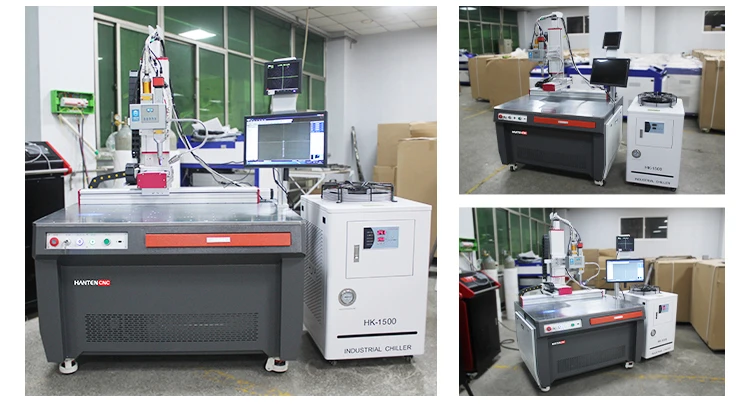

In order to meet the higher welding needs of customers, HANTENCNC has launched a welding equipment that can automatically weld——platform laser welding machine.

Understanding the platform laser welding machine

Compared with ordinary welding equipment, laser welding machine has the following advantages:

- The welding speed of laser welding machine is fast, while the welding speed of ordinary welding equipment is slow.

- Laser welding machine is non-contact welding, while ordinary welding equipment is contact welding.

- The welding quality of the laser welding machine is smooth, while the welding quality of ordinary welding equipment is not smooth.

- The material workpiece welded by the laser welding machine has a small deformation, while the material workpiece welded by the ordinary welding equipment has a large deformation.

- The laser welding machine is simple and easy to operate, has low requirements for welders, does not need a welder certificate, and female workers can weld easily,The operation of ordinary welding equipment is difficult, and the requirements for welders are also higher.

Machine configuration highlights:

Features of servo electric cylinder ball screw

- Small friction loss

- High precision

- High-speed feed and micro-feed

- High axial stiffness

- Not self-locking, with reversibility of transmission

Product function introduction:

Applicable industries of automatic welding machine equipment:

- Various electronic components,

- Stainless steel products,

- Mobile phone case,

- Automatic welding machine equipment for metal welding such as electrical accessories, seamless welding is firm and exquisite.

Advantages of platform welding machine:

- Welding is smoother: there is no pause during the welding process, and the welding effect can be observed during the welding process

- It is more professional and practical to cooperate with tooling:the tooling can be customized, not limited to the rotation axis, and various tooling fixtures can be customized according to the customer’s site and workpiece.

- Reduce welding cost:compared with traditional welding, there is no need for secondary processing and grinding;waste parts are greatly reduced, and labor costs are greatly reduced.

- The welding seam is more beautiful: the welding seam is more delicate and consistent, which is suitable for the welding of batch workpieces without secondary grinding.

Weld display:

- Precision welding of various metal parts

- Welding site fixture

- Flexibility in platform welding use

- On-site demonstration welding video

The cost of using the equipment is compared with the traditional method:

- High efficiency

- Two, long time

- Low technical requirements

- Little damage to the body

- The effect of welding is no different from that of senior welders

Cost comparison of traditional methods:

| salary | Welding Technology | welding time | annual fee rise | |

|---|---|---|---|---|

| Male workers | 300-500 yuan/day | high/super high | 8-9 hours/day | rise |

| female worker | 80-150 yuan / day | low/none | 8-9 hours/day | rise |

| machine | Electricity fee 1 yuan/kWh | None, need to program a program | 24 hours | drop |

The following are the technical parameters of the platform welding machine:

| model | LM5030 | |

|---|---|---|

| Processing stroke | 500*300*300mm (can be customized) | |

| laser power | 1000W 1500W 2000W | |

| welding head | automatic | |

| operating system | Easy Anyray or full-time vision system | |

| Control and drive | Servo screw | |

| Laser wavelength | 1080nm±5nm | |

| Spot size | Ø0.2-1.8mm | |

| welding depth | 2-5mm | |

| Output Power Adjustability | 10-100% | |

| Aiming and positioning | CCD | |

| electricity demand | 380V | |

| cooling method | Pure circulating water cooling | |

| Welding materials | Stainless steel, carbon steel, copper, aluminum, galvanized sheet |

| Platform Welding Parameters | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of axes | Stroke mm | welding pattern | structure | system | computer | voltage requirements | cooling method | display screen | Welding materials | welding gas | barometric pressure |

| x | 500 | round | screw | Yi Anrui | unnecessary | 380v | water cold | Have | aluminum | nitrogen, argon | 0.1-0.5mpa |

| the y | 300 | straight line | Linear guide | Wan Shunxing | need | 380v | water cold | Have | copper | nitrogen, argon | 0.1-0.5mpa |

| z | 300 | rectangle | servo drive | Jiaqiang | unnecessary | 380v | water cold | Have | Stainless steel | nitrogen, argon | 0.1-0.5mpa |

| Auxiliary axis | Spiral pattern | fiber optic | carbon steel | ||||||||

| Laser head rotation axis | character | control board | Galvanized sheet | ||||||||

Application industries of platform laser welding

- Battery welding

- Water cup sealing and back cover

- Air duct interface welding

- Button welding of explosion-proof keyboard

- Exhaust port welding

- Cold water pot for welding gun

Product Application Scenario

- Thermos cup welding

- Air duct interface welding

- Lithium battery welding

- Corner welding

The platform laser welding machine produced by HANTENCNC utilizes advanced sensing elements,

Such as:

- Vision sensor,

- Tactile sensor

- Auditory sensors and laser scanners, etc.,

And with the help of computer software system, database and expert system have the function of automatically generating welding record files.

HANTENCNC automatic welding machine equipment,

- The seamless welding is firm and exquisite, easy to use,

- Low operating cost,

- The welding speed is fast, the efficiency is high, and there are no trace solder joints.

- High welding quality, high efficiency, high precision, high performance welding, easy operation.

It is the best choice for your welding products!

Automotive Laser Welding Technology

In the automobile industry, laser welding is mainly used for the welding of automobile bodies and the welding of splice plates, such as the welding of roofs and side bodies.

Therefore, in order to meet the needs of the market and customers, it is very necessary to improve the body and manufacturing process, and the value of the body accounts for about 1/5 of the total value of the car.

The impact resistance and fatigue resistance of the body can be improved by adopting the laser welding process.

Significant improvements such as

- Reduce the weight of the vehicle body,

- Improve the assembly accuracy of the body,

- Increase the rigidity of the body, etc.

Because laser welding is controlled by computer, it has strong flexibility and mobility.Weldable:

- Shaped door panel,

- Deflector,

- gear,

- Instrument panels and other parts,

- It can also complete the top cover and side panels,

- Engine rack,

- Assembly of cooling racks, etc.

If fiber optic transmission systems and manipulators are added, it can Automated car assembly lines.

When we notice the vehicles coming and going on the road, we will find that there are two unsightly rubber bands on the roof of some cars, while the roof of some cars is like a flat steel plate, which is beautiful and smooth in one go. It looks very beautiful. However, in addition to being beautiful, such a model may be able to maximize the safety of passengers at critical moments. The reason for this difference is whether the car uses laser welding.

Of course, it’s not just FAW-Volkswagen who use laser welding technology. In fact, some luxury cars such as BMW, Audi, Mercedes-Benz, and Porsche basically use laser welding technology. It’s just that German Volkswagen has also adopted it in its mid-to-low-end models. At present, all FAW-Volkswagen series have adopted laser welding technology.

To sum up, laser welding technology can reduce the width of the joint surface between automobile workpieces, which not only reduces the use of plates, but also improves the rigidity of the body and greatly improves the safety. This not only improves the safety factor of the vehicle, but also makes the vehicle body more stable, ensuring the safety of passengers to the greatest extent.

Finally, let me tell you a few details that need to be paid attention to when using a handheld laser welding machine:

- Check the appearance of the laser welding machine: the appearance should be clean, ash-free, oil-free, and free of debris.

- Check the cooling system: the cooling water level should be within the normal range and kept clean. Observe whether the water temperature of the laser welding machine is suitable. Generally, it is set at about 21°C, and it can be adjusted appropriately between 20°C and 25°C according to the situation. When it is cold, antifreeze should be added, and pure water should be replaced when the temperature rises.

- Check the argon gas cylinder: the user should stand on the side of the bottle mouth and slowly open the gas cylinder valve, and then turn on the laser welding machine.

- Using copper nozzles: copper nozzles are mainly divided into whether to feed wire, the size of the welding wire, and the welding angle. Welding wires of different diameters should be matched with corresponding welding heads.

- The focused laser spot of laser wire filling welding acts on the welding wire instead of directly acting on the surface of the workpiece, and the welding wire is heated and melted to fill the weld seam.

- Pay attention during the working process of the laser welding machine, do not touch the laser beam with your hands and other body parts, and do not shoot yourself or others directly at the muzzle of the welding torch of the laser welding machine.

If necessary, please feel free to contact the official website mailbox and WhatsApp.