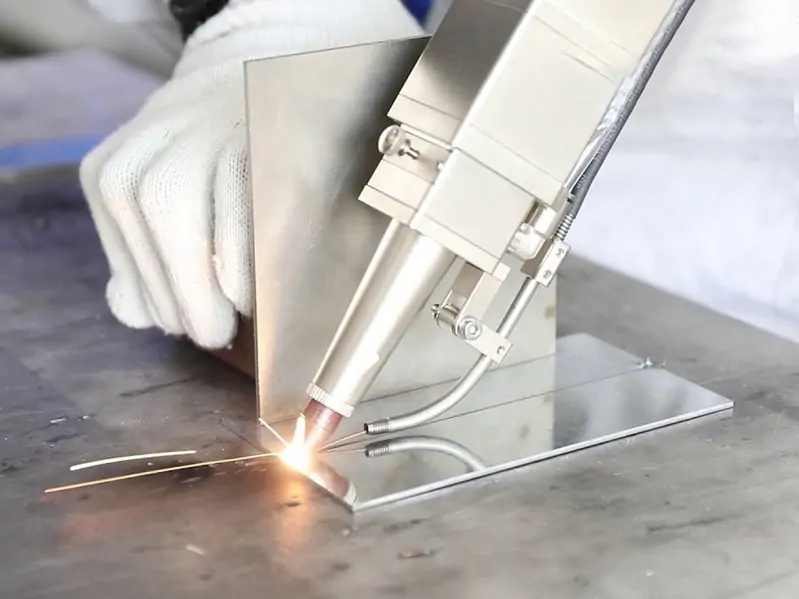

The handheld laser welding machine is a modern welding tool. It uses a laser beam to perform precision welding and is widely used in manufacturing and other fields. However, just like any other tool, they face some common problems. These issues can affect welding quality, efficiency, and safety. Therefore, understanding these issues and how to resolve them is critical for operators using handheld laser welding machines.

In this article, we will explore the sources of common problems with handheld laser welder machines. We will also discuss the solutions to these problems. You may be a professional operator or a beginner. This article will provide you with important information on optimizing your welding process and ensuring the proper operation of your equipment. You follow correct operation and maintenance procedures. You can realize the full potential of your handheld laser welding machine and achieve high-quality welding. Now, let’s dive into everyday problems and solutions you may encounter with handheld laser welding machines.

Handheld Laser Welder Problems And Solutions

Various common problems may occur during the use of handheld laser welder machines. The following are some common problems and corresponding solutions.

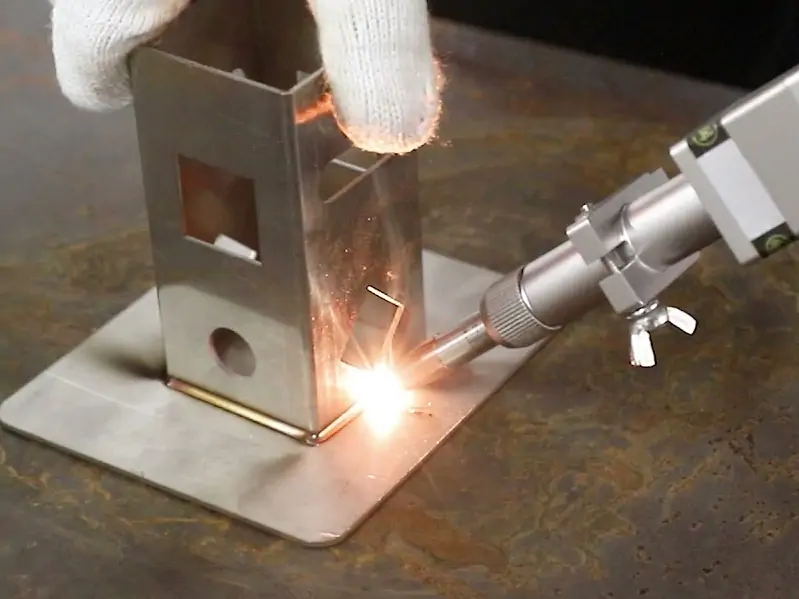

Weld Quality Issues

Problem: Welds develop cracks, holes, pits, or other defects.

Solution:

- Select the appropriate focus position and focus diameter, and adjust the power and speed for the best welding results.

- Keep the workpiece surface clean and use suitable protective gas to prevent oxidation.

- Ensure workpiece preparation and docking are correct.

Welding Speed Problem

Problem: The welding speed needs to be fixed, too slow or too fast. It will affect the welding efficiency.

Solution:

- Adjust the welding speed according to the workpiece material and welding requirements.

- Ensure the hand held laser welder’s focus position is accurate to avoid welding speed that is too slow or fast.

- Maintain cleanliness and stability of optical systems.

Optical System Issues

Problem: The laser beam is unstable, and the optical path may be contaminated or damaged.

Solution: Regularly inspect and maintain the optical system to ensure the lenses and lenses are clean and intact. Calibrate the optical path to ensure the laser beam is accurately focused on the welding point.

Power Issues

Problem: The hand held laser welder’s power supply is unstable, and the current fluctuates.

Solution: Check the power line to ensure the power voltage is stable. If the power problem persists, the power supply unit may need to be replaced or repaired.

Security Question

Problem: Laser radiation poses a hazard to operators.

Solution: Operators must wear appropriate laser safety glasses and other protective equipment. Operators must comply with laser safety regulations. Establish safe areas and ensure operators receive relevant training.

Maintenance Issues

Problem: The equipment requires regular maintenance but is not being maintained.

Solution: Establish a maintenance schedule regularly to replace worn parts, such as lenses. Keep equipment clean to reduce the impact of dirt and dust on welding quality.

Parameter Setting Problem

Problem: Incorrect welding parameter selection.

Solution: Familiarize yourself with the optimal parameter settings for different materials and welding types. Experiment and adjust to the specific situation for the best welding results.

Operation Skills Issues

Problem: Need for operator skills.

Solution: Provide professional training to ensure operators have correct operating skills and safety awareness.

Conclusion

Handheld laser welding machines are an essential tool in modern manufacturing and engineering. It provides us with high-precision and high-efficiency welding solutions. However, like any other technology, it can face some common issues. In this article, we explore these issues in depth and provide solutions. It will help operators realize the full potential of handheld laser welding machines.

For those professionals who are already proficient in this technology, understanding and solving common problems can improve welding quality, efficiency, and equipment life. Understanding these problems and their solutions will help beginners and novices master the operating skills of handheld laser welding machines faster and reduce operational risks.

This article provides solutions to some common problems, but that’s just the tip of the iceberg. Over time, new issues and new solutions may emerge. Therefore, continued learning and continuous improvement are the keys to success in handheld laser welding machines.