In just a few short years, the sales volume of HANTEN CNC laser cleaning machines has reached the leading level in the industry. As a laser cleaning machine manufacturer, HANTENCNC has excellent manufacturing capabilities and constantly explores new technologies to provide leading cleaning services.

As a laser cleaning machine supplier, HANTENCNC has independent design capabilities and can offer customers different options. This article shows why HANTENCNC is a trustworthy laser cleaning machine manufacturer.

Since the establishment of Jinan Hanteng Laser Technology Co., Ltd., we have been full of confidence in the future of lasers, from the earliest infrared CO2 laser to YAG to fiber laser. We have witnessed the rapid development of laser technology and experienced the most rapid development era of laser. There is no doubt that the most popular laser equipment in the laser market currently is the laser cleaning machine. Because of its non-polluting characteristics, it meets people’s purpose of environmental protection. Therefore, laser cleaning technology stands out among all cleaning methods.

1. Development history of laser cleaning machine

Laser cleaning has a long history. Some people applied laser cleaning to stone cleaning decades ago. However, due to the high cost of laser cleaning, it has yet to be popularized.

It was not until a few years ago that China’s laser cleaning machines began to sprout. The laser and the cleaning head are the most essential accessories of a laser cleaning machine. At that time, the laser was on the laser marking machine. So, it’s very bulky, and the output power of the laser is low—generally, only 100 watts or 200 watts of power. However, because the cost of the machine is very high, it has dramatically slowed down the development of laser cleaning to a certain extent.

Ultimately, no one knew about the existence of laser cleaning machines, and they could not afford the high price of the machines. At the same time, the most popular laser equipment is laser cutting machines and laser welding machines. Because of the significant demand in the market, the price of lasers is very suitable.

At this time, some laser welding machine manufacturers began to use continuous laser in laser cleaning. They developed a laser cleaning head based on the structure of a laser welding gun.

Due to the laser cleaning machine’s lower price and higher efficiency, the market has quickly accepted it.

After a period, it was discovered that the continuous laser cleaning machine can effectively remove rust from metal. However, the high temperatures generated by the laser during operation can cause metal deformation. Moreover, fires often occur when cleaning paint, which requires secondary processing of materials.

Another disadvantage is that protective glasses must be changed frequently, requiring experienced operators to change. The market urgently needs a laser cleaning machine that is simple to operate, easy to maintain and does not damage the cleaning materials.

So, laser cleaning machine manufacturers began researching pulsed lasers. Because of its unique light output structure, pulse lasers can control the residence time of the laser on the material. And pulsed lasers have better beam quality. The cleaning effect is excellent; there is almost no damage to the material, and the cleaning surface is smooth. The precision and flatness are good. Laser cleaning machines have developed to a new stage. Users no longer care too much about the machine’s price but the quality after laser cleaning.

2. Development history of laser cleaning machine manufacturer-HANTENCNC

Because HANTENCNC mainly produced laser marking machines before, Relying on the leader’s keen sense of the market, HANTENCNC immediately formulated a plan to develop pulse laser cleaning. We invested many human and financial resources to establish laser cleaning machines in the early stages.

Due to the availability of well-established laser and cleaning head components in the current market, we focused our research and development on the setting of cleaning parameters and appearance design, and we are aiming for the simplest and most efficient laser cleaning machines.

Because various laser cleaning machines have various power levels, applications, and user groups, we have designed over ten different appearances.

Additionally, we’ve conducted experiments and collected data from hundreds of cleaning tests to recommend the most suitable cleaning machine for our customers based on various cleaning materials and achieved cleaning results.

3. Advanced Technology and Equipment of HANTENCNC

a. Use JPT's MOPA lasers

If there are no specific customization requirements, HANTENCNC’s pulse laser cleaning machines use JPT’s MOPA lasers. MOPA lasers have superior operating frequency and pulse width performance compared to regular Q-switched lasers.

The term MOPA is an abbreviation for Master Oscillator Power Amplifier. The master oscillator produces the beam, while the optical amplifier boosts the output power.

Operating frequency refers to the number of laser pulses emitted per second. The MOPA laser has an adjustable frequency range of 1-4000 kHz, emitting up to 4,000,000 pulses per second, allowing for the precision processing of materials. Pulse width, measured in nanoseconds, represents how long the laser beam stays on the material. The MOPA laser’s pulse width can be adjusted within 2-500 nanoseconds. Different cleaning effects can be achieved by varying the laser’s pulse width and operating frequency.

b. Equipped with GY's laser cleaning heads

HANTEN CNC’s laser cleaning machines are equipped with professional laser cleaning heads produced by GY Company.

These cleaning heads are easy to operate, feature a stable, lightweight design, and have user-friendly control handles. They also incorporate a laser protection system developed for safety purposes to prevent potential damage caused by operator errors. Additionally, GY’s laser cleaning heads are top-selling in the Chinese market, having undergone quality verification and offering guaranteed after-sales service.

c. Superior Quality Control

When manufacturing laser cleaning machines, HANTENCNC follows a rigorous process.

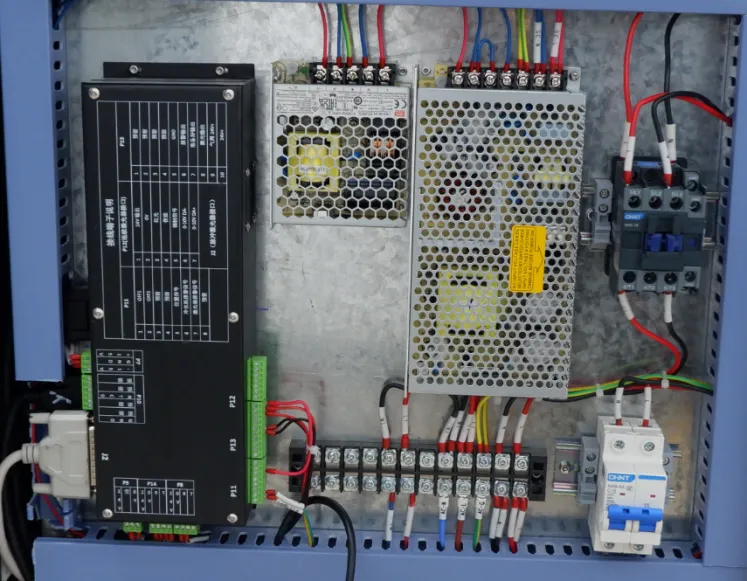

We require every set of wires used in these machines to be of equal length and marked with different colors, enabling our customers to perform simple troubleshooting and maintenance efficiently.

Furthermore, each laser cleaning machine must undergo at least 48 hours of continuous operation before leaving the factory to assess all components’ compatibility and test the machine’s continuous working capability.

d. HANTENCNC provide customised cleaning machine solutions

Since HANTENCNC entered the laser cleaning machine field, we have always aimed to provide customised cleaning machine solutions.

Usually, people require a specific appearance, whether for marketing purposes or improving usability, by removing unnecessary features or configurations. HANTEN CNC has a professional engineering team ready to offer customised services to you; even if you purchase one laser cleaning machine, you can enjoy our customisation services.

e. Diverse Application Fields

The reason why laser cleaning machines are so popular today is inseparable from their wide range of applications. For example, the following are some very classic applications.

Clean rubber residue from tyre moulds

Hundreds of millions of tyres are produced globally yearly, causing severe tyre mould wear. Since the mould is costly, it must be replaced infrequently. Therefore, the rubber residue on the mould surface must be cleaned regularly to reuse the mould.

Before the invention of laser cleaning machines, people used sandblasting or dry ice blasting to clean the residual rubber.

However, this cleaning must wait for the mould to cool down, which will increase the cleaning time and may cause damage to the mould surface. This kind of damage is severe to the mould because it affects the accuracy of the mould and the final product quality.

Introducing the laser cleaning machine improves the cleaning efficiency. Also, it does not cause damage to the mould itself because laser cleaning does not vaporise rubber and does not produce harmful gases.

According to HANTENCNC testing and customer data, the laser cleaning machine can clean large tyre moulds in 2 hours. Compared with traditional cleaning methods, the efficiency is significantly improved.

f. HANTENCNC's Success Case

HANTENCNC’s laser cleaning machines have attracted much attention in the global market, and we have many successful cleaning cases.

For instance, we have a customer from the United Arab Emirates. They need to clean the paint on the surface of the oil pipeline, and after cleaning, it needs to be re-sprayed with new paint. We provided this customer with various solutions, and ultimately, the customer chose to work with us.

They provide feedback that our laser cleaning machines perform well and can effectively clean paint residues from the pipe’s surfaces.

4. HANTENCNC: Your Trusted Laser Cleaning Machine Manufacturer

HANTENCNC is a laser cleaning machine manufacturer that manufactures and sells its products directly.

As a laser cleaning machine supplier, HANTENCNC has independent design and production capabilities; HANTENCNC can provide customers with various cleaning solution options and sales and after-sales service.

HANTENCNC’s sales can provide customers with professional customized cleaning solutions, while after-sales personnel can support customers’ technical support.

In just a few short years, the sales volume of HANTEN CNC laser cleaning machines has reached the leading level in the industry. We have excellent manufacturing capabilities and constantly explore new technologies to provide internationally leading cleaning services.

We welcome you to visit our production workshop, communicate with us, and jointly promote the advancement of laser cleaning technology.