Laser marking is a high-precision, high-efficiency technology. It has been widely used in various fields. Laser marking can mark multiple materials and accurately identify patterns, text, and barcodes. It is essential in improving product quality, safety, and brand recognition.

This article will explore the principles, application areas, and future laser marking technology development trends. We’ll learn how this exciting technology opens new industry opportunities. We also discuss how it shines in manufacturing and drawing tasks. You may be interested in laser technology or want to learn how to apply it to your work. This article will provide valuable information.

What is Laser Marking

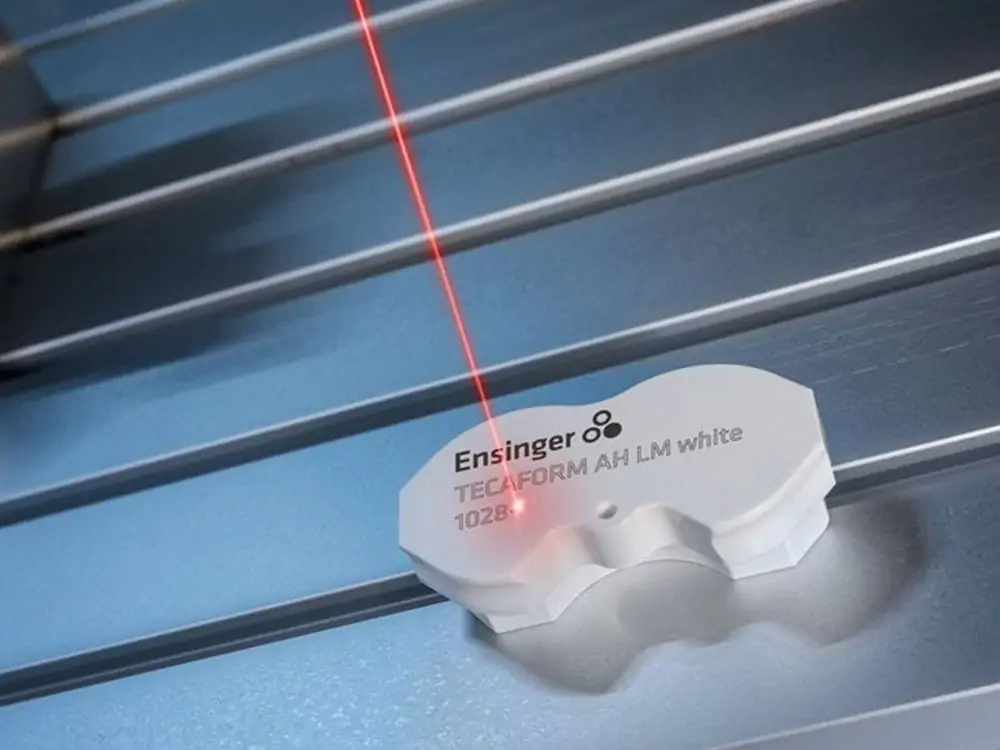

Laser marking technology is based on the working principle of lasers. The laser produces a focused laser beam. The laser beam has consistent optical properties. Such as wavelength, frequency, and low scattering. This focused laser beam can be precisely illuminated on the material’s surface. Materials can be subjected to controlled thermal energy.

There are three main ways to laser mark: engraving, etching, and changing color. A laser beam removes a small part of the material during engraving, creating the desired mark. The etching process is similar but uses a chemical reaction to remove material. In changing color, the laser changes the color of the material surface instead of removing it.

The accuracy and control of laser marking technology depend on several factors. These include laser power, wavelength, focus, and marking speed. Adjusting these parameters enables keeping different depths, accuracy, and speeds. It makes laser marking a versatile process.

How Does Laser Marking Work

Laser marking works by using a focused laser beam to create marks or patterns on the surface of a material. Here’s how laser marking works.

Laser Source

Laser marking systems use laser sources. The laser source can be based on various technologies such as CO2, fiber, or YAG lasers. The choice of laser source depends on the type of material to be marked and the required mark quality.

Focusing Optics

The laser beam is directed through a series of focusing optics. These include lenses and mirrors, which focus the beam into a small but intense spot. The focused laser beam is then aimed at the material’s surface to be marked.

Material Interaction

When a high-energy laser beam interacts with a material surface, a variety of processes can occur, depending on the material type:

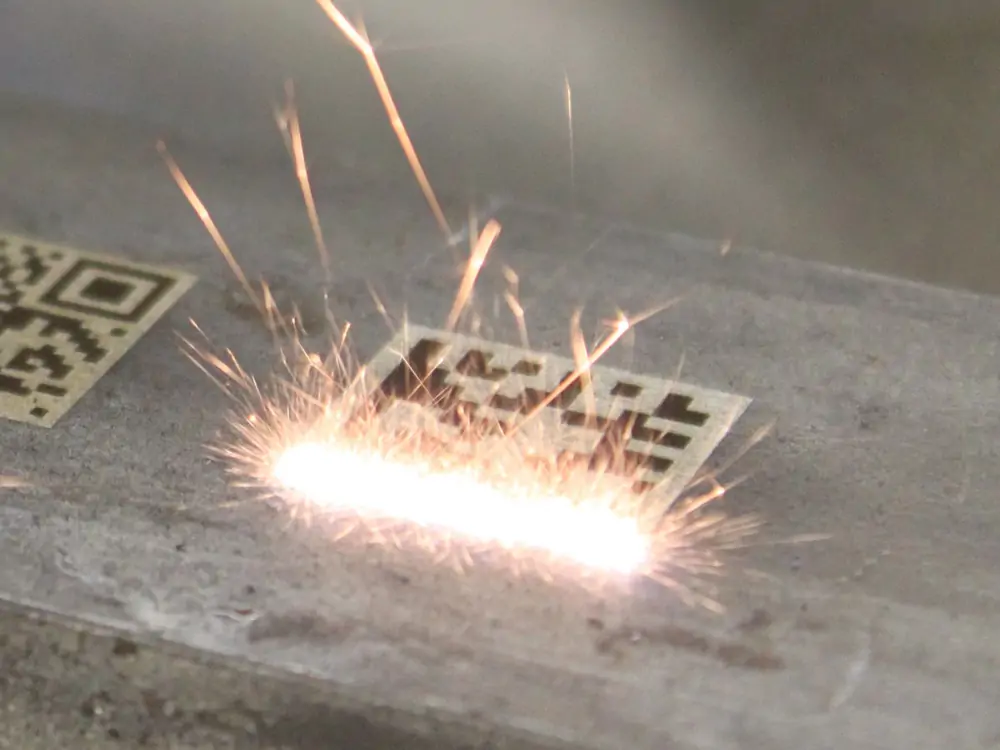

- Ablative: Lasers can remove a thin material layer for materials. Metals and plastics create visible marks. This process is called laser ablation.

- Color change: Some materials, such as ceramics and certain plastics, undergo color changes when exposed to laser energy. This color change creates visible markings.

- Annealing: The laser can heat the surface of metals such as stainless steel. However, this process does not result in significant material removal that would create countermarks due to oxidation or reflectivity changes. This process is called laser annealing.

- Foam formation: Some plastics can be marked by localized heating, creating raised foam marks.

Computer Control

Laser marking systems are controlled by a computer or programmable logic controller (PLC). The operator can enter the desired marking pattern, text, graphics, or barcode into the control software. It allows precise control over the mark’s position, depth, and appearance.

Security Measures

Laser safety precautions are crucial when using laser marking systems. Protection measures include laser safety goggles and interlocking systems. It ensures operator safety and prevents accidental exposure to the laser beam.

Tag Verification

Depending on the application, marked products may undergo verification or quality control. It ensures markup accuracy and readability.

Types of Laser Marking Techniques

Different laser marking technologies are based on different application needs and material properties. Here are some common types of laser marking technologies.

Laser Engraving

Laser engraving is like laser etching. However, laser engraving is often used to create detailed patterns, text, or images on the surface of a material. This technology is commonly used in jewelry, engraving, seal making, and other fields.

Laser Etching

Laser etching is a processing method that uses a laser beam to etch or remove the surface of a material. This technique is often used to mark, cut, or deeply engrave materials. The technology has high precision and resolution and is suitable for various materials.

Laser Annealing

Laser thermal printing uses a laser beam to produce localized heating on the material’s surface. It creates marks by changing the color or oxidation state of the material. It is widely used on metals such as stainless steel and aluminum.

Laser Inkjet Printing

This technology combines laser and inkjet technology. It uses a laser to activate special ink, spraying onto the material’s surface to create images or text. This laser marking technology is commonly used on paper, packaging materials, etc.

Laser Pulse Marking

This technology uses pulsed laser beams. It can produce high-energy light spots in a very short time and be used to mark the surface of materials. It is suitable for applications that have minimal impact on the material.

Laser Ablation Marking

Laser vaporization marking uses the high energy of the laser beam to vaporize part of the material’s surface to form a mark. It is widely used on plastics, ceramics, and some glasses.

Laser Color Transfer Marking

This technique is commonly used to mark plastic surfaces. Marks are created by transferring color from one material to another through laser action.

Deep Laser Engraving

Laser deep engraving technology is used to create deep marks within materials. It is commonly used in applications such as security signs, signage, etc., where long-term durability is required.

Advantages of Laser Marking

Laser marking is a versatile and exact method. Marks or patterns can be added to metal, plastic, and ceramics. The reason why laser marking technology is so popular. It offers a variety of advantages to various industries.

High Precision And Controllability

Laser marking enables exact markings. Whether it is tiny text or complex patterns, they can be accurately engraved on the material surface. In addition, by adjusting the laser parameters, marking at different depths can be achieved to meet various needs.

High Speed And Efficiency

Laser marking is fast and can quickly complete many marking tasks. It improves production efficiency and reduces production costs.

Contactless

Laser marking is a non-contact method that does not damage the material surface. It is particularly important for applications with strict requirements on material quality.

Durability

Laser marked markings are permanent and will not wear off or fade quickly. It makes the mark visible throughout the product’s lifecycle, aiding tracking and management.

Environmental Friendly

Laser marking is an environmentally friendly choice compared to some traditional marking methods. It requires no chemicals or inks and creates no waste. It reduces the risk of environmental contamination.

Applications of Laser Marking

Laser marking is a versatile and precise method. It can add a permanent mark or identifier to a variety of materials. Its applications are diverse and can be found in various industries. Here are some typical applications for laser marking.

- Product Identification And Branding: Laser marking is often used to add logos, serial numbers, barcodes, and other identifying information to products. It helps with traceability, brand recognition, and product certification.

- Automotive Industry: In the automotive industry, laser marking marks engine parts, chassis components, and other critical components. It ensures part traceability and helps prevent counterfeiting.

- Aerospace Industry: Laser marking is critical for aerospace components. Aerospace components must meet strict quality and safety standards. It marks serial numbers, part numbers, and other vital data on aircraft and spacecraft components.

- Electronics And Semiconductor Manufacturing: Laser marking marks chips, PCBs (Printed Circuit Boards), connectors, and other electronic components. It ensures the accuracy and readability of small and complex parts.

- Medical Devices: In the medical industry, laser marking marks surgical instruments, implants, and medical equipment. It ensures patient safety and aids in inventory management.

- Jewelry And watchmaking: Laser marking engraves intricate designs, logos, and serial numbers on jewelry and watches components.

- Firearms And Defense: Laser marking marks serial numbers, model information, and safety warnings on firearms. It can follow legal requirements and help track weapons.

- Consumer Electronics: Laser marking adds branding, serial numbers, and regulatory information to smartphones, tablets, and other consumer electronics.

- Packaging And Labeling: Laser marking adds expiry dates, batch numbers, and barcodes to packaging materials. It can ensure product traceability and compliance with regulatory requirements.

- Plastics And Polymers Industry: Laser marking can be used to mark and decorate plastic parts. Therefore, it is commonly used in consumer products, automotive, and medical devices.

- Promotional Products And Personalization: Laser engraving personalizes promotional products, gifts, trophies, and prizes.

- Food And Beverage Industry: Laser marking marks packaging materials for food and beverage products. It can ensure labeling is accurate, traceable, and complies with food safety regulations.

- Woodworking And Furniture: Laser marking can add intricate designs, logos, and branding to wooden furniture and decorative items.

- Metalworking And Molds: Laser marking marks metal tools, parts, and assemblies in machining and metal fabrication industries.

- Art And Creative Design: Artists and designers use laser engraving to create intricate designs on various materials. These include wood, acrylic, and leather.

- Medical Implants And Orthopedics: Laser marking is used to mark and mark medical implants and orthopedic devices. It can ensure accurate identification during surgery.

Common Types of Laser Marker Machines

There are many types of laser marking machines. Each type is designed for specific applications and materials. The choice of laser marking machine depends on factors. Such as the material to be kept, the depth of mark required, speed, and the level of detail needed. Here are some common types of laser marking machines.

Fiber Laser Marking Machine

Fiber laser marking machines use optical fibers to deliver a laser beam to the marking surface. They are versatile and are mainly used for marking metals, plastics, and ceramics. They provide high-speed marking with high precision and are commonly used in the automotive, aerospace, and electronics industries.

CO2 Laser Marking Machine

CO2 laser marking machines use carbon dioxide gas as the laser medium. They are best for marking organic materials such as wood, glass, paper, fabric, and plastics. CO2 lasers are commonly used in the packaging, textile, and arts and crafts industries.

YAG Laser Marking Machine

YAG laser marking machines can mark various materials, including metals, ceramics, and plastics. They are known for their high power and can be used for deep engraving and cutting applications.

UV Laser Marking Machine

UV laser marking machines use shorter wavelengths to mark materials with high precision. They are suitable for delicate and heat-sensitive materials. Such as plastics, glass, and certain metals. UV laser marking machines are commonly used in the electronics and medical device industries.

Green Laser Marker

Green laser markers use a green laser beam to mark materials. Such as metals, ceramics, and plastics. They are known for their refined drawing capabilities and are used when high precision is required. Especially in applications such as microelectronics and medical devices.

Galvanometer Laser Marking Machine

These machines use a Galvo scanner to quickly move a laser beam across the marking surface. They are ideal for high-speed, high-precision applications. Such as barcode marking, serial numbers, and logos on flat or curved surfaces.

Flatbed Laser Marking Machine

The flatbed laser marking machine has a fixed laser head and a movable workbench. They are suitable for marking larger objects or materials that are not easily moved, such as large pieces of metal, acrylic, or wood panels.

Handheld Laser Marking Machine

Handheld laser markers are portable devices that mark hard-to-reach areas or large, heavy objects. They are commonly used in construction, shipbuilding, and other industries where mobility is critical.

HantenCNC – Meet Your Laser Marking Needs

I am pleased to introduce you to a reputable laser equipment manufacturer – HantenCNC. As a leader in the industry, HantenCNC has been committed to developing and manufacturing high-quality laser equipment. Such as laser cleaning machines, laser welding machines, and laser cutting machines. HantenCNC has the following excellent features and can meet your various needs.

- Excellent Technological Innovation: HantenCNC has a passionate R&D team. They continue to push the cutting edge of laser technology. It can ensure that their equipment remains at the forefront of performance and efficiency.

- High Precision And Stability: Whether it is laser marking, laser cutting, or laser cleaning, the equipment provides excellent precision and stability. It can ensure that your work tasks are completed perfectly.

- Customization: HantenCNC understands that every customer’s needs are unique. They can provide customers with customized solutions to meet the requirements of various industries and applications.

- Excellent After-sales Service: They provide comprehensive after-sales support. Including training, maintenance, and technical support. It can ensure your equipment is always in top condition.

- Environmental Protection And Energy Saving: HantenCNC’s equipment design focuses on environmental protection and energy efficiency. It can ensure reduced resource consumption and lower environmental impact.

Conclusion

When we delve into laser marking technology, it’s easy to see its widespread use in various industries and the excellent benefits it brings. Laser marking has become an essential tool in modern manufacturing and marking. Laser marking is vital in improving product identification, brand recognition, or streamlining production processes.

As technology advances, laser marking will continue to evolve and improve, providing new possibilities in more fields. We expect this technology to play an essential role in future innovations. If you have any questions about laser marking technology or want to know more information, please feel free to consult us. We will be happy to provide you with support and answers. Thank you for reading!