Surface cleaning techniques like plasma or laser cleaning are performed to prepare surfaces for coating, welding, and adhesive bonding. Plasma cleaning uses an ionization gas called plasma, whereas laser ablation uses the force of light to remove impurities.

Understanding the difference between laser and plasma cleaning can be challenging for many manufacturers. Overall, both are non-contact processes that don’t require chemical cleaning. And they’re sought after to replace abrasive procedures like dry ice blasting or sandblasting.

This article will discuss which cleaning approach produces better outcomes and why. Before we talk about the differences, let’s take a quick look at each approach. Start reading now!

Laser Cleaning VS Plasma Cleaning: The Core Difference

Cleaning contaminants like dangerous paints or rust can be challenging. There are many key factors to consider. Including protecting the environment and workers and how the cleaning solution will affect your product.

What about plasma treatments or laser cleaning methods? How do you choose the finest option for your needs when each has several advantages and disadvantages? So, to find the best one, keep reading till the end of this article.

What is Laser Cleaning?

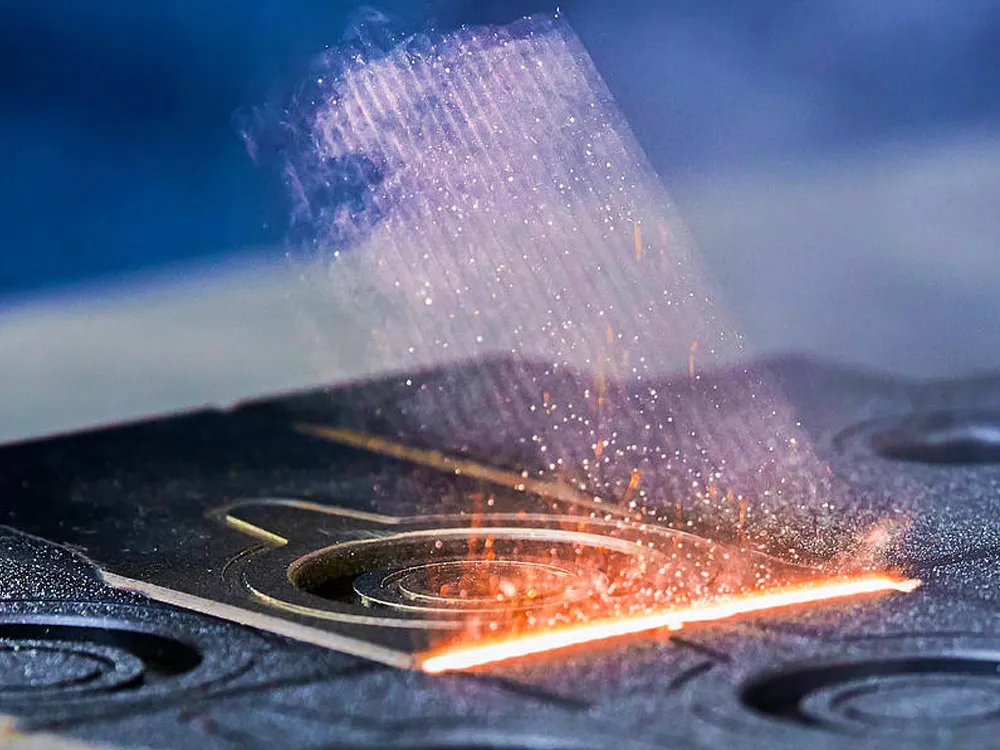

Laser cleaning is an innovative approach to removing all dirt and other things from surfaces. It’s also known as “laser ablation.”

Most of the time, it’s used to clean metals. It can also be used to clean ceramics and stones. Handheld laser cleaning machine rarely works with rubber and plastics.

Industrial laser cleaning machines can eliminate all kinds of pollutants, such as oxide, corrosion, paint, oil, dust, and electrolytes. It works better for specified products. The laser cleaning machine’s reasonable price range will satisfy all your requirements.

Advantages Of Laser Cleaning

- It removes damaging and harmful contaminants completely.

- It has a low running cost and, at the same time, produces no extra waste.

- It’s eco-friendly, pollution-free, and safer for your operators.

- It doesn’t destroy the surface, which means it can extend the overall lifespan of your cleaning equipment rather than lowering it.

- It’s an efficient, energy-saving, and highly clean procedure.

- It’s a simple operation that can quickly remove surface rust, oil, coatings, etc.

Disadvantages Of Laser Cleaning

- It’s not appropriate for rubber and plastics.

- It is not convenient for products with hard-to-see apertures, such as the inside of any pipe or tube.

What is Plasma Cleaning?

Plasma cleaning is one type of plasma treatment. It removes surface pollutants by carbonizing them with plasma. It is a superheated ionization gas. The electrons have been separated from the atoms.

It’s a powerful method used to clean polymers, metals, and ceramics, among other materials. It is applied to eliminate organic pollutants such as dust, oil, electrolytes, and paint. But it is less effective in removing impurities like oxides and rust.

Advantages Of Plasma Cleaning

- Plasma cleaning offers a safer alternative to blasting techniques.

- It can forcefully use abrasives like dry ice or sand to remove contaminants.

- It’s used for many non-metallic products, from glass and plastic to ceramic.

- It can change how the contaminants are made chemically and make the ground look clean.

Disadvantages Of Plasma Cleaning

- Plasma cleaning can’t be operated by hand.

- It usually adds a layer of hazardous contaminants for your operators and shortens the life expectancy of your product.

- It cannot genuinely clean the products or surfaces.

- It requires extra equipment to be purchased and used.

- It can increase your overall expenses by demanding extra tools.

- It quickly degrades the automated gun and necessitates frequent equipment replacement.

How is the Process of Laser Cleaning?

There are some steps to follow when using a laser cleaning machine. Let’s have a quick look!

Step 1: Powering on the Laser Cleaning System

Turn on the laser cleaning machine to get started. Then make sure that the cleaning substance is present in the working area.

Step 2: Direct the Laser Beam Toward the Surface

Now, point the infrared light made by a laser at the surface that has oxides, dirt, rust, or carbon on it.

Step 3: Light-Energy Absorption

When the laser hits the dirty metal surface, the impurities soak up the light energy from the laser. The pollutant is heated and removed from the surface. Throughout this time, the substratum remains frozen. It facilitates the removal of impurities from the surface. It results from the temperature difference between the substrate and the contaminant.

Step 4: Vacuum the Substrate

It uses a filtering system, like a vacuum cleaner, to get rid of dirt on the surface of a material. It guarantees the surface is clean, free of contaminants, and ready for usage.

What Are The Top Benefits Of Laser Cleaning?

Many modern businesses worldwide have started using lasers to clean their surfaces. There are several benefits of using a laser cleaning machine. Keep reading!

Cut Your Expenses

Laser cleaners are an excellent way to save money when cleaning a substrate. It’s because it only needs to be cleaned a few times.

With other cleaning methods, you may have to spend much money on materials and labor. The equipment is easy to keep up with and doesn’t cost much to run. It uses electricity that is easy to get.

Risk-Free

Safety is paramount because people are working on the cleaning process. Laser cleaning is safe because the person doing the cleaning doesn’t have to touch the thing being cleaned. Handheld laser cleaners can be turned into automatic laser cleaners. A person needs to point the laser at the material’s surface.

Flexibility

It’s the best way because it can be done in different ways. As a result, you can clean both large and small items. It’s better than the old cleaning methods in the industry, which only work on a small surface area.

It doesn’t clean well when doing a lot of work, such as chemical cleaning or sandblasting. So, it’s not as flexible as cleaning with a laser.

It's Non-Abrasive

It won’t change the shape or structure of the material. But blasting cleaning systems use abrasive materials that can destroy the layers of the material.

When a laser is used, it doesn’t touch the material, but it touches the contamination. In the end, this ensures that your material keeps its shape and structure.

Eco-Friendly

It’s good for the environment. Unlike chemical etching, ice blasting, and sandblasting, laser surface cleaning doesn’t need to use chemicals that are bad for the environment.

This cleaning method doesn’t involve sand mining, which is awful for the environment. Most importantly, it doesn’t produce a lot of trash that needs to be disposed of, which is also terrible for the surroundings.

Which Cleaning Solution Will Work Best for Your Needs?

|

Type of Product

|

Laser Cleaning

|

Plasma Cleaning

|

|

Rusted Hardware

|

Best Solution

|

Not Appropriate

|

|

Navy Ship Lead-Based Paint

|

Best Solution

|

Not Appropriate

|

|

Attachment to a Metal Surface

|

Best Solution

|

Not Appropriate

|

|

Glass

|

Not Appropriate

|

Best Solution

|

Best Application Of Laser Cleaner Machine

- Using before and after the welding processes

- Exterior and interior ship maintenance

- Cleaning of accumulated portions

- Engrave markings

- Mold cleaning

- Military Industry

- Surface treatment

- Microelectronics

- Heritage protection

- Medical

- Automobile processing and other fields

- Other objects can be cleaned with a laser cleaning machine, including- metal particles, metal corrosion, dust, etc.

Top Features Of Hantencnc’s Laser Cleaning Machines

- They are designed to be lightweight and easy to use.

- Easy to move by hand in any work area.

- Choose positioning and cleaning to reach the goal.

- Cleaning the things without touching them.

- There is no damage to the base, no pollution, and no need for treatment afterward.

- Low maintenance cost, high speed, and high performance.

- It’s reliable and safe and doesn’t hurt the operators’ health.

- The automation system is easy to set up.

- Automatic scanning can be turned on or off.

- It performs remote cleaning appropriately.

- It can be used with technology for numerical control.

Final Thoughts

In a nutshell, plasma cleaning was once the most effective technique for avoiding chemicals, abrasives, and acids. But laser cleaning has advanced significantly, and now it’s producing better outcomes.

Many companies have replaced plasma treatment with a portable laser cleaning machine. They can meet manufacturing speed, reliability, and other key demands.

Now, if you’re looking for a cost-effective, solid, and longer lifespan for your desired cleaning products, go for HantenCNC. It is a leading and professional laser machine manufacturer worldwide. Laser cleaning machines from HantenCNC are reliable. So, you can choose HantenCNC‘s laser cleaning machine within your reasonable budget. And you will be satisfied with their high-quality product’s service. HantenCNC believes in long-term relationships and customer satisfaction.