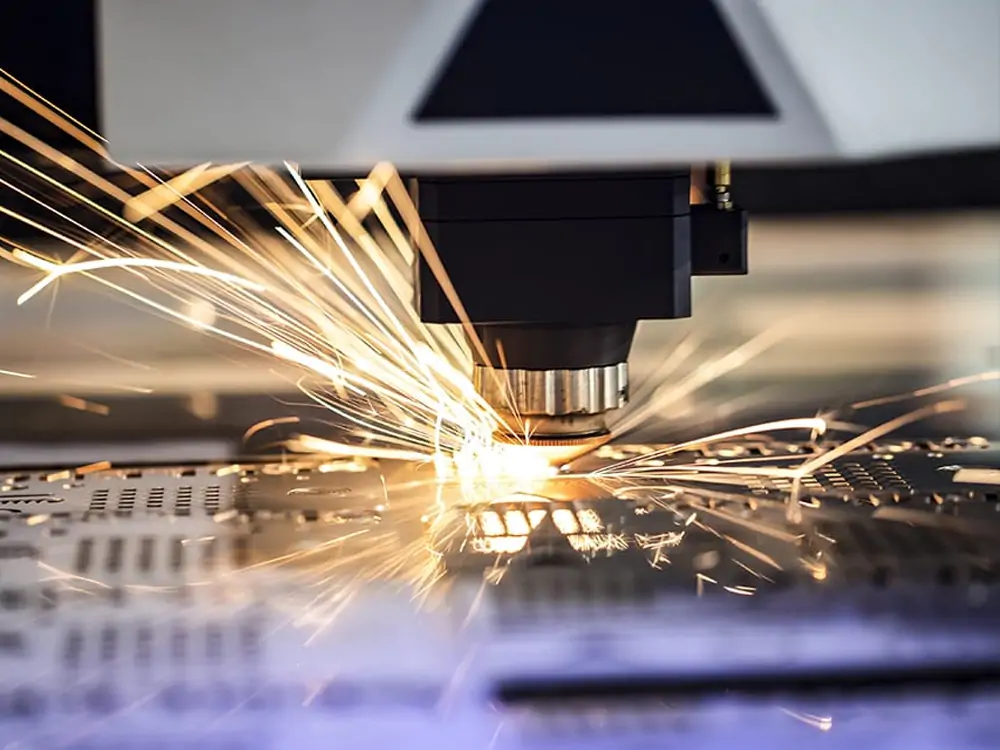

Regarding modern laser cutting technology, fiber laser cutting machines are undoubtedly a topic that gets a lot of attention. It has been widely used in various industrial fields. Everything from metal fabrication to automotive engineering to electronics manufacturing. However, the wide application of fiber laser cutting machines depends on their high precision and efficiency and their excellent material suitability.

In this article, we’ll look closer at the types of materials that fiber cutting laser machines can cut. Understanding the breadth and diversity of these materials ranges will help better understand the potential and applications of laser cutting technology. You may be a manufacturer, designer, or someone interested in laser cutting technology. This article will provide you with exciting insights into fiber laser cutter machines. Let’s explore together. See how this exciting technology demonstrates its unique, innovative capabilities on different materials.

What Can A Fiber Laser Cut

Metallic Material

Fiber laser cutting machines excel at cutting metal materials. The following are some common metal materials. They can be easily cut by fiber cutting laser machine.

- Steel: These include stainless steel, carbon steel, and alloy steel. These materials are commonly used in the manufacturing and construction sectors.

- Aluminum: Fiber laser cutting aluminum is standard. Fiber laser cutter machines are very effective in cutting aluminum and are suitable for aviation, automotive engineering, and other fields.

- Copper: This material is commonly used in electronics manufacturing and electrical engineering. Laser cutters can cut copper with precision.

- Titanium: Titanium alloys are widely used in medical devices and aerospace. Fiber laser cutting machines can handle this difficult-to-cut material.

- Alloy materials: These include various alloys. Such as nickel alloys and chromium alloys. They are widely used in high-temperature and corrosion-resistant fields.

- Other metal materials: Zinc, magnesium, etc., fiber laser cutting machines can also handle them.

The broad applicability of these metal materials makes fiber laser cutter machines the tool of choice in various industrial fields.

Non-metallic Materials

In addition to metal, fiber laser cutting machines can also handle a variety of non-metallic materials. Including but not limited to.

- Organic materials: These include acrylic, wood, and plastic. These materials are widely used in advertising, art, furniture manufacturing, and other fields.

- Composite materials: These include carbon fiber composites. They are used in aerospace and automotive engineering. Fiber laser cutting machines can cut these materials with precision.

- Textiles: Laser cutting machines can be used for cutting textiles, such as clothing and home furnishings.

- Rubber: Laser cutters can be used to make rubber seals and parts.

Other non-metallic materials: These include ceramics, glass, and paper. The fiber cutting laser machines are also applicable.

Industry Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines are widely used in various industries. Fiber laser cutter machines are efficient, exact, and flexible. It has become an indispensable tool in modern manufacturing and engineering fields. Below are some of the primary industry applications.

Manufacturing

Fiber laser cutting machines are widely used in manufacturing to cut metal parts. These include machine tool parts, automobile parts, and electronic equipment casings. It can cut various metals quickly and precisely, improving production efficiency.

Automotive Engineering

Fiber laser cutting machines cut body sheet metal, chassis parts, and exhaust systems in automobile manufacturing. Its precise cutting capabilities help improve the quality and safety of your car.

Electronics Manufacturing

Fiber laser cutting machines can produce housings, panels, and circuit boards for electronic devices. It can perform fine cutting, ensuring the precision and appearance of electronic products.

Building And Construction Industry

In construction, fiber laser cutting machines can cut metallic and non-metallic materials. Such as steel structures, aluminum, glass, and stone. It helps in making precise building components and decorative materials.

Medical Device Manufacturing

In the medical field, fiber laser cutting machines can manufacture medical device parts, implants, and surgical tools. Its high-precision cutting capabilities help ensure the reliability and safety of medical devices.

Aerospace

In the aerospace industry, fiber laser cutting machines can cut aerospace parts, spacecraft, and engine components. Its high-precision and high-speed cutting capabilities are critical for engineering projects in the aerospace sector.

Metallurgy

Fiber laser cutting machines can cut and process sheet metal in the metallurgical industry. It can manufacture pipes, storage tanks, boilers, and other equipment. It improves the efficiency and safety of metallurgical engineering.

Art And Design

Artists and designers use fiber laser cutting machines to create sculptures, installations, furniture, and decorative items. Precision and creativity make it an ideal tool for artwork and design projects.

Conclusion

Different materials have different characteristics and requirements. It requires fiber laser cutting machines to be adaptable and controlled. For example, metallic materials may need higher power, and gas helps maintain cut quality. Non-metallic materials may need more precise focus and speed control.

Fiber laser cutting machines excel at cutting a variety of materials. It brings essential innovation and efficiency to modern manufacturing and engineering. Understanding its material suitability will help you better use this powerful tool. You may be a manufacturer, designer, or technology enthusiast. Understanding the material capabilities of a fiber laser cutter machine will profoundly impact your work.