Continuous laser cleaning machines are powerful tools used in various industries for precise and efficient cleaning. Proper operation is crucial to ensure safety and achieve optimal results.

This guide will walk you through the step-by-step process of operating your continuous laser cleaning machine, from initial setup to starting the cleaning process.

1. Add Water to the Chiller

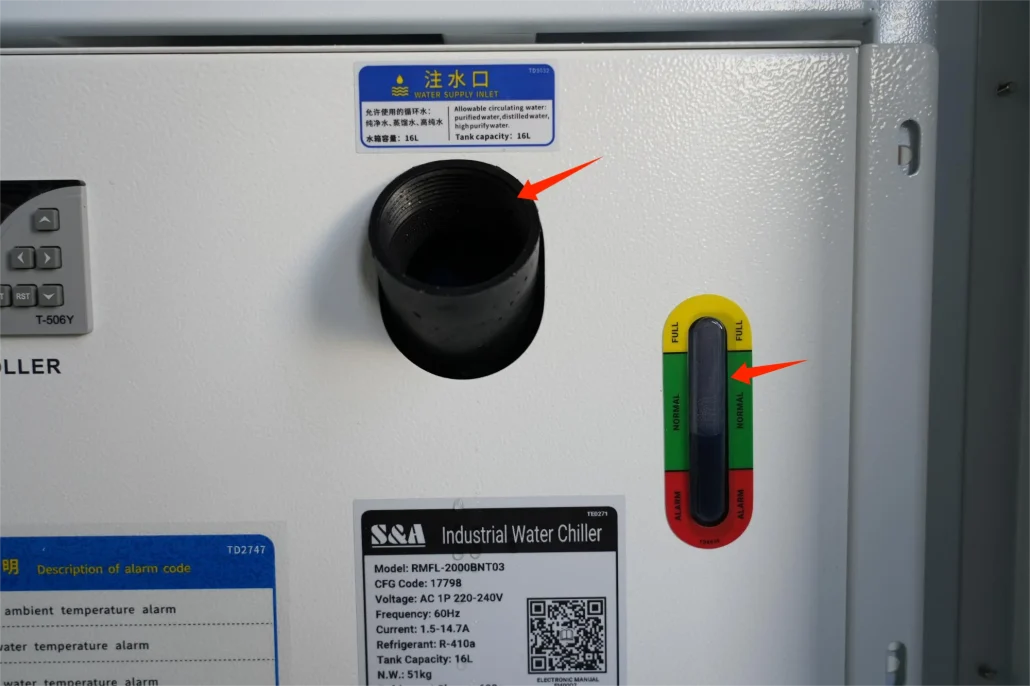

When you receive the continuous laser cleaning machine, the water inside the chiller is drained. We need to add water to the chiller:

Open the chiller’s water inlet cap and add cooling water up to the green standard level marked on the water tank, make sure add the pure water or distilled water.

When the temperature in your place is below 0°C, in the case of water freezing, you must add laser-specific antifreeze in a 1:1 ratio with water.

Water Inlet and Water Level Indicator

Laser-Specific Antifreeze

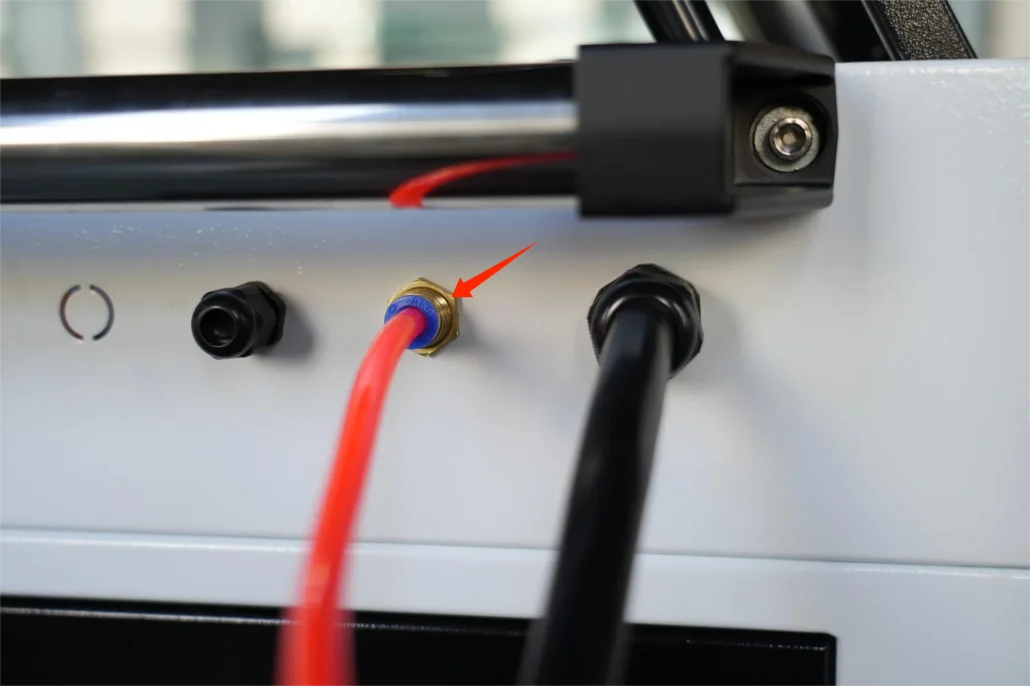

2. Protective Gas Connection

During laser cleaning, a large amount of dust will produced to contaminate the protective lens. So, using the protective gas helps to protect the lenses and prolong their lifespan effectively.

Laser cleaning can use air as a protective gas, but the air must be clean, free of oil, water, and any impurities. An oil-water separator can be used for filtration, which needs to be prepared by the user.

The protective gas inlet is located at the back of the machine cabinet.

The gas pressure should be adjusted to 0.6Mpa (6kg, 87psi) for cleaning.

Gas Inlet

Pressure: 0.6Mpa

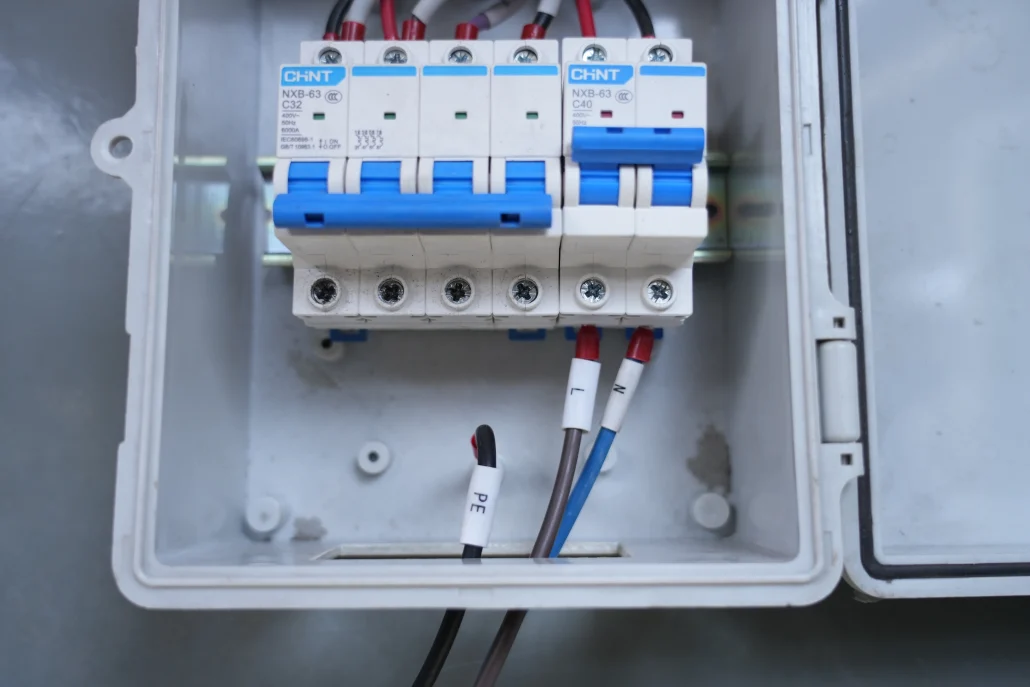

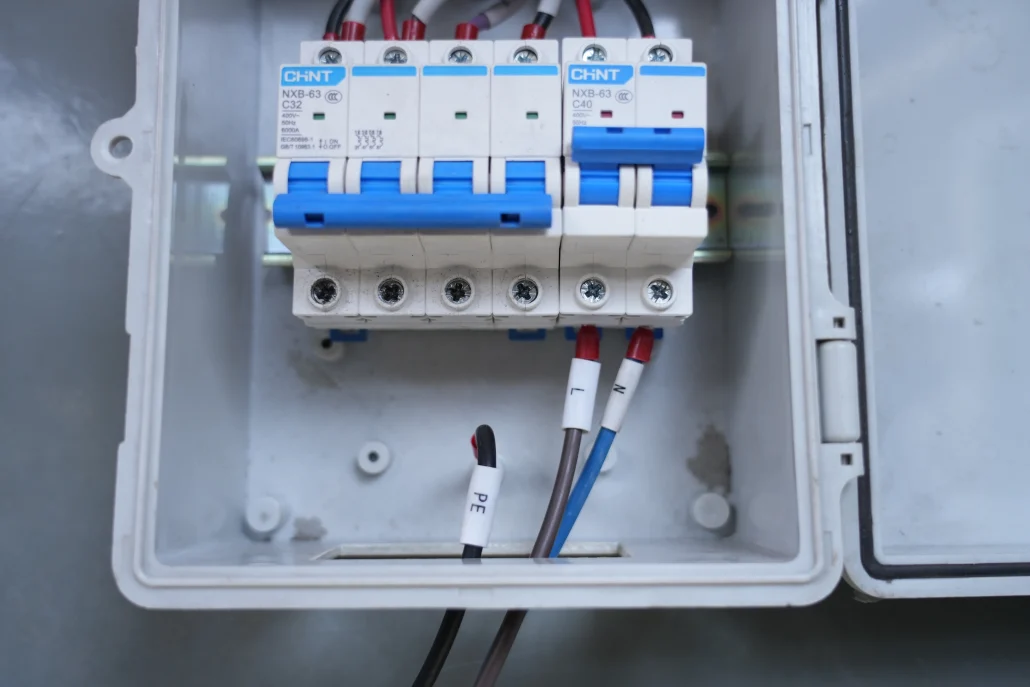

3. Power Supply

There are two types of continuous laser cleaning machines, one powered by 220V and the other by 380V.

The power cable is located at the back of the machine cabinet.

Below are the power connection methods for both types of machines.

220v

380V

4. Power On

Turn on the main power switch at the back of the machine cabinet.

(1) Turn on the emergency stop button,

(2) Turn on the system and chiller buttons,

(3) Turn on the laser button.

Main Power Switch

Emergency Stop Button + Chiller + System + Laser

5. Preparation for Cleaning

Lasers usually have an optimal operating temperature range. Temperatures that are too low or too high will affect their performance.

A temperature above 22°C can ensure that the laser is in a stable operating state, avoiding unstable energy output or decreased efficiency due to low temperature.

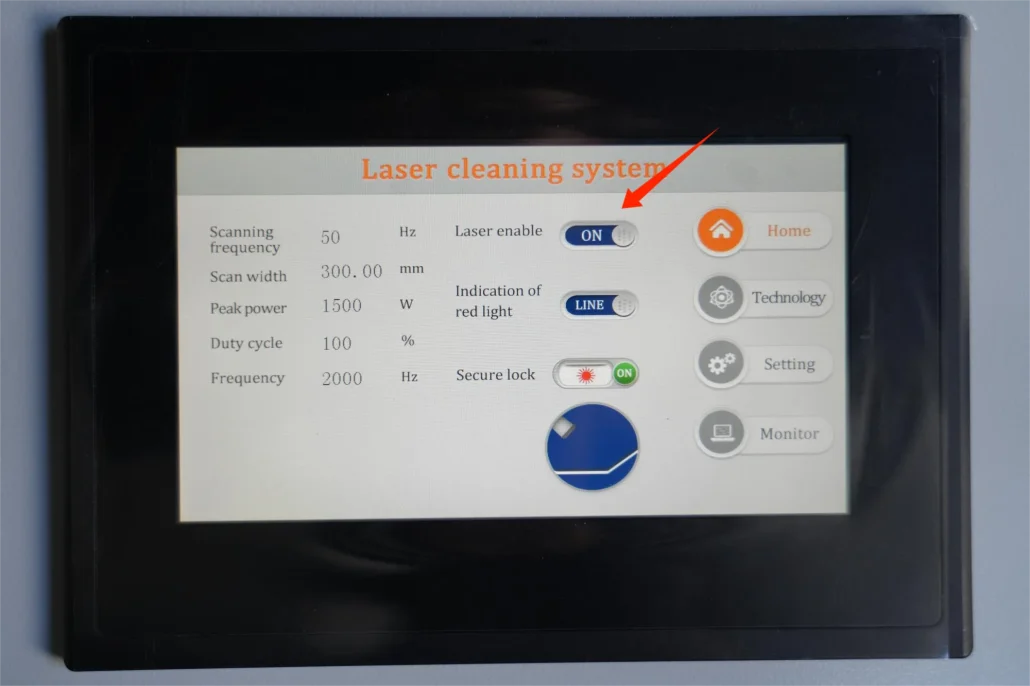

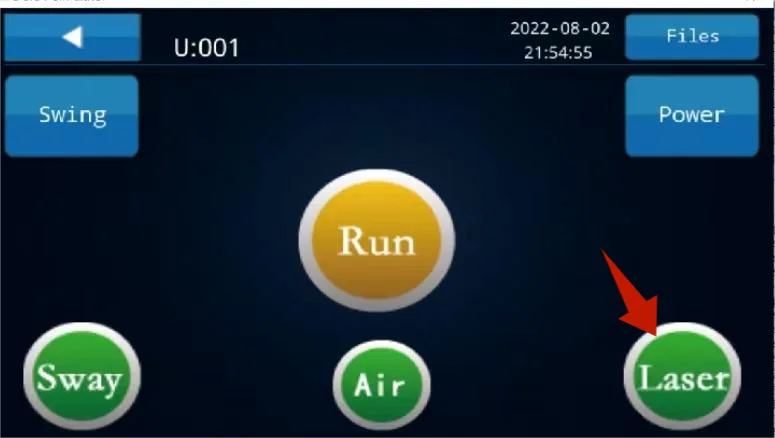

When the chiller temperature reaches 22°C or above, tap the “Laser Enable” button on the touchscreen.

Below are the software interfaces of two different systems.

Figure A Laser Switch: Single Pendulum Cleaning Head Interface Selection

Figure B Laser Switch: Dual Pendulum Cleaning Head Interface Selection

The interface for Figure A or Figure B depends on the model of the cleaning head you purchased.

6. Start Cleaning

First, open the dust cover at the light outlet of the cleaning head.

Then, double-click and press the light button located below the handle of the cleaning head to emit light and begin the cleaning process.

(The light button needs to be held down and released; the laser will turn off when the button rebounds.)

Dust Cover Switch

Dust Cover Closed State

Dust Cover Open State

Light Emission Button

7. Precautions

- The chiller should only be filled with pure water, distilled water, or high-purity water.

- The laser will only emit light when the chiller temperature reaches above 22°

- Ensure that the protective gas is connected before use.

- When replacing the protective lens, do not touch the lens surface directly with your hands. If the lens is contaminated with dust, it can be wiped with high-concentration ethanol.

- In case of an emergency during operation, immediately press the emergency stop switch to quickly cut off the power (pressing down the emergency stop switch turns it off, and rotating the button to the right turns it back on. When the emergency stop switch is off, the entire machine is powered down).

- The minimum bending diameter of the fiber must not be less than 200mm.

- When the machine is powered on, never point the laser output head at people or reflective surfaces.