Before officially introducing the CO2 laser marking machine, let me introduce the differences between the fiber laser marking machine, CO2 laser marking machine and UV laser marking machine. as follows:

- The process principle is different: the optical fiber marking machine marks by passing the laser beam through the optical fiber. The CO2 marking machine is generated by exciting the laser through the CO2 gas medium. The UV laser marking machine is used to mark directly through the UV laser beam.

- The marking effect is different: the lines marked by the optical fiber marking machine are very delicate and fine. CO2 marking machines are more common in large-area marking. UV laser marking machines can mark in very small areas.

- Applicable materials are different: the optical fiber marking machine is suitable for most metal and some non-metal materials. CO2 marking machines are usually suitable for non-metallic materials. UV laser marking machine is suitable for heat-sensitive plastics, ceramics, glass and other materials.

- Different marking speeds: The marking speed of fiber optic and CO2 marking machines is usually faster than that of UV laser marking machines.

What is a CO2 laser marking machine?

Customers who want to buy a carbon dioxide laser marking machine must understand what a laser marking machine is before buying. Only by understanding this product can you know whether it meets your own production needs. Today, engineers from HANTENCNC will explain to you in detail: CO2 laser marking machine is a device that uses laser technology to mark text, patterns, barcodes, etc. on the surface of various materials. The main laser source used is carbon dioxide laser.

The configuration of carbon dioxide laser marking machine usually includes the following parts:

- Laser: CO2 laser is usually used.

- Mirror: used to reflect or refract the laser beam to control the direction and position of the laser beam.

- Scanning system: used for horizontal and vertical scanning of the laser beam.

- Control system: including the host, operation interface, program, etc., used to control the operation of the laser marking machine.

- Cooling system: used to cool the CO2 laser.

- Beam expander: used to expand the laser beam.

The above is the general configuration of carbon dioxide laser marking machine, and the specific configuration will be slightly different according to different brands and models.

The application industry of CO2 laser marking machine

Carbon dioxide laser marking machines are widely used in many industries due to their fast speed, high precision and convenient operation. The following are the main application industries of carbon dioxide laser marking machines. They are also part of the customer groups of HANTENCNC:

- Electronics industry: marking of electronic products such as mobile phones, tablet computers, and televisions. Exterior carving.

- Machinery industry: marking, engraving and cutting of robots, machine tools, mechanical parts, etc.

- Medical device industry: marking of surgical instruments, in vitro diagnostic equipment, etc.

- Food packaging industry: marking of food bags, bottle caps, etc.

- Automobile industry: marking and engraving of auto parts, auto glass, etc.

- Pipeline industry: marking and engraving of PVC pipes, PE pipes and other pipes.

The above are only the main application industries of carbon dioxide laser marking machines. Including all metal and other non-metal products can also send samples to HANTENCNC for free testing. With the continuous development of technology, the application range of carbon dioxide laser marking machine will be more extensive.

Advantages of CO2 laser marking machine

According to the experience of HANTENCNC engineers. Compared with traditional marking methods, CO2 laser marking machine has the following obvious advantages:

- Fast speed: CO2 laser marking machine can quickly complete the marking task. The number of markings per second can reach more than thousands of times.

- High precision: CO2 laser marking machine has high precision marking capability. High-precision marking can be performed on the surface of small objects.

- Strong controllability: CO2 laser marking machine can accurately control the marking shape, size and other parameters by controlling the position, speed and intensity of the laser beam of the marking head.

- Wide applicability: CO2 laser marking machine can mark on the surface of many different materials. Including metal, plastic, glass and other materials.

- Good engraving effect: CO2 laser marking machine has excellent engraving effect. It can realize high-precision, high-definition pattern and text engraving on small objects.

- Environmental protection: carbon dioxide laser marking machine does not need to use chemicals or other materials that pollute the environment. Very friendly to the environment.

After understanding these advantages, you can use CO2 laser marking machines to play a better role in various industries.

The price of CO2 laser marking machine

The price of CO2 laser marking machines on the market varies with brands, models, configurations, manufacturers and other factors. Generally, it’s priced above $2,500.

- Low-priced CO2 laser marking machines are usually suitable for small and light materials. Low power and other occasions with high cost performance.

- Higher priced CO2 laser marking machines are usually suitable for heavy materials. High-power scanning and other processes.

When customers choose a suitable CO2 laser marking machine, they may need to make comprehensive considerations based on their own needs and the industry they are in. If you have any questions, you can consult our professional sales engineers online at any time. We will help you choose the suitable CO2 laser marking machine equipment for you free of charge.

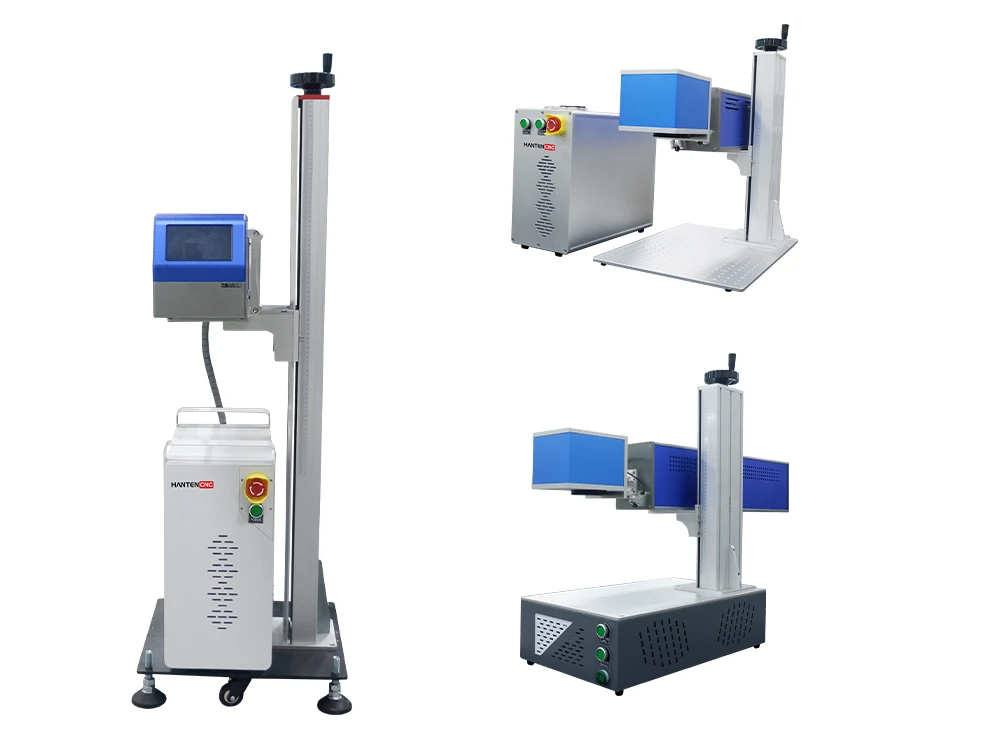

How about the CO2 laser marking machine of HANTENCNC?

HANTENCNC is one of the enterprises that entered the laser marking industry earlier in China. Its CO2 laser marking machine has the following advantages:

- High precision: HANTENCNC CO2 laser marking machine can achieve high precision marking. Precise marking even on tiny material surfaces.

- High stability: The equipment has high stability and can work continuously for a long time without failure.

- Simple operation: HENTENCNC CO2 laser marking machine has friendly interface design and simple operation process. Operators only need simple training to operate the equipment proficiently.

- High efficiency: HENTENCNC’s CO2 laser marking machine adopts the most advanced technology. The marking speed is fast and the efficiency is high.

- Good durability: HENTENCNC’s CO2 laser marking machine has a long service life after years of practice and improvement. It can work stably for a long time in various environments.

At present, HENTENCNC’s CO2 laser marking machine has been well received by many foreign users for its high cost performance, stable quality and good after-sales service. It is one of the most popular laser marking machine brands in China. If necessary, you can contact us at any time, watch the machine online, and look forward to your news.

How to use CO2 laser marking machine correctly?

According to years of experience of HANTENCNC engineers, some problems may occur if the operation is not done properly. The following are some suggestions for the correct use of CO2 laser marking machines:

Install

The installation of the CO2 laser marking machine needs to follow the manufacturer’s instructions or guidance. The marking machine needs to be placed in a dry and well-ventilated place. And it is necessary to correctly connect external facilities such as power supply and gas source. Special attention should be paid to the fact that the laser marking machine needs grounding protection. To ensure the safety of the operation process.

Adjust

Marking machines need to adjust the beam focus to ensure stable and optimal printing quality on different materials. The adjustment process needs to be careful and ensure the correct operation sequence to avoid damage to the accessories of the marking machine.

Choose the right parameters

Select the appropriate printing parameters to ensure the best printing results on different materials. Adjust the printing depth, speed, power, laser control and other parameters. In addition, you need to pay close attention to the printing quality, and if there are signs of bad, you need to adjust the printing parameters in time.

Maintain the marking machine

The marking machine needs irregular maintenance to clean the sundries inside the machine and remove dust. In order to maintain the performance of the laser and extend the life of the marking machine.

Stay Safe

When operating the marking machine, special attention should be paid to safety issues. During the operation, avoid attaching your fingers and clothes to the laser outlet to avoid the danger of the laser.

In general, the correct use of carbon dioxide laser marking machines requires some basic knowledge. Such as marking machine installation, adjustment skills, setting parameters and maintenance, etc. Concentration and care must be maintained during the operation to ensure the correct use of the marking machine. HANTENECNC will give each customer a detailed marking machine tutorial, which is easy to learn and serves you 24 hours a day.

The above is the content about the CO2 laser marking machine shared with you today. If you feel that this article is useful to you, you can share it with your friends and look forward to the next communication with you. If you have any questions, you can communicate online at any time.