In the fast-changing field of laser technology, fiber lasers and CO2 lasers are widely used in various industries, including manufacturing, medical procedures, scientific research, and communications.

Despite their widespread applications, fiber lasers and CO2 lasers differ in their design, operation, and applications. This article explores 7 differences between fiber laser and co2 laser to help you choose the right laser for your specific needs.

Here are two pictures of fiber laser and CO2 laser for your reference.

1.Gain Medium

A fiber laser is a kind of laser that uses a doped optical fiber as the gain medium to amplify and transmit light signals, thereby producing laser output. In contrast, a CO2 laser uses CO2 gas as the gain medium, creating laser output by exciting the vibrational and rotational states of CO2 molecules.

That means fiber lasers do not require a gas medium,CO2 lasers require a gas medium to generate laser light.

The gain medium in CO2 lasers consists of carbon dioxide gas, often mixed with other gases like nitrogen and helium, which is excited to produce the laser output.

2.Laser Wavelength

The wavelength of fiber lasers typically ranges between 800 and 2000 nm, depending on the type of fiber material and dopants used. Different wavelengths are suited for various industrial processing applications.

A common wavelength for fiber lasers is 1064 nm, which makes them ideal for cutting, welding, and cladding metal materials.

CO2 lasers generate a gas beam by exciting carbon dioxide molecules. Their wavelength range is typically between 9400 and 10600 nm, depending on the composition of the gas mixture and the type of laser.

The common wavelength for CO2 lasers is 10600 nm, making them ideal for processing non-metallic materials such as fabrics, leather, and other organic materials.

Different materials have varying absorption and reflection characteristics for specific wavelengths of light. For example, metals have a high absorption rate for the 1064 nm wavelength of fiber lasers, making them effective for metal processing. In contrast, metals poorly absorb the 10600 nm wavelength of CO2 lasers.

Conversely, materials such as glass, plastics, wood, stone, and leather have high absorption rates for this wavelength, making CO2 lasers suitable for marking and processing these materials.

3.Electro-optical Conversion Efficiency

The output power range of fiber lasers and CO2 lasers are similar, ranging from a few watts to tens of kilowatts. However, their electro-optical conversion efficiency differs.

The fiber laser has a high electro-optical conversion efficiency, ranging from 25% to 30%.

CO2 lasers have a lower electro-optical efficiency, ranging from 10% to 20%.

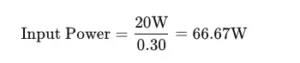

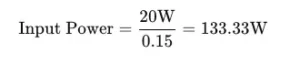

Suppose you have a laser marking machine that requires 20 watts of laser power:

Fiber Laser: Assuming a conversion efficiency of 30%, the required electrical input power is:

CO2 Laser: Assuming a conversion efficiency of 15%, the required electrical input power is:

In summary, fiber lasers have a higher electro-optical conversion efficiency (25-30%) compared to CO2 lasers (10-20%). This means that fiber lasers can produce more laser output power with the same electrical input.

Although the power ranges of CO2 lasers and fiber lasers in marking applications are similar, fiber lasers can generate more laser output power at the same input power, and they are more efficient and energy-saving. CO2 lasers require more power input to achieve the same laser output power.

4.Lifespan

Fiber lasers have a longer lifespan. Their service life is about 100,000 hours.

CO2 lasers, in contrast, have a significantly shorter lifespan than fiber lasers, lasting about 20,000 hours.

Fiber lasers’s lifespan is significantly longer than that of CO2 lasers.

5.Applications for marking

In the laser marking industry, different laser powers are suitable for marking different materials.

Next, we will use fiber laser marking machines and CO2 laser marking machines as examples to discuss the materials that can be marked using different lasers.

Fiber laser marking machines

Fiber laser marking machines use fiber lasers as laser sources. In laser marking applications, fiber lasers’ common power is usually between 30W and 100W, and their common output power is between 20W and 30W.

These 20W and 30W fiber laser marking machines are used for marking most metals and some non-metallic materials.

While 50W or higher fiber laser marking machines can be used for deeper or faster marking needs.

CO2 laser marking machines

The common power of CO2 laser marking machines is usually between 30W and 100W.

These low-power 30W to 50W CO2 laser marking machines are more suitable for marking non-metallic materials.

When it comes to high-power CO2 laser marking machines with 60W to 100W, they can be used in a wider range of applications as their power increases.

6.Maintainance

Fiber lasers require almost no maintenance, while CO2 lasers require more maintenance to ensure their regular operation and output quality.

Fiber lasers are maintenance-free and have a long life and high stability. In contrast, CO2 lasers require regular maintenance, including:

- Regular replacement of laser tubes

- Replacement of reflective lenses

- Supplementation of laser gas

- Cleaning of optical components

- Regular inspection and maintenance of complex cooling systems

In summary, fiber lasers require almost no maintenance, while CO2 lasers require more maintenance to ensure their regular operation and output quality.

7.Price

The prices of fiber lasers and CO2 lasers are influenced by several factors, including power, configuration, and brand.

Fiber Laser Prices

Fiber laser marking machine: Prices generally range from $1,000 to $15,000.

Fiber laser cutting machine: Prices usually range from $10,000 to $300,000, depending on power and configuration.

Fiber laser welding machine: Prices typically range from $10,000 to $150,000.

CO2 Laser Prices

CO2 laser marking machine: Prices range from $500 to $8,000.

CO2 laser cutting machine: Prices range from $10,000 to $200,000, depending on the power and configuration.

CO2 laser engraving machine: Prices usually range from $4,000 to $30,000.

There is a significant price disparity between fiber lasers and CO2 lasers. Fiber lasers are more expensive, but their high efficiency, precision, and long lifespan make them a preferred choice in many industrial applications. CO2 lasers are relatively more affordable, suitable for processing non-metallic materials, and economical options.

Conclusion

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Gain Medium | Optical fiber doped with rare-earth elements | CO2 gas mixture |

| Wavelength | 1064 nm | 10600 nm |

| Material Suitability | Metals (steel, aluminum, copper) | Non-metals (wood, acrylic, plastic, leather) |

| Electro-optical Conversion Efficiency | 25-30% | 10-20% |

| Maintenance | Low maintenance | Requires regular maintenance |

| Operational Cost | Lower due to higher efficiency and less maintenance | Higher due to more frequent maintenance |

| Precision | Higher (finer cutting capabilities) | Lower (suitable for thicker, less precise cuts) |

| Initial Cost | Higher | Lower |

| Lifespan | Longer (up to 100,000 hours) | Shorter (around 20,000 hours) |

| Metal Absorption Rate | High (better absorption by metals) | Low (metals reflect more CO2 laser light) |

| Price | $10,000 – $100,000 depending on power and configuration | $5,000 – $50,000 depending on power and configuration |

Fiber lasers are more efficient, require less maintenance, and offer higher precision, making them ideal for industrial applications involving metals. On the other hand, CO2 lasers, while less expensive, are better suited for processing non-metallic materials and require regular maintenance.

When choosing between the two, it is essential to consider factors such as the type of material, required precision, maintenance capabilities, and budget to determine the most suitable laser for your specific needs.