacles. You must mark the laser work zones with the right signs. Also, you must ensure that your working station has an emergency stop button. The lighting must be good enough to see clearly.

Laser cleaning produces particles and fumes. A sound air system can remove harmful pollutants, and air screens help protect the world around us.

4. Flammable Materials Precautions

For extra safety, you can use fire-resistant walls. Before cleaning, inspect surfaces to find and remove anything that could catch fire.

You can also install fire control systems if you work in a dangerous area. Automatic fire warning systems can help prevent fires before they start.

This laser safety precaution must ensure two crucial tools. (1) keep the fire extinguisher near the work area as near as possible. So that when the situation arises, you can quickly get the necessary tools to stop the fire. (2) Your workplace must have a proper fire alarm and detection system.

5. Power Supply and Grounding Precautions

You know that all laser devices need electricity to run. Therefore, you must ensure proper wiring and power connections with the laser cleaner. In this case, consider three things: grounding, emergency shutdown, and safe wiring.

Proper grounding of your laser cleaner can avoid electrical dangers. Most people are not familiar with grounding’s uses. Also, you should check power lines and connections regularly.

Also, ensure that your laser cleaner rates the power sources correctly. You could use voltage protectors to provide a stable power input.

6. Training and certification

It is always recommended that trained people be allowed to clean the laser. However, most modern laser cleaners are safe to operate. However, when you deal with a high-power laser cleaning machine, you must follow the laser safety precautions. In this case, pay attention to your expertise.

You should know how machines work, how to shut them down in an emergency, and how to control risks. Certification programs help you improve your jobs and follow safety rules more closely.

7. System Checks Before Use

Before you use the machine, check its setup. Check the lenses, power levels, and cooling devices. Check the links and cords for damage. If you find any broken tools, fix them as soon as possible.

Before cleaning the whole surface, you must test the laser on a small area. This helps you find problems with the laser path’s power or balance. Testing needs to be done regularly to maintain accurate performance.

8. Monitoring and making changes to the process

When you do laser cleaning, you must observe the whole process. Are the beam and output straight? How about the device’s performance? Can it clean efficiently? Do you see any unusual cleaning processes? If necessary, you can change the settings based on your observations.

9. How to Shut Down in an Emergency

You should know how to shut down in an emergency. In this case, quick precautions can prevent accidents. The emergency stop buttons need to be easy to access.

You can attend the regular training classes on what to do in an emergency arranged by the manufacturer. You must know what to do in case of a fire, broken equipment, or dangerous fumes.

10. Safe Handling of Optical Components

The lenses and mirrors with the laser cleaners are generally very fragile. Any mishandling can damage these spare parts. Therefore, when cleaning these parts, ensure you do it correctly. In this case, try to use non-rough materials.

11. Routine Checks of Wiring and connections

Your laser system may fail for several reasons. One of the most common reasons is loose electrical wiring and connections. You can find these loose connections when you do regular checking. If you find any broken parts, change them or fix them immediately.

Keep a record of the checks to make maintenance easier. This way, you will know which spare parts need to be replaced.

12. Waste Management

Did you consider the waste you will produce during laser cleaning? How about fume filtration? Ensure that you have taken all these last safety precautions as well.

13. Regular Maintenance and Parts Replacement

Above all, you must do regular checking. This is the most crucial laser safety precaution. This way, you can find out which part of your machine needs to be replaced.

Summary

In this article, you have reviewed 13 laser safety precautions. Each precaution ensures that your work is safe and efficient, and it also ensures that your workpiece and the machine are in good shape. However, if you have further questions, feel free to contact our customer support team.