Today, the engineers of HANTENCNC will explain to you some content about the laser cutting machine. Including the following:

- Types of laser cutting machines

- Advantages and disadvantages of laser cutting machine

- Application industry of laser cutting machine

- The price of the laser cutting machine

What is a laser cutter?

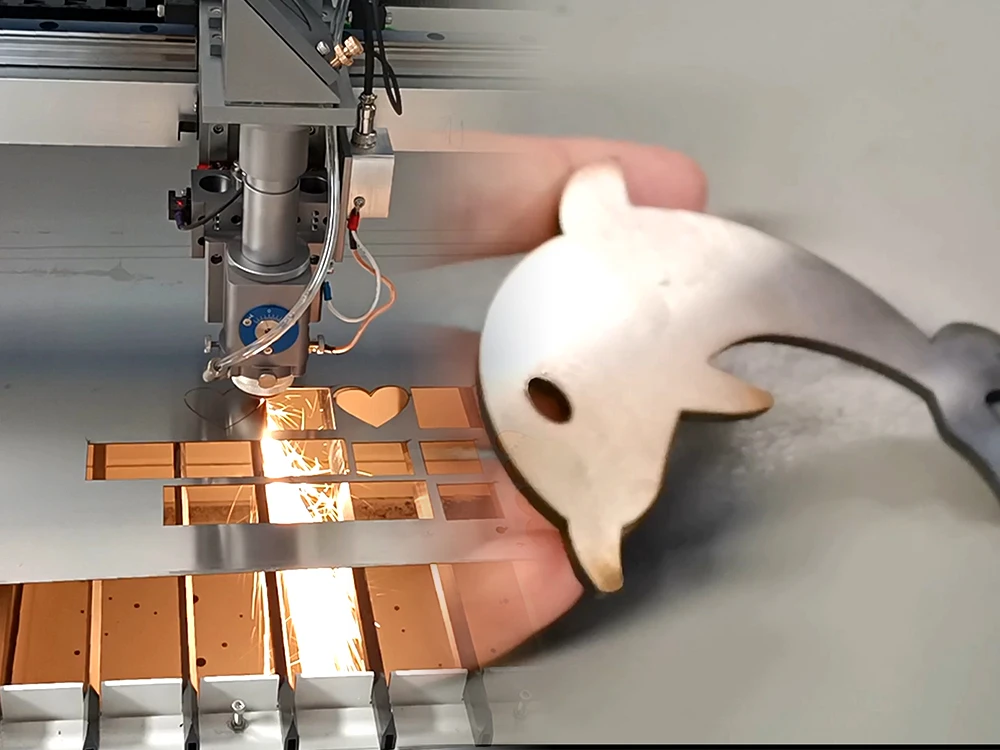

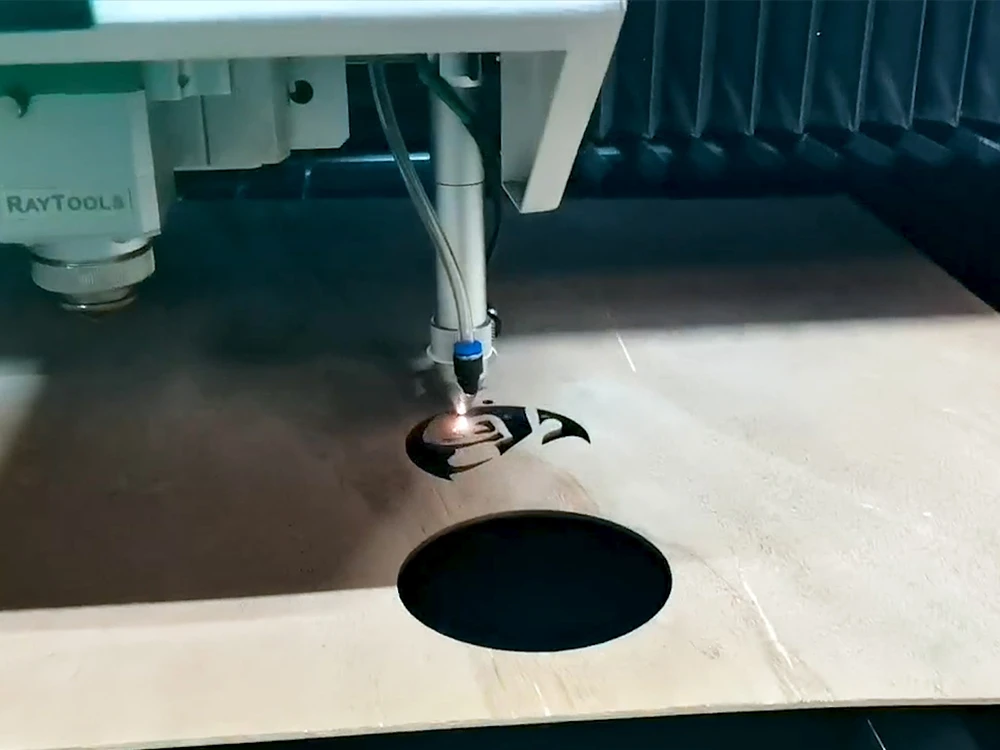

A laser cutting machine is a device that uses laser technology to cut materials. When the laser cutting machine is working, the laser beam is focused into a very small point by the focusing lens, which produces a high-power-density beam that melts, vaporizes or burns the material, making the object move along the cutting line to obtain the required shape. Laser cutting machine is mainly suitable for the processing of metal, non-metal and other materials, including plates, pipes, stainless steel, aluminum alloy, copper, alloy steel, plastic, rubber, organic glass, etc. Compared with the traditional mechanical cutting, the laser cutting machine has the advantages of high cutting precision, fast speed, no burr, no deformation and so on. Laser cutting machines are widely used in the fields of automobiles, electronic equipment, catering equipment, mechanical equipment, medical equipment, architectural decoration, etc.

Price of laser cutting machine

Laser cutting machine price:

The price of laser cutting machine varies with brand, model, power, control system, cutting material and other factors. The price ranges from a few thousand yuan to a few hundred yuan. The following is the price reference of laser cutting machine frequently consulted by some customers of HANTENCNC:

Fiber laser cutting machine:

The price of a fiber laser cutting machine with a power of 500W-2000W is between US$15,000 and US$45,000.

CO2 laser cutting machine:

The price of a CO2 laser cutting machine with a power of 130W-600W ranges from US$7,500 to US$15,000.

Metal laser cutting machine:

The price of metal laser cutting machines is generally relatively high, ranging from US$45,000 to US$30,000.

HANTENCNC engineers remind you: It should be noted that the price of the laser cutting machine is not the only cost. There are other costs to consider, such as transportation, installation, commissioning, training, maintenance, etc. Therefore, when purchasing a laser cutting machine, you must fully consider various factors and choose the right manufacturer and product for you.

If you have other questions, welcome to contact us online. Believe that HANTENCNC is your right choice.

If you have any other questions, welcome to contact us online. Believe that HANTENCNC is your right choice.

Laser cutting machine types

According to different cutting principles and structural characteristics. Laser cutting machines can be divided into the following types:

- CO2 laser cutting machine: use CO2 gas to generate laser beams to achieve cutting.

- Fiber laser cutting machine: uses optical fiber to transmit the laser beam. It has the characteristics of high energy conversion efficiency and small footprint.

- YAG solid-state laser cutting machine: use solid-state laser to generate laser beam. It can adapt to the cutting of metal materials of different colors.

- UV laser cutting machine: using ultraviolet laser as the source. Combined with control technology to achieve high-speed, high-precision cutting.

- Three-dimensional laser cutting machine: It has a laser head that can move and rotate in multiple axes. It can realize the cutting of more complex three-dimensional parts.

- Small power laser cutting machine: small laser cutting equipment. It is mainly for fine cutting requirements of small parts, thin plate materials, micro components and so on.

HANTENCNC engineers suggest you: each laser cutting machine has its unique characteristics and scope of application. Users need to consider comprehensively according to their actual needs and budget when choosing.

Advantages and disadvantages of laser cutting machine

The advantages are as follows:

- High precision: Laser cutting machines can achieve very high precision, capable of precise cutting within the millimeter scale.

- Large cutting area: The laser cutting machine can cut a large area, which is suitable for cutting large parts.

- Fast cutting speed: The cutting speed of the laser cutting machine is very fast, which can greatly improve work efficiency.

- Good cutting quality: The laser cutting machine can achieve smooth and flat cutting edges without leaving marks.

- Wide range of cutting materials: the laser cutting machine can cut most metal materials and non-metal materials.

- Little environmental pollution: the cutting process of the laser cutting machine does not produce any chemical reactions and pollutants. Friendly to the environment.

What are the advantages of laser cutting machines compared with traditional cutting methods? I believe many customers are also concerned about this issue. Let me explain to you in detail today:

- High precision: laser cutting machine can achieve high precision cutting. Ability to precisely cut parts of various shapes and sizes. The accuracy can reach an error of a few millimeters or less.

- High-speed cutting: The cutting speed of the laser cutting machine is fast, and it can quickly cut various materials. Especially for metal materials, the speed of processing is much faster than traditional machining, which improves production efficiency.

- Welding function: The laser cutting machine also has a welding function. Parts can be welded while cutting. It avoids the cumbersome process of cutting first and then welding in the traditional cutting process.

- Precision cutting: Laser cutting machines can cut on small parts. Avoid chips and burrs caused by traditional machining, and quickly complete the processing of parts with simple shapes.

- Low energy consumption: Laser cutting machines use laser beams for processing. There is no need to use a large amount of electricity and fuel, which can save energy and protect the environment.

- High degree of automation: Laser cutting machine can realize automatic production and manufacturing. Reduced manual intervention, more secure and efficient.

However, laser cutters also have some disadvantages:

- High cost: The high price of laser cutting machines makes it unbearable for many small businesses.

- Shallow cutting depth: Laser cutting machine can achieve high-precision cutting. But its cutting depth is relatively shallow.

- There are certain requirements for materials: laser cutting machines have certain requirements for the hardness of materials. Some special materials cannot be cut by laser.

- The optical fiber of the optical fiber laser cutting machine is easy to be damaged: because the optical fiber of the optical fiber laser cutting machine is very thin, it is easy to be damaged. So the maintenance cost is relatively high.

Hanteng CNC engineers suggest you: when choosing a laser cutting machine, you need to consider its advantages and disadvantages and your actual needs. Choose the most suitable laser cutting machine.

Laser cutting machine application industry

HANTENCNC laser cutting machine has the advantages of high precision, high efficiency, large cutting area and good cutting quality. It is widely used in many industries, mainly including the following aspects:

Metal processing industry:

Laser cutting machines can be used for cutting the following metal materials: seamless steel pipes, heaters, condensers, burners, gas tanks, auto parts, aerospace, etc.

Electronic and electrical industry:

Laser cutting machines can be used for optical components. Cutting and processing of semiconductor materials, various electronic components, electronic circuit boards and other materials.

Precision hardware industry:

Laser cutting machines can be used to process precision mold parts. Watches, glasses, jewelry, art and other industries.

Building decoration industry:

Laser cutters are available for stainless steel decorative panels. Production of aluminum alloy mirror frames, copper decorations, metal carvings, carved artworks, etc.

Automobile and shipbuilding industry:

Laser cutting machines can be used for automotive sheet metal processing. Shipbuilding, hull cutting and repair and other occasions.

Textile and garment industry:

Laser cutting machines can be used for cutting and engraving of leather, textiles, clothing, household items and more.

In general, laser cutting machines are widely used in various fields of modern manufacturing and processing. Improve production efficiency, reduce production costs and improve work efficiency for various industries. If necessary, you can contact HANTENCNC online engineers to answer your questions at any time.

After sales of laser cutting machine

Many customers can’t find a seller when they have problems using the laser cutting machine after purchasing it. So after-sales service is also very important. Here are some key points summarized by HANTENCNC:

After-sale guarantee:

When purchasing a laser cutting machine, you should choose a brand with high popularity and good after-sales service. And choose regular channels to buy. In this way, perfect after-sales protection can be obtained.

Repair and maintenance:

laser cutting machine is a kind of complex machine equipment. Frequent repair and maintenance is required to ensure its normal operation and service life. Therefore, when purchasing a laser cutting machine, you should understand the brand’s after-sales service and maintenance plan.

Training support:

The use of laser cutting machines requires certain technical support and training. In order to be able to operate and maintain the equipment proficiently. When purchasing a laser cutting machine, you should know whether the brand provides training support. To avoid technical difficulties in the later stage.

Supply of accessories:

During the use of the laser cutting machine, some consumables or accessories need to be replaced or used. Such as lenses, xenon lamps, fans, etc., you need to choose the corresponding accessories according to the model of the equipment. Therefore, ensuring the sufficiency of spare parts supply is also a key point of after-sales service.

In short, when buying a laser cutting machine, in addition to paying attention to the performance and price of the equipment. Also pay attention to the quality and guarantee of after-sales service. Only with the all-round support of after-sales service can the development and application of cutting equipment be better promoted.