Jewelry is no stranger to everyone, but how the laser spot welding machine can create exquisite jewelry is doubtful.

Daily gold jewelry, silver jewelry, titanium steel jewelry, etc. are all produced by jewelry welding machines. The production and processing of this kind of fine alloy jewelry is very time-consuming and laborious. But the laser jewelry welding machine can solve this problem. After the laser is focused, the specifications are small, the heat hazard zone is small, and the production and processing are fine. Some processing techniques that cannot be realized by ordinary methods can be carried out.

The name of the jewelry laser welding machine will be indicated on the parameter sheet. Refrigeration method: water cooling. The DC welding machine with small output power adopts built-in water cooling to dissipate heat. The one with larger output power is cooled by an external chiller. According to the laser output power of the welding machine, it is equipped with industrial chillers of different specifications. The cooling effect of the chiller can ensure that the working temperature of the laser welding machine is within a suitable range. Excellent temperature control can increase the light output rate of the laser, improve welding quality, and create exquisite jewelry.

When installing the chiller for the first time, it is necessary to check whether there is cooling water in the water tank of the industrial chiller. If it is not added, the water pump will be polished and damaged. When adding cooling circulating water, add it to the green area of the water level line of the water storage tank. After the industrial chiller has been running for a period of time, you will find that the water level has dropped. This is because there is gas in the water channel of the circulating system. The industrial chiller After operation, the gas is discharged, and the water level will be lowered to a certain extent. After the water level is lowered, it can be used again if the water level is still in the green area. If the water level is in the yellow area, it means that the water level is slightly lower and cooling water needs to be added again.

In addition, when applying, turn on the industrial chiller first, and then turn on the welding machine. This can ensure that the industrial chiller has sufficient cooling time, and do not frequently power on and off the industrial chiller. Hanten CNC engineers warmly remind that the industrial chiller must be maintained Chill time of five minutes or more.

Types of jewelry welding machines:

Today, the engineers of HANTENCNC will introduce the types of jewelry laser welding machines to you. According to different welding methods, jewelry welding machines can be divided into the following types:

- Xenon lamp welding machine: use xenon lamp as the heat source for welding. Suitable for soldering small jewelry.

- Laser welding machine: use laser beam for welding. It can realize high-precision welding and is suitable for jewelry that requires high welding precision.

- Electron beam welding machine: use electron beam as welding heat source. It can achieve high energy density welding and is suitable for welding high melting point metals such as tungsten and platinum.

- Anti-oxidation welding machine: Inert gas is used as protective gas to prevent metal from being oxidized and damaged during welding.

- Resistance welding machine: use resistance heating for welding. It is suitable for mass production, such as welding of large products such as jewelry chains.

What is a laser jewelry welding machine?

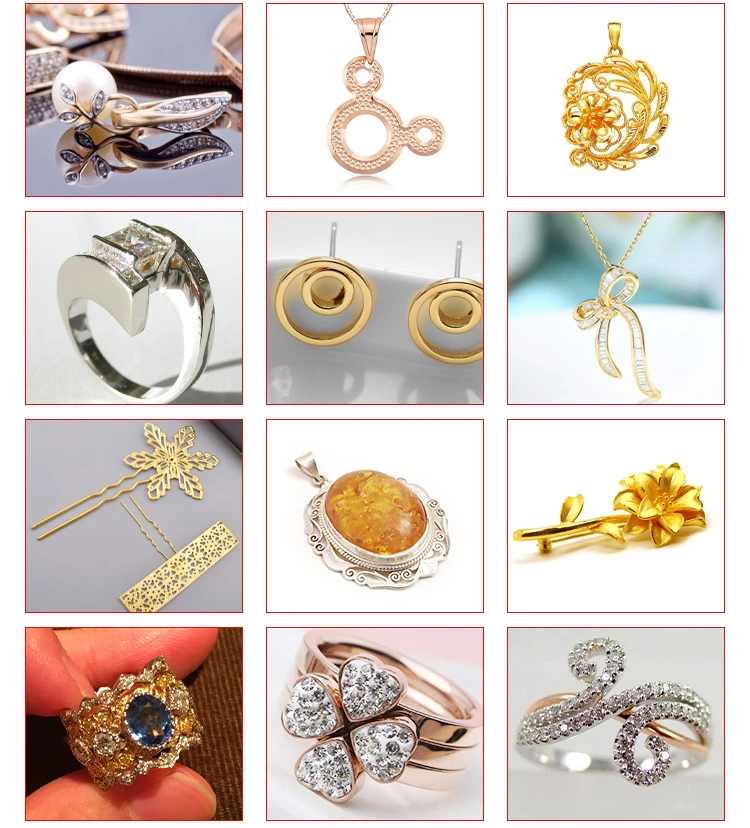

Laser jewelry welding machine is also called jewelry laser welding machine, gold laser welding machine, etc. It uses the precise high temperature of the laser for rapid spot welding. At present, it is mainly used in: laser welding of gold jewelry, laser welding of silver jewelry, laser spot welding of titanium alloy jewelry, laser welding of stainless steel jewelry, laser spot welding of various jewelry, and manual laser welding of small metal parts.

The laser jewelry welding machine not only has firm welding, beautiful appearance and no deformation, but also is easy to operate, easy to learn and use.

Advantages of jewelry laser welding machine

HANTENCNC is a company specializing in the production of jewelry welding machines. We have good after-sales service. At present, it has a wide range of applications. The performance of jewelry laser welding machines is extremely stable. If you choose factory direct sales products, the cost performance of products will be greatly improved. So why do many jewelry companies choose jewelry laser welding machines?

Compared with traditional gas welding, electric welding and other welding methods. Jewelry laser welding machine has the following advantages:

- High precision: Laser welding can realize high-precision welding of tiny metal parts. There is no need to add other materials to the welding area, no discoloration and pollution, good weld shape and high aesthetics.

- High efficiency: laser welding is fast and can be completed at one time. Save work cost and time, improve production efficiency. It can accommodate diamonds and metals of various materials and thicknesses without post-processing.

- Low deformation: Due to the local heat concentration during the welding process, the local thermal deformation can be minimized. Keep the original shape of the part without affecting the hardness and strength of the material.

- Environmental protection: laser welding does not require silver liquid or other chemical materials. Environmental pollution and injury to operators are reduced.

- Energy saving: the heat of the laser welding machine is generated by the laser generator. Unlike the resistance welding machine, which requires heating time, its energy utilization rate is higher. Energy costs can be saved throughout the production process.

Jewelry laser welding machine application industry

The application industry of HANTENCNC jewelry laser welding machine is mainly concentrated in the manufacturing and processing fields of jewelry, watches, glasses, automobiles, and electronic equipment. Especially in the jewelry processing industry, it has been widely used. There are mainly the following aspects:

- Jewelry processing industry:

Including the manufacture of various metal jewelry. Repair and assembly of materials such as gold, silver, copper, titanium, etc., as well as inlaying and welding of jewelry.

- Electronic manufacturing industry:

It can be used for connection and repair of electronic small parts and conductive wires. Such as welding of tiny circuits in electronic devices such as mobile phones, tablet computers, and notebook computers. The connection between IC and IC package.

- Automobile manufacturing industry:

It can be used in the manufacture and repair of auto parts and auto parts. Such as engines, gears, passive safety devices, car hubs, etc.

- Medical device manufacturing:

Laser welding can be used to manufacture fine devices such as artificial joints, medical steel wires, and brackets. It can also be used for dental restoration, glasses welding, etc.

- Precision parts manufacturing industry:

Suitable for aviation industry. Steel manufacturing industry. Manufacture and repair of various precision parts such as machinery manufacturing industry.

Maintenance method of jewelry laser welding machine

Jewelry laser welding machine is a complex high-precision equipment. Regular maintenance and maintenance are required to ensure its normal operation and prolong its service life. The following are the daily maintenance suggestions given by HANTENCNC engineers:

- Regular cleaning: During use, dust and dirt are easy to accumulate on the surface of the equipment, so it should be wiped and cleaned frequently. In addition, the optical lens needs to be cleaned to avoid the deterioration of welding quality due to lens pollution.

- Regularly replace the optical fiber: The optical fiber is one of the important parts of the laser welding machine. After a period of use, it will wear out and age. It needs to be replaced regularly. It is recommended to replace it every 6 months or so. 3. Regularly check the laser: The laser is the core component of the laser welding machine. It needs to be protected and checked regularly to confirm that the laser is working normally to avoid damage and failure.

- Regularly maintain the optical path: The optical path is an important factor affecting the quality of laser welding. It is necessary to regularly clean the optical lens and adjust the optical path to ensure the precision and accuracy of welding.

- Pay attention to equipment safety: strictly abide by the safety operating procedures. Regularly check the electrical part of the machine, and deal with electrical faults in time to avoid serious maintenance problems of the equipment. In short, regular daily maintenance and maintenance. The stability and user experience of the device can be guaranteed. Extend the life of the equipment. At the same time, ensure a safe operating environment and avoid accidents.

The power of jewelry laser welding machine is generally between 100W-300W. Depending on the specific application and welding material, the power will vary. Smaller welding tasks generally require lower power. Larger or complex tasks require higher power. In general, higher power means higher welding speeds and deeper welds. But it may also increase the risk of material deformation or welding flaws. Therefore, when choosing a laser welding machine, comprehensive consideration should be made according to actual needs.

Through the production engineer’s point of view above. Hope to help customers better understand the advantages and disadvantages of jewelry welding machines. In order to better choose the laser welding machine brand that suits you.

If necessary, you can contact HANTENCNC online customer service 24 hours a day, we will serve you wholeheartedly!