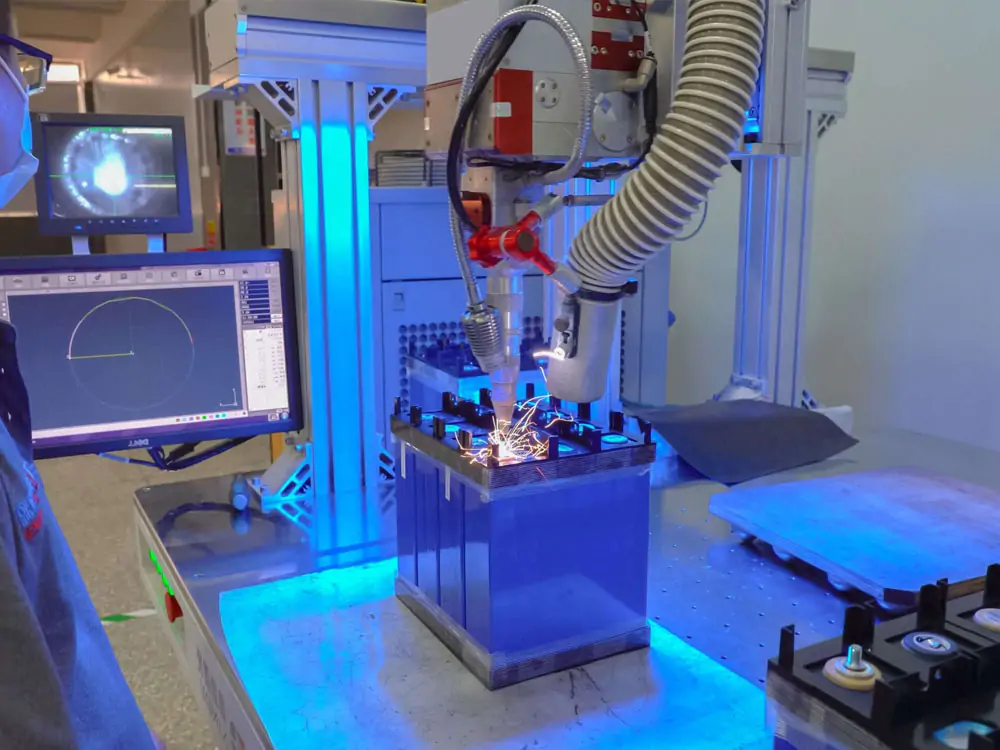

Laser welding technology has been widely used in the modern manufacturing industry. It has the advantages of high efficiency, precision, and no pollution, especially in battery manufacturing. Batteries are core components of various electronic devices. Its manufacturing quality directly affects the performance and service life of the equipment. Choosing a suitable laser welding machine is particularly important for battery manufacturing.

When choosing the right battery laser welding equipment for your needs, there are several factors to consider. These include application requirements, technical specifications, performance, and cost. In this article, we will delve into how to choose the suitable battery laser welding machine for you. Ensure your production processes are efficient and reliable and achieve the best quality.

Technical Specifications And Performance to Consider

It would help to consider several important factors when purchasing a battery laser welding machine. It can ensure the best fit for your needs. Here are some key factors to consider.

Laser Power And Stability

Laser power directly affects the speed and quality of welding. It would help if you chose the appropriate laser power based on the battery material and thickness. Stable laser power ensures consistency and quality of welding.

Pulse Frequency And Pulse Width

Pulse frequency and pulse width determine the energy transfer and control of welding. The appropriate pulse parameters allow for precise welding and avoid over-heating or under-heating.

Welding Speed

High welding speed can improve production efficiency. You need to balance welding speed and welding quality. You are choosing the right speed to ensure the best balance of quality and productivity.

Weld Head Shape And Size

Different laser welding machines may offer other welding head options. Select the right welding head shape and size for your application. It can ensure that it is suitable for different welding scenarios.

System Stability And Reliability

Choose laser welding equipment with good stability to ensure long-term, high-strength working stability. Stable equipment can ensure welding quality and production efficiency. In addition, you also need to consider the maintenance requirements and maintenance costs of the equipment. Choose laser welding machines that are easy to maintain and repair to reduce downtime and repair costs.

Expenses And Return on Investment

Consider equipment buy costs, operating costs, and maintenance costs. Ensure the equipment fits your budget while considering the long-term return on investment. In addition, choose equipment that can adapt to future technological upgrades and developments. Ensure that your investments remain competitive and adapt to new market demands.

Manufacturer Reputation And After-sales Service

Choose a reputable laser welding equipment manufacturer. Make sure you choose a reliable supplier by knowing their customer reviews, history, and confirmed cases. At the same time, we should understand the after-sales service quality of laser welding equipment manufacturers. These include technical support, training, maintenance, etc. Ensure timely and effective support during use.

Suitable For Machines With Different Battery Types

When choosing a battery laser welding machine, you need to consider the characteristics of the battery type. Different battery types may have other materials, thicknesses, and structures. So, choosing a laser welder requires adapting to these changes. The following are some suggestions for choosing laser welding machines with different battery types.

Lithium-ion Battery

- Features: Lithium-ion batteries are used in mobile electronic devices and electric vehicles. Features include high energy density and lightweight.

- Choose a laser welding machine: Choose a laser welding machine that provides the proper energy density and precision welding. Pulsed laser welding technology can control the welding process and avoid excessive heating.

Nickel Metal Hydride Battery

- Features: Ni-MH battery has high safety, long life, and discharge rate.

- Choose laser welding machine: This battery suits for pulsed laser welding machines. It provides high energy density in a short time, ensuring efficient welding.

Lead-acid Battery

- Features: Lead-acid batteries are often used in automotive startups, UPS. It had mature technology and low cost.

- Choose a laser welding machine: Consider a traditional laser welding machine. It can meet the basic welding requirements of lead-acid batteries.

Sodium-sulfur Battery

- Features: The sodium-sulfur battery is a new battery technology. It has high energy density and high-temperature operation characteristics.

- Choose a laser welding machine: Choose one that can adapt to high-temperature conditions. It can ensure welding quality and efficiency.

Solid-state Battery

- Features: Solid-state batteries are emerging technologies with high safety and energy density.

- Choose a laser welding machine: Consider advanced laser welding technologies. Such as ultra-fast laser pulse welding. It can adapt to the high requirements of solid-state batteries.

Conclusion

When you are faced with choosing the right battery laser welder for your needs, keep a few key factors in mind:

- Make sure to understand the specific requirements of your project. These include material type, weld depth, production volume, and budget constraints.

- Carefully study different models and brands of laser welding machines. Compare their technical parameters, performance, and user evaluation.

- Consider getting professional advice.

They can provide customized advice based on your needs. Choosing a suitable laser welding machine for your business will bring efficiency and quality improvements to your production line. I hope you find the best battery laser welding machine and help your project succeed.