This article is divided into three sections. Firstly, it introduces what is battery pack. Secondly, it discusses various battery packaging technologies developed in recent years. Finally, it highlights the advantages of HANTENCNC’s gantry-type Galvo battery laser welding machine.

What is battery pack?

Before understanding what is battery PACK, we must know the single lithium battery. A single lithium battery refers to a single lithium cell. For example, a 4V polymer lithium battery cell is a single lithium battery. Through the above explanation, everyone understands the single lithium battery concept. Next, let’s look at the classification of lithium batteries according to their appearance.

There are differences in the types of lithium battery cells. There are mainly cylindrical batteries, soft pack batteries, and square case batteries. The single capacity of cylindrical batteries is small, generally at most 10ah. Soft-pack batteries have better safety performance, and single cells can be used. To about 60ah, the square case battery can also reach about 100ah.

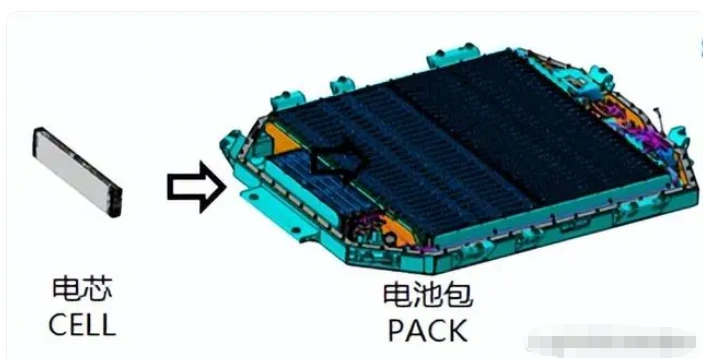

The term “battery pack” refers to a manufacturing process for lithium-ion batteries. A battery pack typically refers to an assembled lithium-ion battery system, which includes packaging, sealing, and assembly. In the battery pack industry, when specific shapes are assembled according to customer requirements, we refer to it as a “pack.”

A ” battery pack” refers to assembling individual lithium batteries into the desired configuration per the customer’s requirements. However, this process is quite complex.

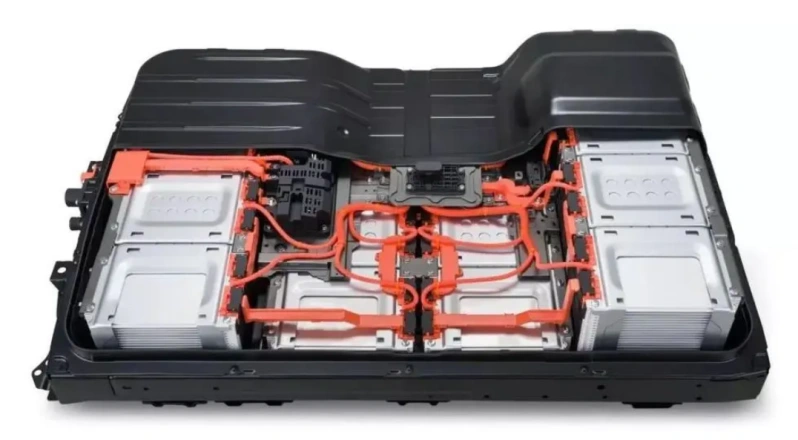

A complete battery pack includes:

- Structural components (the protective casing for the battery pack)

- Thermal management components (such as heat pipes and temperature control systems)

- Battery modules

- BMS (Battery Management System) mounting board

- Wiring harness

- etc.

When designing a battery pack, it is essential to consider factors such as total power, capacity, heat dissipation, and safety of the batteries. This process involves an intricate and active structure, requiring thorough validation. In the early stages of electric vehicle production, Tesla utilized thousands of 18650 batteries. After being assembled into packs, these batteries were installed in early models like the Model S. These battery packs featured sophisticated battery management systems capable of monitoring each cell’s charging and discharging status.

BYD’s newly developed blade battery follows a similar approach, where individual cells are packed into the battery pack. These cells have a length of up to 0.6 meters, making the overall structure even more intricate.

Battery Packaging Technology

After understanding “what is battery pack”, let’s delve into Battery Packaging Technology.

The PACK of the battery cell, also known as CTP (CELL TO PACK), belongs to the second-generation battery packaging technology and is currently the most widely used method. Its advantage lies in its high degree of integration, but it needs to improve its utilization of car space, making PACK design challenging.

The third-generation battery packaging technologies, CTB (CELL TO BODY) and CTC (CELL TO CHASSIS) integrate the battery seamlessly with the car, significantly reducing the use of parts and wiring harnesses, thereby enhancing reliability.

Each of the three methods, CTP, CTB, and CTC, has pros and cons. With the development of advanced technologies, the challenges related to the simplified structure of power batteries (Pack), including strength, safety, and control, will be effectively addressed.

What is Battery Laser Welding Machine

let’s introduce what a battery laser welding machine is.

The battery laser welding machine is a welding equipment used in battery production. The battery laser welding machines are used for welding individual battery cells together, combining them to create larger battery packs with increased energy capacity. This interconnecting individual cells is a crucial step in assembling battery packs.

Advantages of HANTENCNC's Battery Welding Machines

This part will introduce HANTENCNC’s gantry-type Galvo battery laser welding machine and its advantages.

The following product is HANTENCNC’s newly launched gantry-type Galvo laser welder, specifically engineered for high-performance applications. This machine offers remarkable advantages, including rapid welding speeds, exceptional precision, unwavering quality, user-friendly operation, and straightforward maintenance procedures.

Designed with meticulous attention to detail, HANTENCNC’s gantry-type Galvo laser welding machine excels in laser precision spot welding of battery tabs and parts, ensuring seamless and durable connections crucial for the reliability of battery assemblies.

Its gantry-type structure provides stability and accuracy during welding, enabling precise control over the welding points.

1. The gantry-type Galvo battery laser welding machine exhibits efficient welding capabilities

HANTENCNC’s gantry-type Galvo battery laser welding machine employs advanced vibrational mirror technology to complete welding tasks rapidly and accurately. Compared to traditional manual welding, it significantly enhances welding speed, reduces labor costs, and ensures stable welding quality.

2. The gantry-type Galvo battery laser welding machine features high automation

Equipped with an advanced control system, HANTENCNC’s gantry-type Galvo battery laser welding machine achieves automated welding processes. Simple welding parameter settings enable the machine to autonomously complete tasks without human intervention, enhancing production efficiency and reducing operator workload.

3. The gantry-type Galvo laser welding machine delivers exceptional welding quality

HANTENCNC’s gantry-type Galvo battery laser welding machine utilizes high-precision welding heads to achieve superior welding results. The vibration frequency of the welding head can be adjusted based on different welding requirements, ensuring the durability and electrical conductivity of welding points. Additionally, the machine can automatically detect welding quality issues and promptly raise alarms, ensuring the stability of product quality.

4. The gantry-type Galvo laser welding machine exhibits excellent adaptability

HANTENCNC’s gantry-type Galvo battery laser welding machine can accommodate various power batteries, including lithium-ion and nickel-metal hydride batteries. The machine ensures high-quality welding regardless of different battery sizes or structures, making it widely applicable in battery production.

Conclusion

HANTENCNC’s gantry-type Galvo laser welding machine offers efficient welding capabilities, high automation, exceptional welding quality, and adaptability. It not only improves production efficiency and reduces costs but also ensures the stability of product quality. In the future, the gantry-type Galvo laser welding machine will play an increasingly vital role in battery production.

In summary, We’ve included an introduction to the advantages of the gantry-type Galvo laser welding machine. If you don’t know what is battery pack and if you need a battery laser welding machine, we hope this article will help you understand what is battery pack and how to select a suitable battery laser welding machine.