What is laser cleaning? What is pulse laser cleaning?

As the laser industry continues to develop, we at hantencnc are also constantly innovating and developing. With the continuous updating of cleaning methods. Laser cleaning has gradually become a major development trend. hantencnc also firmly grasped the opportunity. Many people have heard of laser cleaning, but they don’t know much about the concept of pulse laser cleaning.

The lasers in laser cleaning machines have specific wavelengths. High-energy beams of specific wavelengths are absorbed by media such as rust and paint layers, as well as pollution layers. A rapidly expanding plasma then forms. At the same time, it will generate shock waves, shock waves, etc. to turn the contaminants into fragments and be removed. The base layer of material does not absorb energy. Therefore, laser cleaning will not damage the surface material of the object being cleaned. The original material will not be reduced to its surface finish.

Compared with traditional cleaning methods and continuous laser cleaning methods. Traditional cleaning methods include chemical cleaning and mechanical cleaning. Pulse laser cleaning machines have the following advantages and disadvantages:

- Hantencnc pulse laser cleaning is an environmentally friendly cleaning process. It is more “green” and belongs to “dry cleaning”. Hantencnc’s pulse laser cleaning machine does not require the use of any consumables. We do not use cleaning agents, chemical solutions. However, the cleaning effect of the pulse laser cleaning machine is much higher than that of various traditional cleaning methods.

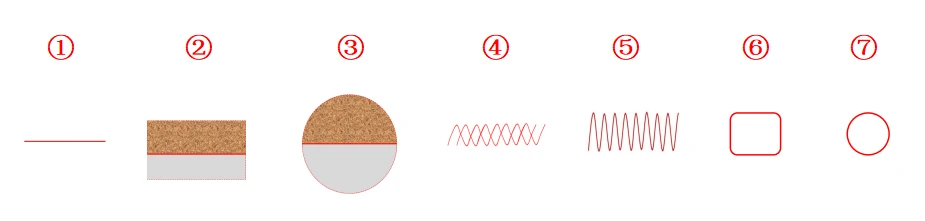

- Hantencnc’s pulse laser cleaning machine has a very wide range of cleaning applications. Hantencnc’s pulse laser cleaning machine has eight cleaning modes. The operation interface of Hantencnc’s pulse laser cleaning machine provides 7 cleaning modes. The operator can switch the cleaning mode by clicking the scan mode option on the operation interface.

7 cleaning modes:

- Linear mode,

- Rectangle mode,

- Circle mode,

- Sine mode,

- Double spiral mode,

- Free mode,

- Circle.

Therefore, the pulse laser cleaning machine produced by hantencnc has the following advantages:

It can clean and fit different curved surfaces and different heterogeneous surfaces. It can clean very fine particles as well as large areas of contaminants and impurities. The hantencnc pulse laser cleaning machine can accurately remove all kinds of rust and paint. and various surface impurities such as coatings.

- Hantencnc’s pulse laser cleaning machine is suitable for almost all solid materials. And in many casesit is possible to remove only the dirt without damaging the substrate. Relative continuous laser cleaning machines can clean rust and paint layers. But continuous laser cleaning can leave cleaning marks on the substrate.

- It can choose different modes according to the requirements of cleaning materials. It can freelyswitch the shapes of different lasers. In order torealize the customer’s needs for cleaning specific areas and specific locations.

- The operation of Hantencnc’s pulse laser cleaning machine is not only very simple. It can also reduce labor costs.

It can control the machine to perform the cleaning process in a non-human contact manner. Laser cleaning parameters can be set on the operation interface of the pulse laser cleaning machine. include:

- Laser power,

- Laser frequency,

- Pulse width or scanning mode,

- Scanning speed,

- Number of scans and scan range (width, height), etc.

Laser output can be precisely controlled through the operation interface without special training. This prevents the base material from deforming due to excessive temperature. At the same time, ensure that the material surface is not deformed or damaged.

The cleaning capabilities of our pulse cleaning equipment are far superior to traditional sand blasting and dry ice cleaning techniques. I believe hantencnc will be your preferred solution for industrial cleaning, rust removal, and paint removal and other surface treatments. At the same time, hantencnc pulse passion operation is safe, and the machine can adapt to various complex working environments. Under normal use, the laser has a service life of up to 100,000 hours.

However, everything has advantages and disadvantages. The laser focus position of the pulse laser cleaning machine has the best laser cleaning effect. Users can achieve this effect by adding a lens mount. In contrast, continuous cleaning machines generally have greater power. Therefore, its cleaning speed and intensity will be higher than that of pulse laser cleaning machine. However, continuous laser cleaning will leave cleaning marks of varying degrees on the material surface. Hantencnc’s pulse laser cleaning machine is more suitable for precision parts. More suitable for cleaning solutions that require higher cleaning surface materials. Moreover, the pulse cleaning equipment can achieve zero damage to the cleaning material substrate after cleaning the dirt. Relatively, its product prices are relatively high.

Here are some frequently asked questions from customers - About pulse laser cleaning

- What is the difference between pulse and continuous cleaning machines produced by hantencnc?

The pulses cause virtually no damage to the cleaned substrate. The continuous cleaning machine has strong cleaning ability. It will leave varying degrees of marks on the cleaned substrate. - For cleaning exquisite crafts such as antique restoration industry. What type of pulse laser cleaning machine is recommended?

It is recommended to choose Hantencnc’s pulse laser cleaning machine-multi-mode - How are single-mode and multi-mode distinguished by pulse energy?

Single mode: 1.5-2mj (millijoule-pulse energy) is a single-mode laser

Multimode: Lasers above 5mj (millijoule-pulse energy) are multimode lasers - What materials and products can be cleaned by hantencnc’s pulse and continuous laser cleaning machines?

① Continuous cleaning machines are generally used to remove rust and paint.

② Pulse laser cleaning machines are generally used to clean precision instruments such as cultural relics. Others include rust and oil stains, as well as layers of graffiti and spray paint.

For more specific materials, it is recommended that you consult hantencnc professionals. - What consumables does Hantencnc’s pulse laser cleaning machine have?

The consumables of Hantencnc’s pulse laser cleaning machine are only protective lenses. - What kind of protective gas does Hantencnc’s cleaning machine use?

Whether it is hantencnc’s pulse laser cleaning machine or continuous cleaning machine. The gases they use are dry, non-flammable gases. For example, argon, nitrogen, compressed air (needs to remove oil and water), or a mixture of argon. - Is Hantencnc’s pulse laser cleaning machine air-cooled or water-cooled?

Hantencnc’s pulse laser cleaning machines are available in air-cooled and water-cooled versions.

Of course, various problems will also arise during the use of Hantencnc’s pulse laser cleaning machine. The following are common failures and solutions for Hantencnc’s pulse laser cleaning machines. I hope they can help you:

If the light of Hantencnc’s pulse laser cleaning machine is weak during use. In the first step, the operator needs to turn off the power and first check the machine’s protective lens. The operator needs to observe whether there is contamination or damage on the surface of the protective lens. If the surface of the protective lens is contaminated, the operator needs to replace the protective lens in time. Hantencnc will provide instructional videos on replacing protective lenses.

If the problem is not solved, you can contact an engineer to provide you with online consultation services. We can inspect the machine for you. Find problems for you and finally solve them.

From the perspective of pulse laser technology principles, it has huge development potential. With the continuous innovation and optimization of pulse cleaning process. It is believed that pulse laser cleaning is gradually becoming the preferred solution for cleaning in various industries. Hantencnc’s pulse laser cleaning machines are also constantly developing and innovating. Colleagues, we are expanding the application areas of our products. Hanteng Laser Technology Co., Ltd. has various styles of laser cleaning machines that can meet the different needs of different customers. If you have any needs, please feel free to contact us, we are ready to provide you with excellent solutions and machines that meet your needs.

Hope this article helps you with the problems you are facing. If necessary, you can consult the official website 24 hours a day. HANTENCNC professionals will answer your questions at any time.