Continuous and pulse laser cleaning machines are two laser types of laser cleaner.

This article will introduce pulse laser cleaning machines and continuous laser cleaning machines around their working principles, laser characteristics, and specific applications. At the same time, the differences between the two will also be analyzed in depth. At the end of the article, we will give professional laser cleaning machine purchasing guidance.

1. What is Pulse Laser Cleaning Machine?

1.1 Working principle of pulse laser cleaning machine

To understand what a pulse laser cleaning machine is, we must first understand what a pulse laser is.

Pulse laser can be understood as: at very short intervals, the laser will be concentrated and released once. In this way, the light is continuously emitted repeatedly. Therefore, pulse light has prominent time interval characteristics.

Pulse laser can achieve high peak power precision laser cleaning tasks by adjusting pulse width and pulse frequency.

1.2 Two output beam modes of pulse laser cleaning machine: single-mode and multi-mode

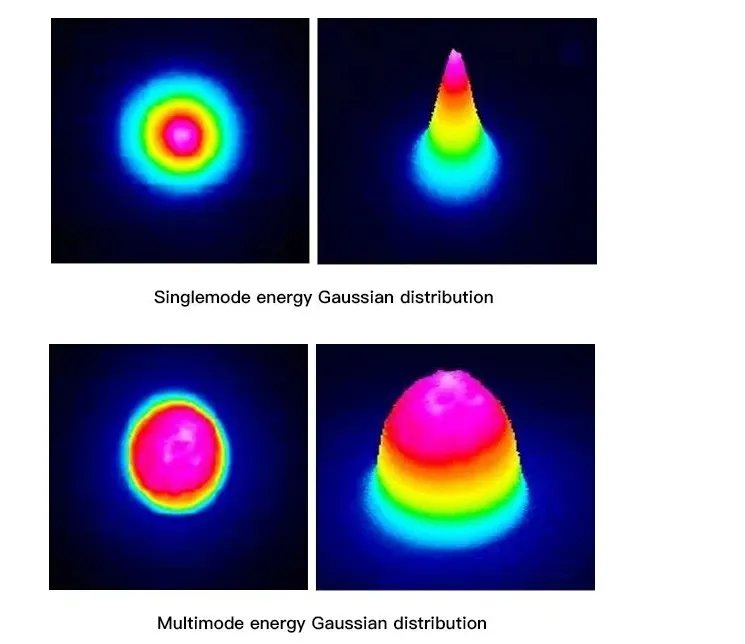

Pulse laser cleaning machines are divided into single-mode and multi-mode pulse laser cleaning machines according to different beam quality, spot size, energy distribution, and output power.

Single-mode pulse laser has higher beam quality, and the value of M² can be close to 1. The spot is smaller, and the laser output energy is more concentrated. The energy distribution of a single-mode pulse laser is Gaussian: high in the middle and low on both sides. These characteristics make single-mode pulse laser sharper, like a needle tip. Therefore, it is more effective when cleaning oil, rust, and other pollutant attachments.

However, single-mode lasers use thinner fiber cores, usually around 4-10 microns. Therefore, single-mode pulse lasers have lower output power than multi-mode pulse lasers.

Multi-mode pulse lasers have larger spot sizes and wider beam distribution. The energy distribution is flat-topped, like a small flat-top house. When performing laser cleaning tasks, it sweeps back and forth like a wide broom. Compared with single-mode pulse lasers, multi-mode pulse lasers are softer. In addition, multi-mode pulse lasers have higher output power, so the cleaning efficiency is faster.

Multi-mode pulse lasers are your best choice for cleaning large areas or thick layers with their high output power and large spot sizes.

1.3 Features of pulse laser cleaning machines:

High peak power: Pulse laser cleaning machines release high energy in the form of short pulses and can release high energy in a very short time, so they have high peak power. When performing laser cleaning tasks, not only can high laser energy be used to remove oxide layers, oil stains, and rust, but the thermal impact on the substrate is also minimal and will not be damaged.

Adjustable pulse width: Our pulse laser cleaning machines all use MOPA lasers so that the pulse width can be adjusted according to demand. If you want to remove light rust, oxide layer, or thin coating or have higher requirements on the surface of the substrate, you can adjust to a shorter pulse width. If you need to clean thicker or stubborn contamination layers, such as paint, heavy rust, or thick oxide, you can adjust to a more extended pulse width.

Adjustable pulse frequency: The pulse frequency of the pulse laser cleaning machine is also adjustable. If you want to remove stubborn contaminants, you can adjust to a low frequency, but the cleaning speed will be relatively slow. If you want to clean a lighter contamination layer or have higher requirements on the surface of the cleaning material, you can adjust to a high frequency yourself.

1.4 Application of pulse laser cleaning machine:

Application materials: Pulse laser cleaning machine can clean most metal and non-metal materials. Generally used for metal materials. For example, ordinary iron, copper, aluminum alloy, stainless steel, etc.

Some metals are exposed to water and oxygen in the air and produce oxidation reactions, thus producing some oxides, scales, or rust. Some metals will come into contact with various lubricants and protective oils during production, processing, transportation, and use, and thick oil stains will form over time.

Laser cleaning machines can clean them very well.

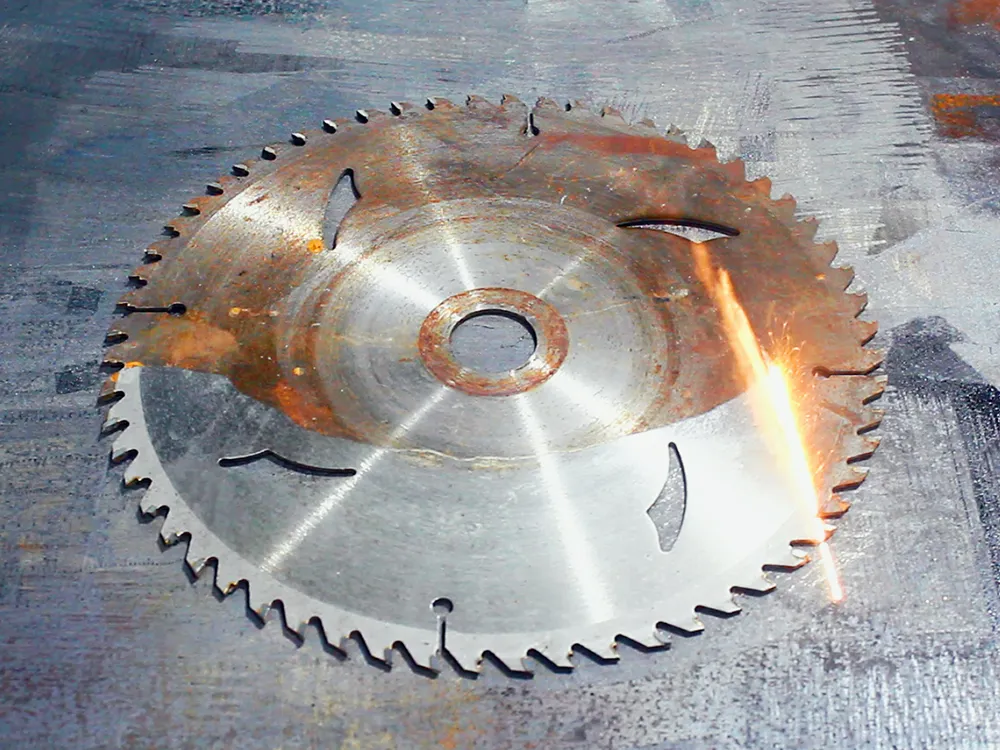

Application industries: Pulse laser cleaning machines are widely used in a wide range of industries. For example, the automobile manufacturing industry, mold industry, and various transportation industries. These industries are prone to accumulating oil stains, oxide layers, rust layers, sticky substances, and other dirt.

Traditional cleaning methods take more time and also need to be more thorough. Pulse laser cleaning machines are more efficient, more detailed, and more non-destructive and can quickly remove various surface dirt.

2. What is Continuous Laser Cleaning Machine?

2.1 Working principle of continuous laser cleaning machine

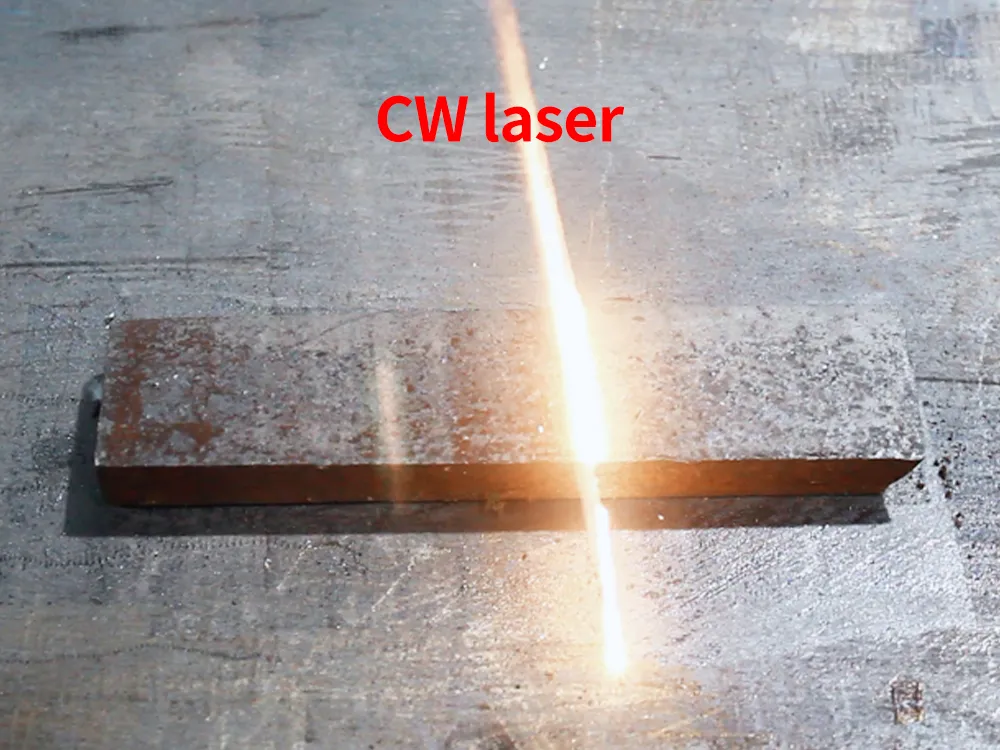

ciple of continuous laser cleaning machineContinuous laser cleaning machine refers to continuous wave laser (CW laser). It acts on the surface of the workpiece by continuously emitting high-energy continuous beams. The laser energy instantly heats and vaporizes surface pollutants such as oxide layers, rust, oil stains, coatings, etc., decomposing, vaporizing, or peeling them off without damaging the substrate.

2.2 Characteristics of continuous laser cleaning machine

High power and continuous output

A continuous laser cleaning machine can continuously output high-energy laser beams. Suitable for large-area, high-efficiency cleaning.

Non-contact cleaning: No need to contact the workpiece to avoid physical wear

Non-destructive cleaning

The cleaning process only targets pollutants and does not damage the substrate. It is suitable for a variety of metal and non-metal materials

Very suitable for removing thick layers of dirt

Especially ideal for removing stubborn pollutants such as thick rust and heavy oil stains

2.3 Application of continuous laser cleaning machine:

Application materials

Continuous laser cleaning machines are generally used for large metal materials. Especially suitable for removing heavy rust, thick coatings, and industrial-grade pollution.

Application industry

Continuous laser cleaning machine quickly removes pollutants on the surface of the workpiece through high-power continuous beams, which are suitable for cleaning scenes with large areas and thick layers of pollution. Combining the single pendulum and double pendulum modes can achieve efficient, environmentally friendly, and non-destructive cleaning effects for different workpiece shapes, cleaning areas, and pollution levels.

Continuous laser cleaning machines play an essential role in many fields such as automobiles, ships, rail transportation, and energy.

3. Key Differences: Continuous and Pulse Laser Cleaning Machine

3.1 Output power intensity

Generally speaking, the higher the power of the laser cleaning machine, the higher the cleaning efficiency. The power range of the pulse laser cleaning machine is 200 watts to 1000 watts. The power of the continuous laser cleaning machine is 1000 watts to 3000 watts. In this way, the continuous laser cleaning machine is more advantageous in terms of cleaning efficiency.

However, it should be noted that the substrate temperature will be too high during the cleaning process with too high power, which will cause more significant damage to the surface of the material.

3.2 Cleaning depth

The cleaning effect of the pulse laser cleaning machine will be more thorough for stubborn dirt.

Due to the working principle of the pulse laser cleaning machine, the energy of the pulse laser is more concentrated, and the spot is smaller, so it can deeply clean dirt that has accumulated for a long time. For example, oxides, rust, coatings, spray paint oil stains, etc.

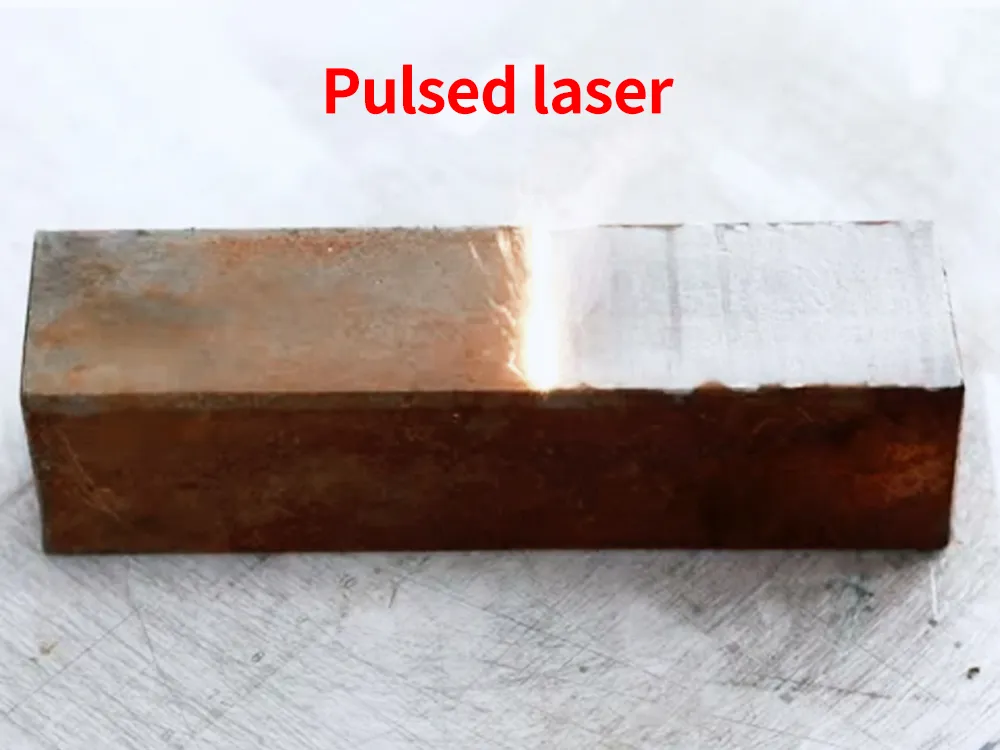

3.3 Cleaning effect

After the pulse laser cleaning machine cleans the material, there is almost no damage to the bottom of the substrate. Not only that but after the material is cleaned, it can also be very close to the original base color of the material. After the continuous laser cleaning machine is finished, there will be slight white marks on the surface of the metal material. Although it is cleaned very well, its appearance could be better than that of a pulse laser cleaning machine.

3.4 Different materials are suitable for cleaning

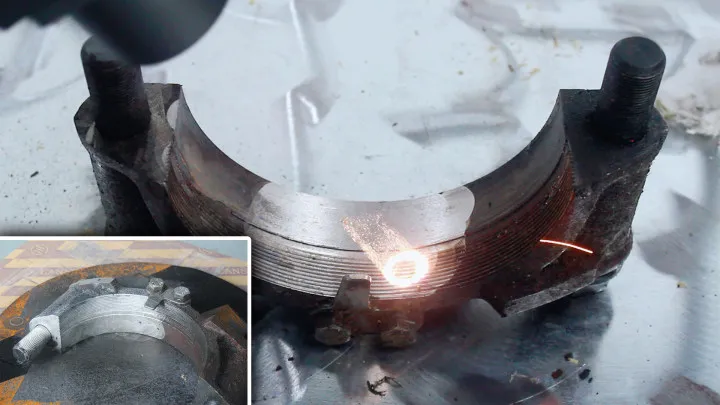

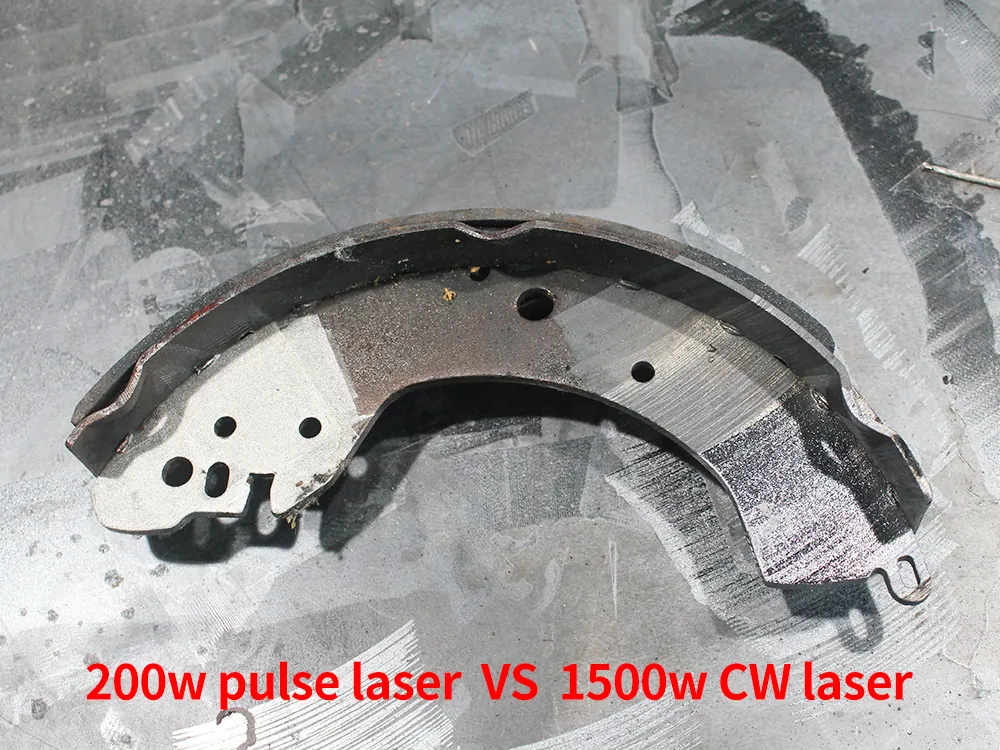

we have used a 1000-watt pulse laser cleaning machine and a 1500-watt continuous laser cleaning machine to test rust and oil stains.

- For light rust, both pulse and continuous lasers can easily remove it. Both have good cleaning speed and effectiveness. However, for thicker rust and larger areas, continuous lasers deliver better cleaning results.

- For oil stains, pulse lasers clean more thoroughly and effectively, with almost no damage to the material. Continuous lasers, on the other hand, are less effective at removing oil stains and may leave some black residue on the surface.

If you need to clean a thick rust layer, it is recommended to use a continuous laser cleaning machine. If you need to clean oil stains and thin rust layers, a pulse laser is a better choice.

3.5 Thermal impact on materials

The pulse laser cleaning machine uses short pulses for cleaning, so the laser will not always irradiate the surface of the material, and the heat accumulation will be minimal. Suitable for processing heat-sensitive materials.

During the long cleaning process, the continuous laser cleaning machine accumulates more heat because the light-cutting power is high. It may cause thermal effects on the cleaned materials.

3.6 Light uniformity

The laser of the pulse laser cleaning machine is continuously output at very short intervals and has high peak power. However, the laser of the continuous laser cleaning machine outputs stably and constantly, so its beam uniformity will be better.

3.7 Price and cost

The cost of the pulse laser cleaning machine is higher because it requires a more sophisticated control system to generate high-peak-power laser pulses. Coupled with high-precision optical systems and cooling devices, the overall price is higher than that of ordinary continuous laser systems.

Continuous laser cleaning machines are relatively cheap, especially continuous laser systems with mature technology. Due to the stable output power and relatively simple, the production and maintenance costs are low.

4.How to Choose the Right Laser Cleaner?

Choosing the right laser cleaning machine is a process that requires comprehensive consideration of many factors. The following points can help you make the best choice:

4.1 Material to be cleaned

Pulse laser cleaning machines are suitable for cleaning heat-sensitive or relatively expensive materials, such as thin metals and precious metals. Composite materials and coating-sensitive materials, etc. Since the heat-affected zone of pulse lasers is small, it can effectively avoid material deformation or damage.

Continuous laser cleaning machines are more suitable for cleaning high-temperature resistant or thicker metal materials, such as steel, iron, cast aluminum, etc. The stable output of continuous lasers is ideal for large-area, deep-level cleaning.

4.2 Desired cleaning effect

During the cleaning process of the pulse laser cleaning machine, the substrate will basically not be damaged. For the material itself, it is more protective. After cleaning with a pulse laser cleaning machine, the material will be closer to the color of itself without coating and dirt.

The continuous laser cleaning machine uses high-power lasers to quickly heat and evaporate pollutants during the cleaning process, which is suitable for the initial removal of large areas and stubborn stains. It can efficiently peel off thick rust and coatings, but due to the extensive heat input, the protection of the substrate is relatively weak. Continuous laser is more suitable for industrial cleaning tasks that do not require high material damage

4.3 Purchase budget

The price of pulse laser cleaning machines is generally higher compared to continuous laser cleaning machines, especially for high-power pulse laser equipment. However, pulse lasers offer flexible adjustment of parameters such as pulse width, making them suitable for a wider range of materials and applications.

Continuous laser cleaning machines, on the other hand, are more affordable than pulse laser cleaning machines, particularly for medium and low-power models. If your budget is limited and you need to clean larger areas, prioritizing cleaning efficiency over cleaning precision, a continuous laser cleaning machine could be a better choice.

4.4 Flexible choice

If you still have difficulty choosing between a pulse laser cleaning machine and a continuous laser cleaning machine, there is another option:

HantenCNC composite laser cleaning machine.

The composite laser cleaning machine combines the advantages of a pulse laser cleaning machine and a continuous laser cleaning machine. It achieves efficient, precise and non-destructive cleaning effect through a dual laser system. The core of this cleaning technology is to make full use of the characteristics of the two lasers to adapt to different cleaning needs.

1. Advantages of continuous laser: rapid heating

2000W continuous laser is mainly used for rapid heating of the substrate surface. Its high power density can quickly heat up the surface material, such as rust or thick paint, to the peeling paint, loosening it, or partially evaporating it. This pretreatment process can significantly improve cleaning efficiency and is suitable for treating large-area, complex, or highly adherent pollutants.

2. Advantages of pulsed laser: precise cleaning

The 300W pulsed laser, with its short pulse and high peak power characteristics, can accurately remove surface pollutants without causing excessive thermal impact or damage to the substrate. It is particularly suitable for eliminating thin and high-precision covering layers, such as oxides or durable protective coatings.

3. Combination of advantages: non-destructive cleaning and efficient processing

The composite laser cleaning machine quickly heats the loose surface with a continuous laser first and then uses a pulsed laser for precise cleaning to complete the detail processing. This combination not only improves the cleaning efficiency but also effectively avoids thermal deformation or damage to the material.

4. Application Scenarios

The composite laser cleaning machine is particularly suitable for treating heavy rust and thick paint, such as ship surfaces, metal structures, and oil derricks in industrial fields. It can effectively remove rust layers up to 25mm thick, as well as heavy protective paints (such as epoxy paint and fluorocarbon paint) up to 2mm thick, showing efficiency and precision that is difficult to match with traditional methods.

By combining the advantages of two lasers, the hybrid laser cleaning machine provides an efficient, environmentally friendly, and non-destructive solution for heavy cleaning tasks.

Conclusion

Continuous and pulse laser cleaning machines can meet various cleaning needs. Both continuous and pulse lasers have their unique advantages, allowing flexible selection based on the application scenarios.

Pulse laser cleaning machines, due to their working principles and laser characteristics, have minimal heat-affected zones and can achieve deep cleaning. They are ideal for applications requiring high surface quality or where substrate protection is crucial.

Continuous laser cleaning machines, on the other hand, excel in high power and efficiency, making them better suited for large-scale cleaning tasks and tackling stubborn contaminants like heavy rust or thick paint layers.

For users with diverse needs, composite laser cleaning machines combine the advantages of both pulse and continuous modes. They deliver efficient cleaning while minimizing material surface damage caused by laser cleaning.

After reading this article, you can better understand the difference between continuous and pulse laser cleaning machines, and choose the most suitable laser cleaning machine according to your actual needs.