Cylindrical laser welding machine

With the development of emerging industries such as electric vehicles and drones. The application of lithium batteries is also becoming more and more extensive. Laser welding technology is an efficient and precise welding method. It is also widely used in lithium battery production. However, for the selection of various lithium battery models, many customers are not very professional. Next, HANTENCNC will classify and introduce different lithium battery models.

This is a cylindrical battery. The working principle of the cylindrical battery laser welding machine is: by controlling the laser beam emitted by the laser. Focus energy on the surface of the battery to be welded. Allows the material in the weld area to heat up rapidly. A molten pool forms and fuses with adjacent materials. During the welding process, parameters such as the power and pulse frequency of the laser beam and the focus position. They can all be adjusted and optimized according to the requirements of the battery. In this way, high-quality welding can be achieved.

Cylindrical batteries are mainly small-sized welding points and seams. This is very important for the sealing and safety of the battery. Therefore, if the cylindrical battery is to be welded, a galvanometer laser welding machine is required. As shown below.

Cylindrical battery laser welding equipment can be integrated with automated production lines. It can realize fully automated production process. And improve productivity and consistency. It can also be adjusted by welding parameters and fixture design. In order to flexibly respond to different production needs.

So cylindrical battery laser welding machine is a very suitable welding solution. Offers battery manufacturers the opportunity to optimize the production process. It also helps to improve the quality and performance of the battery.

Power battery laser welding machine

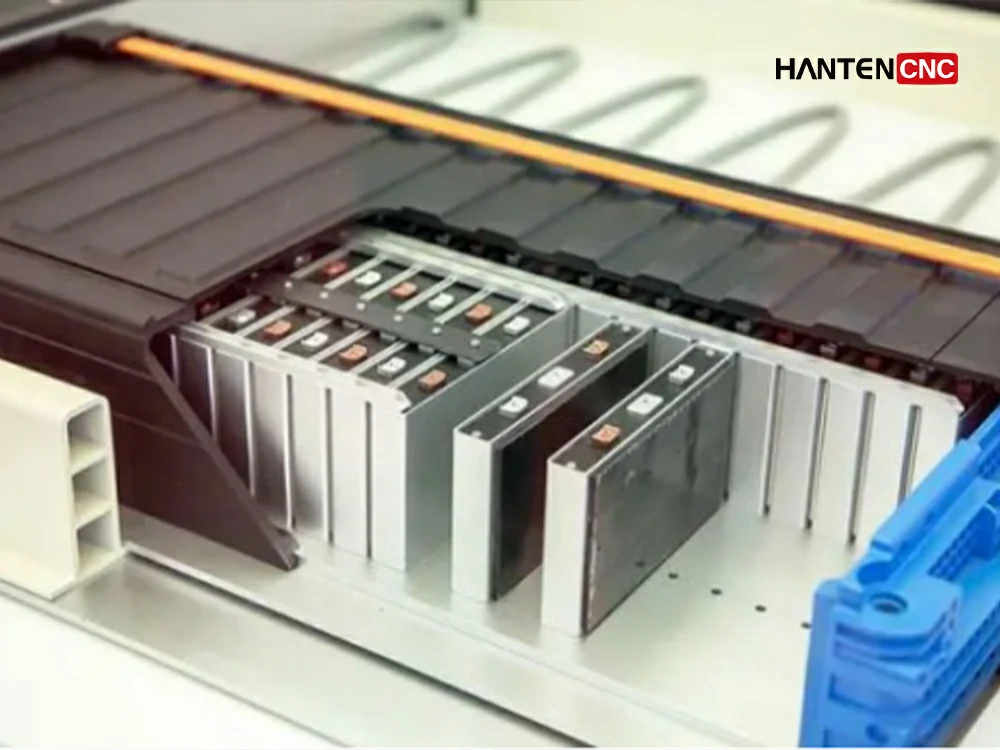

Power battery laser welding machine is a very important process link in battery production. It has a great influence on the consistency, stability and safety of the battery. There are many laser welding parts for power batteries. And the process is difficult. High requirements on welding technology. Efficient and precise laser welding can greatly improve the safety of automotive power batteries. It also improves reliability and longevity. Laser welding technology will provide an important guarantee for the future development of automobile power.

This is the power battery. The advantages of power battery laser welding machine are as follows:

- Small loss of welding materials.

- The deformation of the welding workpiece is small.

- The performance of the equipment is stable.

- Simple operation.

- High welding quality.

- High degree of automation.

Therefore, the welding of power batteries also needs to choose a galvanometer laser welding machine.

Tab battery laser welding machine

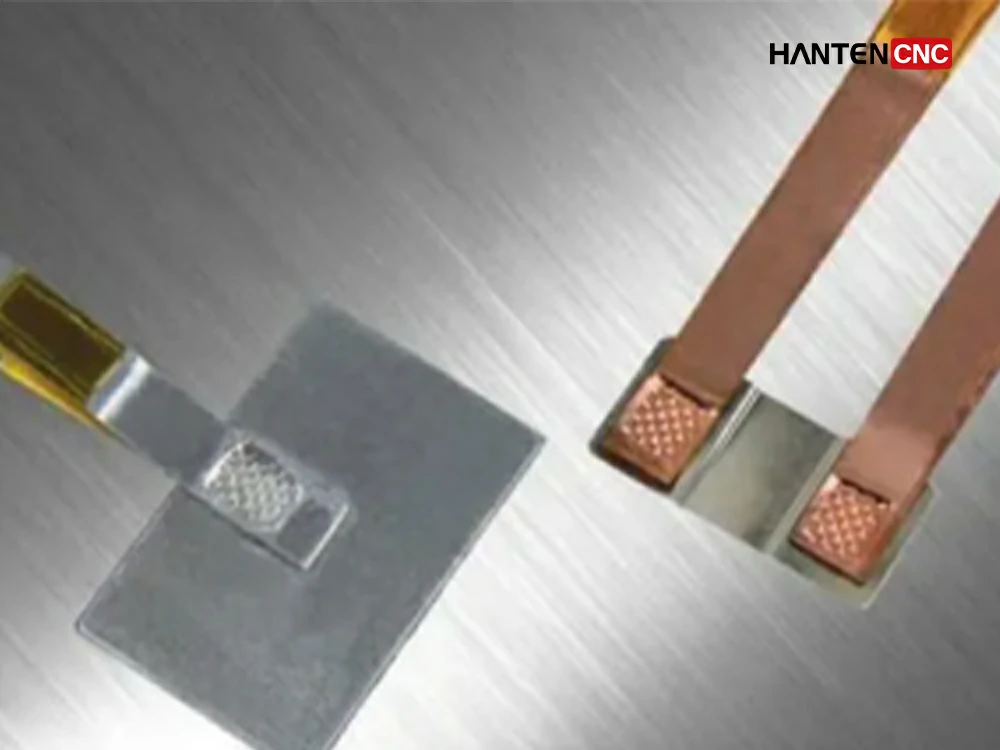

A lithium battery has two positive tabs and two negative tabs. The top cover has conductive posts with positive and negative poles. Conductive pillars are located on both sides of the lithium battery. The two positive and negative tabs of the lithium battery are respectively located on both sides of the conductive column. And the conductive column is electrically connected with the tab of the lithium battery.

During the lithium battery assembly process, the battery and tabs are first welded. Then weld the nickel sheet. Before welding tabs and nickel sheets, the battery needs to be tested for OCV. The tabs are trimmed and cut, and then welded with nickel sheets. Most of the existing above-mentioned operations are independently completed manually with corresponding devices.

The energy and spot position of the galvanometer laser welding of HANTENCNC can be precisely controlled. It is especially suitable for precision machining. For small lithium battery tab welding in the field of consumer electronics. At present, ultrasonic welding is mainly used in the industry to weld battery tabs. Ultrasonic welding is less efficient than laser welding. And it is easy to bring pollution to the inside of the battery. Therefore, HANTENCNC has developed a battery tab laser welding machine. That is, high-speed galvanometer laser welding machine.

As shown below.

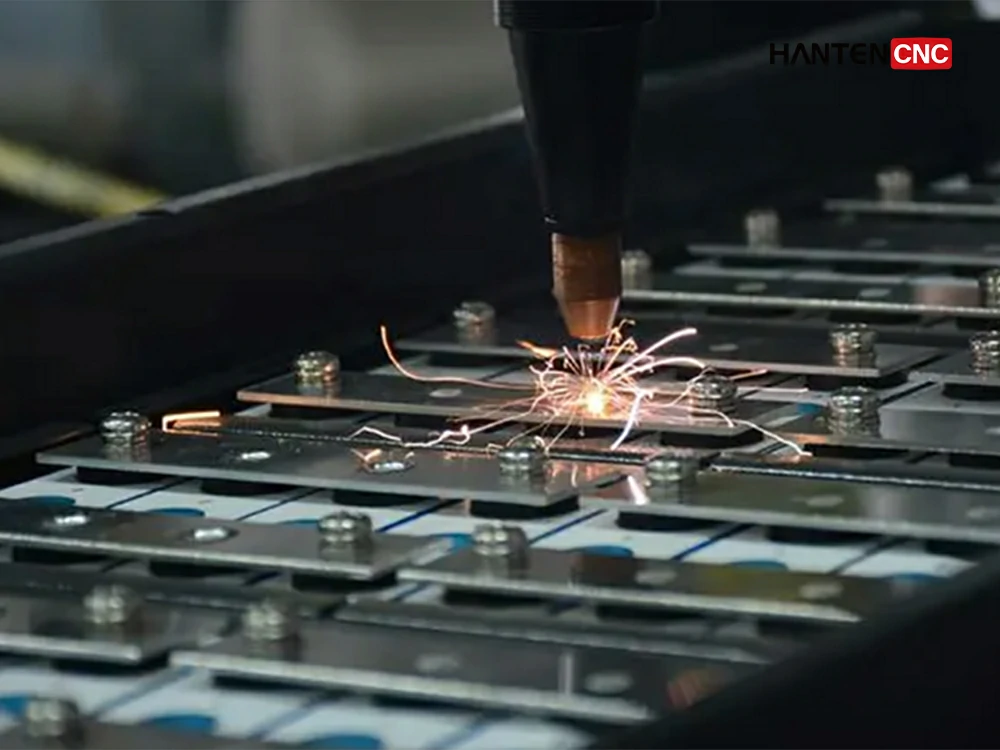

Battery PACK module connection sheet laser welding machine

The battery PACK module is the core component of new energy vehicles. Its configuration for conductive connection is its top priority. For example: the connection method between the single battery cell of the power battery and the busbar of the module. It not only affects the manufacturing efficiency of power batteries. It also determines whether power battery production can be automated. It also has a non-negligible impact on the performance of the power battery module after assembly. The selection of welding equipment also directly affects the quality of the battery module. The gantry type galvanometer laser welding equipment developed and produced by HANTENCNC is mainly used in the following scenarios. That is, the welding of the connection piece of the battery PACK module. Customize laser welding equipment according to its welding requirements.

The connecting piece of the power battery module mostly adopts the method of multi-layer material composite material. One of the layers of material is the connection layer between the connector and the pole. It can guarantee welding performance. Multi-layer materials are used to superimpose to ensure the conductivity of the connecting piece. The connection board substrate is processed into shape after multi-layer foil stacking. A flexible area can be formed. Later, it is used to compensate the displacement caused by the expansion of the power battery core. Reduced impact on low-strength interfaces.

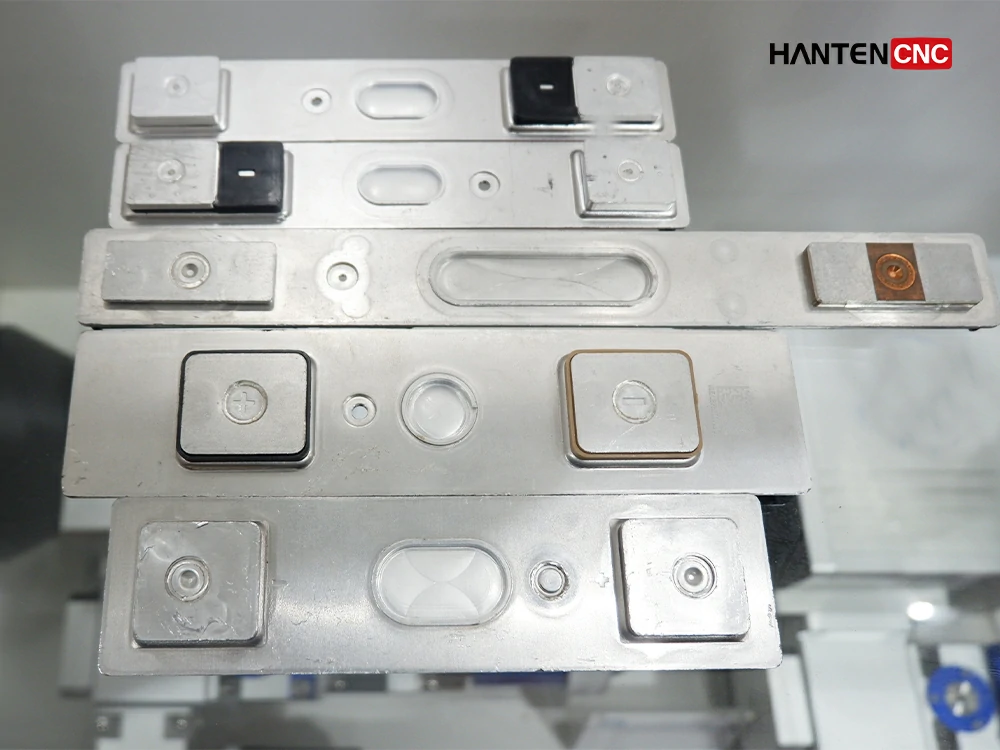

Battery sealing welding and explosion-proof valve welding

The shell thickness of the prismatic battery is generally less than 1 mm. There are two types of 0.6mm and 0.8mm depending on the capacity. Laser welding of prismatic battery casings can be mainly divided into side welding and top welding. The side welding has less influence on the inside of the cell, and the spatter will not enter the inside of the shell. However, it is easy to produce bumps after welding, which will affect the subsequent process. Top welding is due to welding on one plane. It has high requirements on the shell entry and positioning of the previous process. Therefore, the requirements for automation are high. So choose the automatic continuous laser welding machine of HANTENCNC to weld the thin shell lithium battery. Efficiency can not only be increased several times. And its appearance is beautiful. The sealing of the device is better.

The laser welding parts of the power battery also include the welding of the explosion-proof valve of the cover plate and the welding of sealing nails.

The advantage of HANTENCNC’s automatic laser welding is that the loss of welding materials is small and no solder is required. Beautiful welds. The performance of the equipment is stable and easy to operate. Welding quality and high degree of automation. Process repeatability is high. It is widely used in the processing of power lithium battery components. If it is necessary for the sealing welding of the power battery and the welding of the explosion-proof valve. You can choose HANTENCN’s platform automatic laser welding machine.