The type of laser beam matters a lot when you work with a laser engraving machine. There are two common types of laser beam: Gaussian beam and top-hat beam. Both laser beams are prevalent in modern manufacturing. Each has its own benefits and limitations. You can choose the suitable device for your project by comparing these benefits and limitations. This article, “Gaussian Beam VS Top Hat Beam,” can be your best guide.

What is a Gaussian Beam?

In school, we all learned some basics about optics. When planner waves pass through a plano-convex lens, they meet at a focal or 0 point. So, when laser beams meet at the focal point, they should create a laser intensity of infinity.

In the real world, it doesn’t work like that. Instead of meeting at 0 points, it produces a small, finite focal sport with very high intensity but not infinity. So, you can realize that the laser can not create an intensity of infinity. In reality, you can see some small beam waste at the focal spot point. It usually has a minimum size.

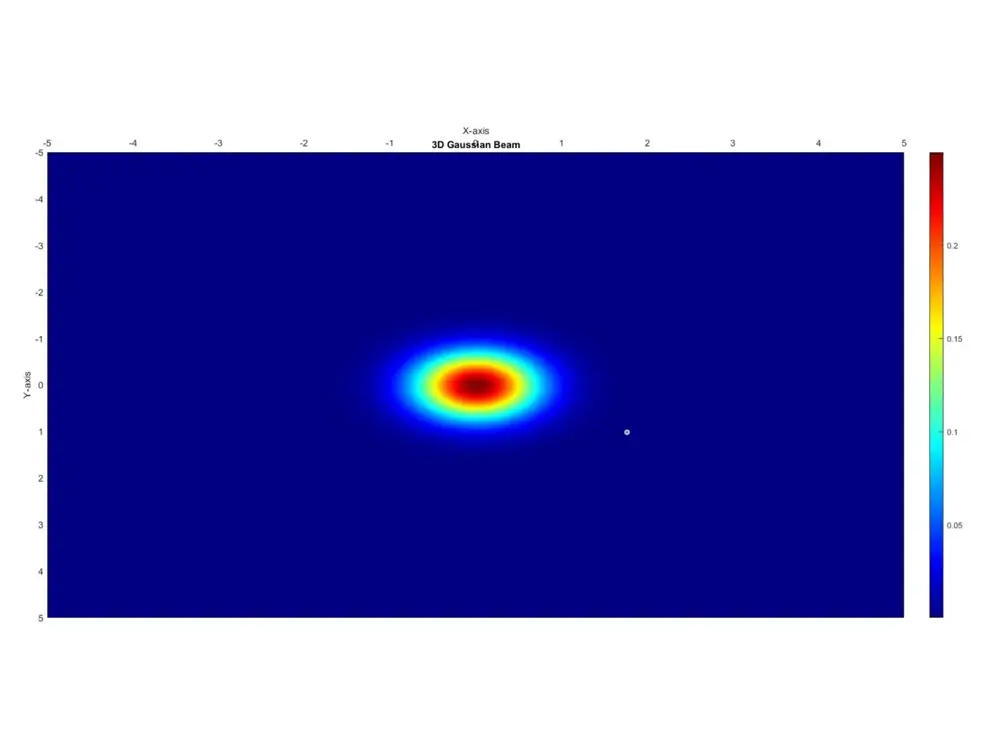

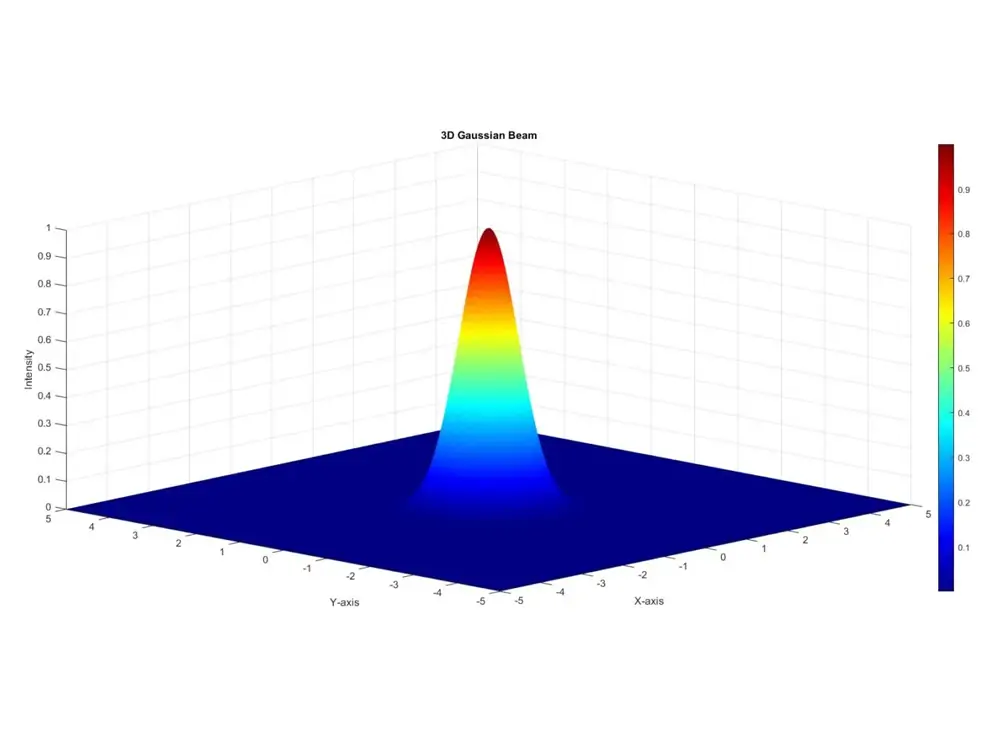

The intensity profile of a typical laser shows a bell-shaped structure. This shape is usually called Gaussian Distribution or Gaussian Intensity. The laser beam used in this case is called Gaussian Beam.

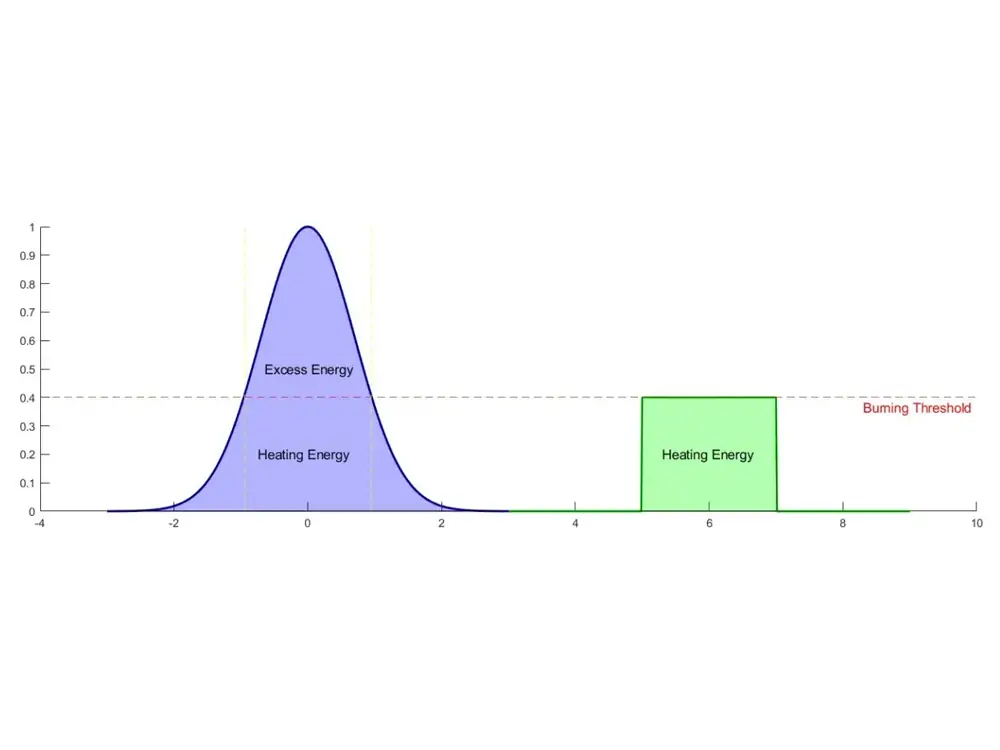

The most intense part is in the middle of the distributions. The two wings on both sides are less intense. In laser engraving, the denser part typically engraves materials. When it hits the material, it creates intense heat and melts the specific area. It also vaporizes the molten material. In this way, the process completes the laser engraving/cutting.

The two wings on both sides typically have lower intensity. They can not melt the material, so they technically don’t help in the cutting process. However, they may damage the surrounding areas. In particular, they create wider HAZ zones. So, this energy is wasted during the whole process.

Advantages of Gaussian Beam

Gaussian beam propagation is typical in laser beams. It offers several advantages. They are:

1. High Intensity and Precision

Gaussian beam produces high-intensity beam. It is ideal for a wide range of tasks. You can use this beam for laser cutting, engraving, and other medical procedures.

As you can see from the image, the inner core (red section) produces more intensity, while the outer part produces less intensity. This beam can cut/engrave any materials using less power input. However, the outer part or wings may create more HAZ zones.

2. Long Distance Propagation

Gaussian beams are naturally laser beams. It doesn’t need any adaptors to change the phase and amplitude of the electromagnetic wave. Thus, these beams offer longer propagation than top hat beams.

3. Possible Maximum Beam Intensity

Gaussian beam produces the best possible beam intensity. This means that the Gaussian beam is the first stage of a laser beam. Later, various adaptors are used to create different types of beams. So, it is proved that the Gaussian beam produces the highest possible beam intensity. The Gaussian beam produces more intensity on the same power input than the top hat beam.

4. Low Cost

Making a Gaussian beam is generally a cost-effective solution. The manufacturing cost is decreased since you don’t need additional tools to reshape the beam. Because of this, Gaussian beams are trendy in many industrial and consumer products.

Disadvantages of Gaussian Beam

Although the Gaussian beam is cheap and creates high-intensity beams, it has some limitations.

1. Low-Intensity Portions

The main drawback of the Gaussian beam is its low-intensity portion. In laser engraving/cutting, this section cannot provide an effective result. It only damages the surroundings or creates HAZ areas. These sections are also called the wings of a high-intensity beam.

2. Less Efficient

Since a large portion of the laser beam is low-intense, it doesn’t participate in the main operation. As a result, Gaussian beam propagation is less efficient than the top hat beam.

3. Not Suitable for Certain Applications

The Gaussian beam is unsuitable if the highest possible beam quality is needed. This means that applications that require consistent beam quality don’t prefer a Gaussian beam. In these cases, the top hat beam works better. For instance, the Gaussian beam is unsuitable for surgeries and materials processing.

4. May Damage the Surrounding Area

The wings of the high-intensity portion may damage the surrounding area of the cutting area. In laser engraving and cutting, this is called a heat-affected zone (HAZ). It affects the quality of the engravings.

Applications of Gaussian Beam

The Gaussian beam is widely used in laser cutting and engraving machines. You may also find its use in spectroscopy. Besides, the Gaussian beam is famous in barcode scanning and alignment systems.

What is Top Hat Beam?

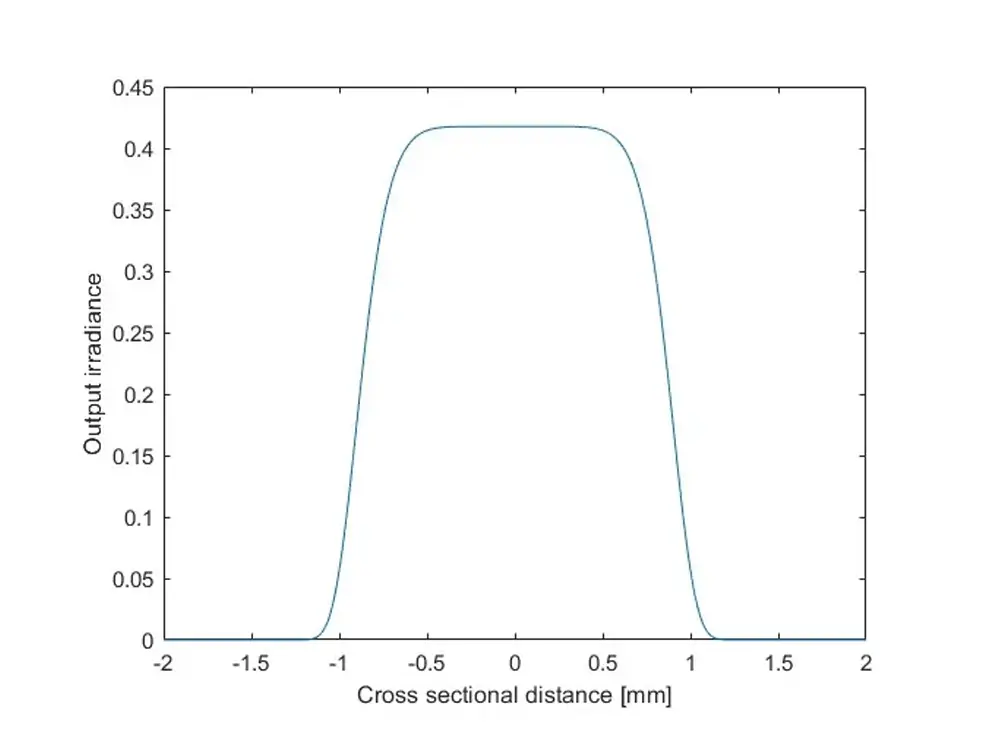

A top hat beam is also known as a flat-top beam. It has uniform intensity distribution across its entire cross-section. As you know, the Gaussian beam has a peak intensity at the center. Then, it gradually decreases towards the edges. On the other hand, a top hat beam maintains the same intensity level throughout its profile.

As you can see from the above picture, the intensity level is topped by a flat surface. This flat surface indicates a uniform intensity from the center to the edges.

Advantages of Top Hat Beam

Top hat beam offers several benefits. These benefits make Top Hat laser popular in many industries. Here are some expected benefits:

1. Uniform Intensity

Beam shaping creates a uniform intensity distribution. A top-hat beam is ideal for these situations. It ensures even energy delivery, which is necessary for many applications.

For instance, material processing, medical surgery, and optical inspections are noteworthy. In laser engraving, it plays a crucial role. Due to the uniform intensity, the laser produces less HAZ.

2. Improved Beam Quality

The top hat beam produces a very negligible amount of less-intense beam. As a result, you will get an improved beam quality. This benefit reduces the risk of burning or incomplete cutting in material processing.

3. Higher Accuracy

The even intensity ensures high precision. You can achieve tolerances up to ±0.0001mm. A top-hat laser beam is also used for laser marking and photolithography.

4. High Efficiency

Top hat beams can increase the efficiency of various processes. As you know, it produces negligible, less-intensity beams, which reduces waste. This proves that the top hat beam is more efficient than the Gaussian beam.

Disadvantages of Top Hat Beam

Although the top hat beam offers many benefits, it has some limitations. Let’s check them out.

1. High Cost

You will need special adaptors to create the top hat beam from the gaussian beam. As a result, the manufacturing cost of the top hat beam is comparatively expensive.

2. Less Intensity Compared to Gaussian Beam

As you know, a top hat beam spreads its energy evenly across the entire beam profile. As a result, it creates a lower peak intensity than the Gaussian beam. Therefore, when laser cutting/engraving, you may need higher laser power.

3. Short Distance Propagation

As you have seen, the top hat beam’s intensity shape changes due to beam shapers’ use. As a result, the intensity level is steeper than the Gaussian beam. So, the top hat beam can offer short-distance propagation.

Applications of Top Hat Beam

Because of the benefits mentioned before, the top hat beam is widely used in many applications. This beam gives a precise and consistent cut in laser cutting or engraving. In surgery, this laser beam ensures an accurate incision and reduces damage. You can also find its use in dermatology, ophthalmology, and more.

Gaussian Beam VS Top Hat Beam: What’s the Difference?

Top hat beam is a transformed version of a gaussian beam. A laser passing through the plano-convex lens usually creates a Gaussian distribution. Both laser beams are widely used in many applications. The following table, “Gaussian Beam VS Top Hat Beam,” highlights their primary differences.

| Aspect | Gaussian Beam | Top Hat Beam |

| Intensity Profile | High intensity at the center gradually decreases toward the edges. | Uniform intensity across the entire beam profile |

| Beam Quality | High peak density | Low peak density but high precision |

| Cost | Lower Cost | Higher Cost due to the adaptors |

| Propagation | Long distance propagation | Short distance propagation |

| Efficiency | Less Efficient | High efficient |

| Suitability | Ideal for laser cutting/engraving | Ideal for laser marking and etching |

Gaussian Beam VS Top Hat Beam: Which is Better?

Which is better mainly depends on your project needs. A Gaussian beam produces high peak intensity, which is better for long-distance propagation. On the other hand, a top-hat beam produces uniform intensity. The top hat beam is ideal for laser marking, cutting, and engraving. It gives more accurate results.

When you consider the efficiency, the top hat beam is better. However, these devices are relatively expensive. On the other hand, the gaussian beam is cheaper. In addition, it consumes less power to create high-intensity beams. Overall, the top hat beam is better for all types of work and precision.

Summary

We have reviewed an exciting topic: “Gaussian Beam VS Top Hat Beam.” Recently, this topic has become one of the hot topics among laser engraver users. Precision and quality are important for developing products and production lines. Gaussian beam and top hat beam are two popular laser beam types. They are widely used in all kinds of laser devices.

Gaussian beams are the primary stage of laser beams when they travel through a plano-convex lens. They produce a high peak intensity at the center and less intensity on the two wings. This beam type may be suitable for cutting thick metals but can not offer precision like a top hat beam.

The top hat beam is a transformed version of the gaussian beam. There are several types of gaussian to top hat beam shaper. The specific beam shaper is used based on your project type. Top hat beam offers high precision and uniform laser intensities. It is efficient and widely used in many applications.

If you have any questions, feel free to contact us. We are always ready to assist you.