The laser cleaning machine has long been used in many industries for cleaning purposes. In general, it comes with two options: continuous and pulsed. Although the working principle of each item is different, they serve a similar purpose. Each has unique features and an efficiency level. However, both are very precise and ensure a perfect finish. In this case, the power of a laser cleaning machine plays a crucial role.

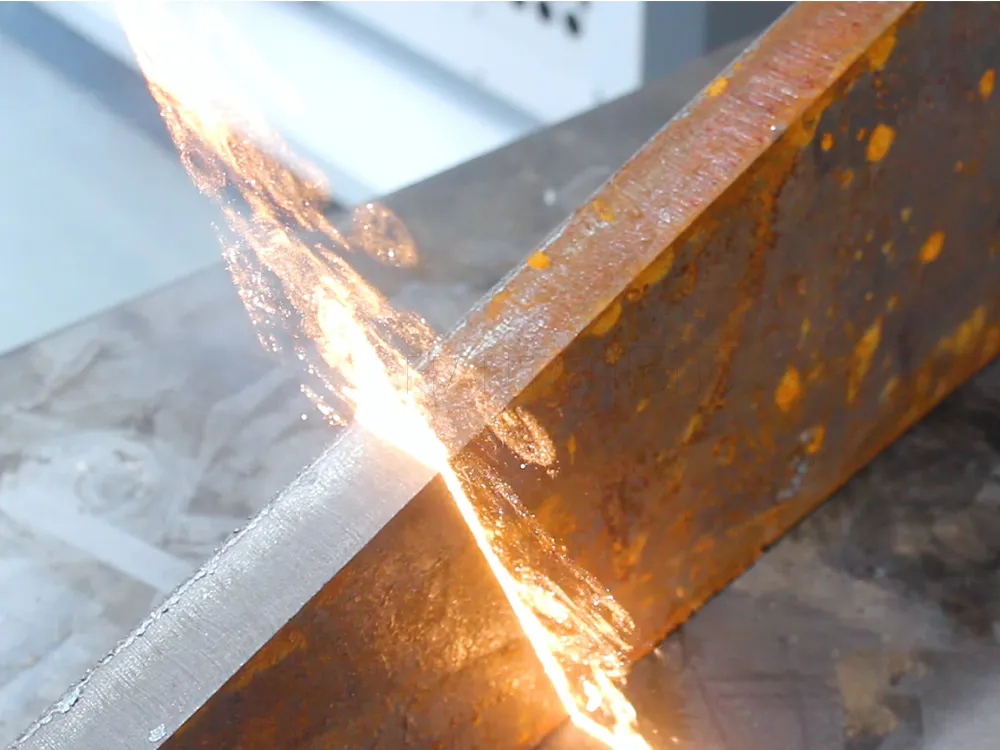

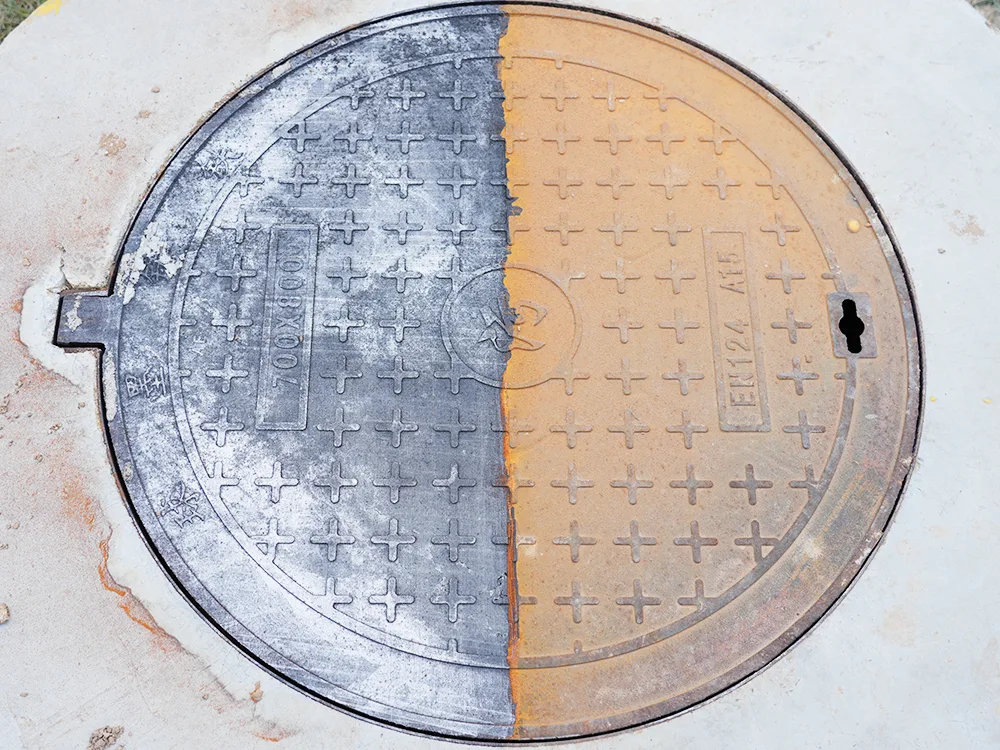

Where do people use laser cleaners the most? Laser cleaning is a non-contact process, so it is safe and exact. Traditional cleaners often damage delicate components. A laser machine for cleaning uses a highly focused laser beam to remove unwanted surfaces. The laser causes the dirt to evaporate immediately when it encounters the surface, cleaning rust, oxide layers, oil, and paint from material surfaces. Therefore, laser cleaners are mainly used where precision and safety are required.

Laser cleaner machines ensure a very secure and reliable way to clean surfaces of fragile parts and components. Its uses are usually in aerospace, automotive, defense, and medical industries. This machine greatly depends on the shipbuilding, marine, heritage restoration, and semiconductor industries. You may also use it in the energy sector and manufacturing industries. Its versatility and precision are the main reasons for its wide application.

It seems effortless, but the difficulty arises from cleaning different types of materials. Each material and dirt thickness requires different settings for proper cleaning. This article will assist you in selecting the precise power settings needed for your specific tasks.

Choose the Right Power Level for a Laser Cleaning Machine

Choosing the Right Power Level is a critical step towards the desired result. The correct one will provide adequate speed, power, safety, and quality. Below, we will break down every feature. There are several reasons why choosing the right power level is crucial. Let’s go through each of the main ones.

#1 Cleaning Quality and Finishing

The correct power level is necessary for proper cleaning and a good finish. Choosing a machine with lower power may not work properly to clean off rust, oxide layers, and others. Ultimately, the surface remains unclear. On the other hand, too much power may destroy your base material and burn the surface. Therefore, you should use the exact power level to get the best outcome.

#2 Precision & Control

These two parameters of a laser cleaning machine depend heavily on the exact power level. Higher laser powers are typically difficult to control, and in a second, they can damage the surface of an object. On the other hand, lower laser power takes time to damage the object. Thus, it is easy to control and must be reliable for marking delicate components.

#3 Safety

A high-power laser cleaning machine may produce sparks, burns, or damage the surrounding parts. Thus, it can hurt people who operate the device. To resolve this, the right power machine can prevent this type of accident. Therefore, using proper power ensures safety by reducing risks and keeping people safe.

#4 Cleaning Speed

Speed is another crucial factor when cleaning with a laser power cleaner. For example, higher-power machines can clean smoothly and work well at removing thick rust, paint, or other waste.

In contrast, low-laser-power cleaning machines operate well on thin and delicate materials and are better for small jobs. The machine you choose depends on the materials you want to clean.

#5 Cost Efficiency

Choosing the right power machine will help you save money and make your work more efficient.

High-power laser machines are typically more expensive. It also requires maintenance costs and can lead to material damage expenses. However, they are versatile and can be used for different applications.

On the other hand, low-power laser cleaners are cheap but not as adaptable as high-power laser cleaners. They don’t work well on thick contaminants. You might need two or three passes to work on thick dirt layers, significantly increasing the electricity bill.

Thanks to modern technology, most manufacturers are now offering customization solutions. You can modify the parts based on your project needs, reducing costs and making your work much more efficient.

Factors to Consider when Choosing the Right Power Level

You are clear about the roles of laser power in cleaning processes. Here comes the question, “How do you choose the right power level then?” You can check some factors and evaluate whether the spec matches your project.

#1 Considerations of Certain Cleaning Tasks

Laser power heavily depends on your project needs. For example, you may need a high-power laser cleaning machine to remove rust. On the other hand, typical paints or surface cleaning do not require high power.

As you know, rust is the oxide layer of the metal. For effective laser rust removal, you will need high-power lasers. This type of laser cleaning machine typically ranges from 1000W to 2000W.

On the other hand, typical paints or coatings need less laser power. A 200W to 1.5 kW laser cleaning machine is typically enough. In this case, too much energy may damage the base material. Therefore, you must carefully adjust the laser settings before jumping into the cleaning work.

Mold cleaning is one of the most complex tasks, but not for laser cleaners. Traditional cleaning is challenging because it cannot reach hard-to-reach areas. Laser cleaning, in this case, is a non-contact process, meaning you can do this work easily. A 200W to 1.5kW laser cleaning machine is typically enough for this job.

Surface preparation for welding, painting, or coating sometimes requires cleaning. This is known as pre-treatment of the surface. For better results, people choose laser cleaners over traditional methods. The recommended power range for pre-treatment is between 100W and 1000 kW.

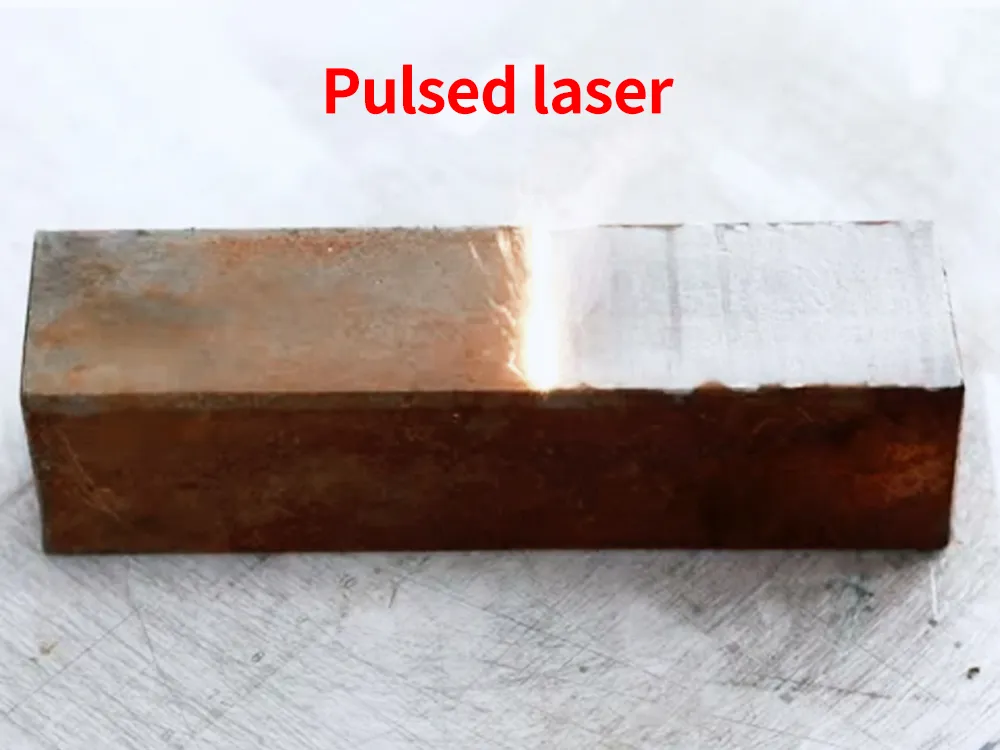

#2 Types of Lasers (Continuous Laser vs Pulsed Laser)

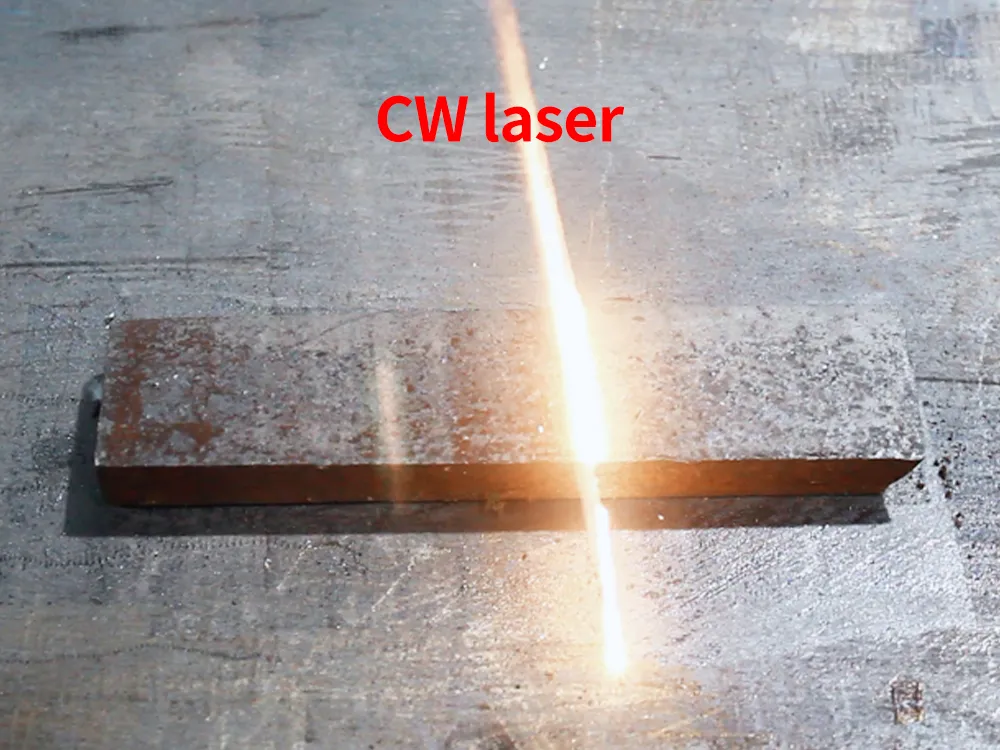

As mentioned earlier, there are usually two types of lasers: continuous and pulsed. Continuous lasers give a constant, reliable laser to the surface, which means you may work continuously. This type of laser is very appropriate for removing thick rust/ coatings. However, it is not ideal for delicate materials. It can easily destroy the surface or the associated parts.

On the other hand, pulse lasers give a short burst of energy to the surface. This reduces heat accumulation and gives you more control. Consequently, people use it to clean sensitive and fragile materials.

#3 Types of Laser Source (CO₂ vs. Fiber vs Nd: YAG)

There are various ways to produce lasers, but not all are suitable for cleaning work. CO2, fiber, and Nd: YAG are three of the most common lasers in this case.

CO2 lasers typically have wider wavelengths. This laser cleaning machine is highly suitable for cleaning non-metal surfaces. On the other hand, fiber lasers have a narrower wavelength, which can produce heat faster and complete the work in a second. This type of laser cleaning machine is suitable for metallic surfaces.

Nd: YAG lasers use neodymium ions as the laser medium. They are solid-state lasers applicable to both metal and non-metal surfaces.

#4 Material Properties

Material properties are also essential when choosing the power level for laser cleaning. Solid materials can handle high power, while soft materials are effective with low power. For optimal cleaning, reflective materials need specialized settings. The right machine and settings will ensure you clean safely and effectively.

#5 Surface Area and Cleaning Speed Needs

When deciding on your laser power, consider the surface area and speed of cleaning. For example, if you are dealing with a broader surface, you may opt for higher-power laser devices. These types of surfaces are also ideal for continuous laser cleaning.

When working with smaller or more detailed spots, using the machine with less power is better. Balancing power, cleaning speed, and surface area will make your cleaning tasks much more efficient.

Common Laser Power Ranges and Their Applications

A laser cleaning machine typically has a power level between 100W and 3000W, but the exact power level may vary depending on your project needs.

A laser system of 100W to 500W is sufficient for light work. It is effective at eliminating light rust from delicate or sensitive surfaces. These machines are also ideal for mold cleaning and pre-adhesion applications. Medium-power lasers, 500W to 1000W, generally work well to remove sticky rust, paint, or surface preparation before welding.

Laser machines ranging from 1000W to 3000W are best for stripping thick paints, heavy rust, oil, and other contaminants. These applications are often seen in shipbuilding, construction, and automotive industries.

Summary

This article explained the right power for a laser cleaning machine. It covered various important topics, such as why it matters and the role of laser power in cleaning work. Finally, it highlighted five critical factors determining the right power level for your project.

Specific material or application requires different power types to do the job flawlessly. The right power saves time, protects surfaces, reduces costs, and gives the best cleaning results. Eventually, you will benefit easily. For further inquiries, feel free to contact us. We will be glad to help you.